How Does A Double Diaphragm Pump Handle High-Viscosity Fluids?

2025.10.27

2025.10.27

Industry News

Industry News

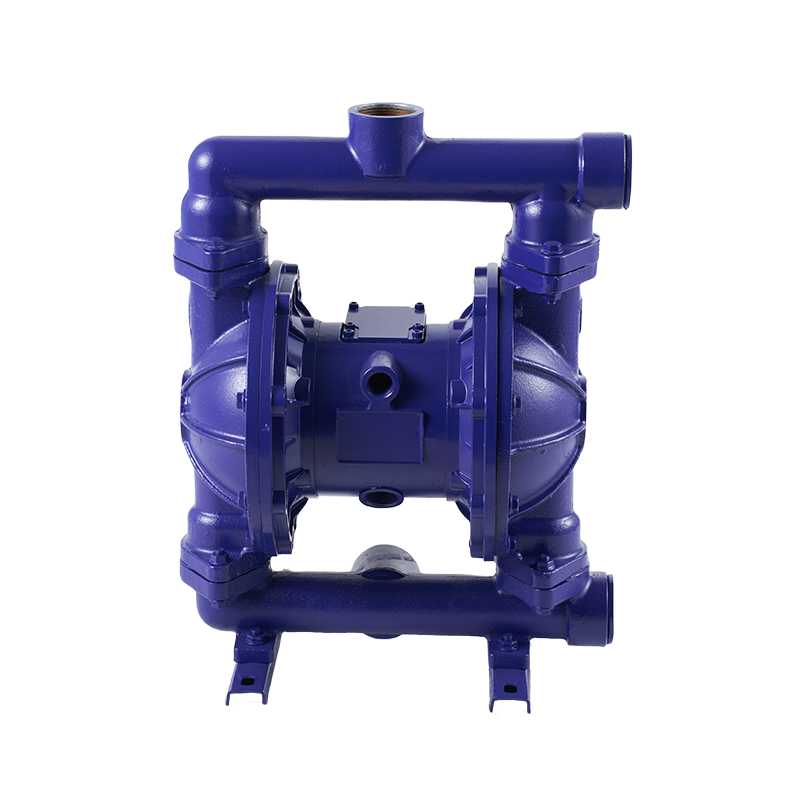

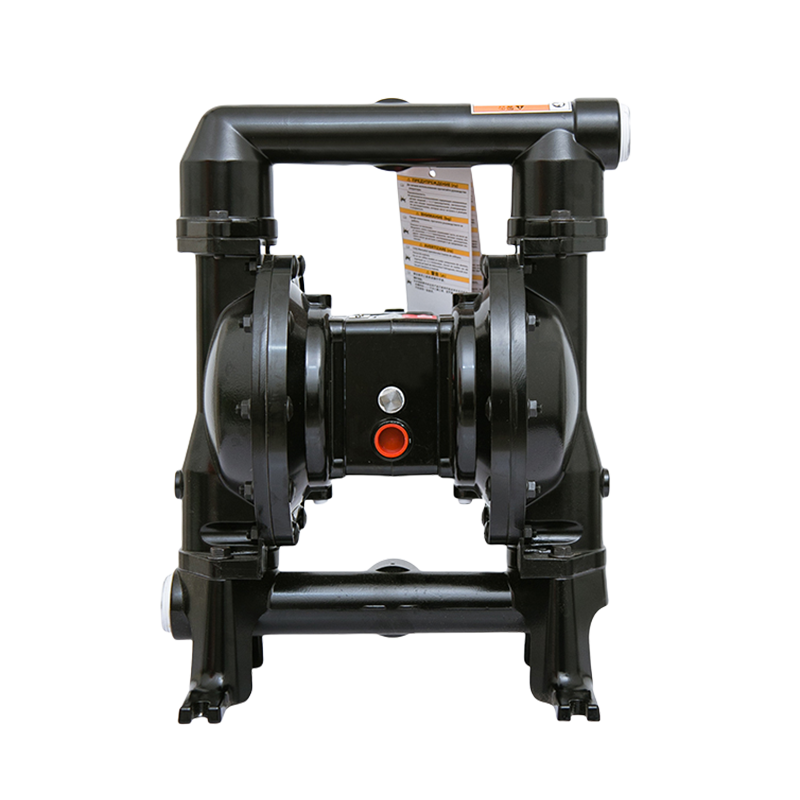

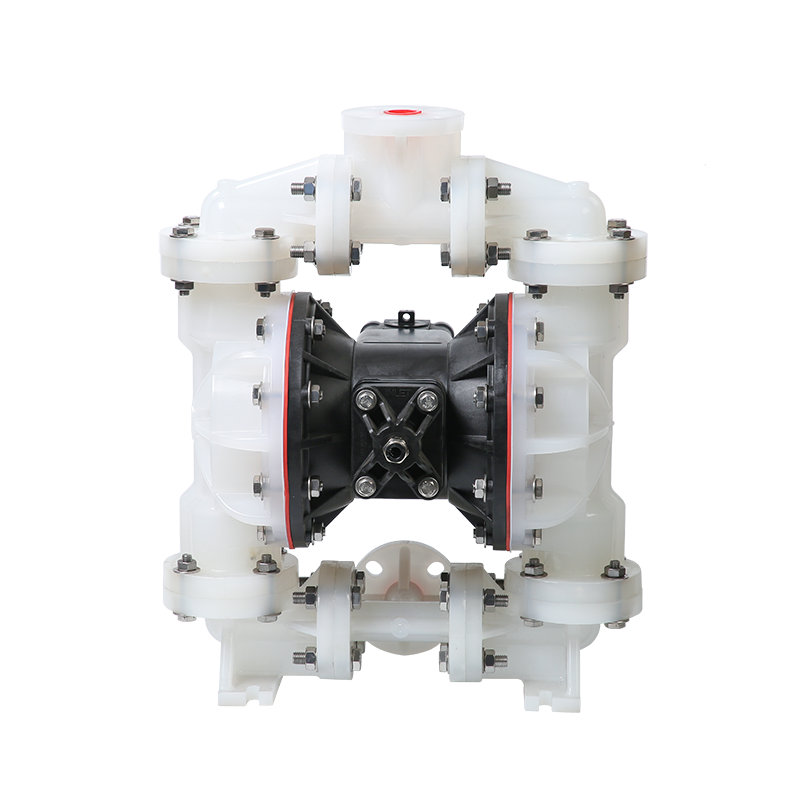

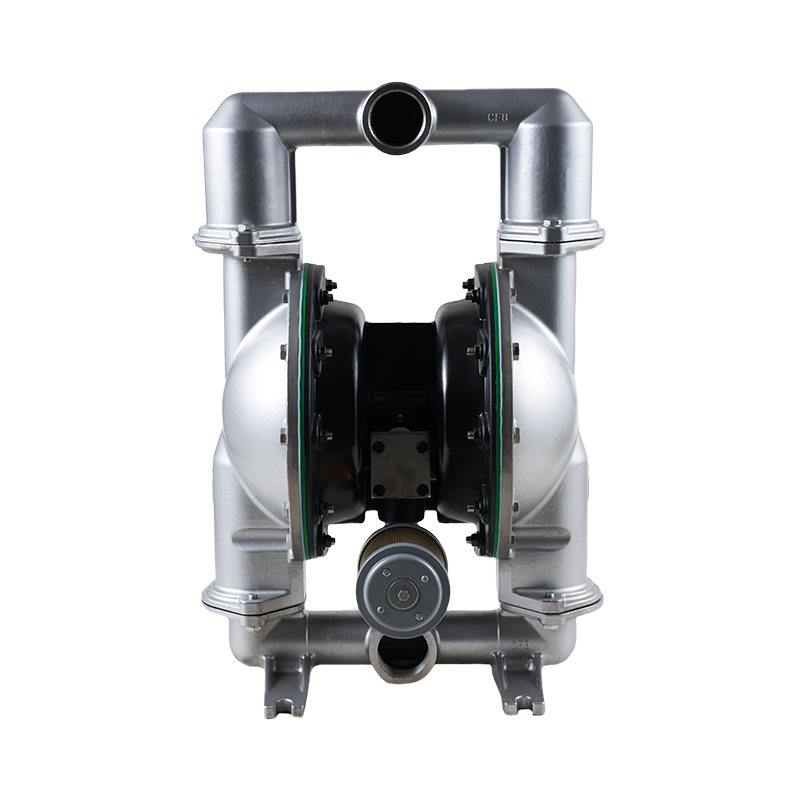

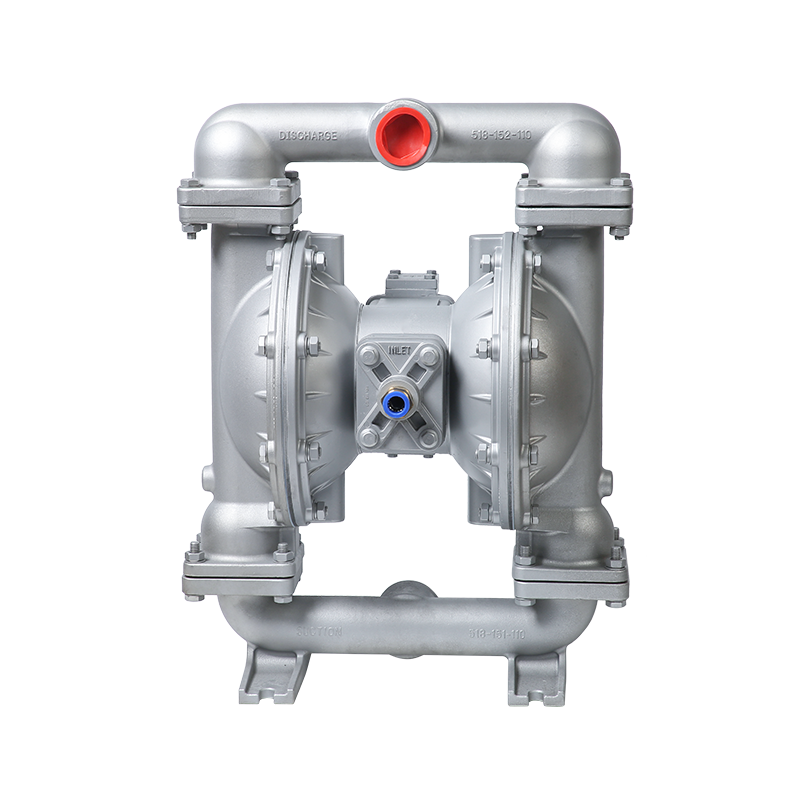

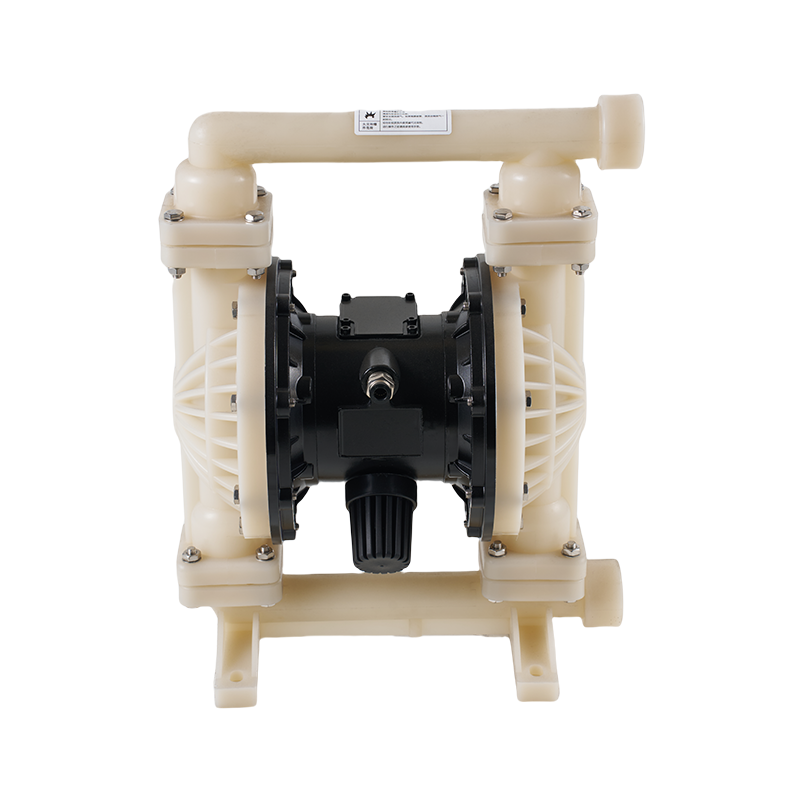

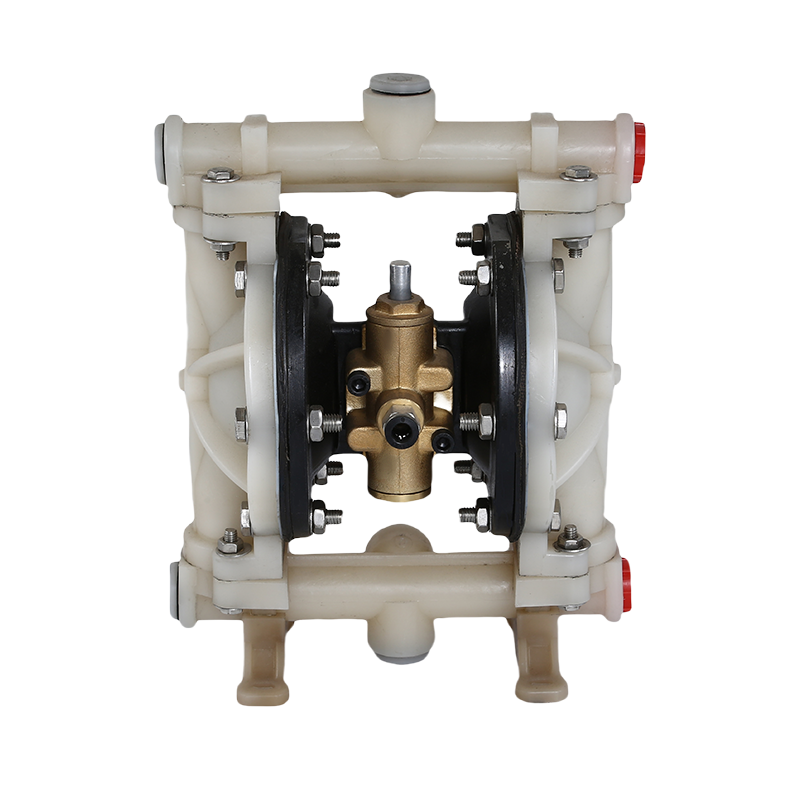

In numerous industrial processes, from transferring paints and adhesives to handling sludge and food pastes, the challenge of moving high-viscosity fluids is a common hurdle. These thick, resistant materials can stall centrifugal pumps, overwhelm progressive cavity pumps with high shear, and cause significant energy waste. In this demanding arena, the Double Diaphragm Pump has established itself as a preferred solution. But what specific characteristics enable an Air-Operated Double Diaphragm Pump to manage these challenging fluids so effectively, and how does the design philosophy of a Double Diaphragm Pump Factory influence this capability?

