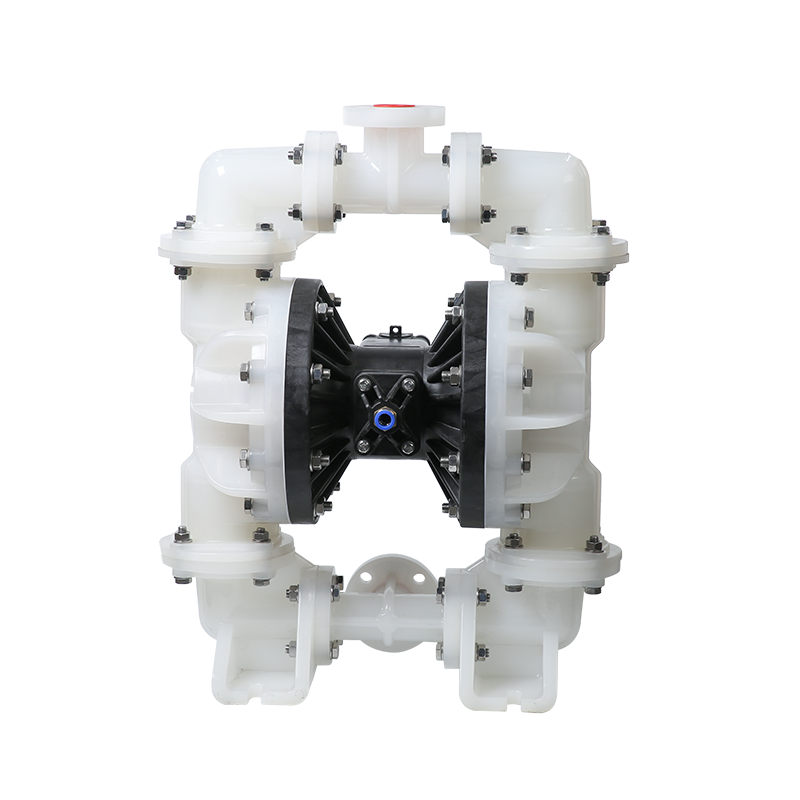

How A Polypropylene Pneumatic Diaphragm Pump Improves Fluid Handling Efficiency?

