Revolutionary Advances in Air Driven Diaphragm Pump Technology

2025.08.18

2025.08.18

Industry News

Industry News

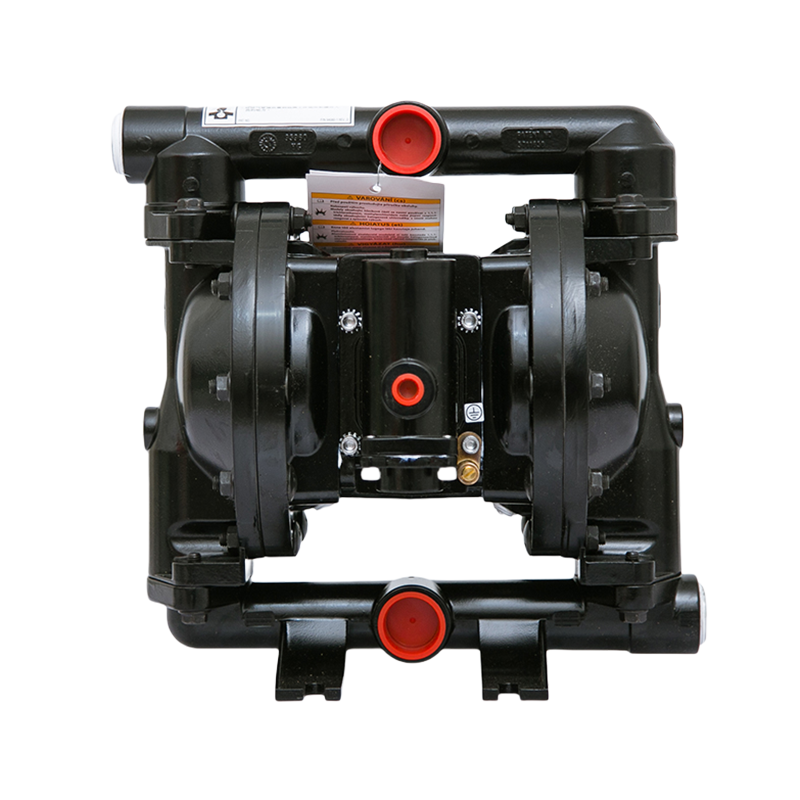

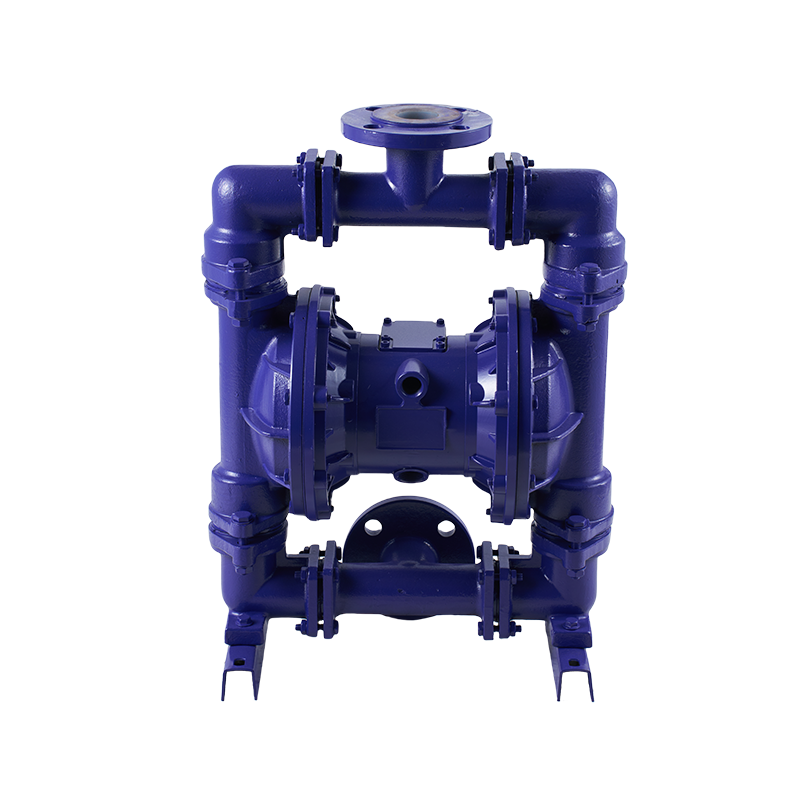

In the dynamic world of industrial fluid transfer, the air driven diaphragm pump has long been a reliable workhorse. Known for its ability to handle a wide range of fluids, including those that are corrosive, abrasive, or viscous, the air driven diaphragm pump has cemented its place in various industries such as chemical processing, manufacturing, wastewater treatment, and more.

