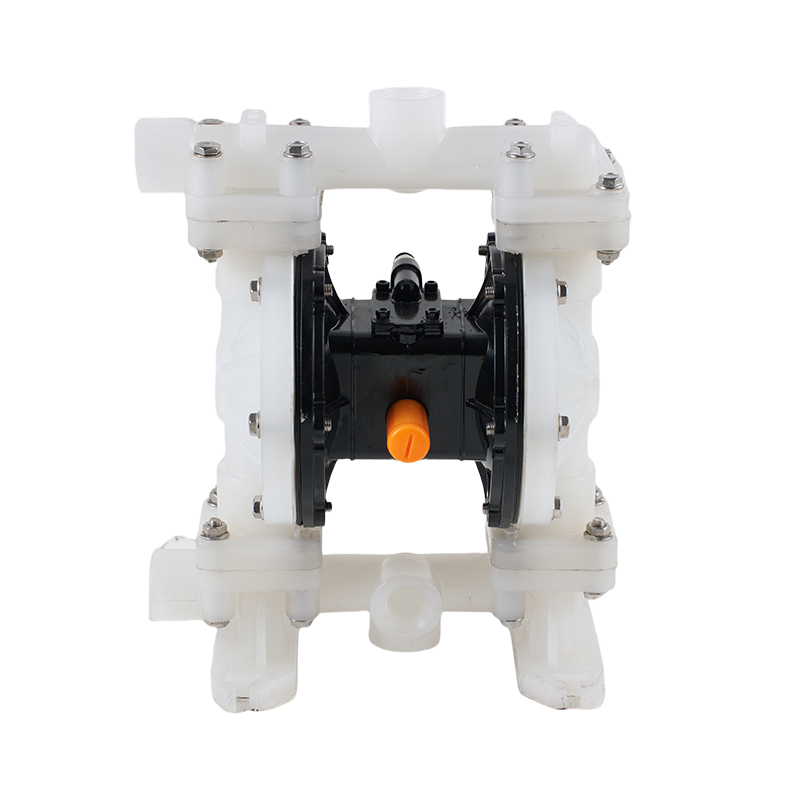

How Can A Polypropylene Pneumatic Diaphragm Pump Handle Acids?