2025.11.25

2025.11.25

Industry News

Industry News

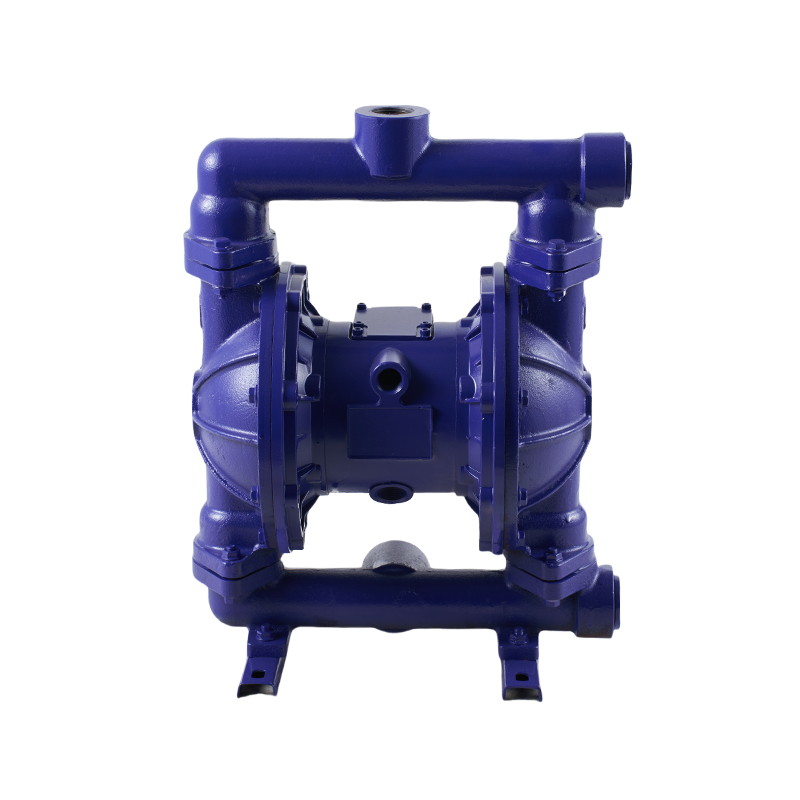

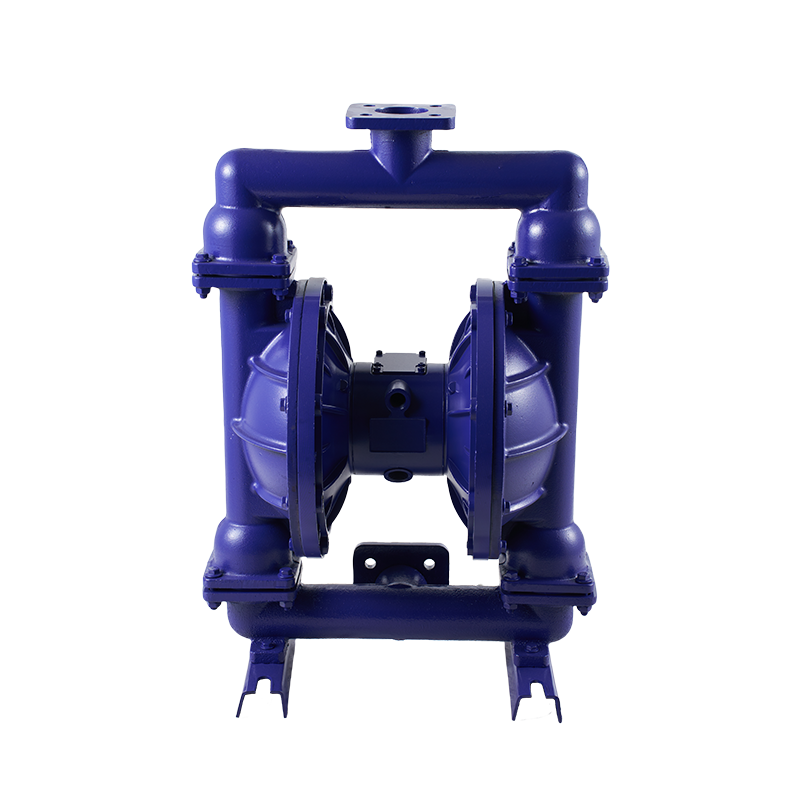

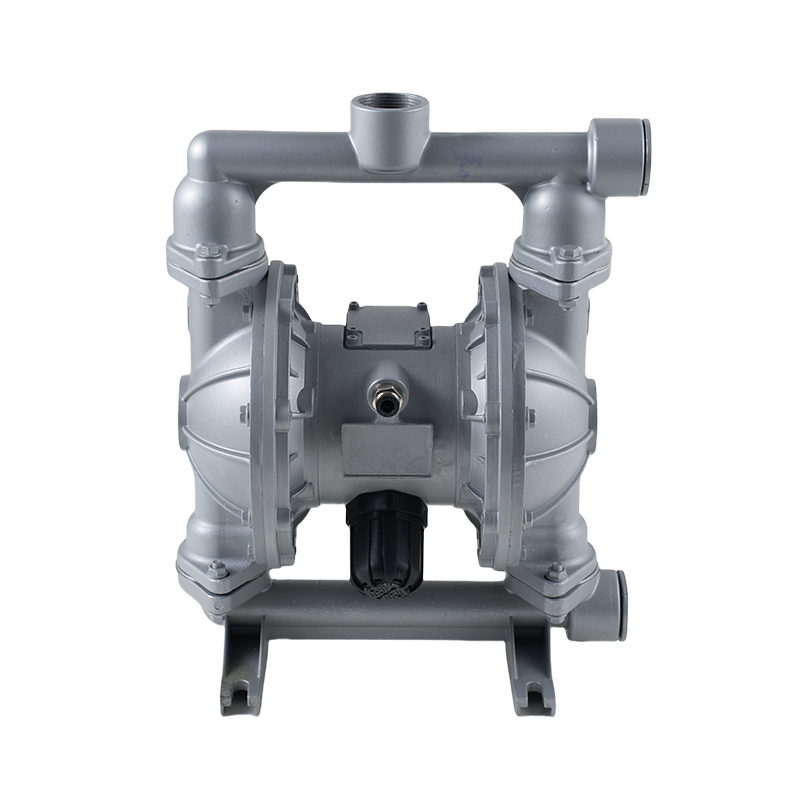

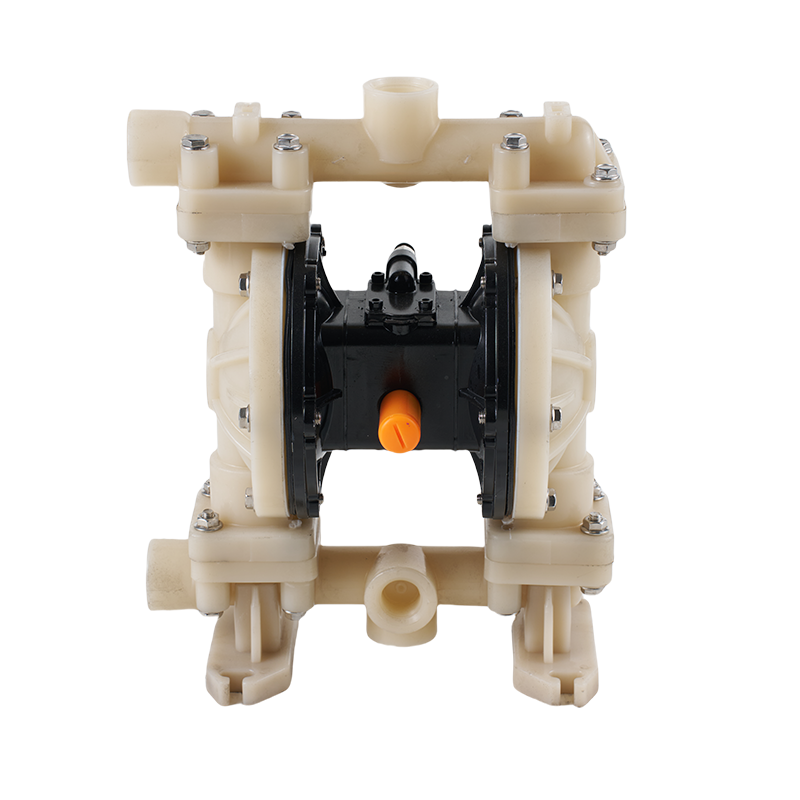

1. Strong Chemical Resistance and Structural Stability

Polypropylene is known for its resistance to acids, alkalis, and solvents, making it ideal for demanding industrial environments. A Polypropylene Pneumatic Diaphragm Pump built from this material performs steadily even when exposed to aggressive fluids. This durability reduces maintenance frequency and allows continuous operation under tough conditions. Many Polypropylene Pneumatic Diaphragm Pump Manufacturers design their pumps to handle a wide range of chemicals, supporting industries that deal with fluid transfer challenges daily.

2. Efficient and Adjustable Performance

Industrial applications often require pumps that can adapt to varying flow rates and pressures. Models such as QBK-25 or QBK-50 are designed to provide smooth flow from 0 to 20 m³/h with head capabilities up to 69 meters. These specifications make the pump suitable for small to large-scale processes. The air-driven design of a Polypropylene Pneumatic Diaphragm Pump allows it to start and stop instantly without electrical hazards, offering flexible control and energy efficiency. This performance versatility appeals to factories seeking reliable and low-cost fluid management equipment.

3. Leak-Free and Maintenance-Friendly Design

Many buyers from the chemical and wastewater sectors prioritize clean operation. The diaphragm mechanism separates the fluid from moving parts, preventing leaks and contamination. The pump operates without dynamic seals, meaning fewer parts are exposed to wear. This makes maintenance simple and cost-efficient. Polypropylene Pneumatic Diaphragm Pump Manufacturers often use threaded or flange connections, allowing quick installation or replacement. Whether it's a QBK-20 for compact systems or a QBK-100I for higher flow rates, the pumps maintain stable operation while keeping maintenance time low.

