What Is A Diaphragm Pump?

2025.05.10

2025.05.10

Company News

Company News

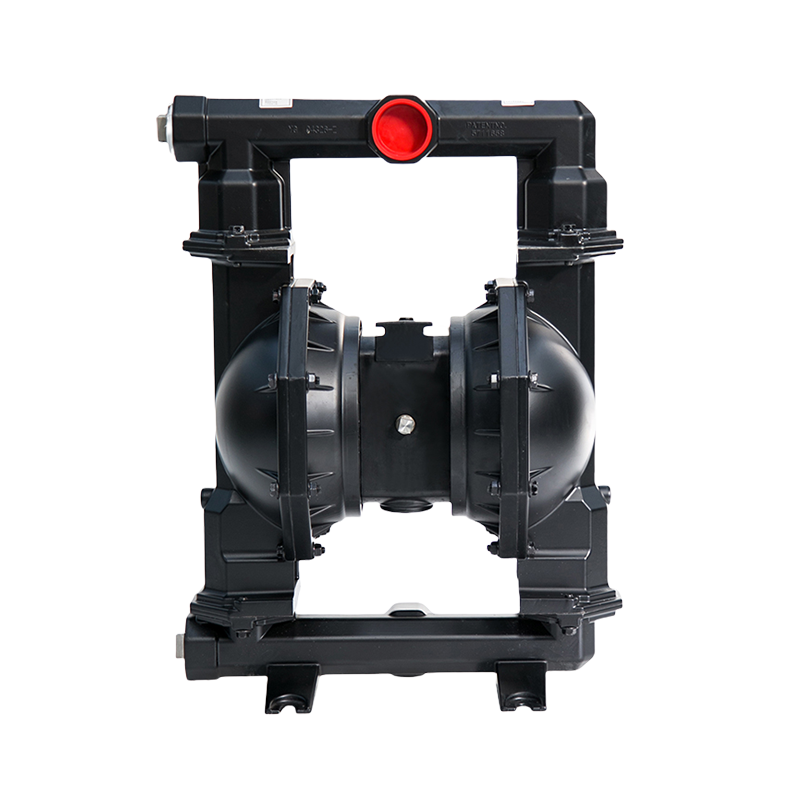

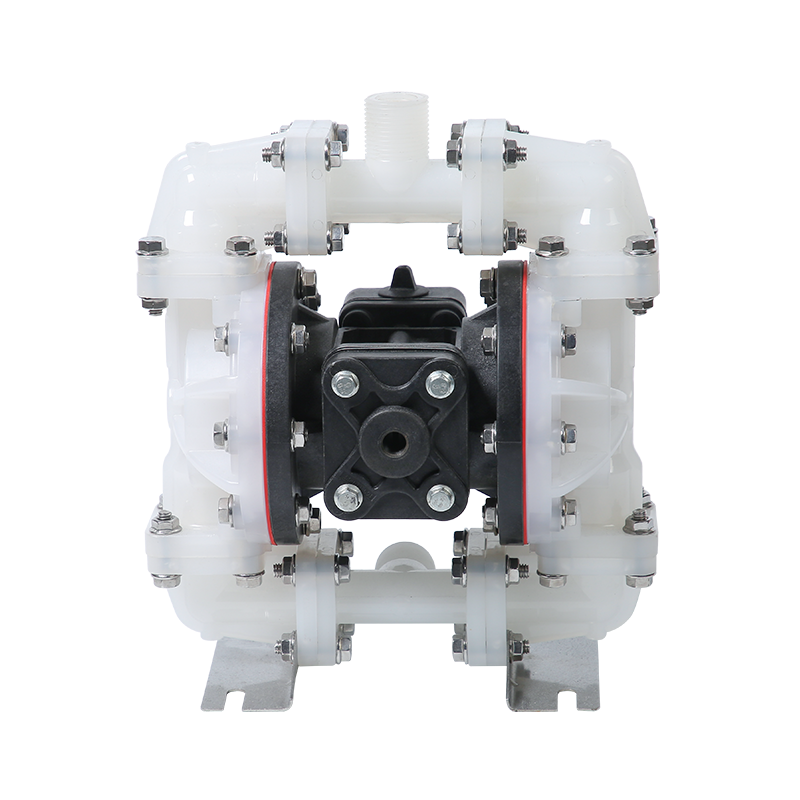

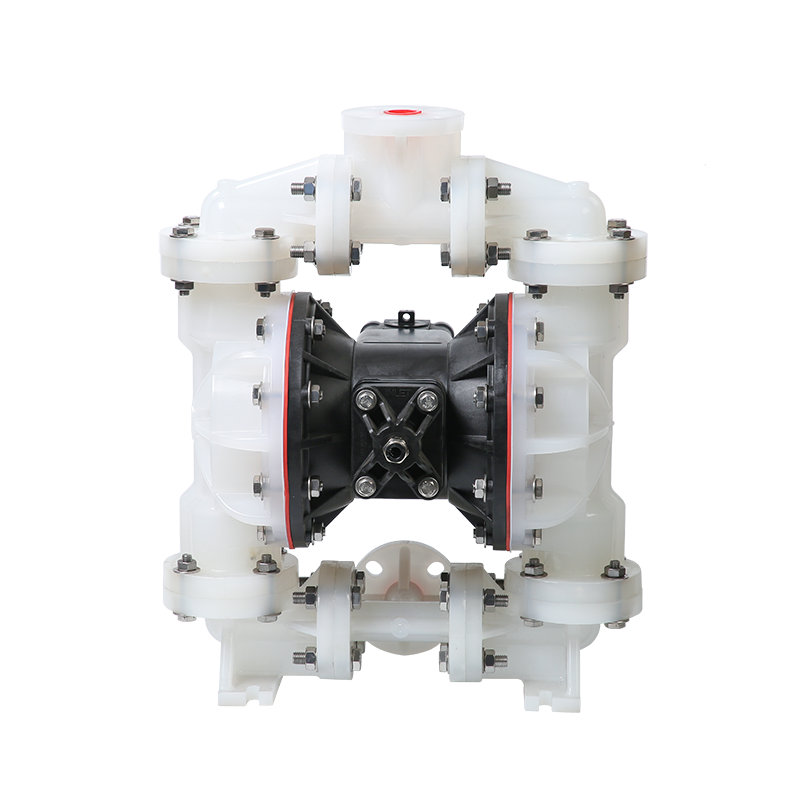

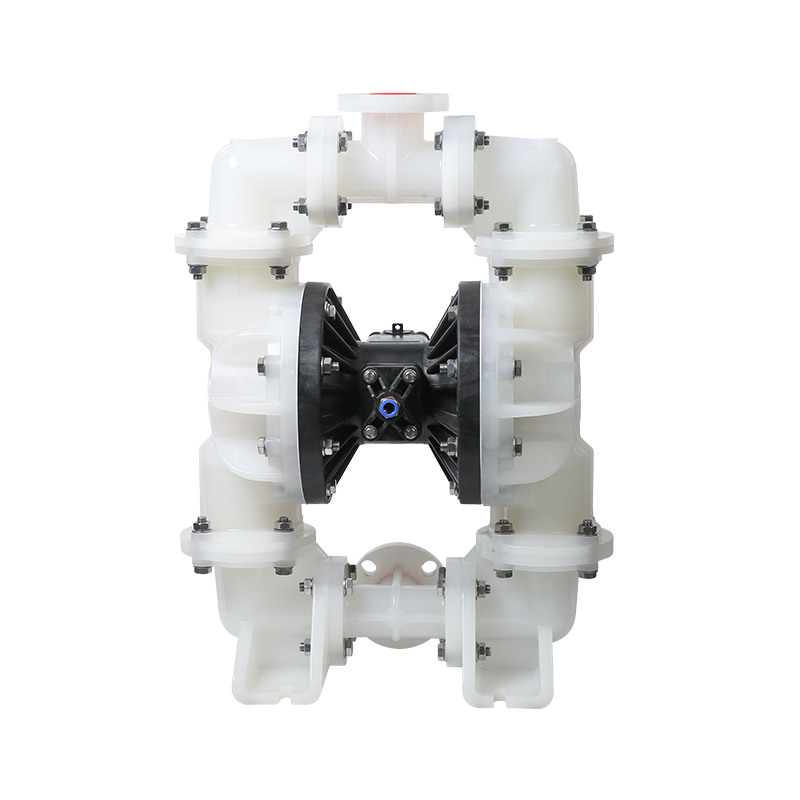

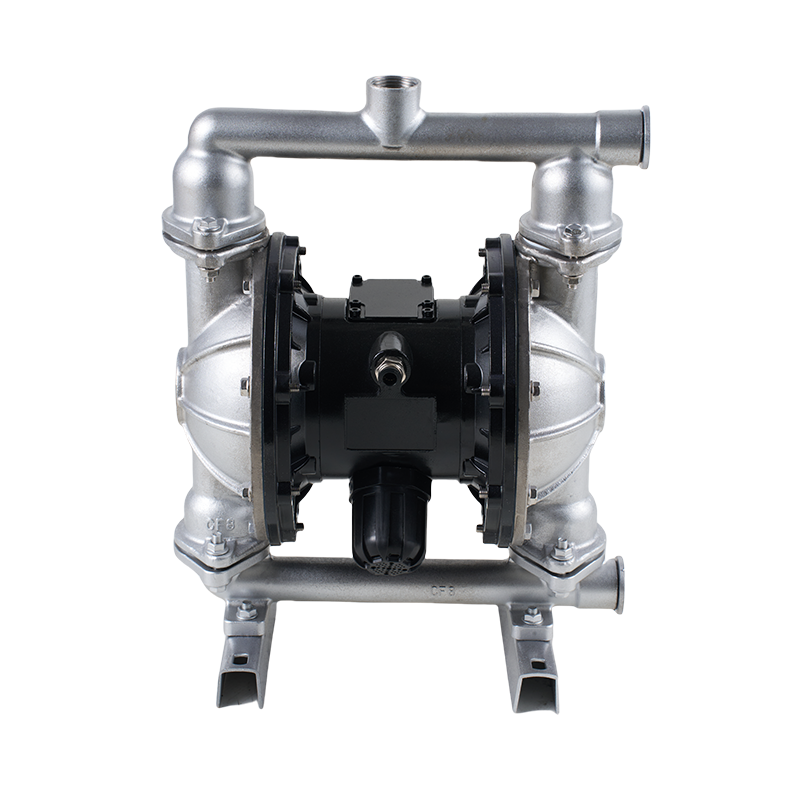