However, recent technological advancements have taken this tried-and-true tool to new heights, revolutionizing its capabilities and efficiency. Air operated double diaphragm pump suppliers are at the forefront of this innovation, driving the industry forward with cutting-edge developments.

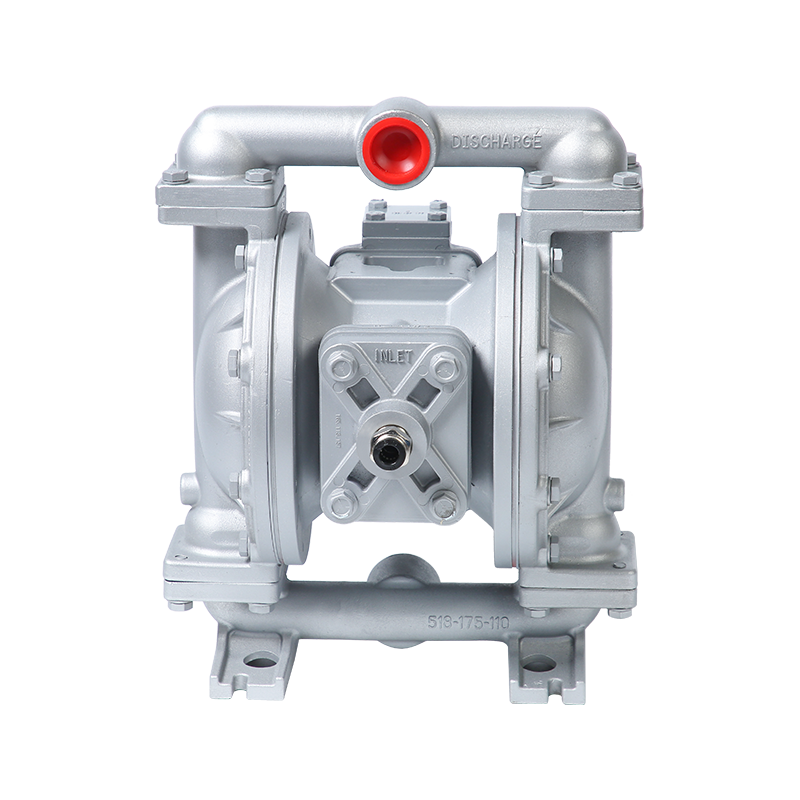

One of the significant advancements in air driven diaphragm pump technology is the improvement in energy efficiency. Traditional air driven diaphragm pumps have been criticized for their relatively high air consumption, which can increase operational costs. However, modern innovations have addressed this issue head-on. New designs and materials have been developed to optimize the air usage of these pumps, resulting in substantial energy savings.

For example, some air operated double diaphragm pumps now feature advanced air distribution systems that ensure more efficient use of compressed air, reducing waste and lowering overall energy consumption. This not only benefits the environment but also provides cost savings for end-users, making air driven diaphragm pumps an even more attractive option in the long run.

