How Air Operated Double Diaphragm Pumps Cut Downtime in Thick Fluid Transfer

2025.08.18

2025.08.18

Industry News

Industry News

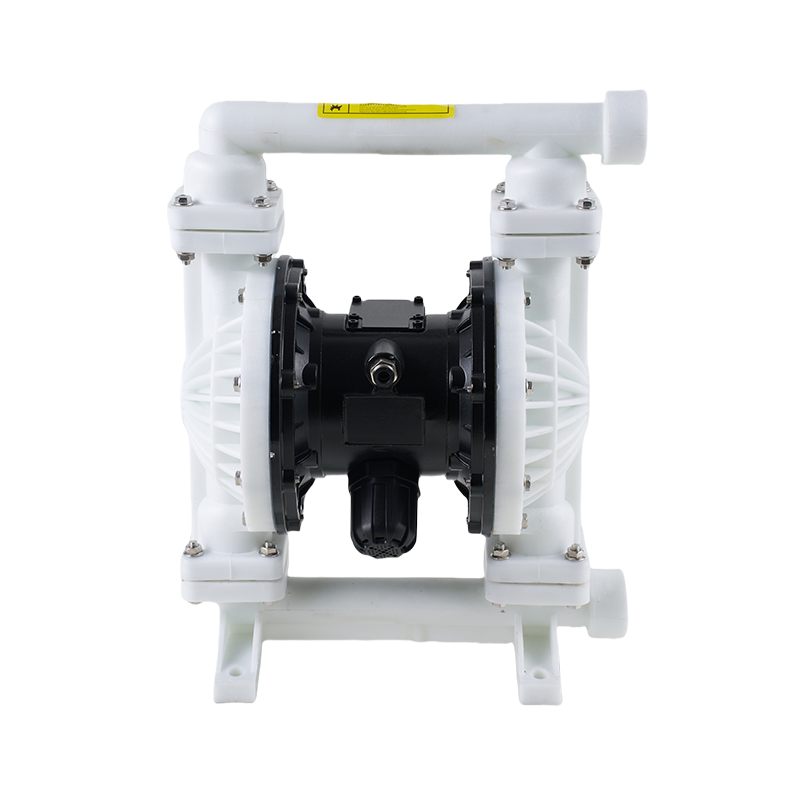

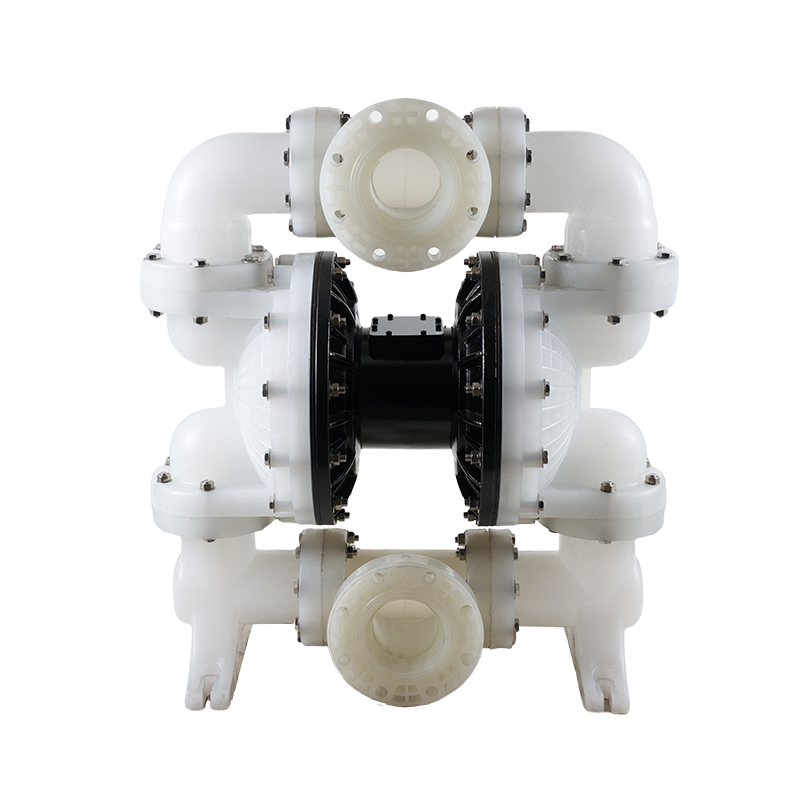

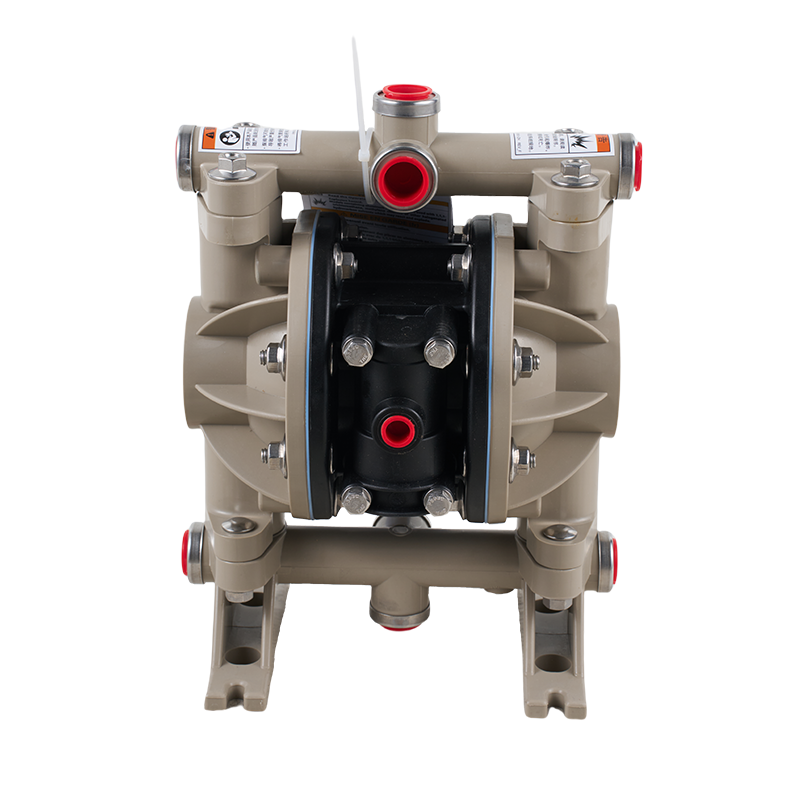

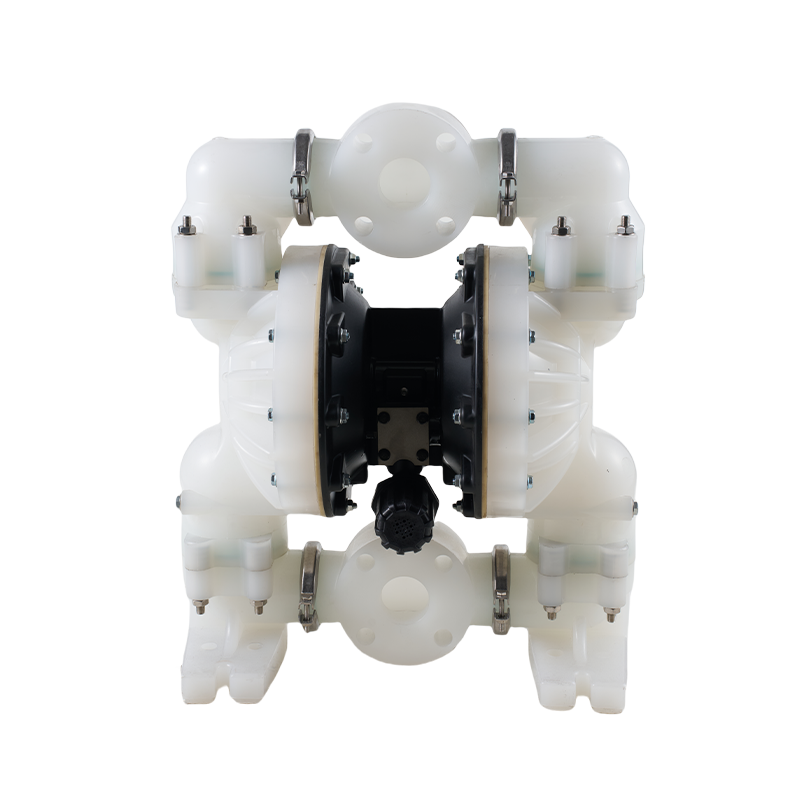

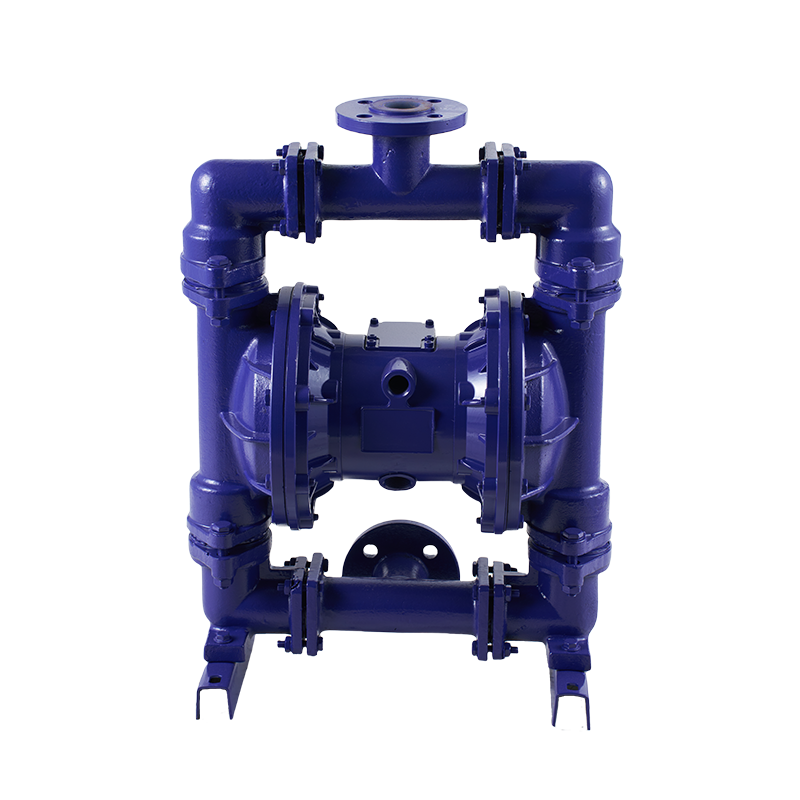

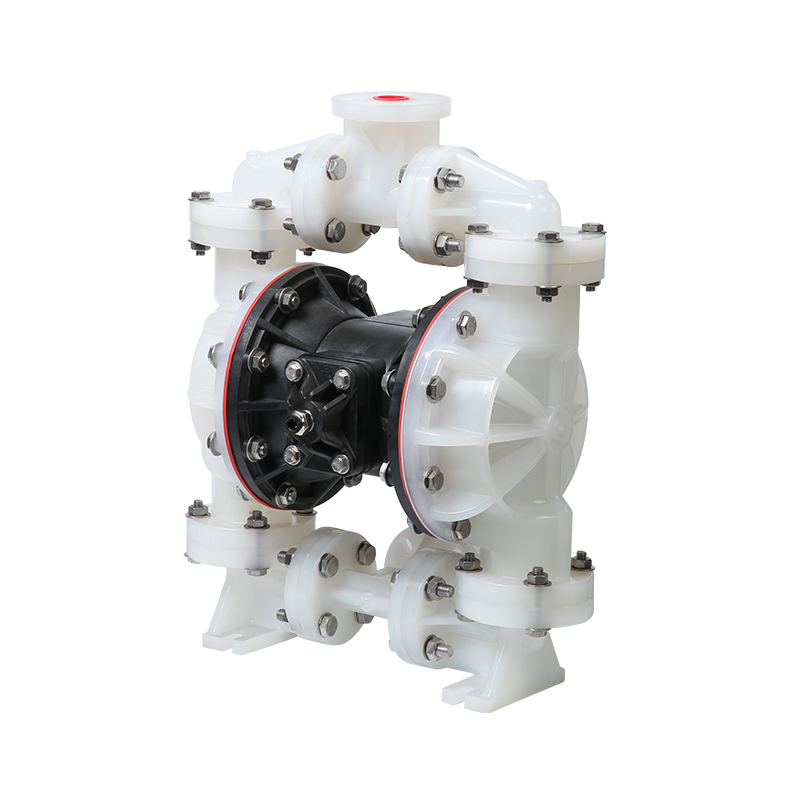

In industries where fluid transfer involves heavy, sticky, or abrasive materials, keeping operations running smoothly can be a challenge. The Air Operated Double Diaphragm AODD Pumps have emerged as a dependable solution for such conditions, especially when paired with the right Diaphragm Pump For High Viscosity Fluids. These pumps are designed to handle challenging materials with minimal interruption, ultimately reducing downtime and improving productivity.

The core strength of Air Operated Double Diaphragm AODD Pumps lies in their simple yet robust design. Operating with compressed air instead of electricity, they are capable of moving fluids that would quickly wear out other pump types. In applications where thick, viscous materials must