What Makes Air Operated Diaphragm Pumps So Reliable?

2025.08.18

2025.08.18

Industry News

Industry News

In the industrial world, reliability is one of the important factors when selecting fluid transfer equipment. Among the many pumping solutions available, the Air Operated Double Diaphragm pump has earned a solid reputation for consistent performance across multiple applications. From chemical manufacturing to fuel distribution, these pumps deliver dependable operation in demanding environments.

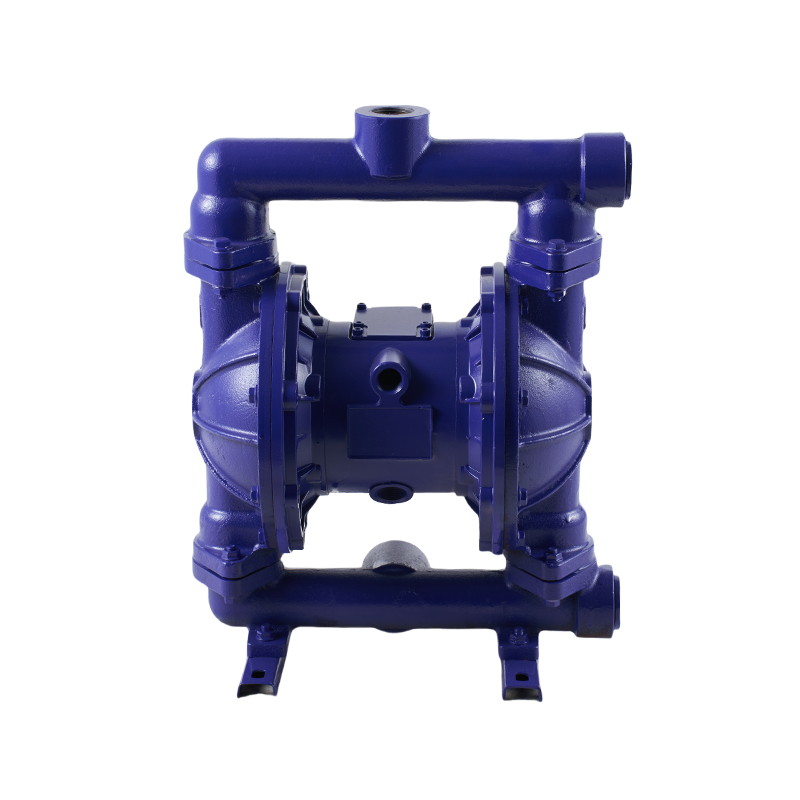

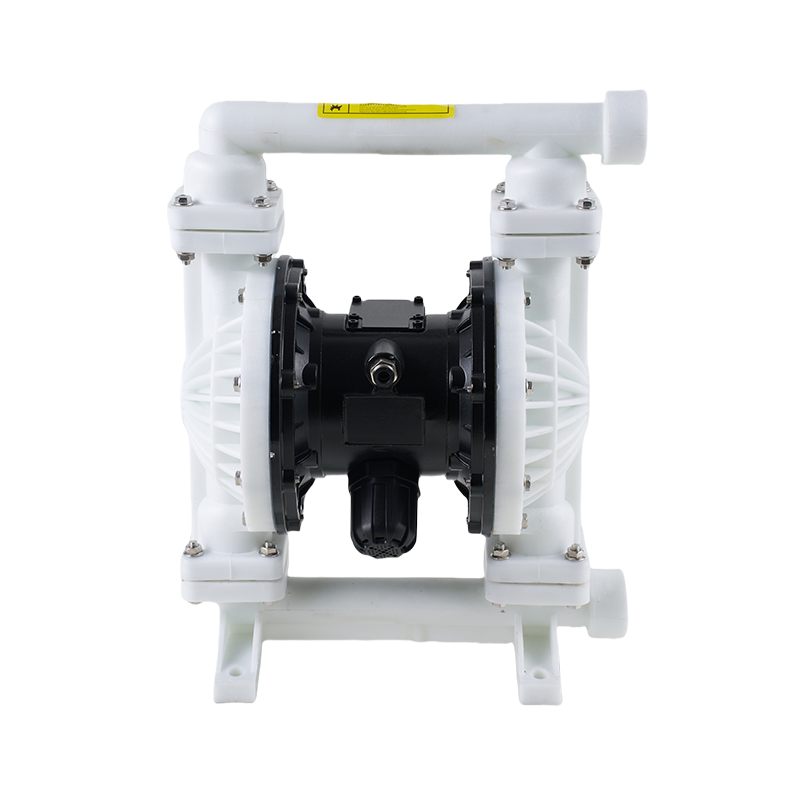

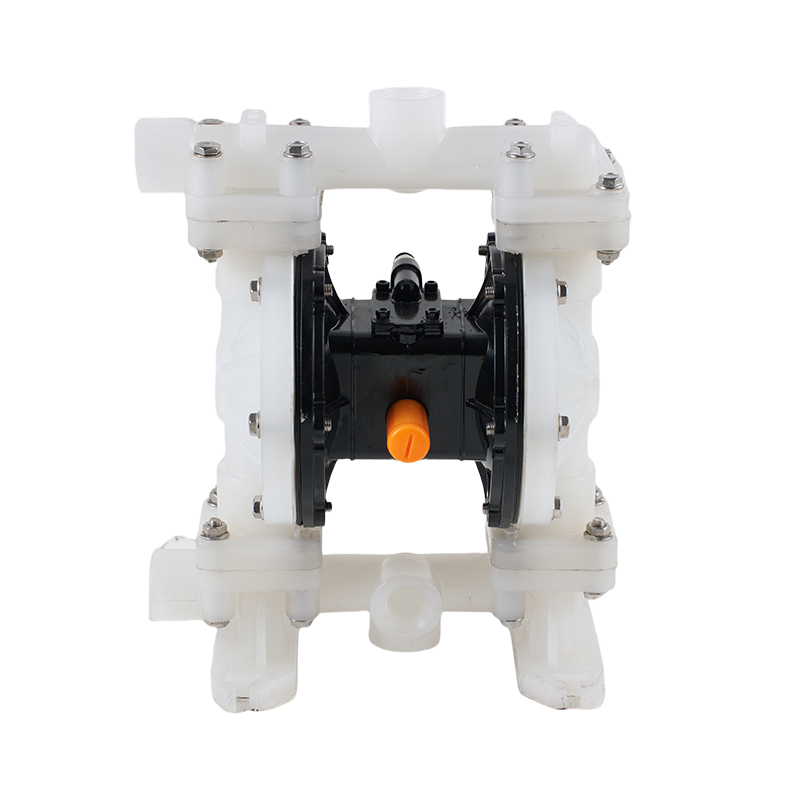

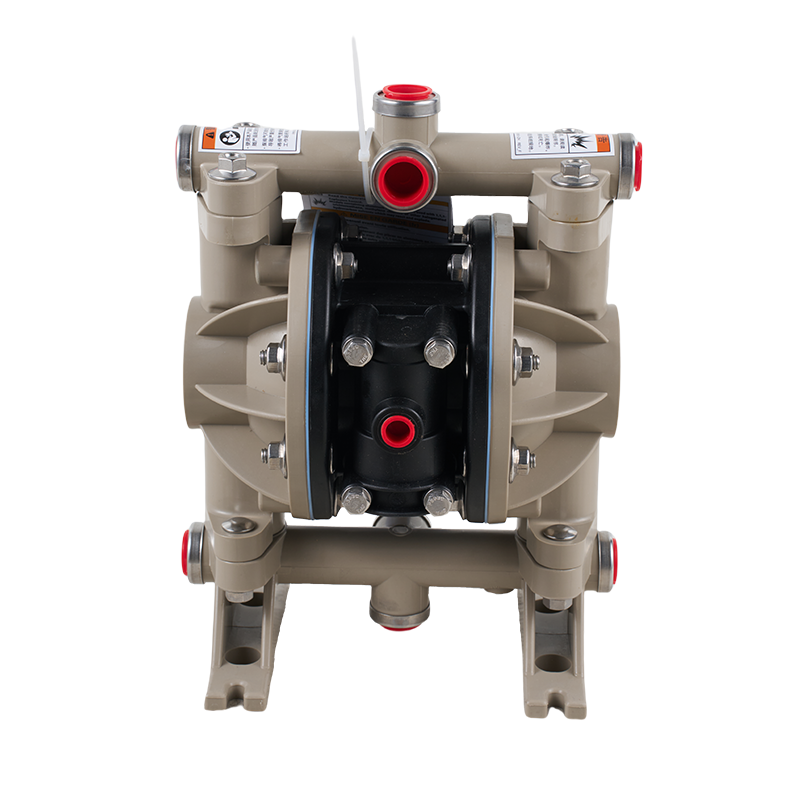

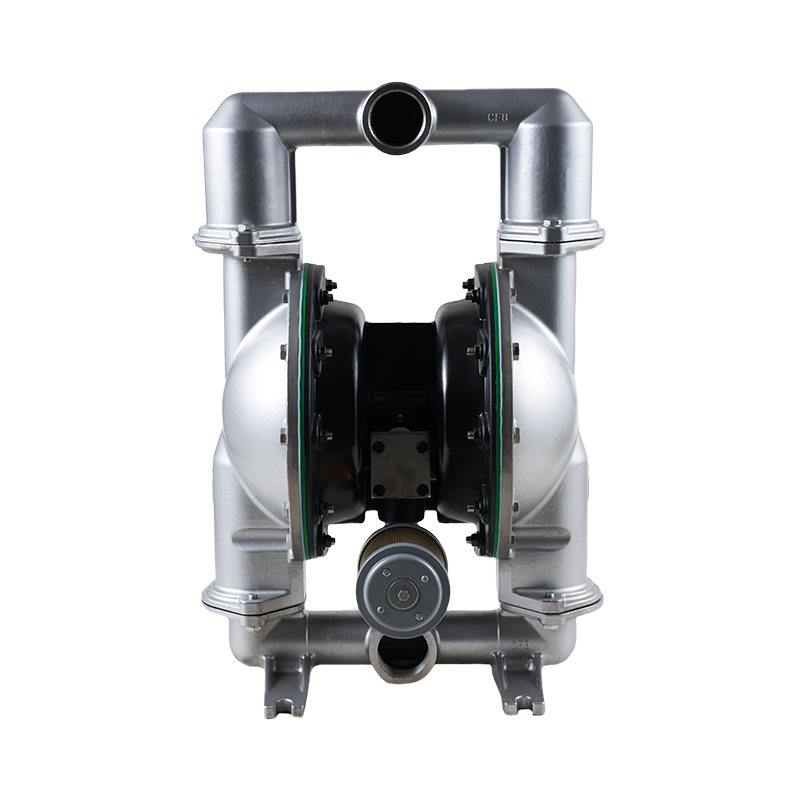

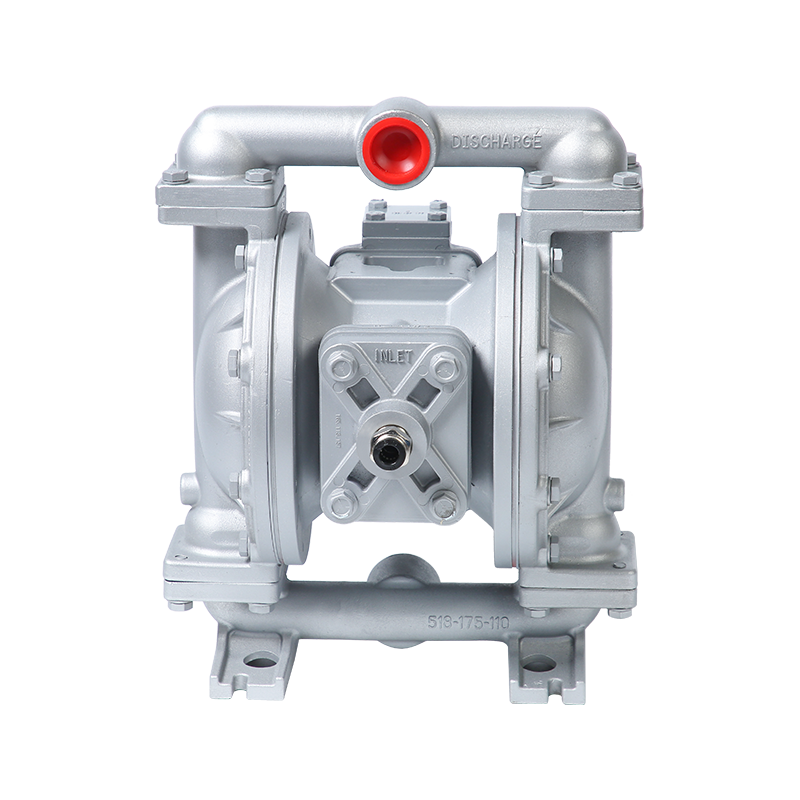

One of the main reasons the Air Operated Double Diaphragm pump stands out is its simple yet effective design. With only a few moving parts and no need for electric power, the risk of mechanical failure is greatly reduced. The