What Problems Does A Double Diaphragm Pump Help Solve Onsite?

2025.12.25

2025.12.25

Industry News

Industry News

A growing number of buyers across chemical processing, wastewater handling, coatings, mining, and general manufacturing are turning to diaphragm-driven transfer solutions because they offer a practical mix of reliability and flexibility. Factories specializing in these pumps understand the daily challenges industrial users face: unpredictable fluid conditions, inconsistent maintenance cycles, higher operating costs, and the need for equipment that simply keeps running. This is why the interest in pneumatic diaphragm technology continues to rise, especially among global buyers who prefer a stable supply and steady performance.

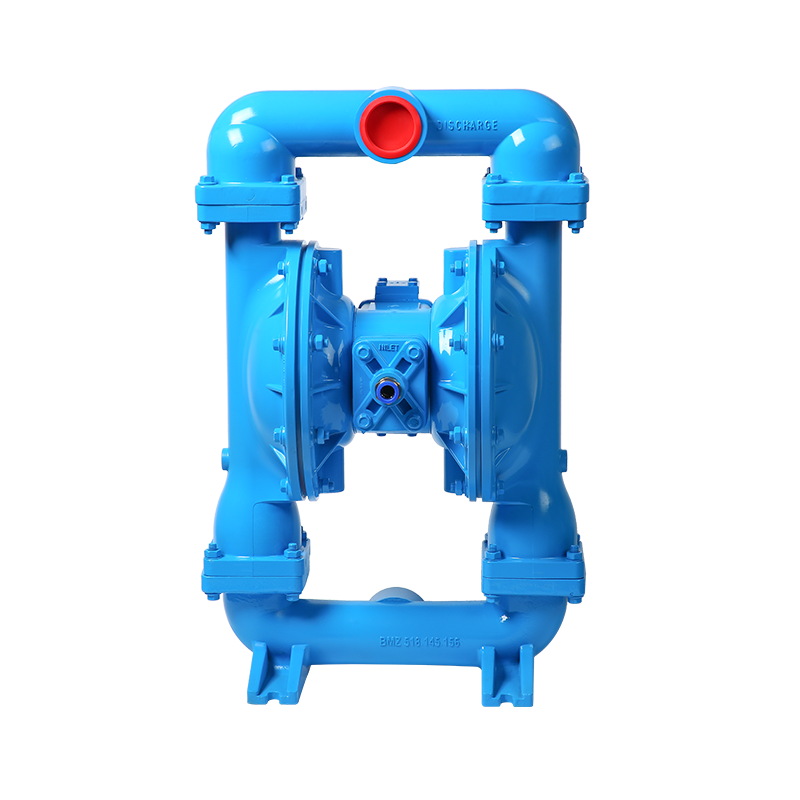

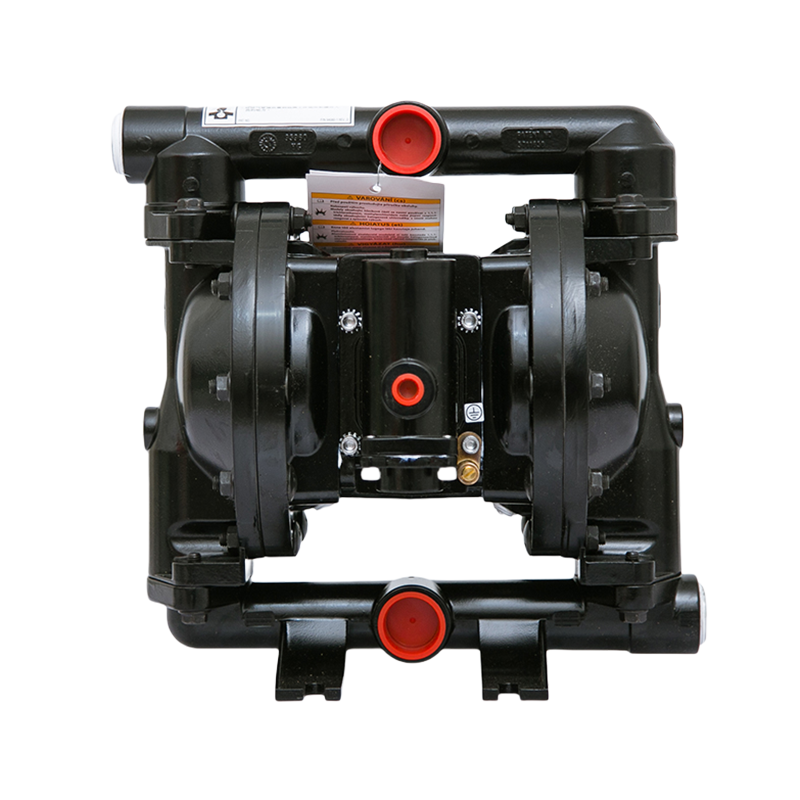

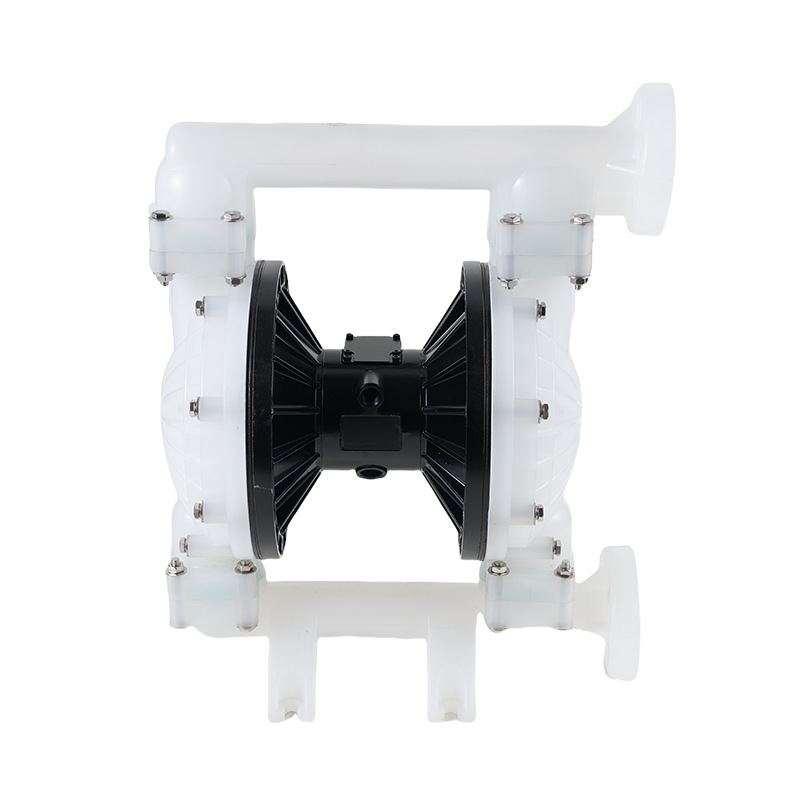

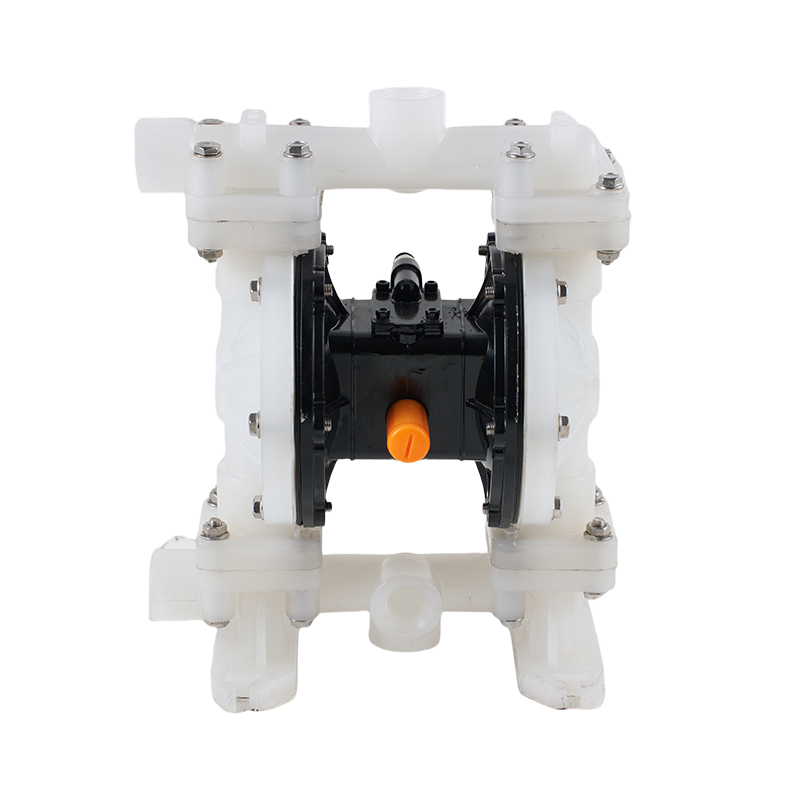

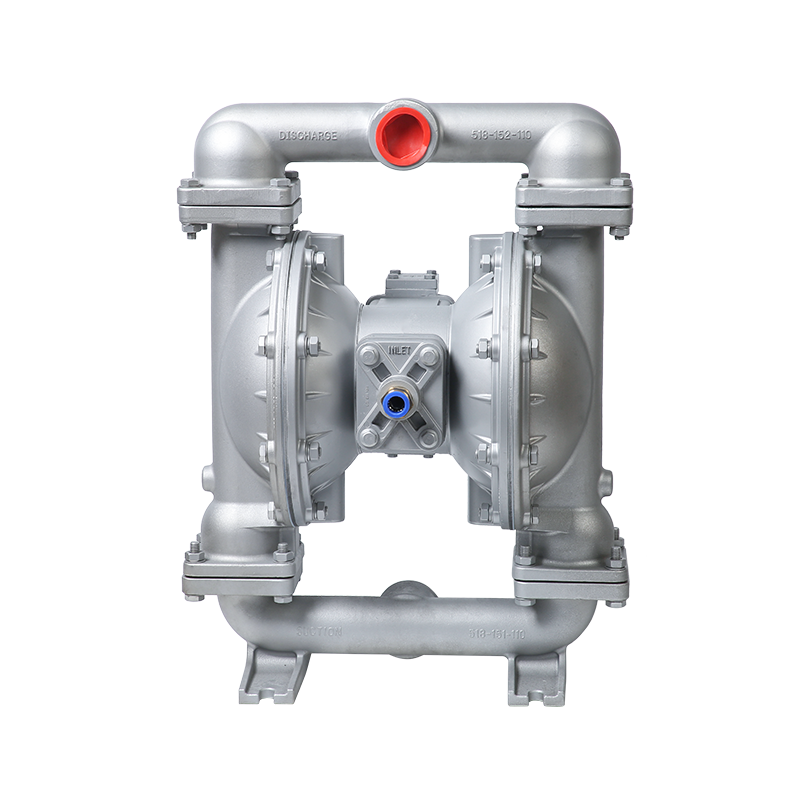

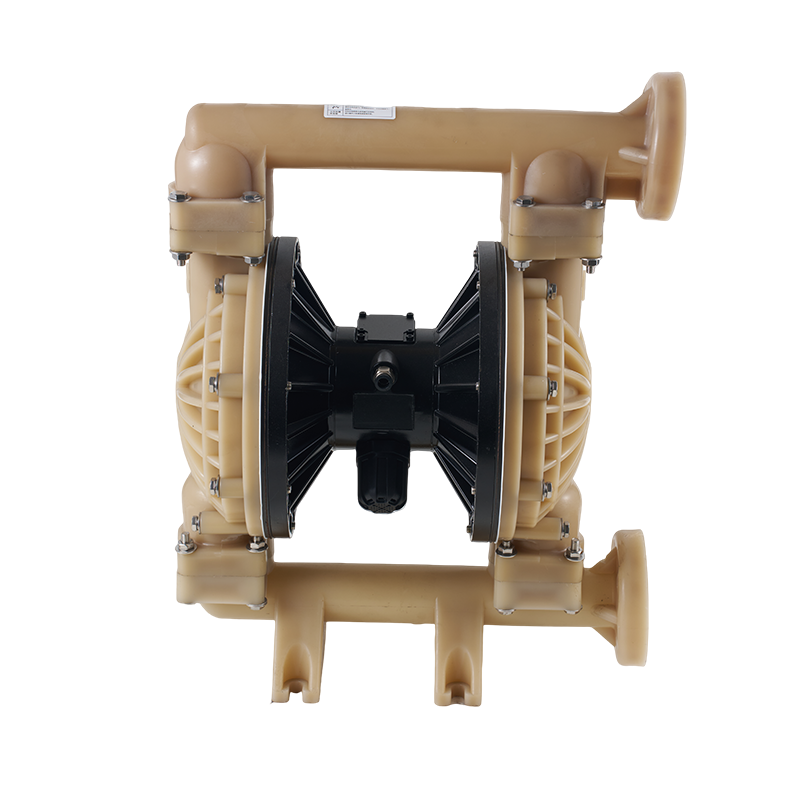