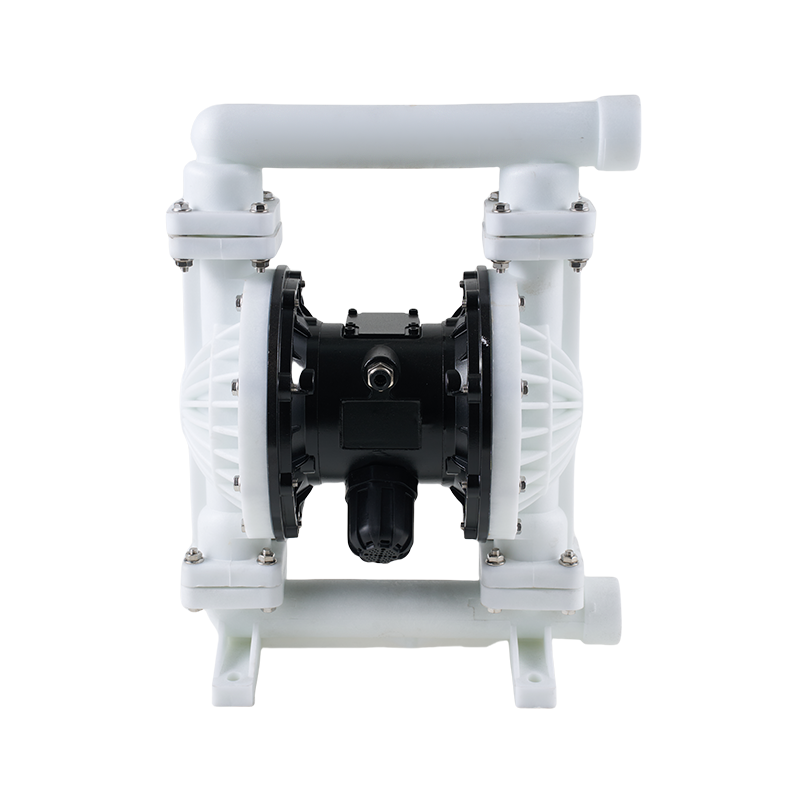

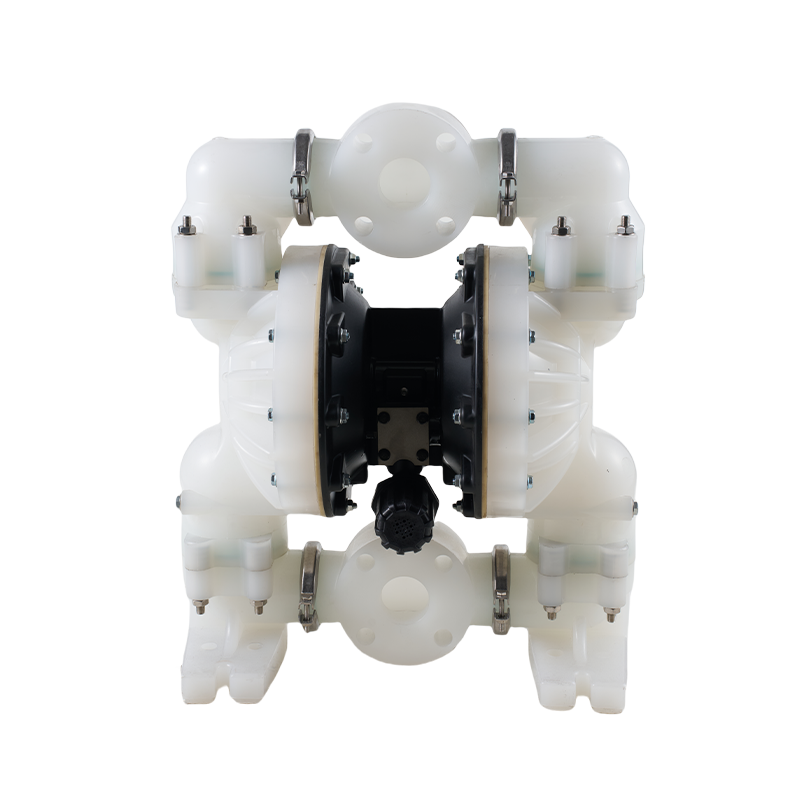

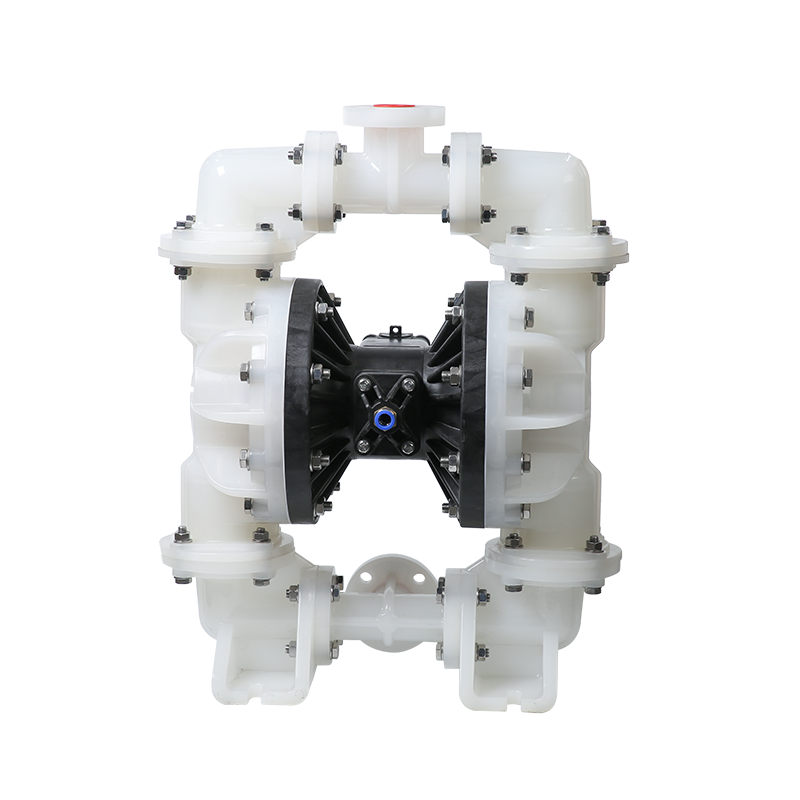

Another area of innovation is the enhancement of the pump's durability and reliability. Industrial applications often involve harsh operating conditions, including exposure to corrosive chemicals, temperatures, and abrasive materials. To address these challenges, manufacturers are investing in advanced materials and manufacturing processes. High-performance polymers and composites are increasingly being used in the construction of air driven diaphragm pumps, offering enhanced resistance to chemical attack and wear. Additionally, improved sealing technologies are being developed to prevent leaks and ensure the long-term integrity of the pump. These advancements mean that air operated double diaphragm pumps can now withstand more demanding environments, reducing maintenance requirements and downtime.

The versatility of air driven diaphragm pumps is another key area of focus for manufacturers. These pumps are already renowned for their ability to handle a wide variety of fluids, but recent innovations have further expanded their capabilities. New designs have optimized the pump's performance with different types of fluids, including those with high viscosity or containing solid particles. This makes air driven diaphragm pumps suitable for an even broader range of applications, from transferring thick slurries in mining operations to pumping delicate pharmaceuticals. Air operated double diaphragm pump suppliers are well-positioned to capitalize on this versatility, offering customized solutions to meet the specific requirements of their clients.

In addition to these technical advancements, air operated double diaphragm pump suppliers are also focusing on user-friendliness and ease of maintenance. Modern air driven diaphragm pumps often come with simplified designs that make them easier to install, operate, and maintain. Some models feature modular components that can be quickly replaced without the need for specialized tools, reducing downtime and maintenance costs. Additionally, advanced monitoring and control systems are being integrated into some pumps, allowing operators to remotely monitor performance, receive alerts for potential issues, and adjust operating parameters in real-time. This level of control not only improves the efficiency of the pumping process but also enhances safety and reliability.