pump operates using compressed air, which drives two flexible diaphragms connected by a shaft. As one diaphragm moves to discharge liquid, the other draws in fluid, creating a smooth, continuous flow of fluid. This mechanism enables the Air Operated Double Diaphragm pump to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive liquids.

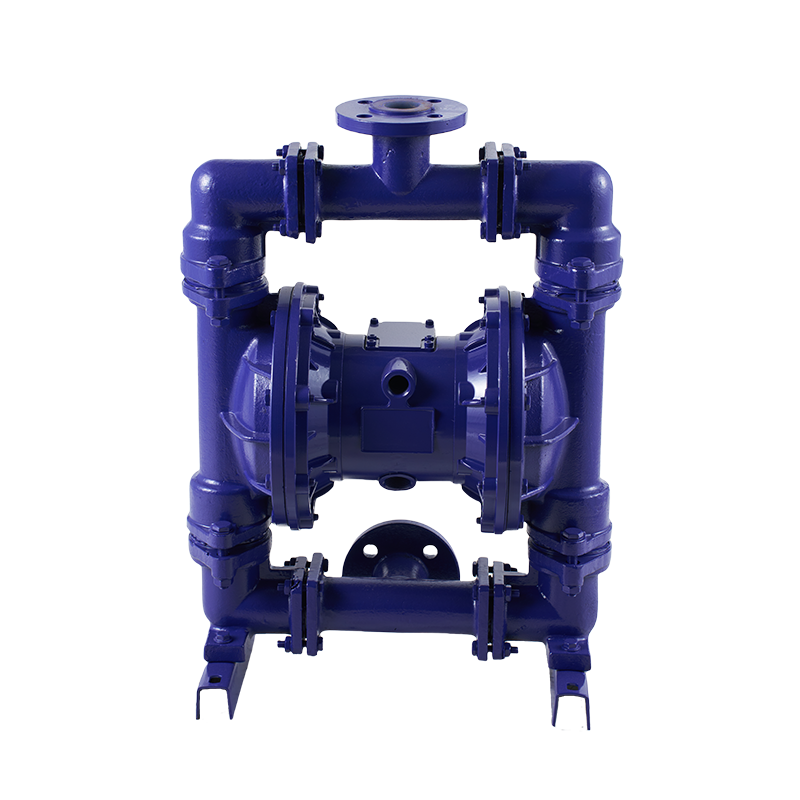

In fuel handling operations, the Double Diaphragm Fuel Transfer Pump has become a trusted choice. Its ability to safely transfer diesel, gasoline, kerosene, and other fuels without generating sparks makes it suitable for environments where fire safety is essential. The Double Diaphragm Fuel Transfer Pump also offers self-priming capabilities, enabling it to draw fuel from tanks located below the pump level. Whether installed in a fixed fueling station or used in a mobile setup, the Double Diaphragm Fuel Transfer Pump maintains a steady flow rate without overheating or requiring constant monitoring.

