Chemicals

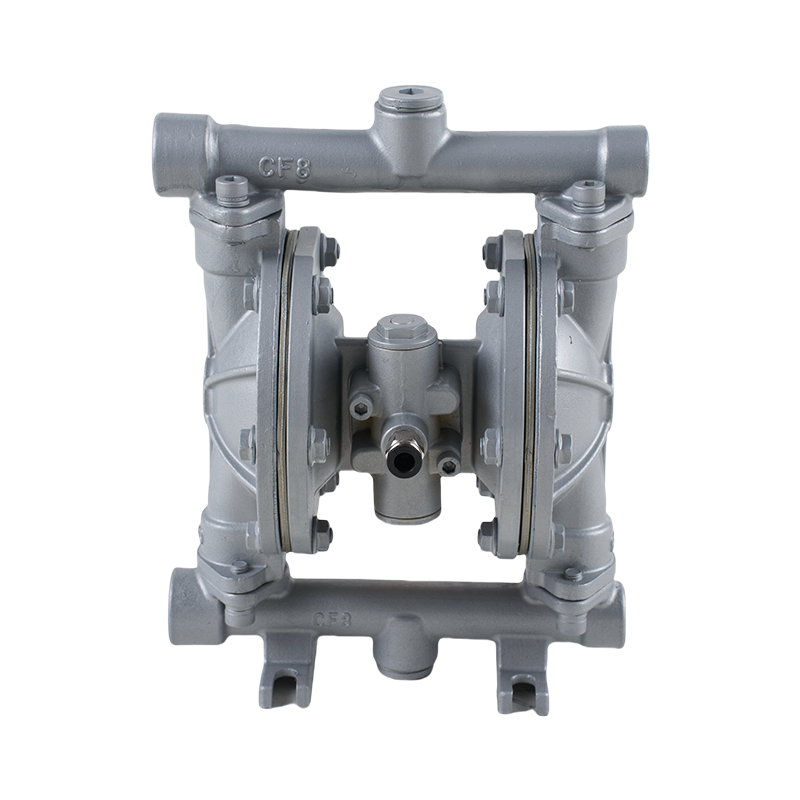

The chemical industry has extremely stringent requirements for fluid-conveying equipment and needs to deal with complex working conditions such as strong corrosion, high toxicity, flammability and explosion. Diaphragm pumps have become an ideal choice for chemical production due to their safe sealing, corrosion-resistant materials, and precise controllability. The following are its key application scenarios and solutions:

Typical application scenarios

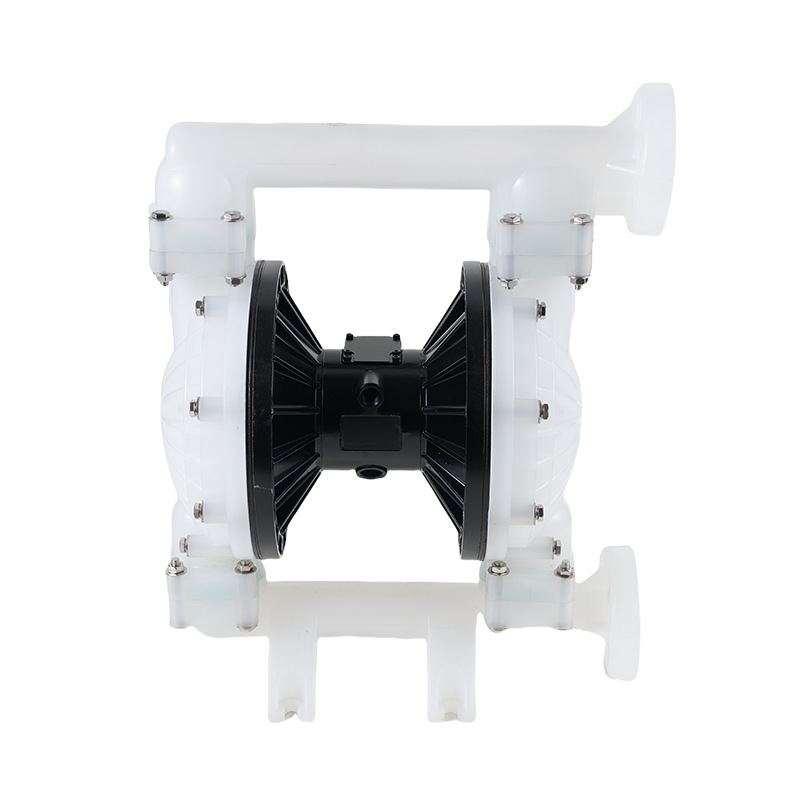

1. Transport of highly corrosive media

Application media: sulfuric acid, hydrochloric acid, hydrofluoric acid, sodium hypochlorite, etc.