The global market for air driven diaphragm pumps is highly competitive, with numerous suppliers vying for market share. However, it is those who can innovate and adapt to the changing needs of the industry that will ultimately succeed. Air operated double diaphragm pump suppliers are the way to continuously push the boundaries of what is possible with this technology. Through their efforts, they are not only meeting the current demands of the industry but also laying the groundwork for future advancements.

One of the exciting developments in air driven diaphragm pump technology is the integration of smart features. With the rise of the Industrial Internet of Things (IIoT), manufacturers are incorporating advanced sensors and connectivity options into their pumps. These smart pumps can communicate with other devices and systems, providing real-time data on performance, maintenance needs, and potential issues. This allows for predictive maintenance, reducing the risk of unexpected downtime and improving overall operational efficiency. Air operated double diaphragm pump suppliers are at the forefront of this digital transformation, offering solutions that are not only technologically advanced but also future-proof.

Another significant advancement is the development of more environmentally friendly air driven diaphragm pumps. As industries increasingly focus on sustainability and reducing their carbon footprints, manufacturers are exploring ways to minimize the environmental impact of their products. This includes using more sustainable materials in the construction of the pumps and optimizing their energy efficiency to reduce greenhouse gas emissions. Some air operated double diaphragm pumps now feature eco-friendly designs that reduce air consumption and waste, making them a more sustainable choice for environmentally conscious companies.

The ongoing innovation in air driven diaphragm pump technology is a testament to the industry's commitment to progress and improvement. From energy efficiency and durability to versatility and user-friendliness, these advancements are transforming the capabilities of air driven diaphragm pumps. Air operated double diaphragm pump suppliers are playing a crucial role in this transformation, ensuring that their products meet the evolving needs of their customers. As industries continue to face new challenges and opportunities, the role of air driven diaphragm pumps will become even more important. With these revolutionary advances, air driven diaphragm pumps are well-positioned to meet the demands of the future, providing reliable, efficient, and sustainable solutions for fluid transfer applications.

English

English русский

русский Español

Español عربى

عربى