What Problems Can A Diaphragm Pump Manufacturer Help You Solve?

2025.12.05

2025.12.05

Industry News

Industry News

An industrial plant depends heavily on stable and predictable fluid transfer, especially when dealing with corrosive, abrasive, or chemically active materials. Many production managers face similar concerns: frequent downtime, component wear, rising repair expenses, and unclear product quality differences between suppliers. Working with a Diaphragm Pump Manufacturer that understands these challenges can meaningfully improve daily operations.

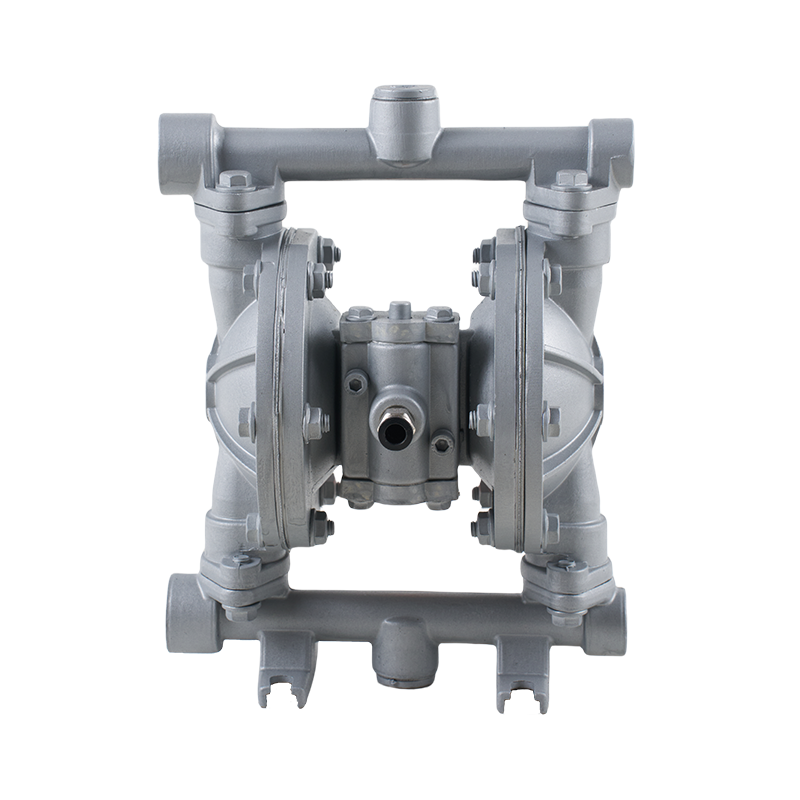

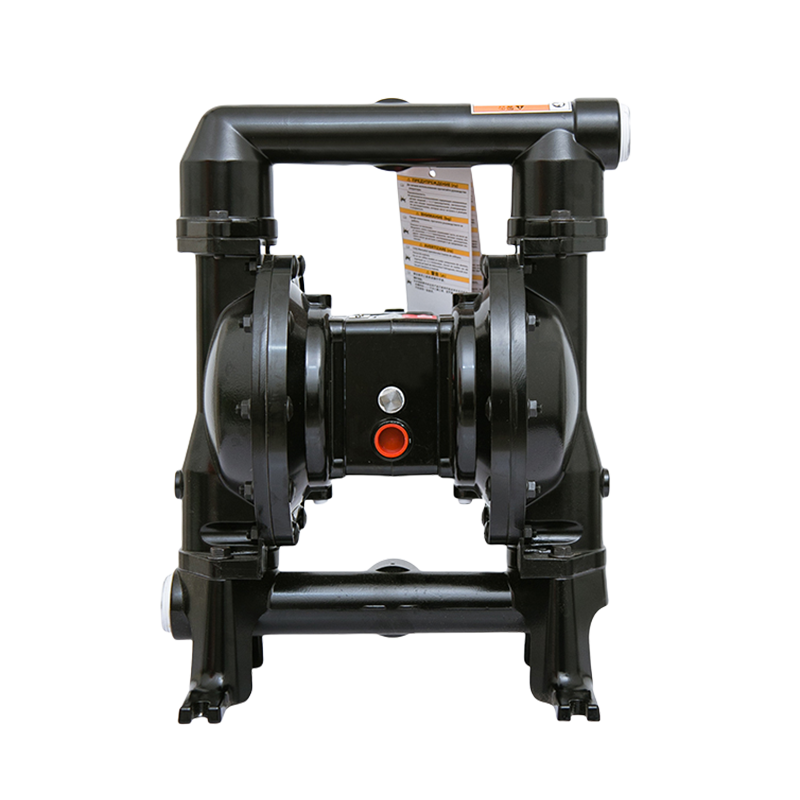

