Air Powered Double Diaphragm Pumps vs. Traditional Pumps: What You Need to Know

2025.08.18

2025.08.18

Industry News

Industry News

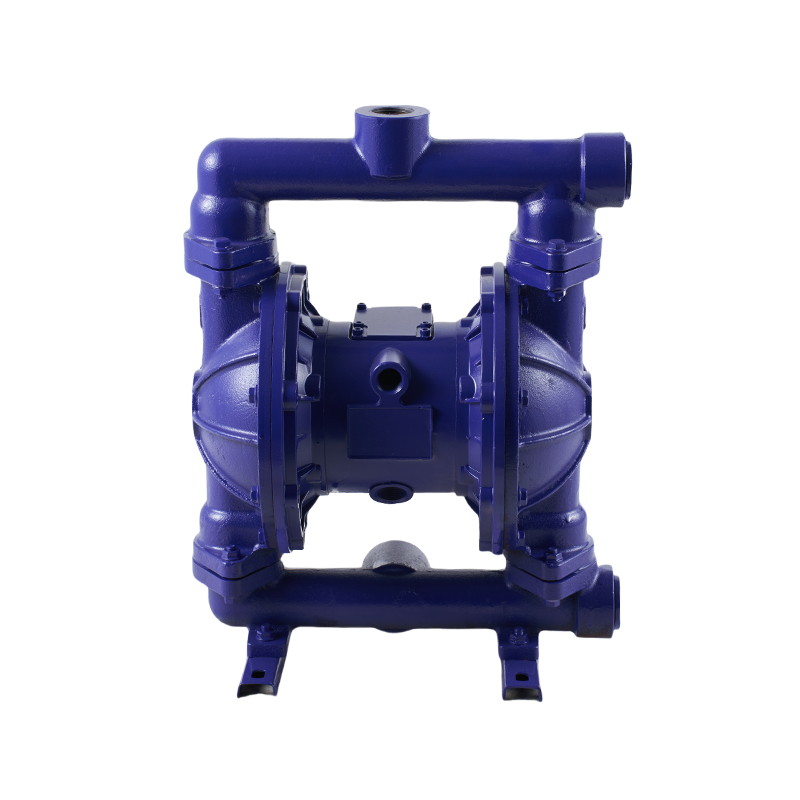

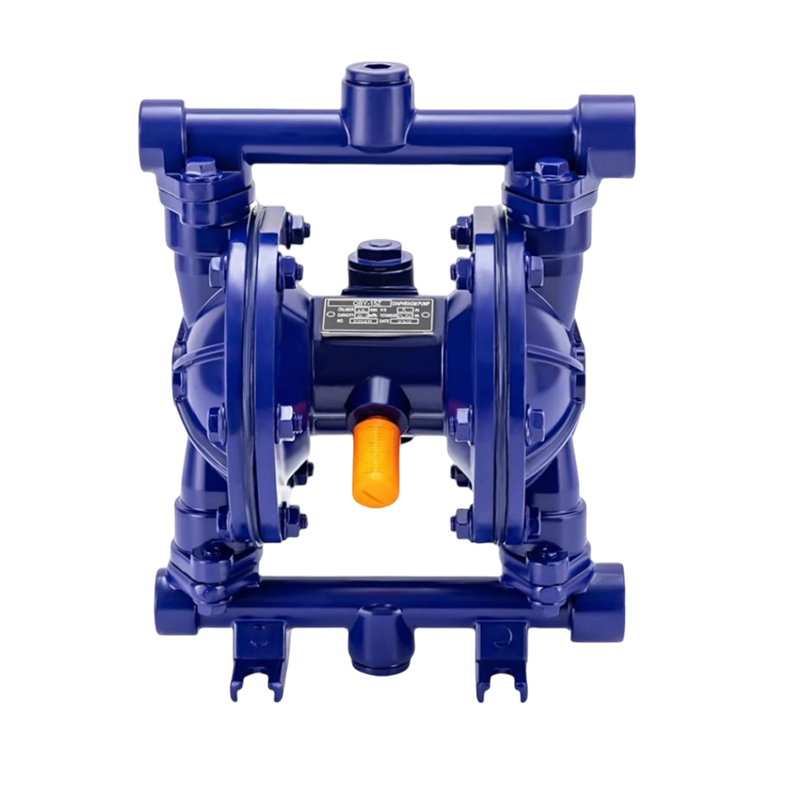

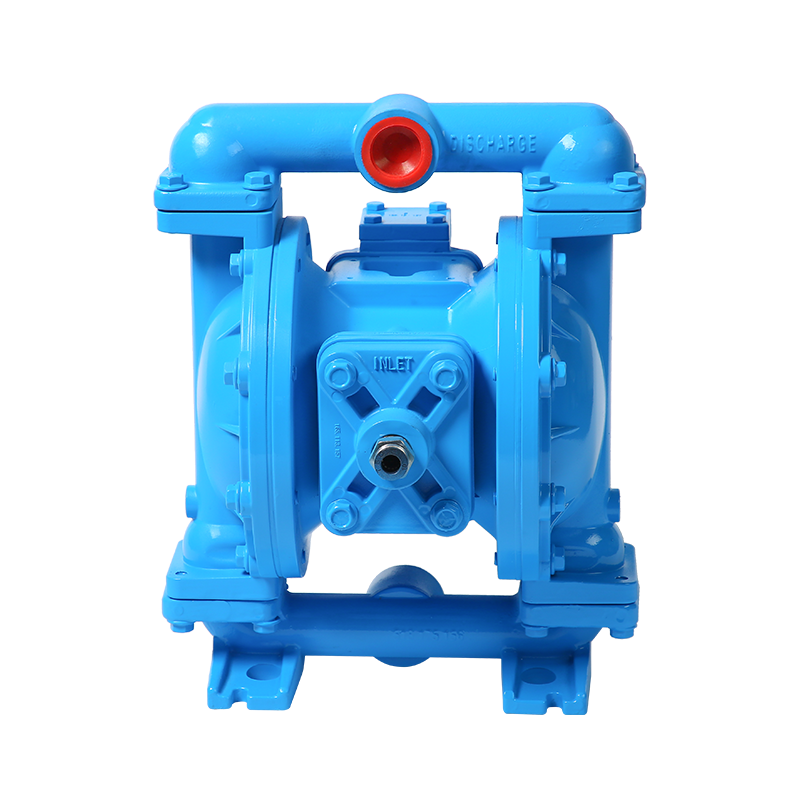

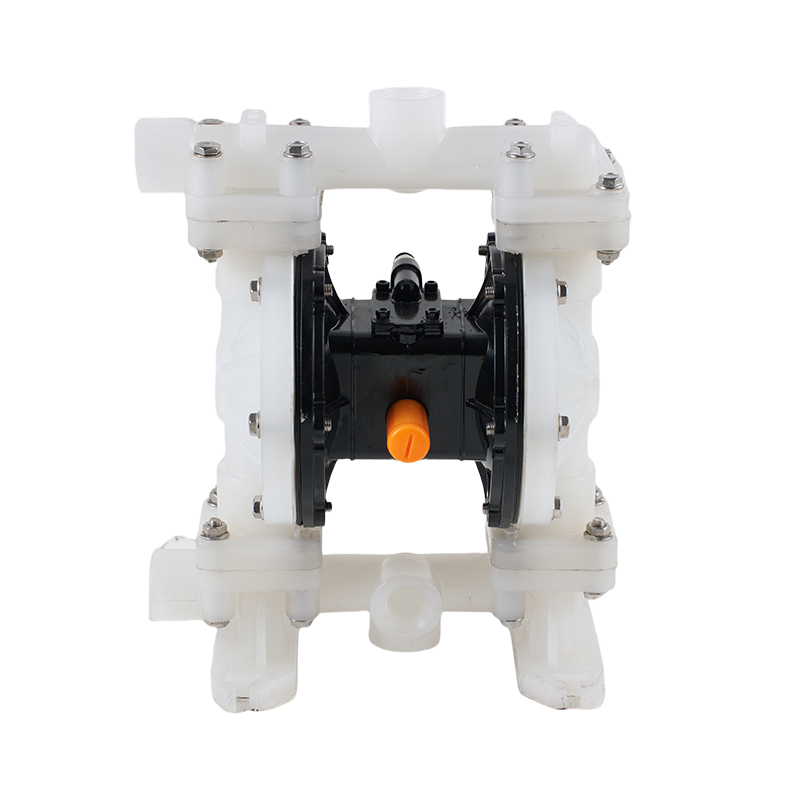

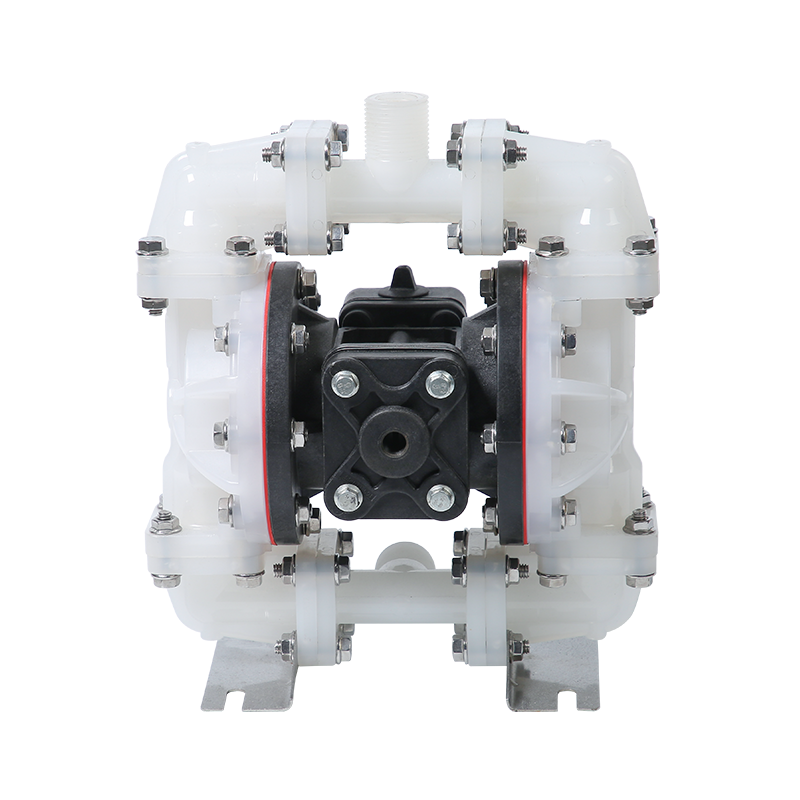

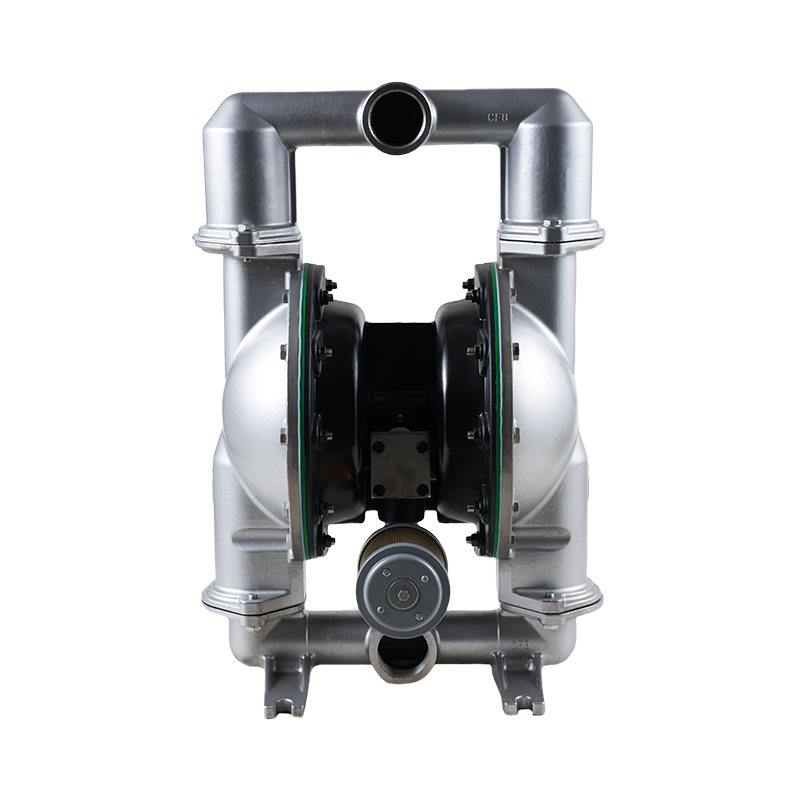

