How Can A Diaphragm Pump Improve Your Fluid Handling Process?

2026.01.16

2026.01.16

Industry News

Industry News

Understanding Diaphragm Pump Functionality

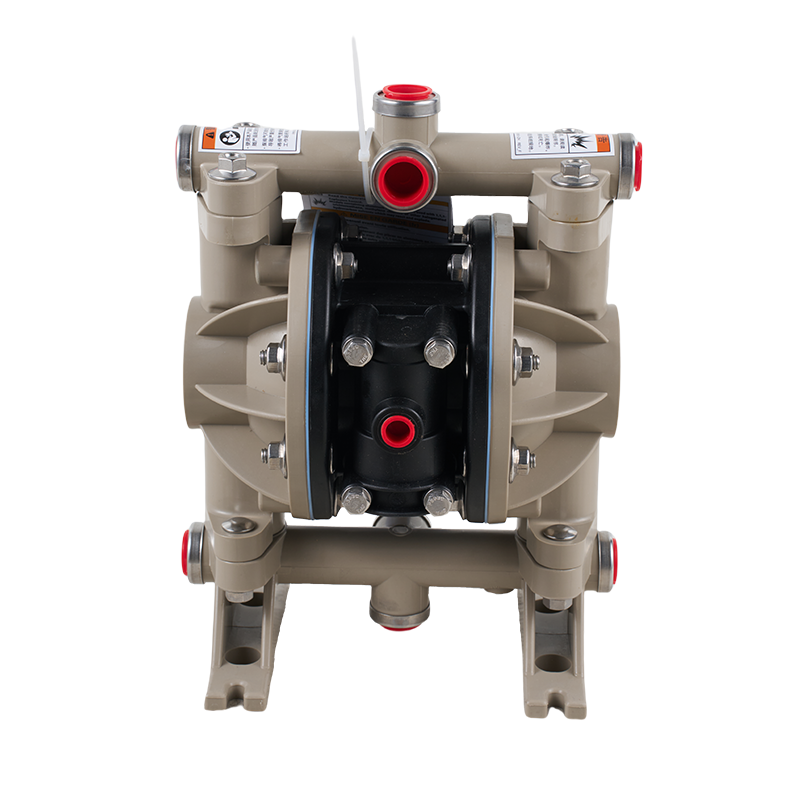

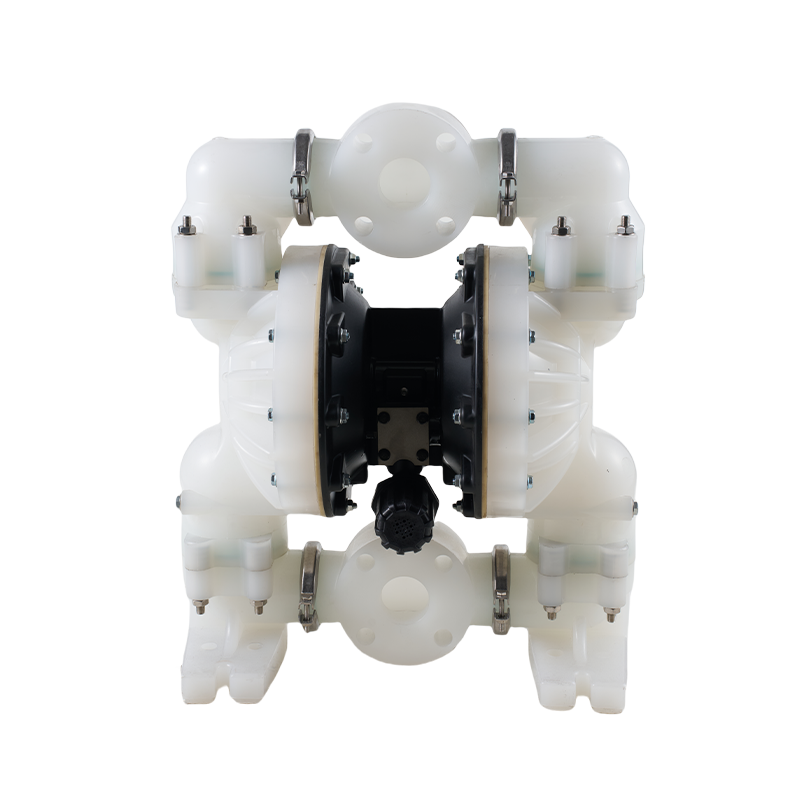

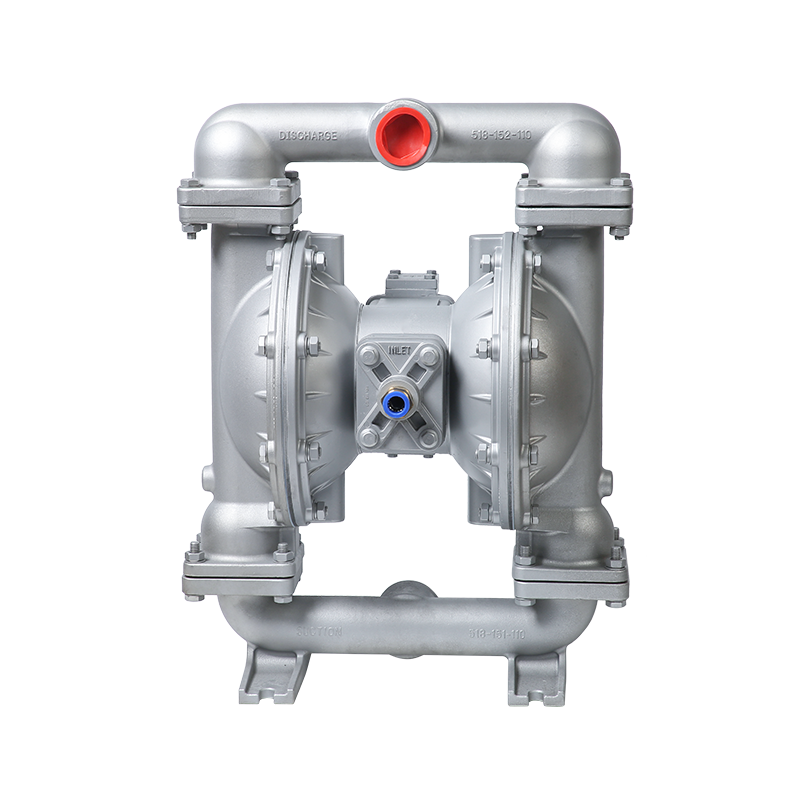

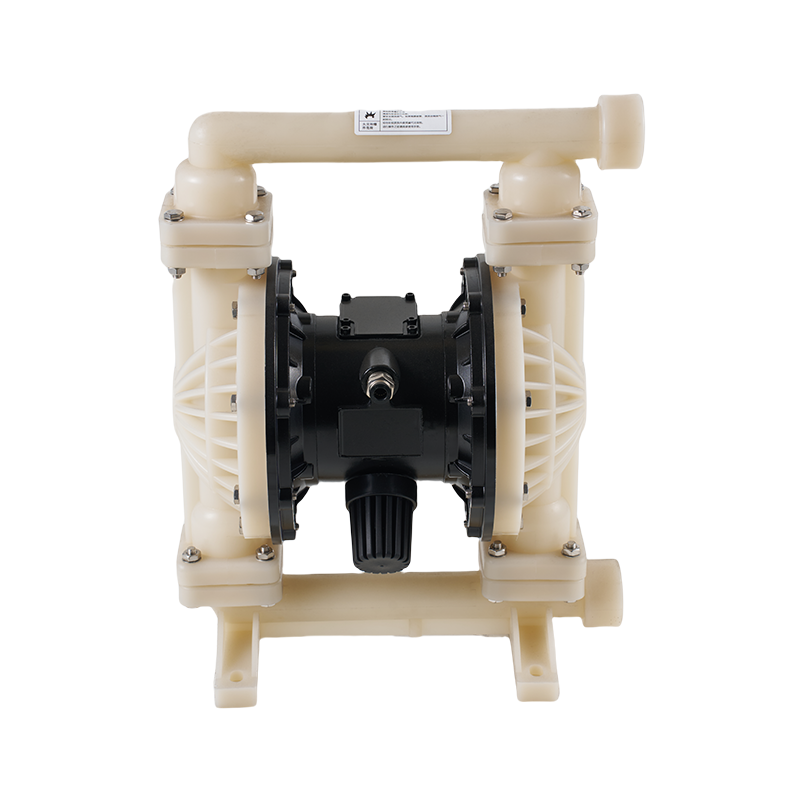

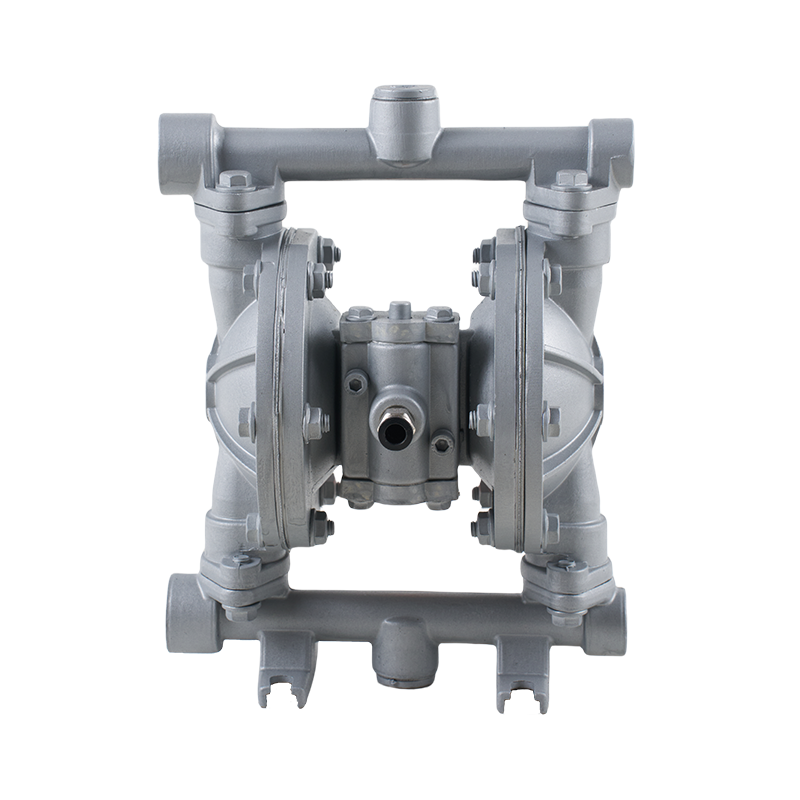

A Diaphragm Pump is a versatile fluid-handling solution widely used across industrial sectors. Unlike traditional centrifugal or gear pumps, diaphragm pumps rely on a flexible diaphragm that moves back and forth, creating a vacuum to draw fluid in and then push it out. This design allows the pump to handle liquids with varying viscosity, abrasive particles, or corrosive chemicals without damaging internal components.

Industries such as chemical manufacturing, food and beverage processing, and wastewater management rely heavily on diaphragm pumps for their reliability and adaptability. Choosing the right Diaphragm Pump involves considering fluid properties, flow rate, pressure requirements, and the operating environment. For highly corrosive or abrasive fluids, selecting the correct diaphragm material—like PTFE, rubber, or other elastomers—is critical to prolonging pump life and minimizing maintenance.

Working with an OEM/ODM Diaphragm Pump manufacturer ensures you get access to models specifically suited to your industrial needs. Factories in China specialize in producing pumps with consistent quality, offering both standard and customized configurations that meet international standards.

Selecting the Right Diaphragm Pump

