Air Operated Diaphragm Pumps in Industrial Fluid Handling

2025.08.18

2025.08.18

Industry News

Industry News

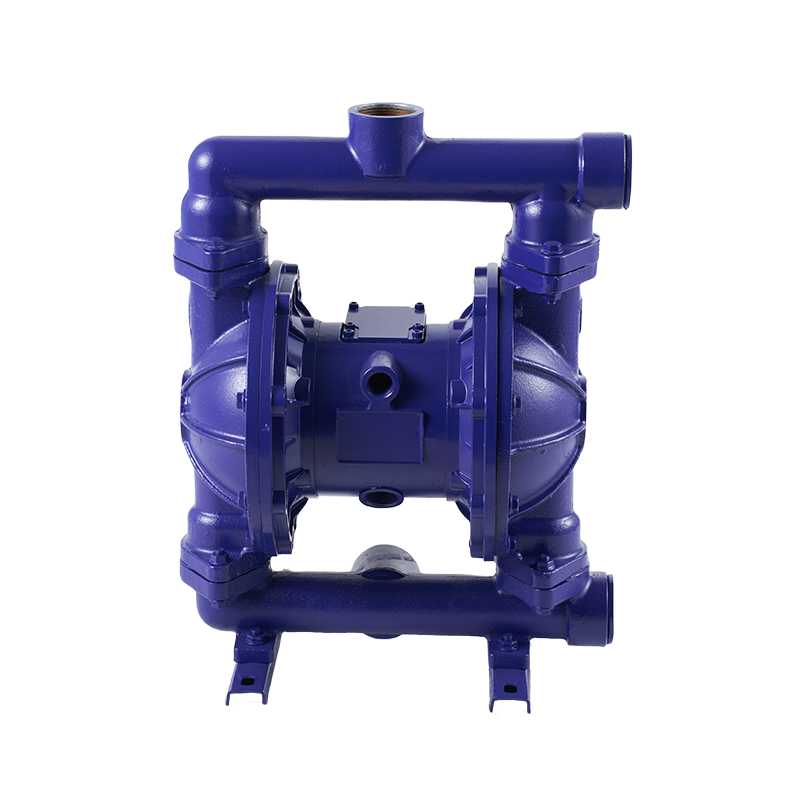

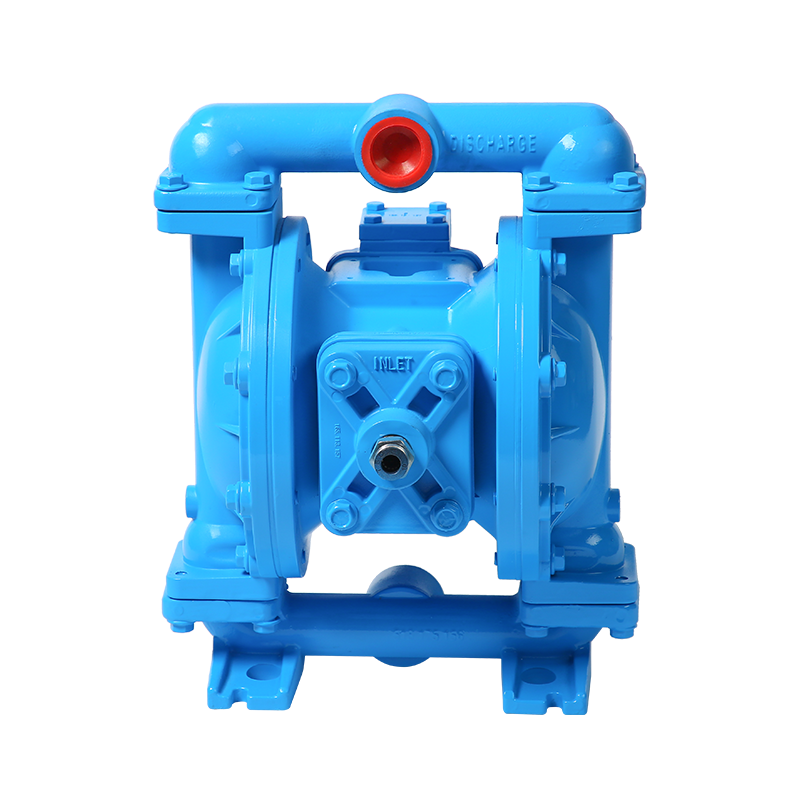

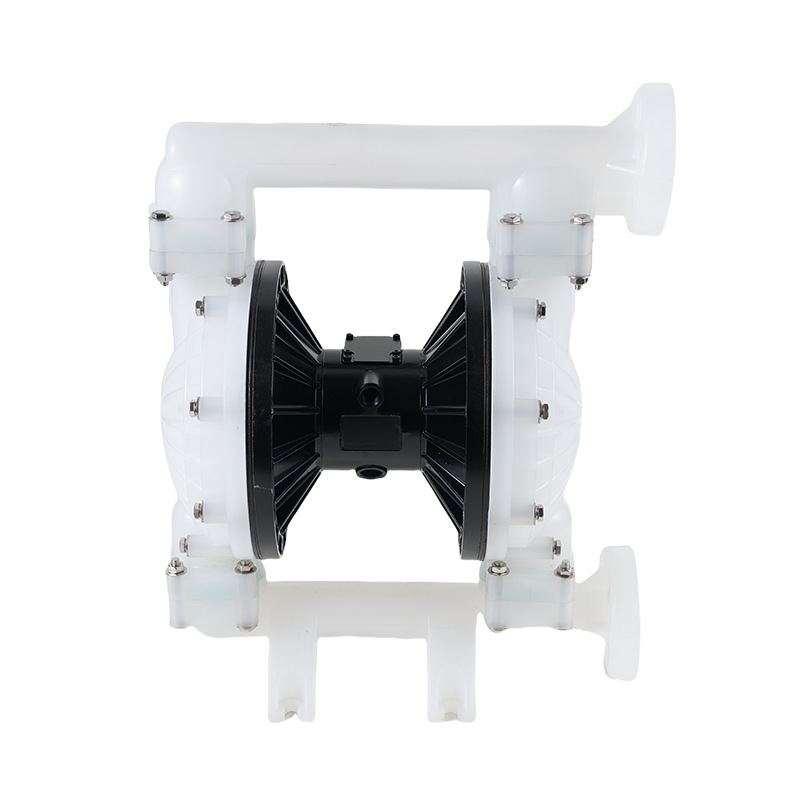

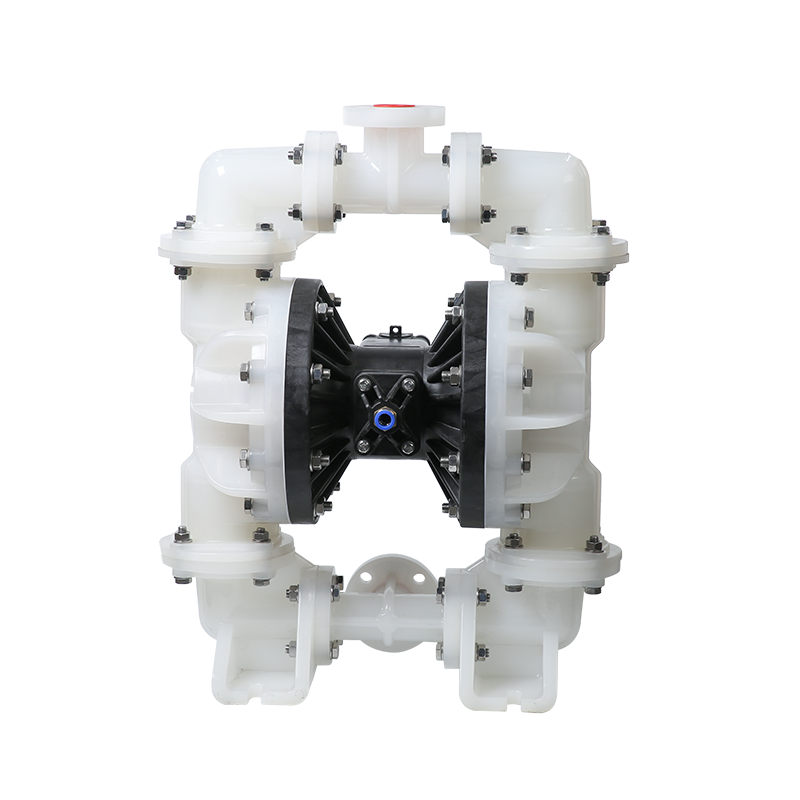

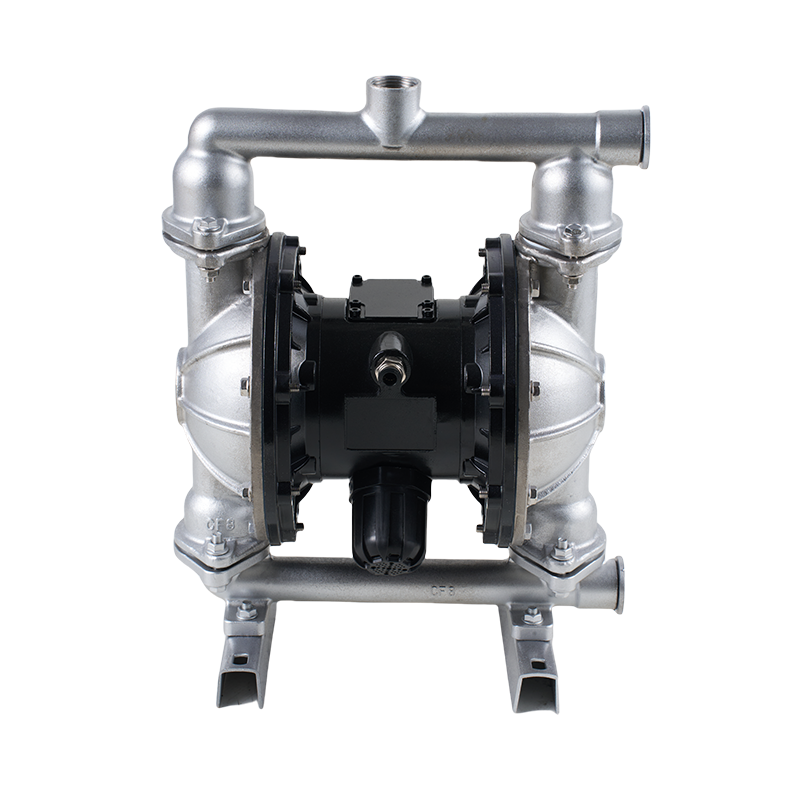

In the vast and intricate realm of industrial fluid handling, the air operated