How Do Flow Rate And Pressure Affect Double Diaphragm Pump Operation?

2026.01.23

2026.01.23

Industry News

Industry News

1. Understanding the Double Diaphragm Pump

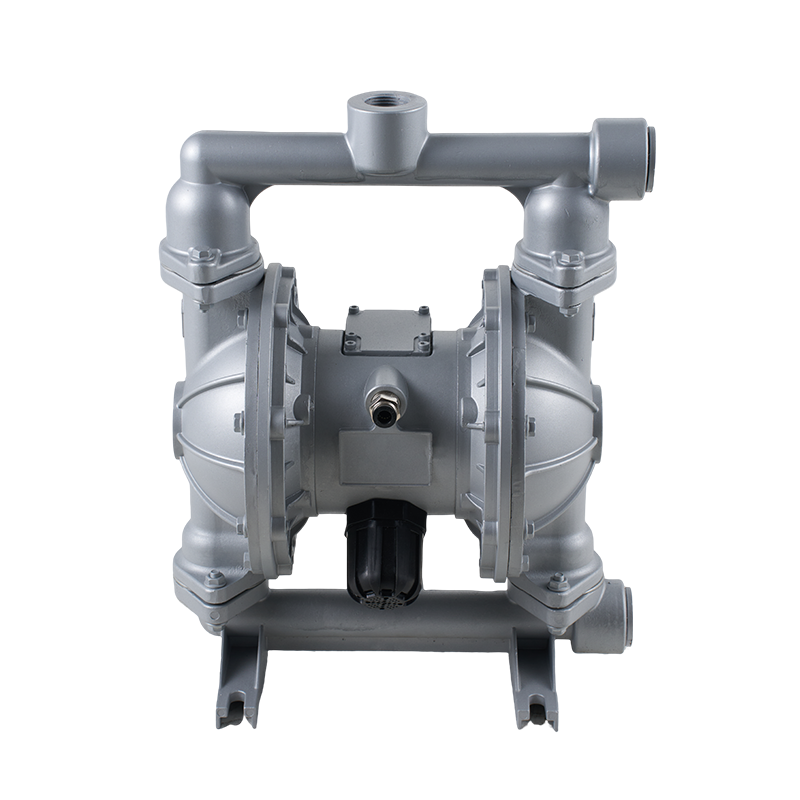

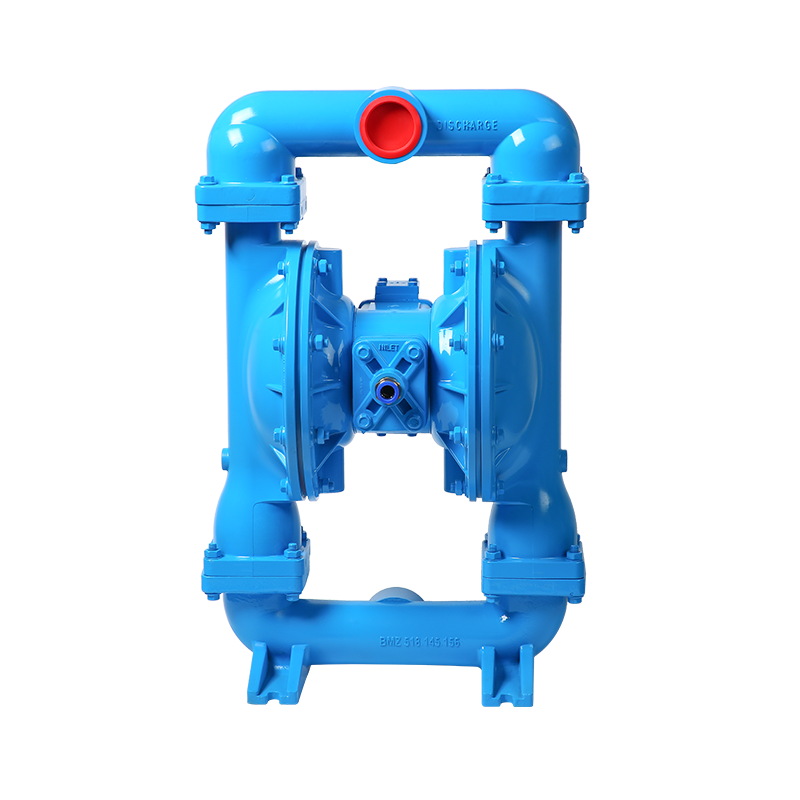

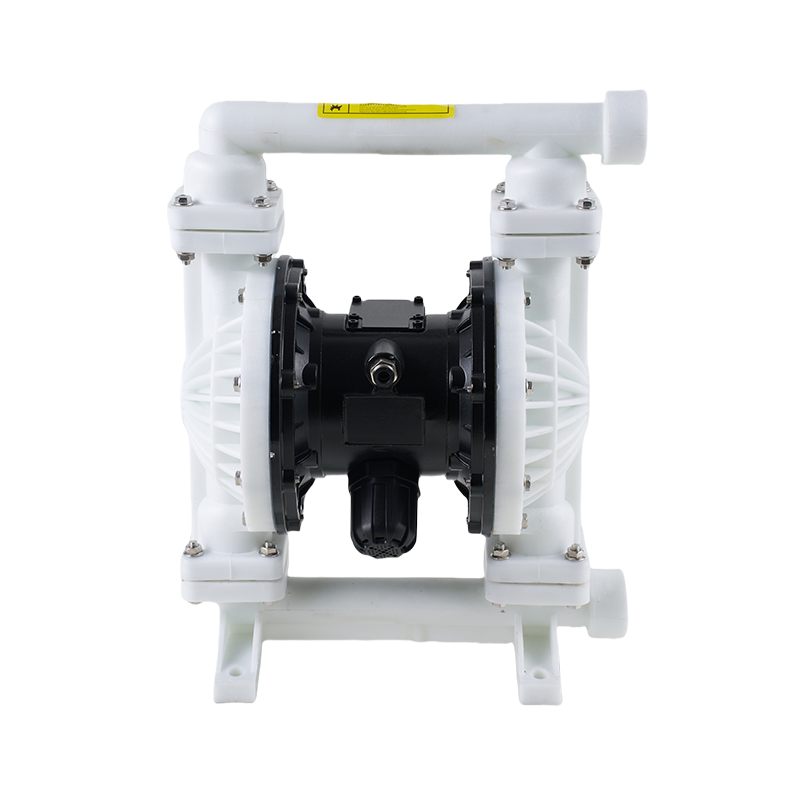

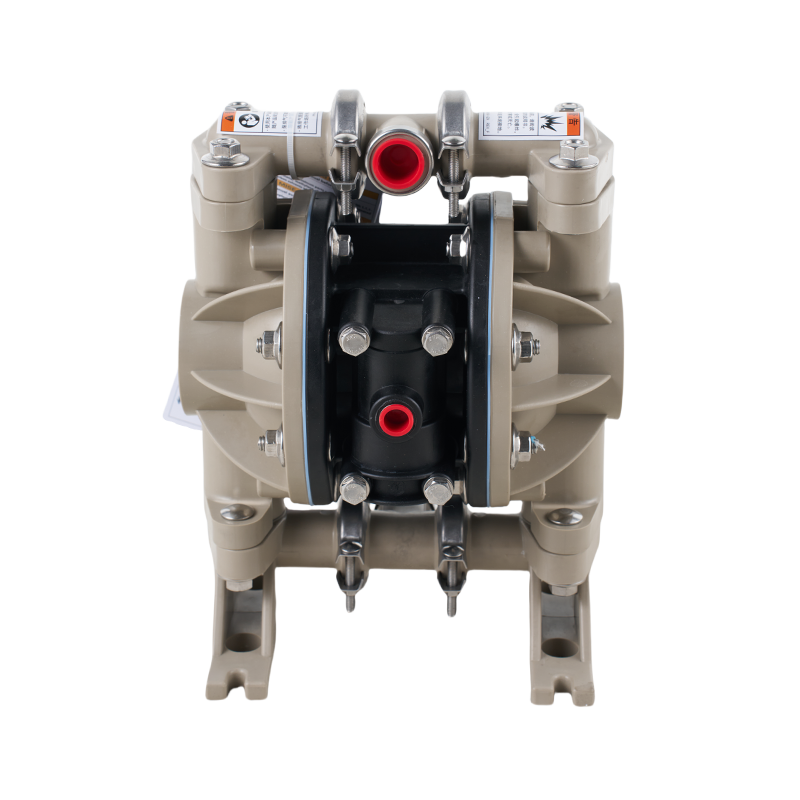

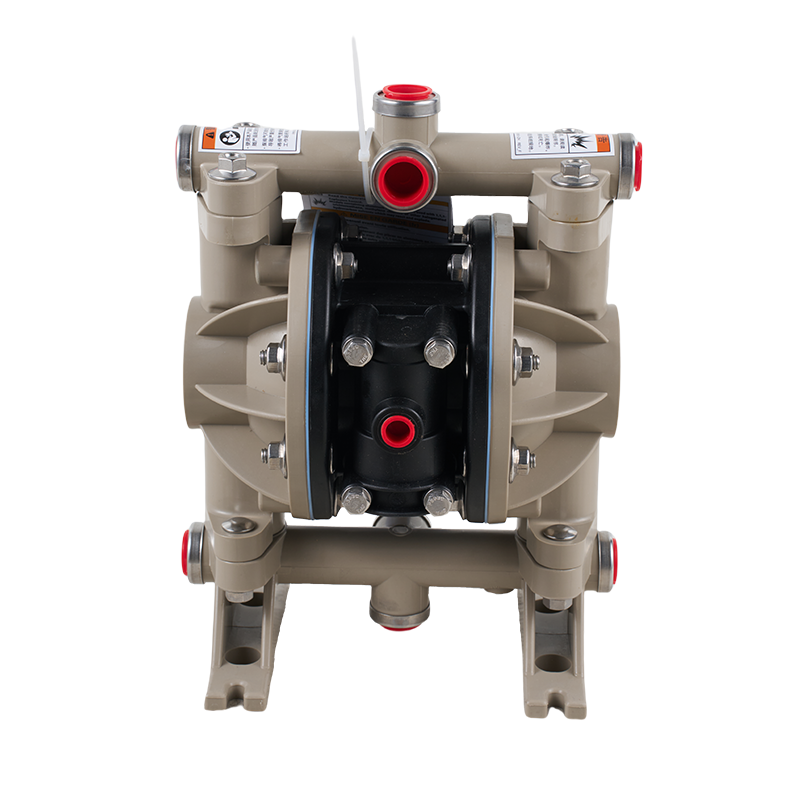

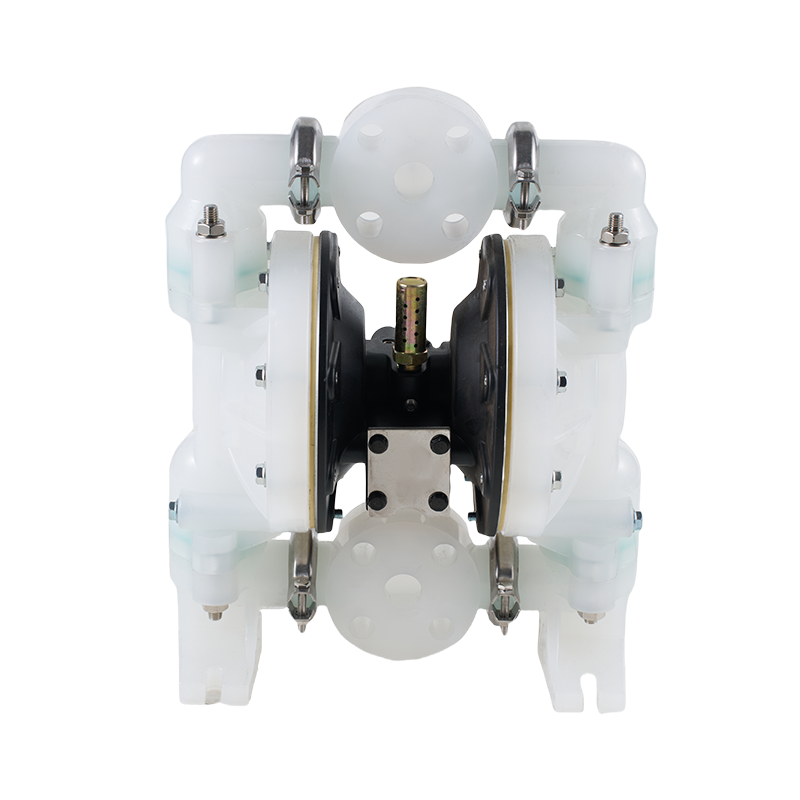

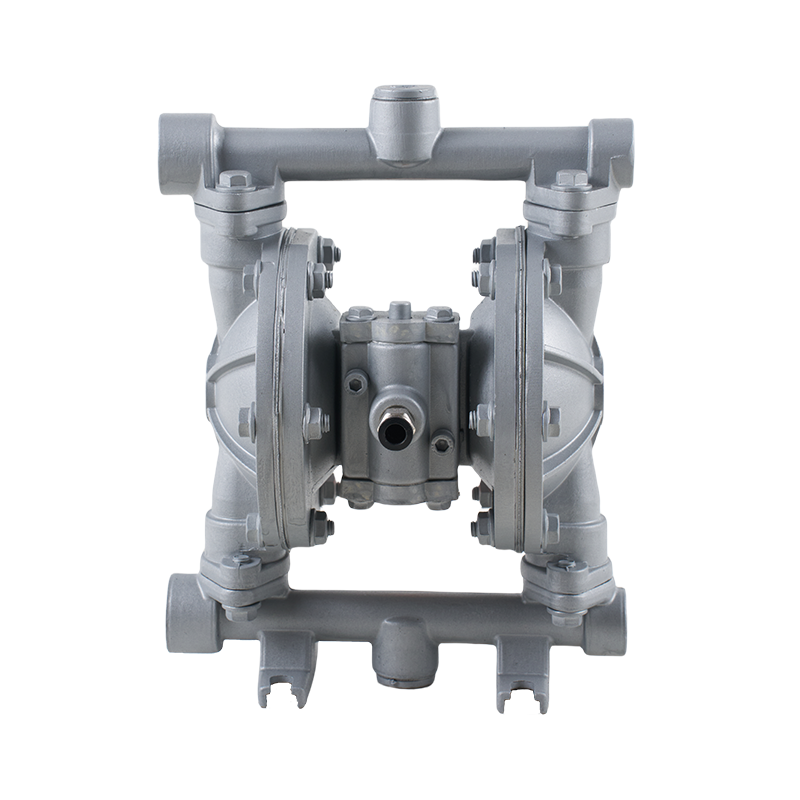

A double diaphragm pump is a versatile fluid-handling solution widely used in industries like chemical, food processing, and wastewater treatment. Unlike centrifugal pumps, double diaphragm pumps use two flexible diaphragms that create a suction and discharge action, allowing them to move liquids with solids, viscous fluids, or aggressive chemicals safely. Their ability to operate without electricity, using pneumatic energy instead, makes them adaptable for hazardous or remote environments.

Choosing a Double Diaphragm Pump Factory with experience ensures you receive a pump built with quality materials, reducing downtime and operational issues. Factories specializing in pneumatic diaphragm pumps understand the importance of consistency and durability for industrial processes.