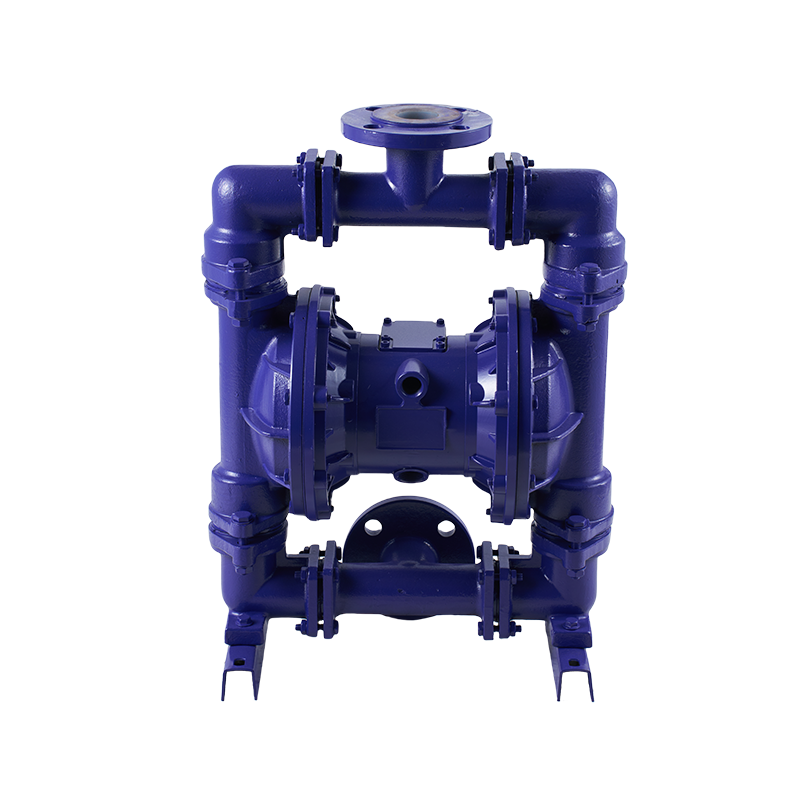

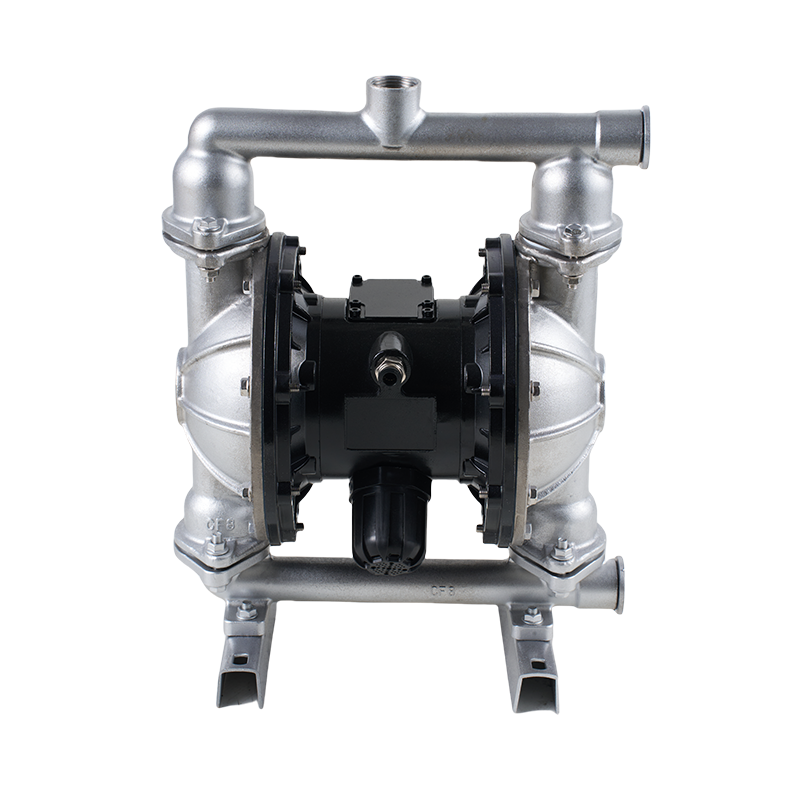

A Diaphragm Pump offers a structure that suits complicated working conditions. When produced by a factory with strong material control, the pump operates with steady performance while resisting chemical stress and temperature changes. For example, aluminum alloy pumps are chosen in many plants because they balance strength and weight. The material can handle aggressive liquids while remaining easy to lift, mount, or relocate during system adjustments. This is valuable for teams that deal with tight installation spaces or equipment relocation.

