Independent production of the entire industry chain

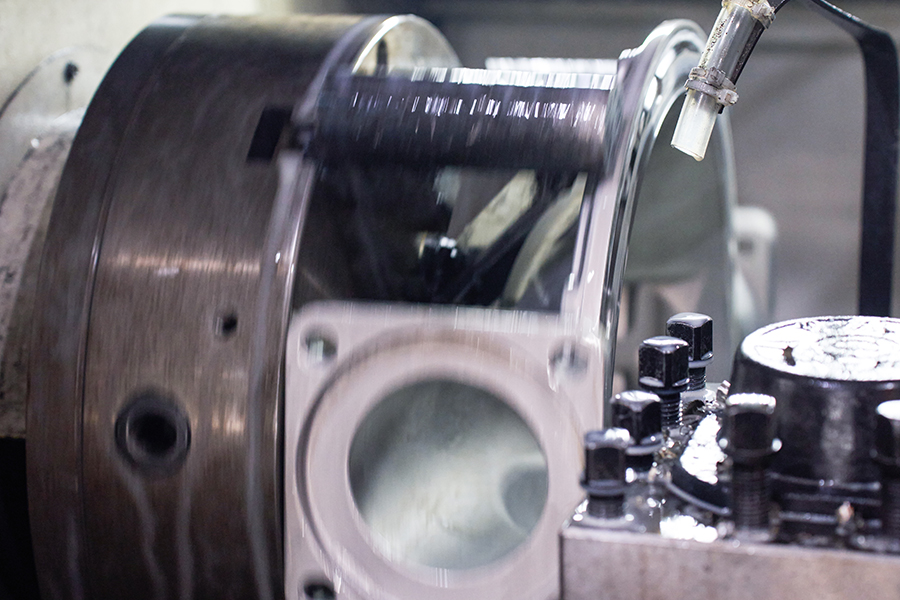

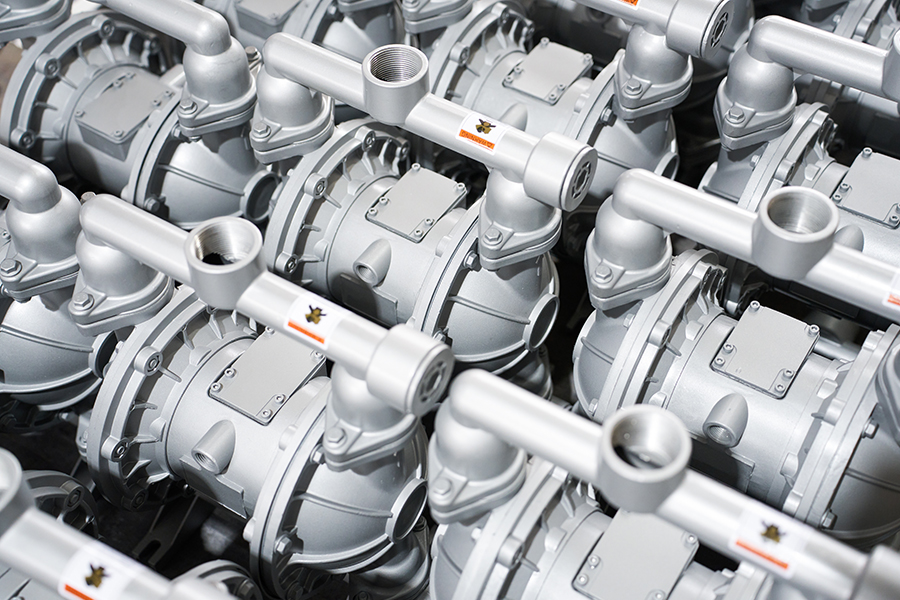

We have a 32,000 square meter modern production base, covering a complete manufacturing process including precision casting, CNC machining, and automated assembly, ensuring full control from raw materials to finished products. Advanced CNC machining centers, laser welding equipment and intelligent assembly lines enable our diaphragm pumps to reach advanced levels in terms of precision, durability and sealing.

Strict quality control

Each diaphragm pump must undergo a rigorous quality inspection process, including material composition analysis, pressure burst test, dynamic performance test, etc., to ensure that the product can still operate stably under harsh working conditions. Our quality management system has passed ISO 9001 and other international standards certification, providing customers with reliable protection.

Innovation driven, professional customization

Relying on patented technology, we have made continuous breakthroughs in diaphragm materials, fluid dynamics optimization and intelligent control. We use different materials to meet the needs of different users.

There are eight specifications in total: DN10mm (3/8''), DN15mm (1/2''), DN25mm (1''), DN40mm (11/2''), DN50mm (2''), DN65mm (21/2''), DN80mm (3''), DN100mm (4''). DN125mm (5").

Five materials: aluminum alloy, cast iron, stainless steel, engineering plastics, and fluid lined with fluorine.

Diaphragm pumps use nitrile rubber, chloroprene rubber, fluororubber, polytetrafluoroethylene, and Teflon diaphragms according to different liquid media.

Factory Environment

English

English русский

русский Español

Español عربى

عربى