2. Key Benefits of Working with a Double Diaphragm Pump Factory

Selecting a reliable Double Diaphragm Pump Factory offers several advantages. These factories typically provide a wide range of pump models to match different industrial needs. Whether you need a pump to handle abrasive slurries or gentle fluid transfer, the factory can provide the right design.

Second, Chinese Double Diaphragm Pump Factories often implement great production techniques and rigorous quality checks, producing pumps that meet global performance standards. This means fewer breakdowns and lower maintenance costs over time.

Another benefit is the competitive pricing. Working directly with a factory usually reduces intermediary costs, while customization options allow you to get pumps tailored to your specific applications. This combination of quality, variety, and affordability is why many companies prefer sourcing from specialized double diaphragm pump manufacturers.

3. Selecting the Right Pump for Your Needs

When choosing a double diaphragm pump, consider the type of fluid, flow rate, pressure requirements, and the material compatibility of the pump. For example, some diaphragms are better suited for corrosive chemicals, while others handle abrasive slurries effectively.

A Double Diaphragm Pump Factory can guide model selection based on these parameters. Pneumatic diaphragm pumps are highly flexible, but matching the pump design with the operational environment ensures longevity and efficiency.

Additionally, factories that produce double diaphragm pumps often offer certifications, testing documentation, and technical support. These services give buyers confidence that the pump will perform reliably in real-world industrial settings.

4. Maintenance Tips for Longer Pump Life

Even high-quality double diaphragm pumps require routine maintenance to maintain peak performance. Key practices include checking the diaphragms for wear, inspecting valves for debris, and ensuring that the air supply is clean and regulated.

A reputable Double Diaphragm Pump Factory can provide maintenance manuals and spare parts, simplifying repairs and reducing downtime. Regular servicing helps maintain consistent flow rates, prevents leaks, and extends the pump's operational life.

China has become a global hub for pneumatic and double diaphragm pumps due to its specialization, skilled workforce, and great manufacturing capabilities. Working with a Double Diaphragm Pump Factory in China provides access to cost-effective pumps that meet international standards.

These factories focus on innovation and customer support, offering flexible delivery schedules, customization, and post-sale assistance. Their pumps can handle a variety of challenging fluids, making them suitable for multiple sectors, from food production to chemical processing.

The competitive market encourages continuous improvements, meaning buyers receive technologically up-to-date pumps with reliable performance. Overall, partnering with a trusted Double Diaphragm Pump Factory combines quality, affordability, and efficiency, making it a practical solution for businesses requiring reliable fluid-handling equipment.

English

English русский

русский Español

Español عربى

عربى