A strong advantage comes from working directly with a producer that focuses on pneumatic and double-acting designs. A Double Diaphragm Pump Factory often runs dedicated lines for different materials such as aluminum alloy, stainless steel, polypropylene, or rubber-lined assemblies. This approach gives buyers more choices when balancing corrosion resistance, abrasion handling, or compatibility with food-grade environments. It also helps solve the common pain point where a single pump model might not match multiple fluid types across different production stages.

Many industrial users look for transfer equipment that handles both thin liquids and thicker slurries without demanding constant adjustment. This is where a Double Diaphragm Pump shows its value. Its air-driven structure allows smoother movement across viscous, abrasive, or chemically aggressive media, reducing the risk of staling or clogging. Factories building these pumps usually test them under varied pressures to match real-world batch shifts and uneven fluid behavior found in mixing rooms, draining pits, or material storage tanks.

When sourcing from a production partner in China, buyers gain access to manufacturers that have spent years refining pneumatic diaphragm technology. These factories typically adopt structured assembly methods, updated tooling, and experienced technicians who understand how diaphragm movement, valve geometry, and material selection influence pump durability. This expertise matters because users often need a unit that can stay stable during long-running cycles, even when handling solids or sudden flow changes.

Buyers from overseas markets also appreciate the wider model range available. Whether the goal is soft pumping action for shear-sensitive fluids or steady flow for abrasive waste streams, suppliers can adjust diaphragm material, inlet size, or valve structure to suit the task. Working with a Double Diaphragm Pump Factory allows customers to discuss details such as elastomer choice, noise reduction options, or upgrades that help the pump handle fluctuating air supply conditions. This level of customization helps companies avoid the frustration of buying general-purpose equipment that later requires additional modifications.

Cost efficiency remains another reason international buyers continue selecting Chinese diaphragm pump factories. Large-volume production combined with stable raw-material sourcing keeps pricing competitive. At the same time, these factories usually maintain controlled inspection steps. Each assembled pump goes through performance checks to confirm smooth operation before shipping, which reduces the chance of unexpected issues during installation. This is particularly helpful for buyers running tight project schedules.

For industrial buyers planning an upgrade or preparing for higher output demands, sourcing from a manufacturing partner with dedicated pneumatic diaphragm experience offers practical benefits: steady operation, broader customization options, and responsive support. With production strength and a clear understanding of industrial transfer needs, a Double Diaphragm Pump Factory can deliver solutions that support long-term, stable performance across various applications.

English

English русский

русский Español

Español عربى

عربى