1. Material Design That Fits Real Production Conditions

Many customers need equipment that can withstand solvents, acids, and mixed compounds. Aluminum alloy units answer this need with durability and corrosion resistance. The design also supports heat dissipation, which helps during continuous pneumatic cycles. When a Diaphragm Pump Manufacturer invests in proper alloy selection, the result is a pump body that resists fatigue and stays dependable through long operation hours.

Another advantage comes from the reduced pump weight. Transportation, setup, and routine checks become easier for maintenance teams. Instead of struggling with heavy steel assemblies, technicians can focus on alignment and hose connections, cutting time spent on preparation. Manufacturers that refine machining accuracy also improve sealing performance, which helps avoid unexpected leakage.

2. Production Control That Directly Impacts Reliability

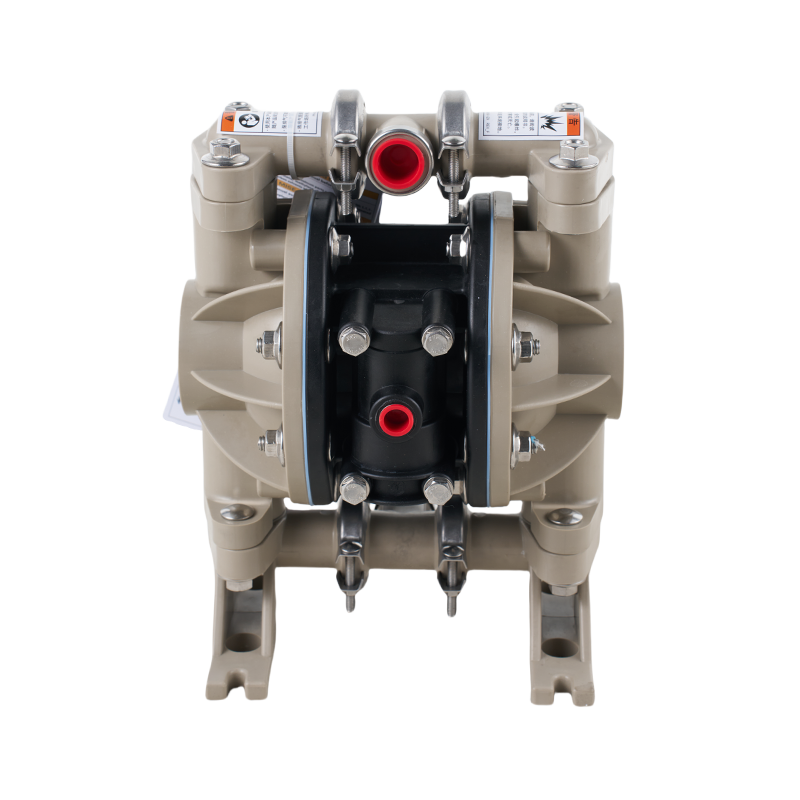

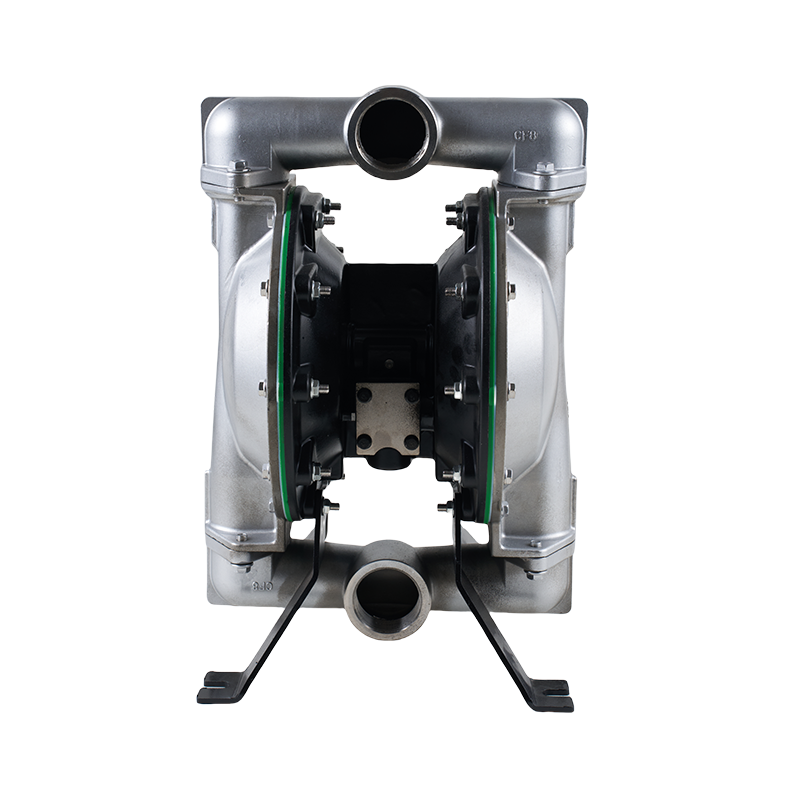

A factory’s workflow plays a direct role in how a Diaphragm Pump performs in the field. A professional Diaphragm Pump Manufacturer applies CNC machining to maintain uniformity across every batch. Tight tolerance control means valves, chambers, and diaphragms fit as intended, keeping pressure output stable.

Beyond machining, extensive testing helps filter out early failure points. Pressure cycle trials, chemical compatibility checks, and flow rate evaluations make sure the pump can operate in typical industrial conditions without surprises. This helps customers avoid the frustration of early wear or recurring breakdowns.

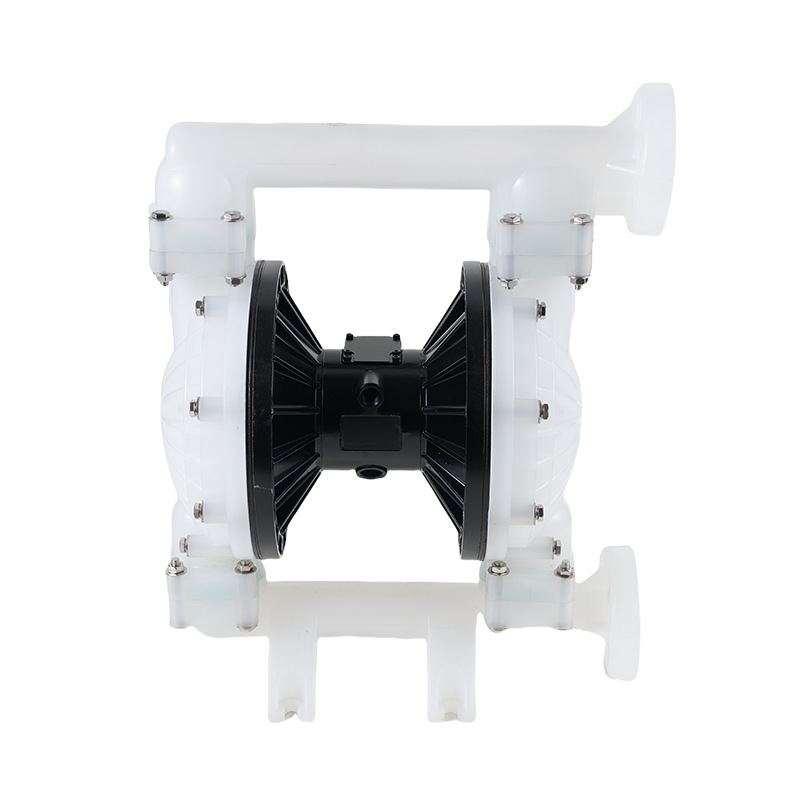