Solution:

Perfluorinated material pump body: PTFE and PVDF linings are used to withstand corrosion of pH 0-14.

Composite diaphragm: EPTFE + rubber laminated diaphragm, chemical corrosion resistance life is increased by more than 3 times.

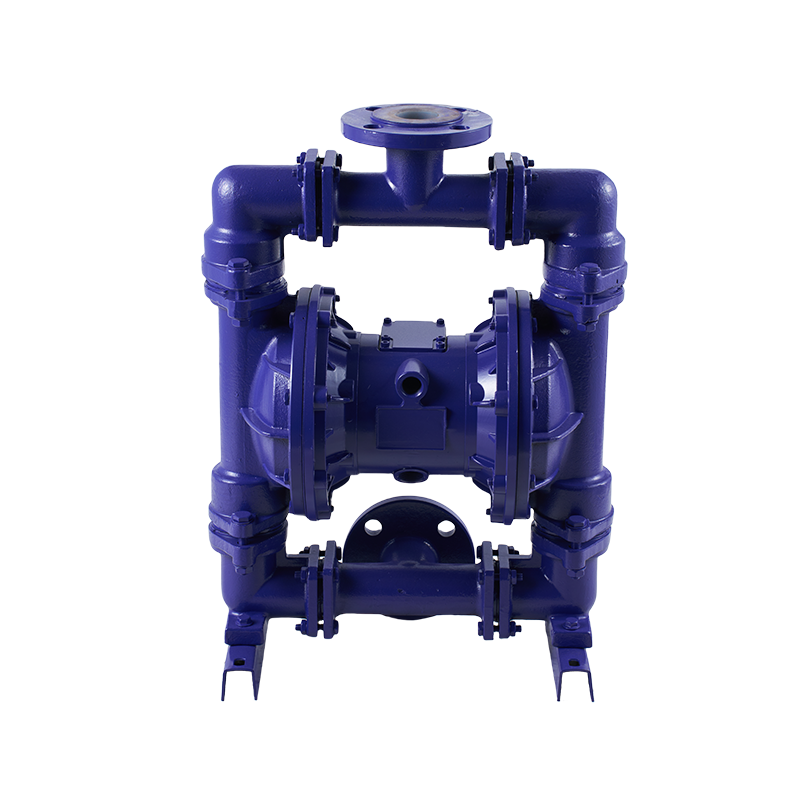

2. High-purity chemical metering

Application scenarios: electronic-grade chemicals (such as semiconductor etching liquid), pharmaceutical intermediates.

Solution:

Pollution-free design: polished stainless steel flow channel (Ra≤0.4μm) + dead cavity-free structure.

Measuring accuracy ±0.5%: servo motor driven diaphragm pump (such as LEWA ecoflow).