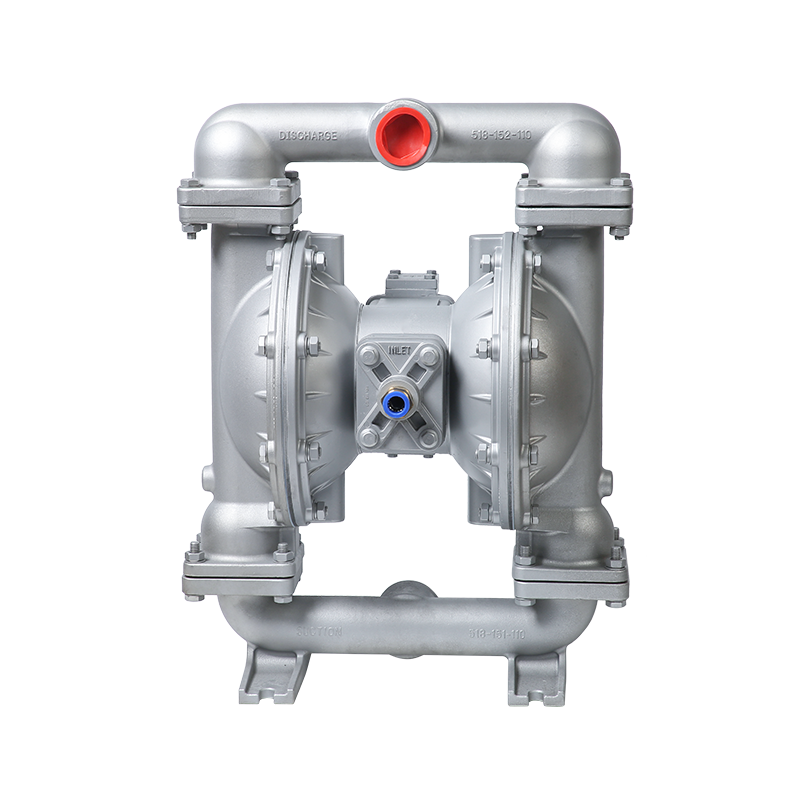

A diaphragm pump is a type of positive displacement pump that utilizes a flexible diaphragm to move fluids. This unique mechanism separates the fluid being pumped from the mechanical driving components, ensuring a leak-free operation. Among diaphragm pumps, the Twin Diaphragm Pump is especially popular due to its enhanced efficiency and reliability. The pump's core working element—the diaphragm—can be made from various materials, such as rubber, PTFE, or metal, making it highly adaptable to different industrial environments.

