How A Customized Diaphragm Pump Solves Real Factory Problems?

2025.11.14

2025.11.14

Industry News

Industry News

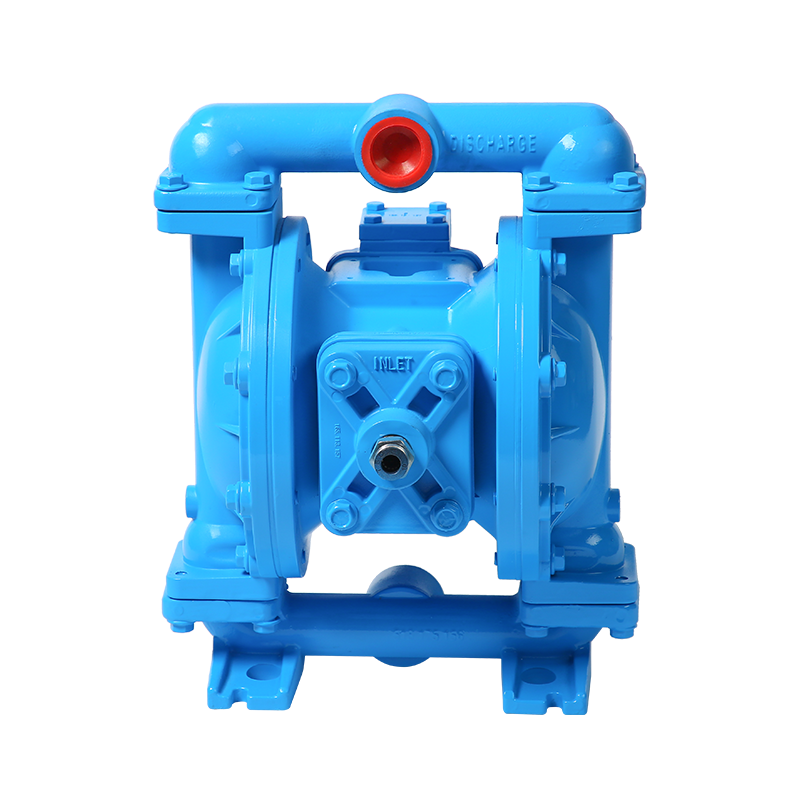

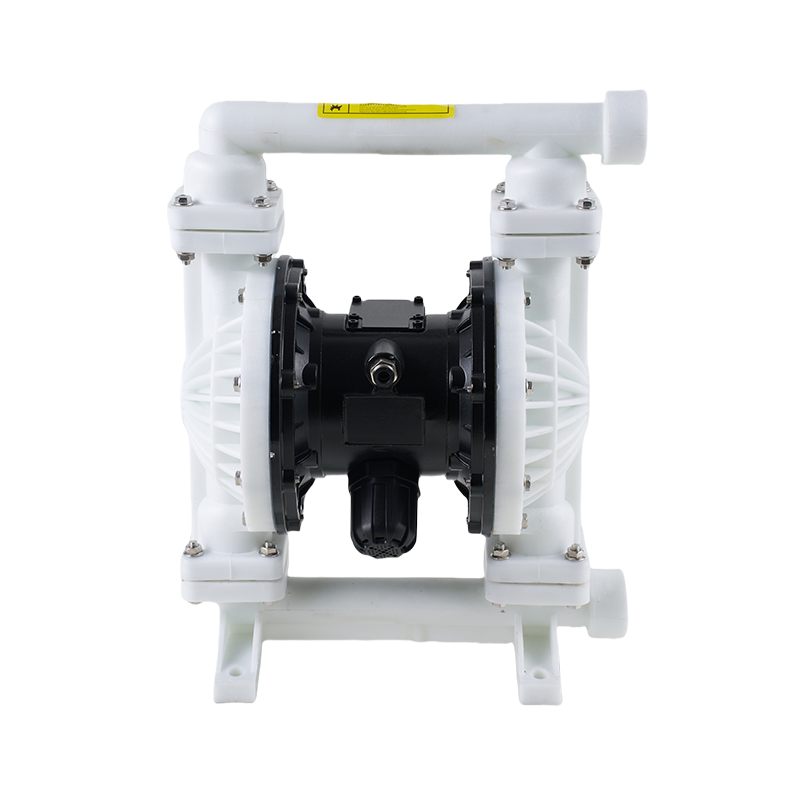

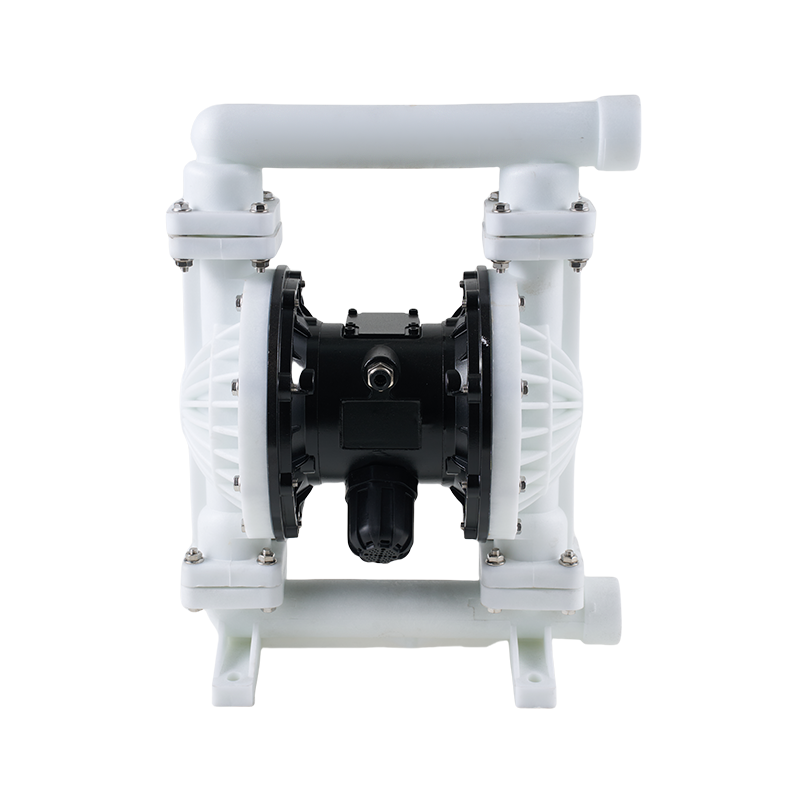

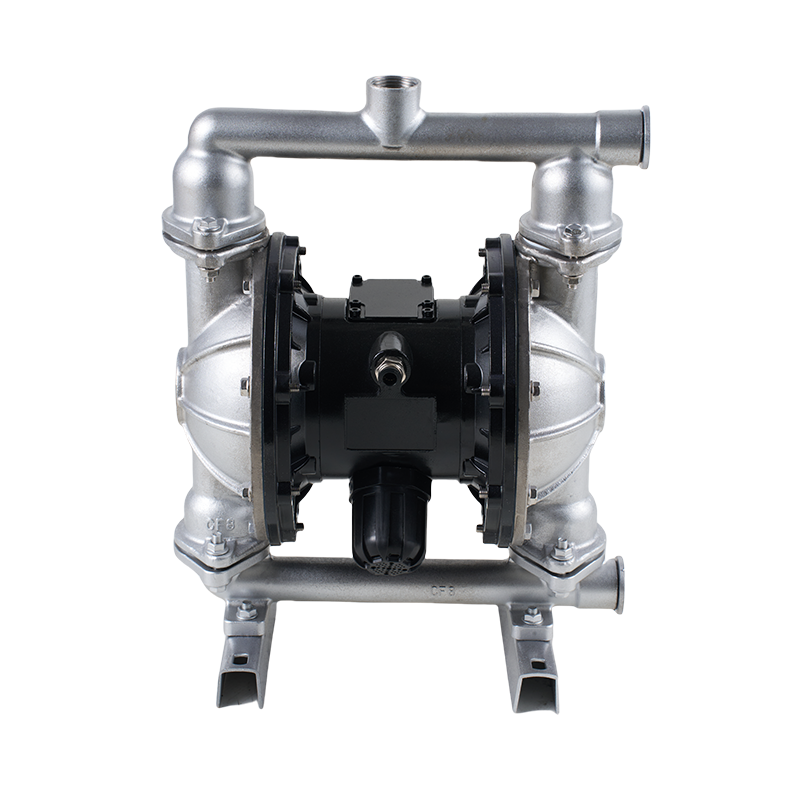

Across industries, from chemicals to food processing, many operations rely on the Diaphragm Pump to handle everything from thick slurries to corrosive liquids. It's durable, flexible, and air-driven - a combination that suits countless jobs. But as production lines evolve, standard models sometimes fall short. That's where the Customized Diaphragm Pump becomes the smarter choice. It's not just about a unique design; it's about creating a pump that fits your work instead of forcing your work to fit the pump.