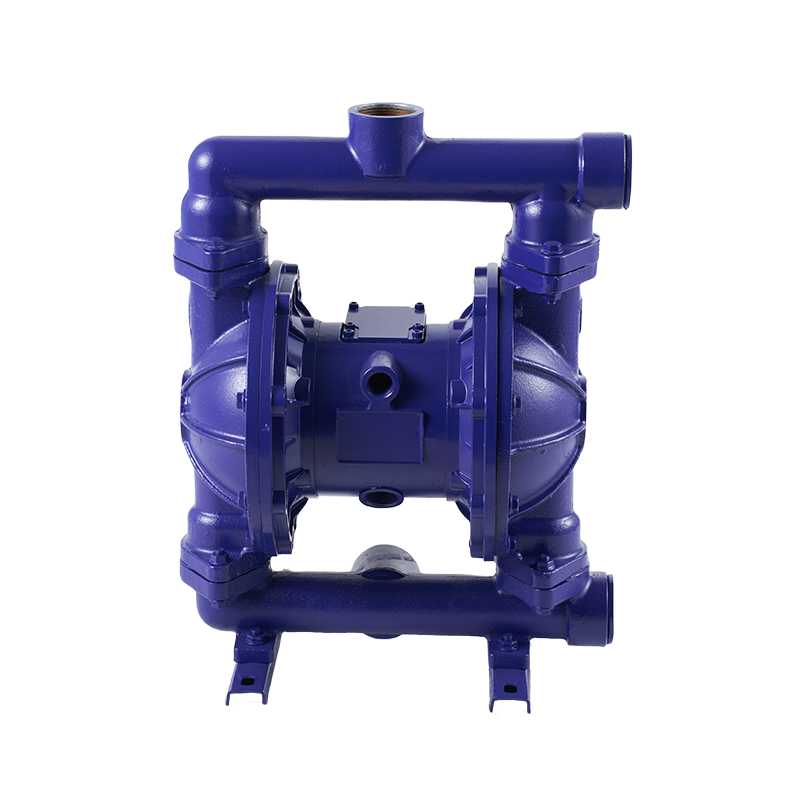

3. Handling of flammable and explosive media

Applicable media: benzene, ether, liquefied petroleum gas (LPG).

Solution:

Pneumatic explosion-proof pump: ATEX/IECEx certified, no electric drive required.

Static elimination: metal pump body grounding + conductive diaphragm (such as carbon fiber-filled PTFE).

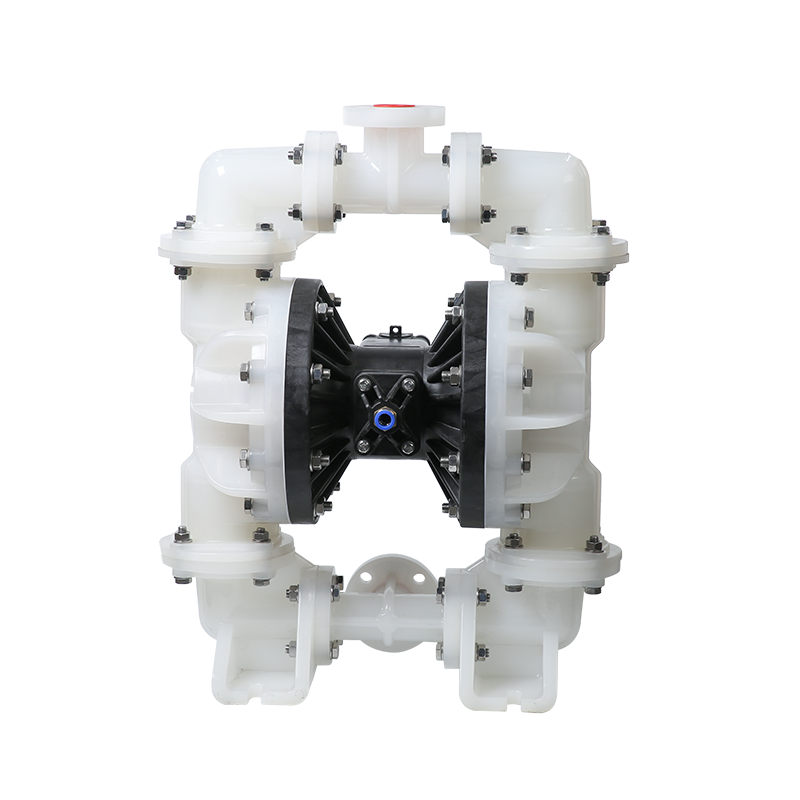

4. High viscosity and solid-containing fluids

Applicable media: polymer melt, catalyst-containing slurry.

Solution:

Large flow channel design: inlet and outlet above DN50 + swing valve structure, passing particle diameter ≤15mm.

Heating jacket: steam or electric heating to maintain medium fluidity (such as asphalt delivery pump).

Why do chemical companies prefer diaphragm pumps?

Safer than centrifugal pumps: no risk of shaft seal leakage, or dry running.

More durable than plunger pumps: no piston ring wear, 50% lower maintenance costs.

More accurate than gear pumps: adjustable flow range up to 1:100 (such as metering applications).

As an "all-round player" in chemical fluid processing, diaphragm pumps are driving the industry toward a safer, more efficient, and smarter direction. If you need a chemical media compatibility report, please contact our technical team!

English

English русский

русский Español

Español عربى

عربى