diaphragm pump has emerged as a versatile and indispensable piece of equipment. Its unique design and operational principles make it an ideal solution for a wide range of applications, from transferring corrosive chemicals to pumping abrasive slurries.

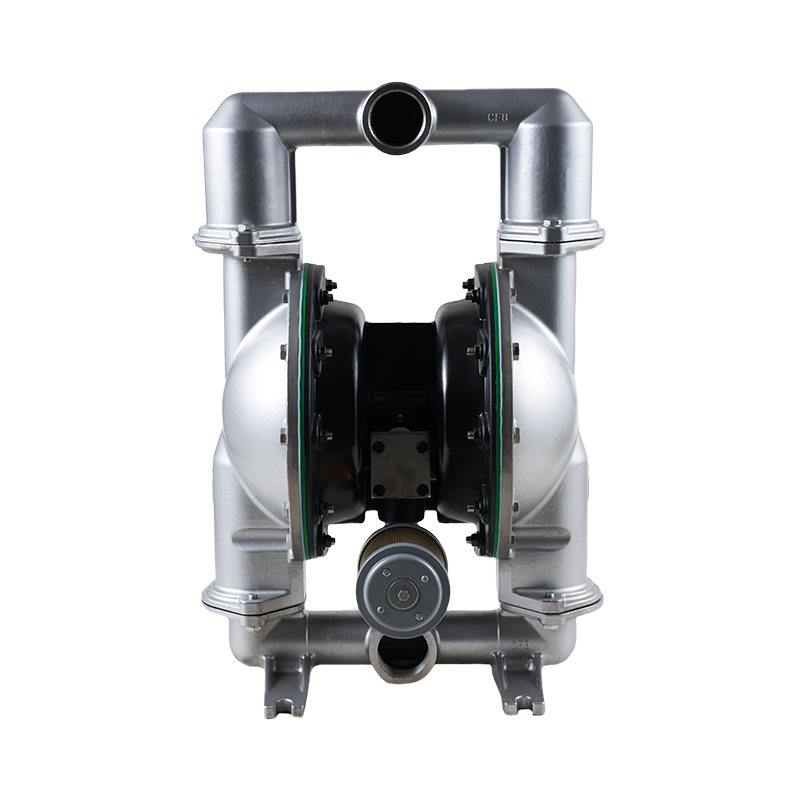

The dual diaphragm pump, a specific type of air operated diaphragm pump, is renowned for its ability to handle fluids with varying viscosities and solid content. This innovative pump operates on the principle of positive displacement, utilizing two flexible diaphragms that reciprocate to create a suction and discharge action. The dual diaphragm design ensures that the fluid being pumped is kept separate from the air supply, minimizing the risk of contamination and enhancing overall safety.