The proficiency of a Double Diaphragm Pump with viscous fluids is not the result of a single feature, but rather a combination of its operating principle, design flexibility, and inherent safety features. Unlike pumps that rely on high-rotation, the Double Diaphragm Pump operates on a positive-displacement, low-shear principle. It moves fluid through a cyclical suction and discharge process driven by compressed air, which is inherently forgiving and adaptable to the resistance posed by thick liquids.

Self-Priming and Dry-Run Capability: Overcoming Resistance

A primary challenge with viscous fluids is often getting the flow started, especially if the pump is located above the fluid source. The Double Diaphragm Pump is an exceptional self-primer. Its diaphragm action creates a strong vacuum that can pull thick fluids into the pump chamber without requiring the system to be pre-filled or primed. This is a significant operational advantage. Furthermore, if the fluid source is temporarily interrupted, the Double Diaphragm Pump can run dry without sustaining damage. This capability provides a crucial safety margin when handling fluids that may air-lock or have an inconsistent feed, a common scenario with non-Newtonian fluids whose viscosity changes under stress.

Gentle, Low-Shear Handling: Preserving Product Integrity

For many viscous products like polymer solutions, latexes, or certain foodstuffs, maintaining the product's structure is as important as moving it. High-shear pumps can break down molecular chains, emulsify mixtures, or damage suspended solids, altering the product's properties. The action of a Double Diaphragm Pump is remarkably gentle. The fluid is pushed through the pump by the sweeping motion of the diaphragm, experiencing small shear and agitation. This low-shear transfer ensures that the product arrives at its destination with its integrity unchanged, a critical requirement in industries like cosmetics, pharmaceuticals, and specialty chemicals. A knowledgeable Double Diaphragm Pump Factory will often offer large, smooth-flow ball valves and port sizes to further reduce flow resistance and shear for high-viscosity applications.

Adjustable Flow and Pressure: Built-in Control

The air-operated nature of the Double Diaphragm Pump provides a natural and simple method for handling viscosity variations. The pump's flow rate and discharge pressure are directly controlled by the incoming air pressure and the resistance on the discharge side. When pumping a thick fluid, the pump will automatically slow its cycle rate as it works against the viscosity, reducing the flow but maintaining pressure. This inherent controllability is a key reason why a Double Diaphragm Pump is so versatile. A Double Diaphragm Pump Factory with strong application expertise can provide guidance on the ideal air system setup for specific viscosity ranges.

The Double Diaphragm Pump handles high-viscosity fluids effectively through a powerful combination of its self-priming ability, gentle pumping action, and easily controllable operation. Its robust, sealless design avoids the pitfalls that plague other pump types when faced with thick, difficult-to-move materials. When sourcing such a pump, partnering with an experienced Double Diaphragm Pump Factory ensures that the unit is configured with the appropriate port sizes, valve designs, and materials to deliver reliable, efficient performance, turning the challenge of high-viscosity fluid transfer into a manageable, routine operation.

English

English русский

русский Español

Español عربى

عربى