Choosing a Diaphragm Pump is not just about picking a model—it's about matching the pump to the application. For instance, pneumatic diaphragm pumps are ideal for environments where electrical hazards exist, whereas hydraulic or mechanically actuated diaphragm pumps might be more suitable for high-pressure industrial settings.

Key factors in pump selection include:

- Fluid type: acidic, alkaline, slurry, or viscous fluids

- Flow rate: ensuring the pump delivers the required volume efficiently

- Pressure: matching the pump to system demands

- Material compatibility: preventing corrosion or wear

An OEM/ODM Diaphragm Pump manufacturer can provide guidance on selecting the appropriate pump configuration, including single or double diaphragm models, valve types, and construction materials. For example, a double diaphragm pump offers a gentle pumping action and is capable of handling solids without clogging, which is useful in wastewater or chemical slurries.

Customization is another advantage. Many factories can adjust diaphragm thickness, valve seat materials, and even the pump's connection type to fit unique industrial setups. This flexibility ensures that each pump operates efficiently, safely, and with minimal downtime.

Benefits of Partnering with a China Diaphragm Pump Factory

Partnering with a China-based Diaphragm Pump factory offers several advantages for industrial buyers:

- Wide Product Range: Factories produce various pump sizes and types, including pneumatic, hydraulic, and double diaphragm pumps, ensuring there's a solution for nearly any application.