One of the key advantages of the double diaphragm air pump is its ability to self-prime. This feature is particularly beneficial in industrial settings where the pump may need to handle intermittent flow or fluids with high vapor pressure. The self-priming capability eliminates the need for additional priming devices, reducing maintenance costs and downtime. Moreover, the double diaphragm air pump can run dry without causing damage to the pump components, making it suitable for applications where fluid supply may be inconsistent.

The diaphragm pump air-operated system is also highly adaptable to different fluid types. Whether it is a viscous liquid, a slurry containing solid particles, or even a shear-sensitive fluid, the air operated diaphragm pump can handle it with ease. This versatility is due to the pump's ability to adjust its flow rate and pressure based on the fluid characteristics and process requirements. The pulsating flow generated by the diaphragm movement can also help in mixing and homogenizing the fluid, which is advantageous in certain chemical processing applications.

Safety is another crucial aspect of air operated diaphragm pumps. Since these pumps are powered by compressed air, they eliminate the risk of electrical hazards associated with other types of pumps. This makes them particularly suitable for use in hazardous environments, such as those where flammable or explosive gases may be present. The absence of mechanical seals also reduces the risk of leaks and fluid spillage, further enhancing safety and environmental protection.

In terms of maintenance, air operated diaphragm pumps are relatively low-maintenance compared to other pump types. The diaphragms, which are the main wearing parts, can be easily replaced without the need for specialized tools or extensive downtime. This ease of maintenance translates to lower overall operating costs and increased reliability in industrial operations.

The dual diaphragm pump is also highly energy-efficient. The air operated mechanism allows for precise control of the pump's operation, ensuring that only the required amount of energy is used. This not only reduces energy consumption but also contributes to a more sustainable industrial process. The ability to throttle the air supply to match the process demand makes the diaphragm pump air operated system an attractive option for companies looking to optimize their energy usage.

In the chemical industry, air operated diaphragm pumps are used extensively for transferring corrosive and hazardous chemicals. The pump's ability to handle these fluids without the risk of contamination or leakage makes it a preferred choice for chemical processing plants. The double diaphragm air pump can also be equipped with various materials, such as stainless steel, PTFE, or other corrosion-resistant materials, to ensure compatibility with different chemical substances.

In the food and beverage industry, the diaphragm pump air operated system is used for pumping sensitive liquids like fruit juices, sauces, and dairy products. The gentle pumping action of the dual diaphragm pump helps to preserve the quality and consistency of these products. Additionally, the pump's ability to be easily cleaned and sanitized makes it suitable for applications where hygiene and food safety are of importance.

In the mining and mineral processing industry, air operated diaphragm pumps are employed for handling abrasive slurries. The robust design of the double diaphragm air pump allows it to withstand the wear and tear caused by solid particles in the slurry. The pump's ability to handle high solid concentrations without clogging makes it an essential tool in these harsh industrial environments.

As industries continue to evolve and face new challenges, the air operated diaphragm pump remains a reliable and efficient solution for fluid handling needs. Its versatility, safety, low maintenance, and energy efficiency make it a preferred choice for a wide range of applications. Whether it is in chemical processing, food production, or mineral extraction, the dual diaphragm pump and its air operated mechanism are proving to be indispensable tools in modern industrial operations.

The air operated diaphragm pump, with its dual diaphragm design and innovative operational principles, is a vital component in industrial fluid handling. Its ability to handle a variety of fluids, adapt to different process requirements, and operate safely and efficiently makes it a valuable asset in various industries. As technology continues to advance, we can expect further improvements and innovations in the design and application of air operated diaphragm pumps, ensuring their continued relevance and effectiveness in the industrial fluid handling landscape.

English

English русский

русский Español

Español عربى

عربى