When customization is required—such as altered inlet sizes or modified air systems—the factory can adjust specifications based on actual production lines. This is especially helpful for chemical plants, coating factories, and wastewater stations where each fluid behaves differently.

3. Support for Multiple Industrial Uses

A wide range of industries rely on aluminum alloy pneumatic units. Chemical processors use them because they tolerate corrosive and particle-filled liquids. Water treatment teams use them for dosing or sludge movement. Food and pharmaceutical sites choose them for their smooth interior surfaces and easy cleaning procedures. Oil and gas plants rely on pneumatic operation when working in environments with flammable vapors.

In each case, the combination of mechanical strength and lower weight makes the pump more practical for on-site handling. When a Diaphragm Pump Manufacturer understands these scenarios, they can give clearer guidance on model selection, diaphragm materials, and performance adjustments.

4. Long-Term Value Through Stable Operation

Production managers want equipment that reduces unexpected stoppages. A well-built Diaphragm Pump provides long service life because the internal movement is gentle and the structure does not depend on rotating parts. When matched with the right alloy, the pump stays resistant to chemical wear and keeps internal components functioning smoothly.

Working with a capable Diaphragm Pump Manufacturer offers more than a simple product purchase. It supports ongoing plant stability, gives operators confidence in daily work, and helps businesses run smoothly across different applications.

English

English русский

русский Español

Español عربى

عربى