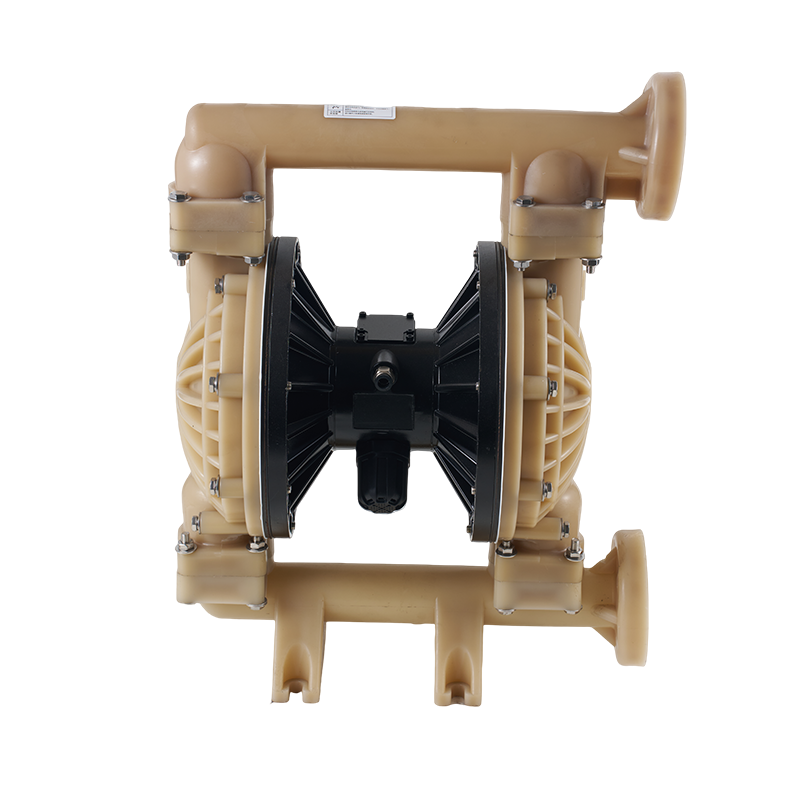

Another critical advantage is the adaptability of the Air Operated Double Diaphragm Pump Working principle. Because the pump relies on air pressure rather than electrical motors, it can be used in hazardous or remote areas where electricity is not available. The Air Operated Double Diaphragm Pump Working process is also gentle on the fluid, which reduces the risk of damage to sensitive materials such as emulsions, slurries, or fuel blends. This versatility means the same basic design can be applied in different industries with minimal modifications.

Maintenance is another area where these pumps excel. The straightforward Air Operated Double Diaphragm Pump Working mechanism makes servicing quick and uncomplicated. Components such as diaphragms and check valves are accessible and can be replaced without removing the entire unit from service. This reduces downtime and extends the operational lifespan. Many operators choose Air Operated Double Diaphragm pumps precisely because their maintenance needs are predictable and cost-effective over time.

Durability is further enhanced by the variety of construction materials available. The Double Diaphragm Fuel Transfer Pump can be built with aluminum, stainless steel, or polypropylene housings, as well as different diaphragm materials to match specific fluid properties. This means a pump can be tailored to resist corrosion, abrasion, or chemical attack, ensuring it continues to perform reliably in challenging conditions.

Another point worth noting is efficiency. The Air Operated Double Diaphragm Pump Working cycle allows for controlled flow rates simply by adjusting air supply pressure. This eliminates the need for complex control systems, reducing energy consumption and operational complexity. The result is a pumping solution that is both versatile and easy to integrate into existing processes.

The long-standing reputation of the Air Operated Double Diaphragm pump is built on a combination of design simplicity, operational safety, and adaptability. The Double Diaphragm Fuel Transfer Pump continues to serve as a dependable choice for fuel handling, while the core Air Operated Double Diaphragm Pump's Working principle remains relevant across countless industries. For companies seeking a reliable, low-maintenance, and flexible pumping solution, these pumps remain a proven option that consistently delivers results.

English

English русский

русский Español

Español عربى

عربى