2026.01.02

2026.01.02

Industry News

Industry News

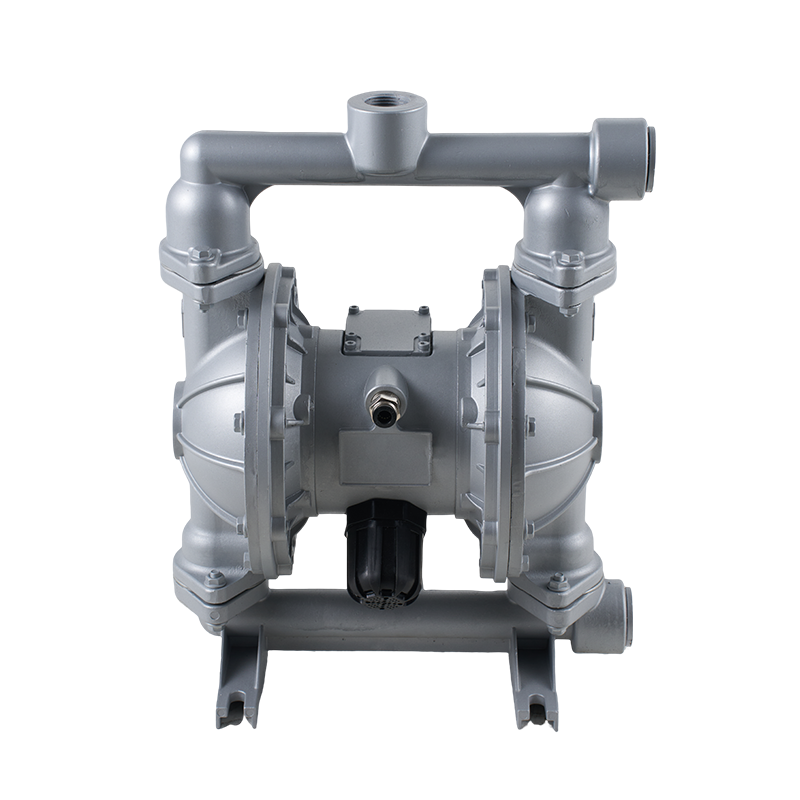

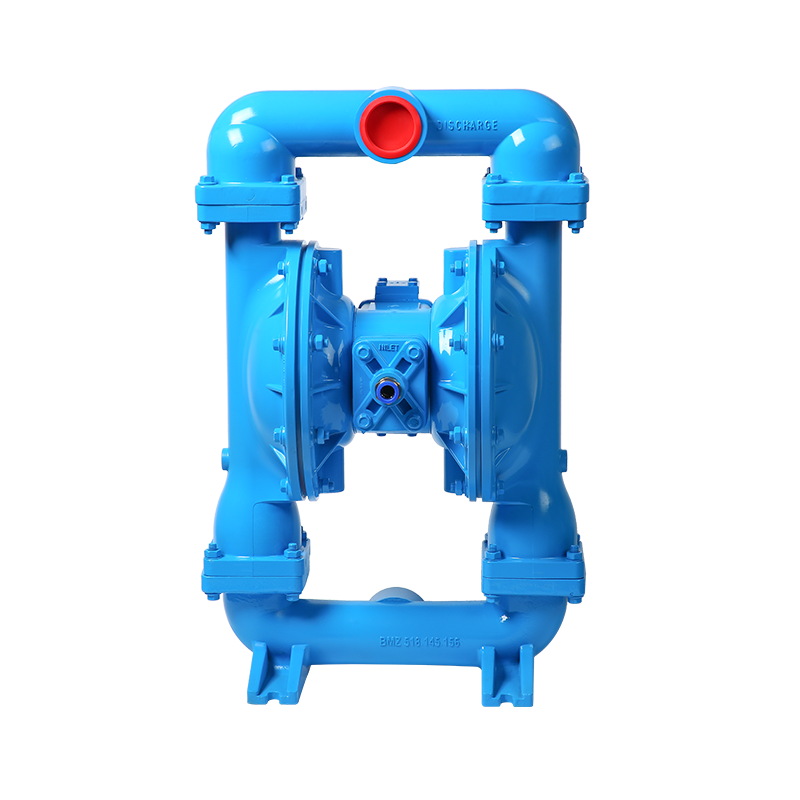

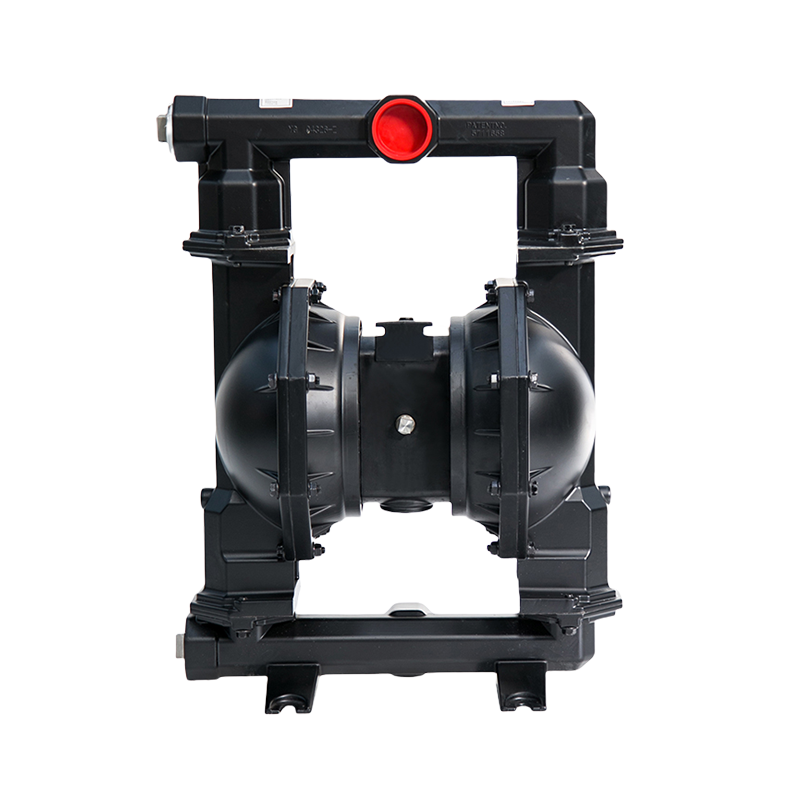

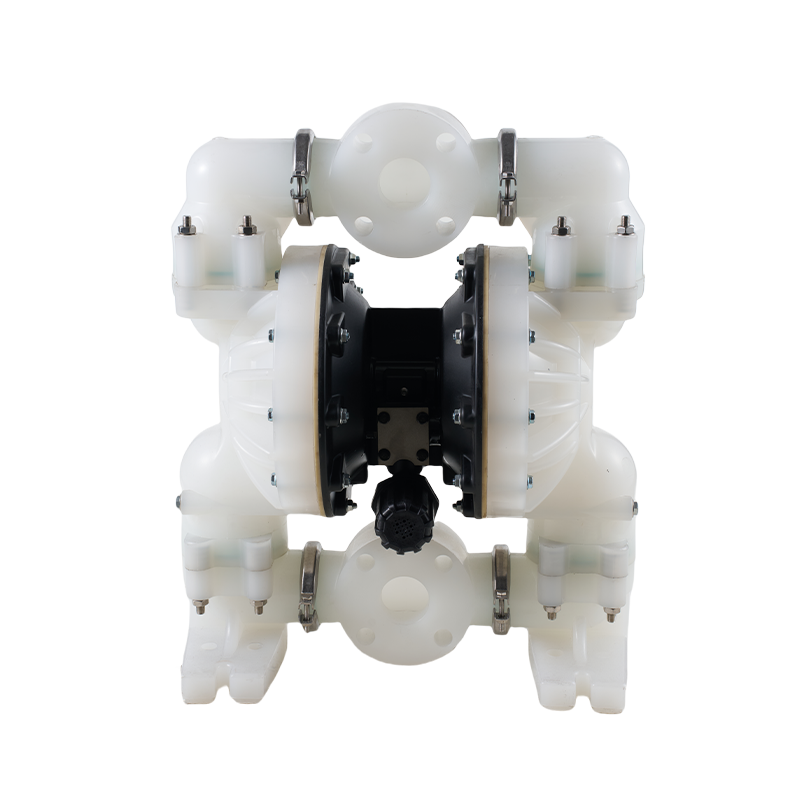

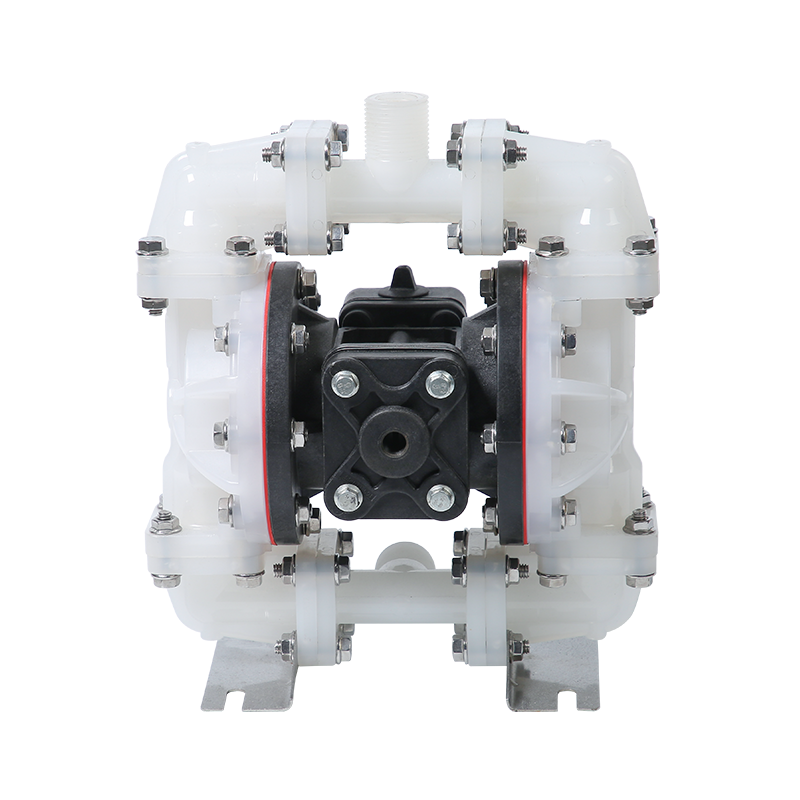

A Polypropylene Pneumatic Diaphragm Pump often becomes the preferred option for companies that handle corrosive or unpredictable fluids. Many users approach us with issues such as unstable flow, frequent corrosion, high maintenance bills, and downtime caused by seal failures in traditional pump designs. These problems slow production and raise operational costs. By focusing on real-world challenges, our factory has spent years developing a reliable pumping solution built around polypropylene and air-driven diaphragm technology.

