Oil Extraction

Diaphragm pumps are widely used in the oil field to transport high-risk, high-viscosity or impurity-containing media due to their corrosion resistance, explosion-proof and leakage-free properties. The following are its main application scenarios and advantages:

1. Crude oil and refined oil transportation

Application scenarios:

Transport high-viscosity crude oil, heavy oil or waxy oil products.

Transferring light oil (such as diesel and gasoline) between loading and unloading ships and storage tanks.

Advantages:

Leak-free design: Avoid leakage of volatile oil products and reduce the risk of fire and environmental pollution.

Self-priming ability: Can handle residual gas in the pipeline or intermittent liquid supply.

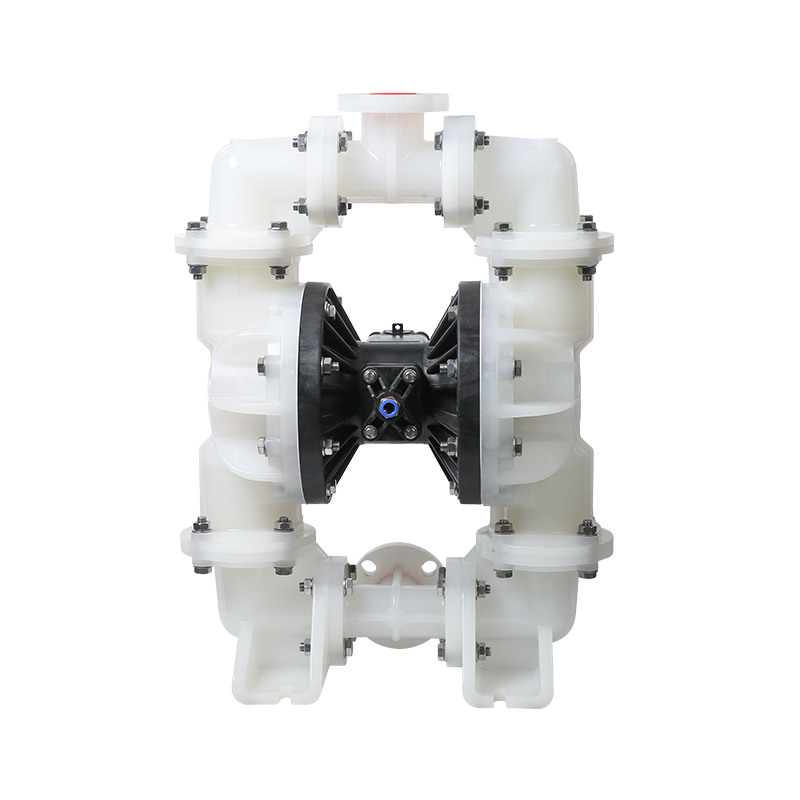

Corrosion-resistant material: The pump body can be made of stainless steel or lined with fluoroplastics (such as PTFE) to prevent sulfide corrosion.

2. Oilfield chemical injection

Application scenarios:

Injection of drilling fluids, corrosion inhibitors, demulsifiers and other chemical agents.

Precise metering and delivery of fracturing fluids (containing abrasive particles).

Advantages:

High-precision metering: Hydraulic diaphragm pumps can stably control the flow rate (error ±1%) and are suitable for chemical proportioning.

Resistant to particle media: Handle sand-containing liquids through elastic diaphragms and wear-resistant valves (such as ceramic ball valves).

3. Oily wastewater and sludge treatment

Application scenarios:

Recovery and transportation of oilfield produced water and sludge.

Waste liquid treatment containing solid particles (such as drilling cuttings).

Advantages:

Anti-clogging design: Large-diameter valves and flow channels can transport slurries with a solid content of ≤80%.

Dry running capability: No need to worry about idling damage when pumping intermittent sludge.

4. Operation in flammable and explosive environments

Application scenarios:

Oil product transportation in explosion-proof areas such as offshore platforms and refineries.

Handling of volatile media (such as benzene and xylene) in oil and gas recovery systems.

Advantages:

Pneumatic drive explosion-proof: No electricity required, operated by compressed air, compliant with ATEX/IECEx standards.

No spark risk: All-metal pump body optional to avoid static electricity accumulation.

5. Other special applications

Asphalt transportation: High-viscosity asphalt after heating requires an insulated diaphragm pump (with steam jacket).

Liquefied petroleum gas (LPG): Special seals and metal diaphragms are used under low temperature conditions.

Key points for selection in the oil field

Material selection:

Corrosive media: Hastelloy, fluoroplastics.

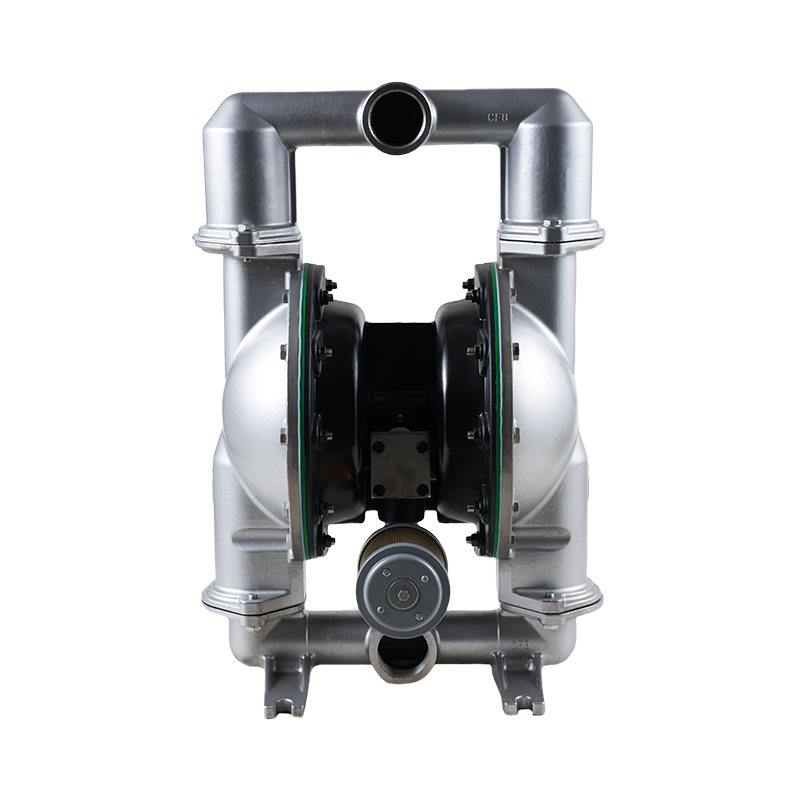

High-temperature oil products: Metal diaphragms (such as 316L stainless steel).

Safety certification: Explosion-proof certification (such as ATEX), API 675 standard (metering pump).

Maintenance requirements: Regularly check diaphragms and valves (petroleum media are prone to accelerated aging).

Diaphragm pumps have become key equipment in the oil industry due to their safety and adaptability, and are irreplaceable in scenarios with strict environmental protection and explosion-proof requirements.

English

English русский

русский Español

Español عربى

عربى