be transferred—such as heavy oils, slurries, or adhesives—a properly configured Diaphragm Pump For High Viscosity Fluids can maintain flow without clogging or excessive strain.

Unlike many conventional pumps, Air Operated Double Diaphragm AODD Pumps can run dry without damage, a critical benefit in systems where flow conditions can change unexpectedly. Their double diaphragm design also ensures smooth operation, with one diaphragm drawing fluid in while the other pushes it out, creating a balanced pumping action. This mechanism makes them particularly effective as a Diaphragm Pump For High Viscosity Fluids, since it can move heavy materials without losing prime or damaging internal components.

Maintenance downtime is a major concern in high-demand industries. Here, Air Operated Double Diaphragm AODD Pumps excel by offering straightforward serviceability. Diaphragms can be replaced quickly, and the pump's modular design allows operators to access key components without dismantling the entire system. For facilities using a Diaphragm Pump For High Viscosity Fluids, this quick maintenance translates into less disruption and lower labor costs.

Versatility is another advantage. The Air Operated Double Diaphragm AODD Pumps can handle a variety of fluid types, from water-like solvents to ly viscous compounds. With proper diaphragm and housing material selection, a Diaphragm Pump For High Viscosity Fluids can also resist abrasion, corrosion, and chemical attack. This adaptability makes them suitable for industries such as food processing, mining, wastewater treatment, and chemical manufacturing.

Energy efficiency is increasingly important in pump selection. Modern Air Operated Double Diaphragm AODD Pumps incorporate advanced air distribution systems that minimize air consumption while maintaining output. Similarly, selecting a Diaphragm Pump For High Viscosity Fluids with optimized flow channels reduces resistance, allowing heavy materials to pass through with less effort and lower operating costs.

In real-world settings, thick fluid transfer often involves additional challenges such as temperature sensitivity or solids content. Air Operated Double Diaphragm AODD Pumps address these by offering gentle pumping action, which helps protect delicate materials from shear damage. For high-solids applications, the Diaphragm Pump For High Viscosity Fluids can be fitted with larger ball valves and flow passages to prevent clogging, keeping production lines running without unplanned stoppages.

For decision-makers, the choice to invest in Air Operated Double Diaphragm AODD Pumps often comes down to reliability under demanding conditions. When combined with a properly selected Diaphragm Pump For High Viscosity Fluids, the result is a pumping system capable of delivering consistent performance in the tougher environments.

Industries that rely on the efficient movement of thick or challenging materials can benefit significantly from the use of Air Operated Double Diaphragm AODD Pumps. By pairing them with the right Diaphragm Pump For High Viscosity Fluids, businesses can cut downtime, improve operational efficiency, and extend the lifespan of their equipment. With their durability, adaptability, and ease of maintenance, these pumps are proving to be an essential tool in modern fluid handling operations.

English

English русский

русский Español

Español عربى

عربى