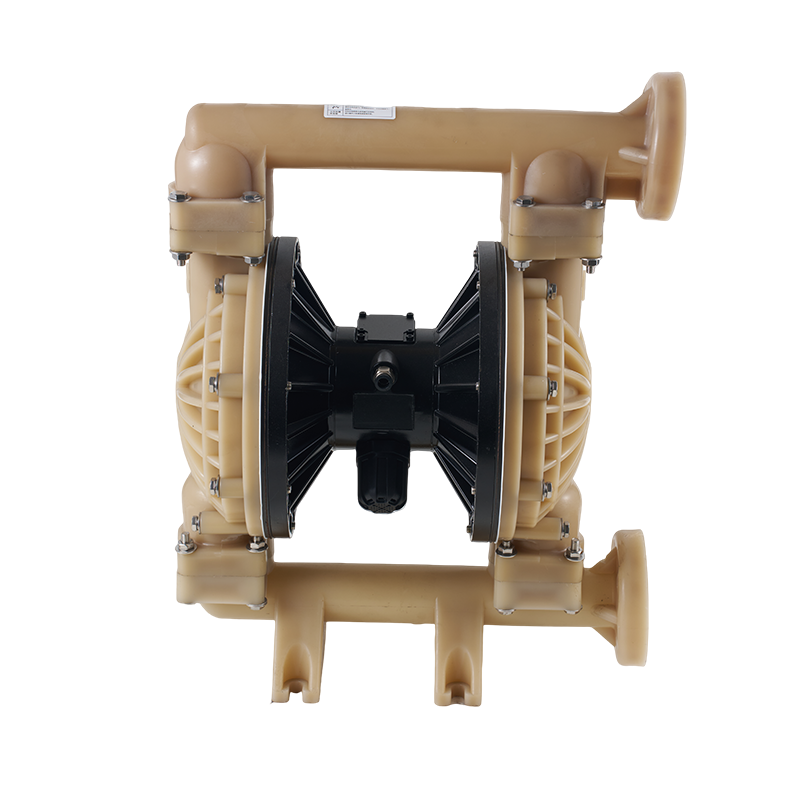

In the vast landscape of industrial fluid transfer solutions, the choice of pump technology can significantly impact efficiency, cost, and overall operational success. Among the myriad options available, Air Powered Double Diaphragm Pumps (ADDPs) have emerged as a formidable contender against traditional pumps. Understanding the nuances between these two types of pumps is crucial for making an informed decision. This article explores the key differences, advantages, and considerations of Air-Powered Double Diaphragm Pumps in comparison to their traditional counterparts.

Air-powered double diaphragm pumps are renowned for their ability to handle a wide range of fluids, from viscous liquids to abrasive slurries. The unique design of these pumps, which utilizes compressed air to drive the diaphragms, allows for a self-priming and dry-running capability that traditional pumps often struggle to achieve. Traditional pumps, such as centrifugal or gear pumps, may require priming and can suffer from cavitation when dealing with low-viscosity fluids or those with high vapor pressure.