- Competitive Pricing: High-volume manufacturing allows these factories to offer competitive prices without compromising quality.

- Great Technology: Many factories use modern production equipment and strict quality control processes, producing durable and reliable pumps.

- Technical Support: Experienced teams guide buyers through pump selection, installation, and troubleshooting, reducing operational risk.

- Fast Delivery: Proximity to major logistics networks ensures that pumps can reach global buyers efficiently.

Double diaphragm pumps from Chinese factories are particularly valued for handling abrasive and corrosive fluids. An OEM/ODM Diaphragm Pump manufacturer can also provide testing reports, certifications, and compliance documentation, which is essential for regulated industries.

Maintenance and Longevity Considerations

Maintaining a Diaphragm Pump is straightforward but crucial for longevity. The diaphragm and valves should be inspected regularly to prevent leaks, reduced flow, or sudden failure. The choice of materials greatly affects maintenance intervals and operating life. PTFE diaphragms, for example, resist chemical attack but may require more frequent inspection under high-pressure operation.

An OEM/ODM Diaphragm Pump manufacturer can provide spare parts kits and maintenance instructions tailored to each pump model. Regular maintenance helps avoid downtime and ensures consistent performance, which is particularly important in continuous industrial processes like chemical dosing or slurry transfer.

English

English русский

русский Español

Español عربى

عربى