1. Designed Around Your Fluids and Workflow

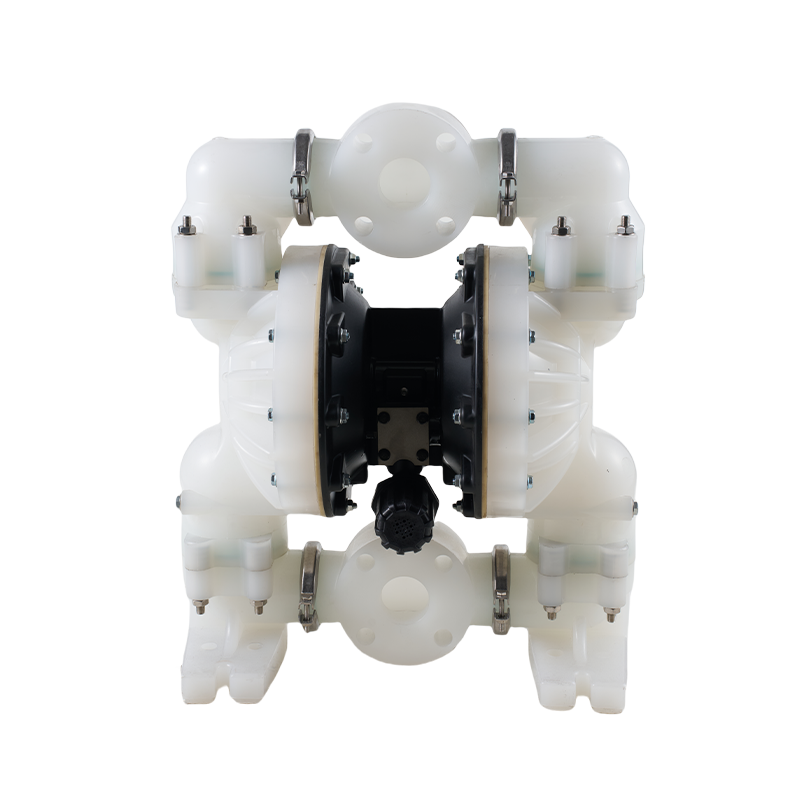

Every liquid behaves differently. Some are abrasive, some sticky, and others highly reactive. A Customized Diaphragm Pump lets you match materials and internal structure to your specific fluids. The diaphragms, valve balls, and pump body can be built with materials that resist chemical corrosion or reduce wear over time.

This kind of precision helps reduce blockages, extend service life, and keep flow rates stable. In environments where consistency matters, small details - like diaphragm flexibility or valve shape - can make a big difference. Customization also allows pumps to fit existing pipework or automation systems, avoiding unnecessary layout changes.