1. Strong Material Performance for Acidic Applications

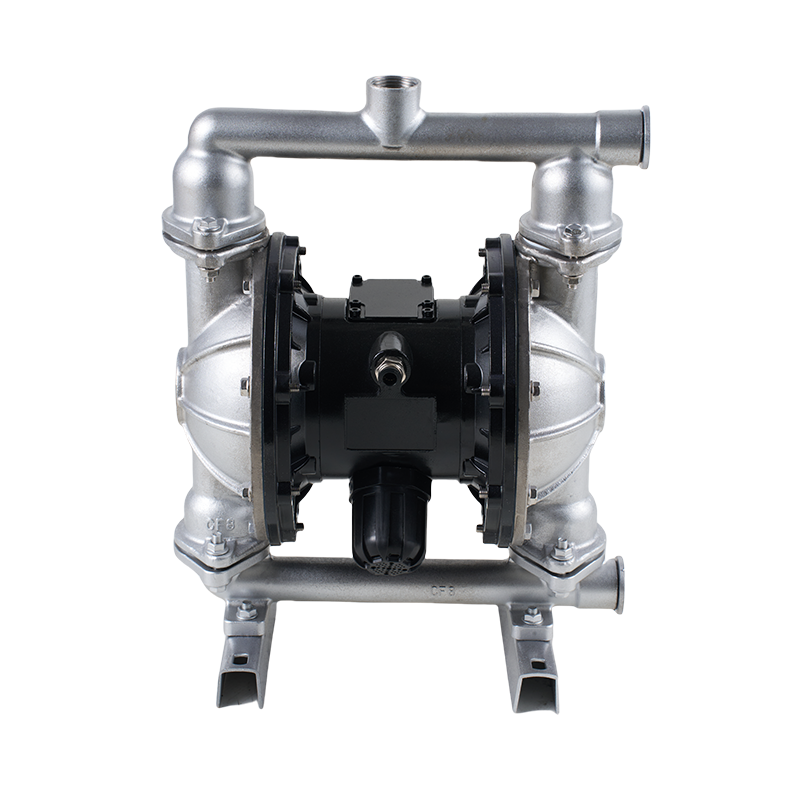

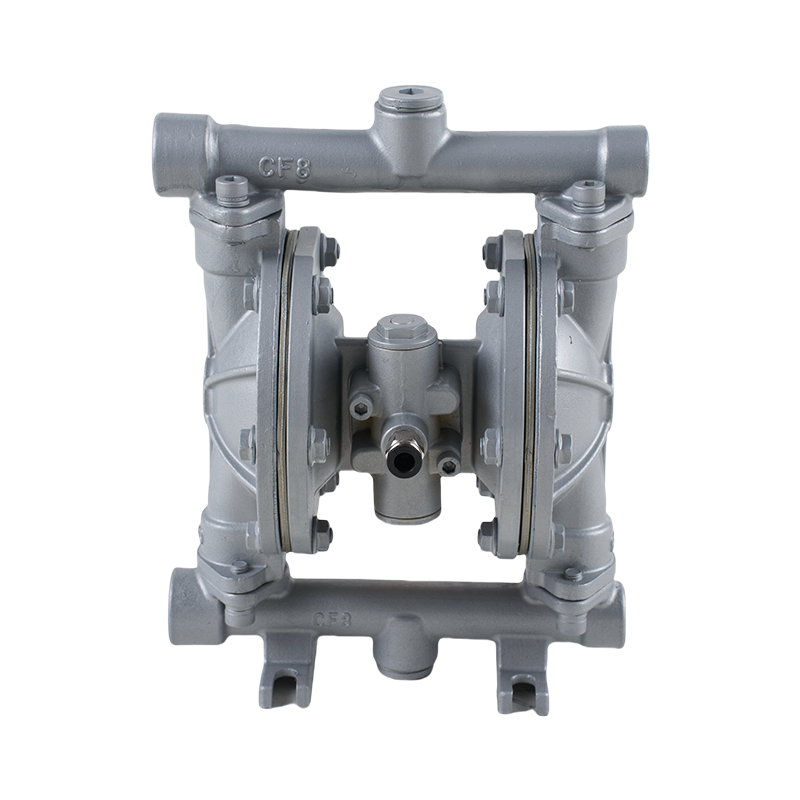

One of the biggest concerns in chemical production is the long-term impact of aggressive acids on pump components. Metal pumps may pit, rust, or weaken after repeated exposure. In contrast, polypropylene offers steady resistance to a wide range of acids, which is why the Polypropylene Pneumatic Diaphragm Pump performs so well in acid transfer lines.

The inert structure of polypropylene allows the pump chamber to withstand chemicals such as sulfuric and hydrochloric acid without surface reaction. A smooth internal finish also helps prevent buildup, which often occurs with viscous or settling liquids. This reduces the chance of clogging and keeps the pump running without interruption. Users who once struggled with short equipment life notice far longer service intervals when switching to a polypropylene build.

2. Air-Driven Operation Supports Safety and Flexibility

Facilities that deal with flammable liquids or combustible dust often avoid electric pumps due to ignition risks. An air-operated diaphragm system fits these environments well. The Polypropylene Pneumatic Diaphragm Pump runs solely on compressed air, removing electrical motors and wiring from the setup. This makes installation easier and improves process flexibility, especially when production lines change or move.

The air supply drives the diaphragm movement. As the diaphragm shifts back and forth, it draws liquid into one chamber and pushes it out through the discharge side. This simple motion gives the pump the ability to run dry temporarily, handle abrasive particles, and push thicker fluids without damaging its internal components. Many operators appreciate the ability to control flow by adjusting air pressure, which gives them smoother process management.

3. Manufacturing Design Focused on Durability

In our factory, the production of each Polypropylene Pneumatic Diaphragm Pump begins with precision-molded polypropylene parts. These parts form a uniform chamber structure that reduces wear during cycles. The diaphragm selection is equally important. We choose elastomers that maintain flexibility after continuous bending and resist attack from acidic or solvent-based liquids.

During assembly, careful attention is placed on sealing points. A diaphragm pump has no mechanical shaft seal, reducing the common leakage points found in centrifugal pumps. This helps operators maintain clean workspaces and avoid contamination. Every pump undergoes chemical compatibility checks, pressure testing, and leakage inspections before leaving the factory. These steps give users confidence that the pump will support demanding applications without frequent repairs.

4. Support for Industrial Users with Practical Needs

Many customers ask not only for performance but also for predictable operation and easy maintenance. The Polypropylene Pneumatic Diaphragm Pump is designed so technicians can access components quickly. Diaphragms and valves can be replaced without specialized tools, helping reduce downtime during routine service.

Users in chemical mixing, wastewater processing, surface treatment, and general industrial transfer often choose polypropylene because it handles varied fluids without constant material compatibility concerns. By combining durable polypropylene with a pneumatic drive, the pump supports daily operations where reliability is essential.

English

English русский

русский Español

Español عربى

عربى