The efficiency of ADDPs is further enhanced by their ability to run at variable speeds, controlled by the air supply pressure. This flexibility enables precise flow control, making them ideal for applications where fluid transfer rates need to be adjusted dynamically. In contrast, traditional pumps often operate at a fixed speed, which may necessitate additional control mechanisms to achieve the desired flow rate.

The durability of Air Powered Double Diaphragm Pumps is another key factor that sets them apart from traditional pumps. The diaphragm pump diaphragm, a critical component of ADDPs, is designed to withstand harsh operating conditions, including exposure to corrosive chemicals and abrasive particles. Traditional pumps, particularly those with mechanical seals, can be more susceptible to wear and tear, to frequent maintenance, and to potential downtime.

Maintenance of ADDPs is generally less complex compared to traditional pumps. The absence of mechanical seals and rotating parts reduces the risk of leaks and mechanical failures. Traditional pumps, on the other hand, often require regular maintenance of seals, bearings, and other internal components to ensure reliable operation. This difference in maintenance requirements can translate to significant cost savings over the life of the pump.

Safety is a paramount concern in industrial operations, and Air Powered Double Diaphragm Pumps offer several advantages in this regard. Their ability to handle hazardous fluids without the risk of seal failure makes them a safer choice for applications involving toxic or flammable liquids. Traditional pumps, especially those with mechanical seals, pose a higher risk of leakage, which can to environmental contamination and potential safety hazards.

Moreover, ADDPs are designed to operate without the need for electricity, reducing the risk of electrical hazards in wet or explosive environments. This feature makes them particularly suitable for use in hazardous locations where traditional electric pumps may not be permitted.

When it comes to cost, Air Powered Double Diaphragm Pumps and traditional pumps each have their own set of advantages and trade-offs. While the initial purchase price of ADDPs may be higher than that of some traditional pumps, the long-term cost savings associated with lower maintenance requirements and reduced downtime can offset this initial investment. Additionally, the ability of ADDPs to handle a wide range of fluids without the need for specialized pump designs can to cost savings in terms of pump inventory and spare parts.

Traditional pumps, on the other hand, may have a lower upfront cost but can incur higher operational and maintenance expenses over time. The need for regular maintenance, replacement of seals, and potential downtime due to mechanical failures can add up to significant costs in the long run.

The versatility of Air Powered Double Diaphragm Pumps is one of their compelling attributes. They can be used in a wide range of industries, including chemical processing, mining, wastewater treatment, and food and beverage production. The ability of ADDPs to handle both liquid and semi-solid materials makes them suitable for applications such as sludge transfer, paint mixing, and even the transfer of viscous adhesives.

Traditional pumps, while also versatile, may have limitations in handling certain types of fluids. For example, centrifugal pumps are less effective with highly viscous fluids, while gear pumps may struggle with fluids containing solid particles. The diaphragm pump diaphragm of ADDPs, however, is designed to accommodate a wide range of fluid types, making them a more flexible solution.

In the battle between Air Powered Double Diaphragm Pumps and traditional pumps, there is no one-size-fits-all answer. The choice ultimately depends on the specific requirements of the application, including fluid type, flow rate, operating conditions, and budget constraints. Air Powered Double Diaphragm Pumps offer significant advantages in terms of efficiency, durability, safety, and versatility, making them an attractive option for many industrial applications. However, traditional pumps still have their place, particularly in applications where their unique characteristics are better suited.

As industries continue to evolve and demand more efficient and reliable fluid transfer solutions, the role of Air Powered Double Diaphragm Pumps is likely to grow. Their ability to handle a wide range of fluids, coupled with low maintenance requirements and enhanced safety features, positions them as a strong contender in the pump market. For those considering a new pump installation or an upgrade to existing equipment, a thorough evaluation of the benefits and limitations of both Air Powered Double Diaphragm Pumps and traditional pumps is essential to making the decision for long-term operational success.

English

English русский

русский Español

Español عربى

عربى