2. Better Efficiency Through Practical Adjustments

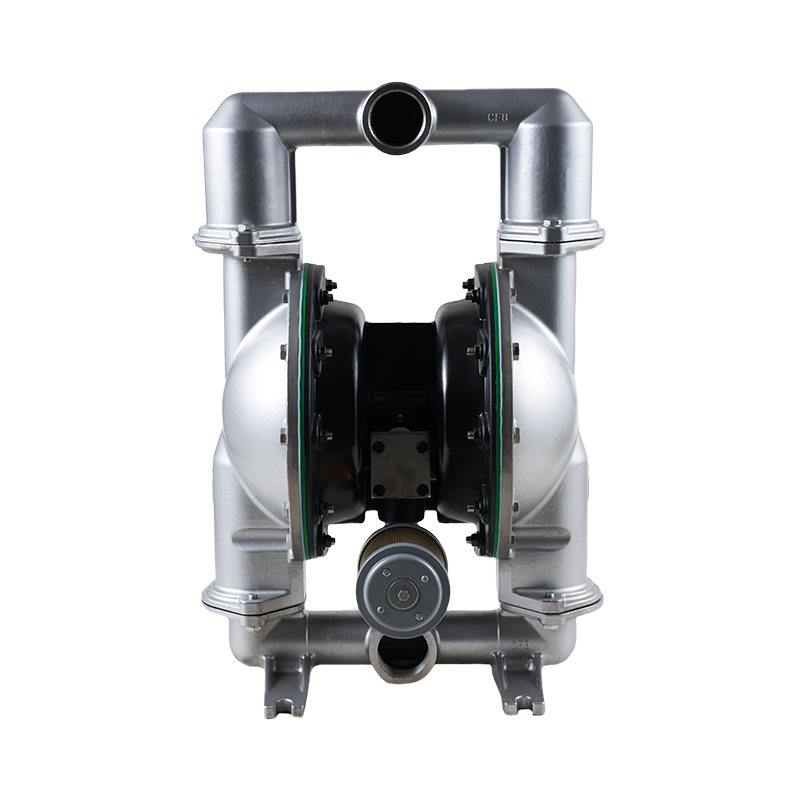

When engineers fine-tune a Diaphragm Pump, they can adjust more than just size or pressure. Air distribution systems, suction capacity, and outlet design can be tailored to make the pump run more smoothly under real conditions. For example, pumps handling viscous products can have wider internal channels, while those used in precision dosing can include tighter control on pulsation.

These changes translate into practical gains - fewer maintenance interruptions, steady flow, and reduced air consumption. For production lines that run long hours, even small improvements in efficiency can save noticeable time and cost across the year.

3. Easier Operation and Maintenance

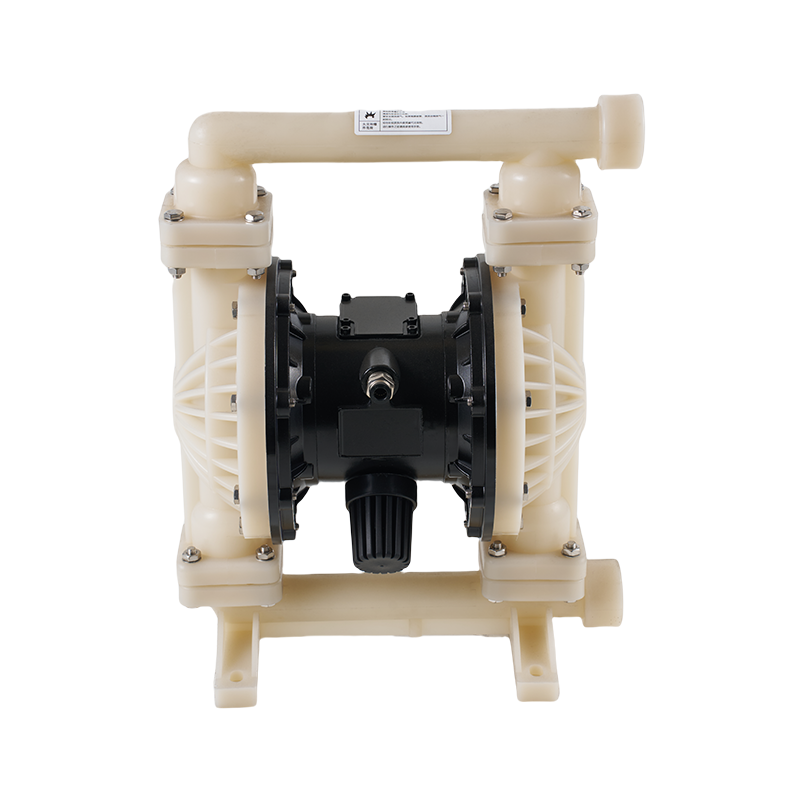

A Customized Diaphragm Pump isn't only about what happens inside the pump; it also considers how operators interact with it. Many factories request easier disassembly, visible inspection points, or simplified connections for cleaning and maintenance. Customization helps manufacturers build pumps that fit these preferences.

That means technicians spend less time figuring out compatibility issues or sourcing seldom parts. Some setups even allow quick diaphragm replacement without disconnecting the pump from the pipeline. Over time, this practical approach reduces downtime and keeps operations running predictably.

4. Collaboration That Delivers Real Value

Customization often starts with a conversation. Instead of choosing a pump from a catalog, you describe your process, challenges, and goals - and the supplier builds the Customized Diaphragm Pump around that. Many manufacturers now support flexible design discussions and quick prototyping, making the process smoother than before.

This collaboration helps both sides: users get a pump that truly matches their needs, and manufacturers learn how to improve future designs. It's a partnership built on problem-solving rather than just sales. The result is a reliable pump that performs steadily and grows with your production requirements.

A Diaphragm Pump is already a trusted workhorse across industries, but customization adds a new layer of practicality. By adjusting materials, flow paths, and structures, a Customized Diaphragm Pump gives you confidence that your system is working efficiently and safely.

For many factories, customization isn't just an upgrade - it's a way to simplify operations, reduce long-term maintenance, and keep production consistent. When the pump fits your process good, everything downstream benefits, too.

English

English русский

русский Español

Español عربى

عربى