Working Principle of a Diaphragm Pump

The fundamental operation of a diaphragm pump relies on the reciprocating motion of the diaphragm. Driven by pneumatic, hydraulic, mechanical, or electrical power, the diaphragm moves back and forth inside the pump chamber. When the diaphragm contracts inward, the volume of the chamber increases, creating negative pressure that draws fluid into the chamber. On the expansion stroke, the diaphragm compresses the fluid and forces it out through the outlet. In many diaphragm pumps, a one-way valve—either a ball valve or a flap valve—ensures the fluid flows only in the desired direction, preventing backflow.

Specifically, in a Pneumatic Membrane Pump, compressed air powers the diaphragm movement. The Air Pump Membrane within these pumps is flexible and resilient, allowing the pump to handle aggressive fluids without leakage or contamination. The Twin Diaphragm Pump variant uses two diaphragms connected by a shaft, allowing one diaphragm to move the other, which improves pumping stability and reduces pulsation.

Types of Diaphragm Pumps

Pneumatic Diaphragm Pump:

This pump uses compressed air to drive the Air Pump Membrane. It requires no electrical power, making it explosion-proof and suitable for hazardous environments. The Pneumatic Membrane Pump is known for its simplicity, durability, and ability to run dry without damage.

Electric Diaphragm Pump:

Powered by a motor connected to the diaphragm via a crankshaft, this pump is ideal for applications requiring consistent flow rates. While not as explosion-proof as pneumatic types, electric pumps are efficient in many industrial settings.

Hydraulic Diaphragm Pump:

Uses hydraulic fluid pressure to move the diaphragm, capable of handling higher pressures. This type is often used in chemical processes requiring precision and control.

Among these, the Twin Diaphragm Pump is favored for its balanced design, where two Air Pump Membranes operate in tandem, resulting in smoother flow and reduced vibration.

Core Features of Diaphragm Pumps

Leak-Free Design: Thanks to the flexible diaphragm, the pumped medium is isolated from the drive mechanism, preventing leakage issues common in other pump types. The Air Pump Membrane plays a critical role in this sealing function.

Self-Priming Capability: Many diaphragm pumps, including the Pneumatic Membrane Pump, can self-prime and handle dry suction up to 5-6 meters without additional priming equipment.

Corrosion and Wear Resistance: Depending on the application, diaphragms are made from materials like PTFE or rubber, resistant to corrosive chemicals or abrasive solids. This makes the Twin Diaphragm Pump ideal for harsh environments.

Flow Regulation and Pulsation Control: The flow rate in pneumatic diaphragm pumps can be easily controlled by adjusting air pressure or frequency, and the Twin Diaphragm Pump design helps minimize pulsation compared to single-diaphragm models.

Applications of Diaphragm Pumps

The versatility of diaphragm pumps, especially Pneumatic Membrane Pumps, extends across numerous industries:

Chemical Industry: Handling highly corrosive liquids like acids and alkalis safely, where the Air Pump Membrane material choice is crucial.

Food and Pharmaceuticals: Sanitary designs ensure contamination-free fluid transfer of sensitive or high-purity products.

Mining and Environmental Protection: Capable of pumping slurries, abrasive particles, and sludge without damage, making the Twin Diaphragm Pump popular in these sectors.

Nuclear Industry: The sealed nature of diaphragm pumps makes them suitable for safely moving radioactive fluids.

Advantages and Disadvantages

The major advantages of diaphragm pumps includesealing, easy maintenance, and adaptability to various fluids and operating conditions. The Pneumatic Membrane Pump type stands out for explosion-proof operation and dry-run capability. However, diaphragms are subject to fatigue and require periodic replacement. Additionally, pulsation can be a concern but is greatly reduced in Twin Diaphragm Pump designs and can be further minimized with pulsation dampers.

Key Parameters for Selecting a Diaphragm Pump

When choosing a diaphragm pump, it is essential to consider flow rate, pressure requirements, diaphragm material, and valve type. For granular media, ball valves combined with a Twin Diaphragm Pump are . High-viscosity fluids may benefit more from flap valves. The choice of diaphragm material, such as rubber or PTFE, depends heavily on the chemical and physical nature of the fluid.

In conclusion, a diaphragm pump—especially the Twin Diaphragm Pump and the Pneumatic Membrane Pump—offers unmatched safety, reliability, and versatility for demanding fluid transfer applications. The flexible Air Pump Membrane is the heart of these pumps, ensuring leak-free, efficient operation across various industries and special conditions.

English

English русский

русский Español

Español عربى

عربى