4. Wide Industrial Applications

The flexibility of a Polypropylene Pneumatic Diaphragm Pump allows it to be used across multiple industries. In chemical plants, it transfers strong acids and alkalis; in pharmaceutical manufacturing, it handles sensitive ingredients safely; in wastewater treatment, it moves sludge and neutralizing agents with ease. The air-powered drive system prevents sparks, making it suitable for flammable or moisture-prone environments. This adaptability is one reason why Polypropylene Pneumatic Diaphragm Pump Manufacturers are gaining recognition among industrial buyers worldwide.

Beyond its technical strengths, the true advantage of the Polypropylene Pneumatic Diaphragm Pump lies in its balance between cost and reliability. Manufacturers now produce models with flow capacities ranging from 1 to 70 m³/h and suction lifts up to 10 meters, providing options for both light and heavy-duty processes. The ability to handle particles up to 12 mm further enhances its usability for thicker or particulate-laden fluids.

For factories aiming to upgrade or replace their fluid transfer systems, working directly with trusted Polypropylene Pneumatic Diaphragm Pump Manufacturers can simplify sourcing while offering dependable product support. Buyers can expect pumps that combine efficient air consumption, corrosion resistance, and a long operating life-all critical factors for stable production environments.

Choosing a Polypropylene Pneumatic Diaphragm Pump is not just a technical decision; it's a strategic investment in operational reliability and process efficiency. With its durable polypropylene body, diaphragm-driven flexibility, and easy maintenance, it continues to prove itself as a valuable asset across a range of industrial applications.

English

English русский

русский Español

Español عربى

عربى