Which Materials Are Ideal for a Customized Diaphragm Pump?

2026.02.20

2026.02.20

Industry News

Industry News

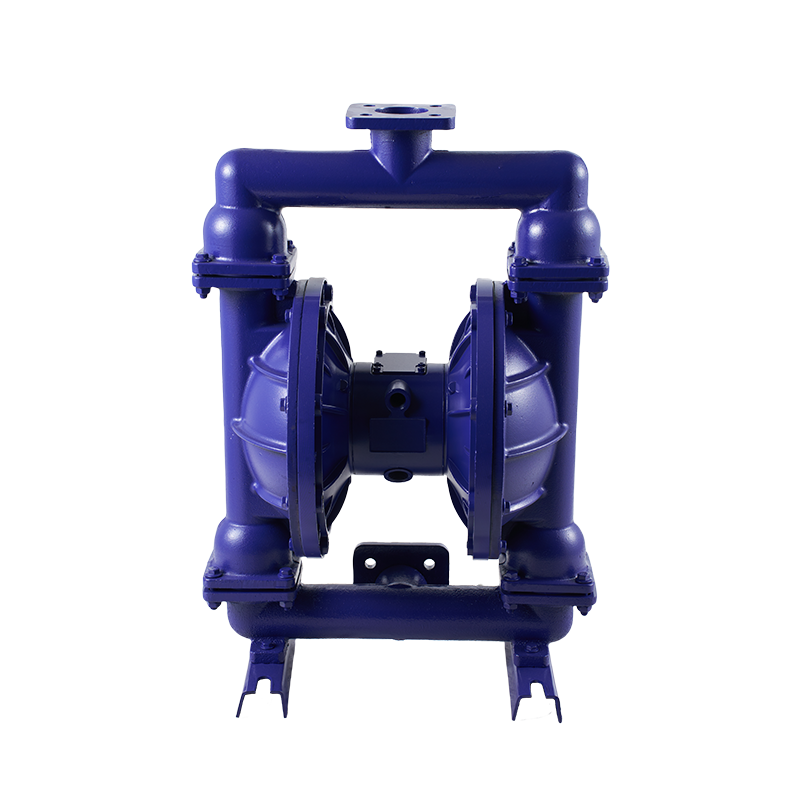

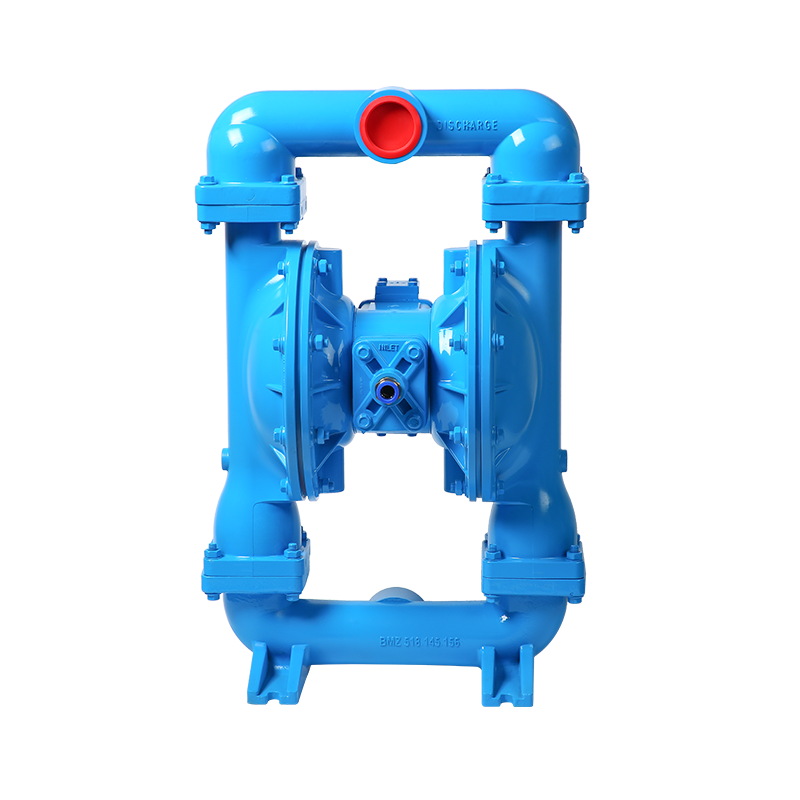

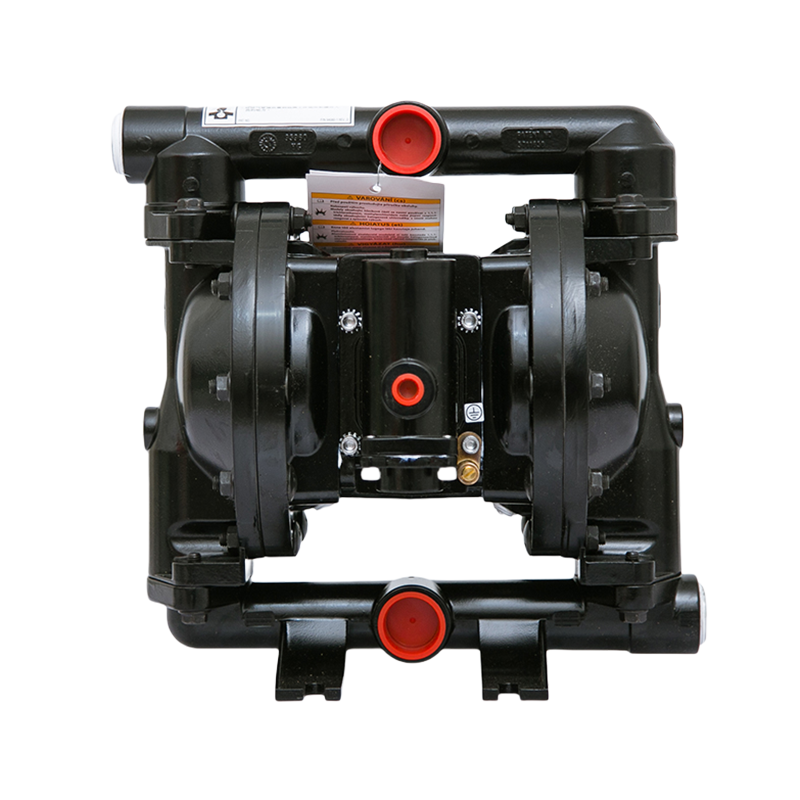

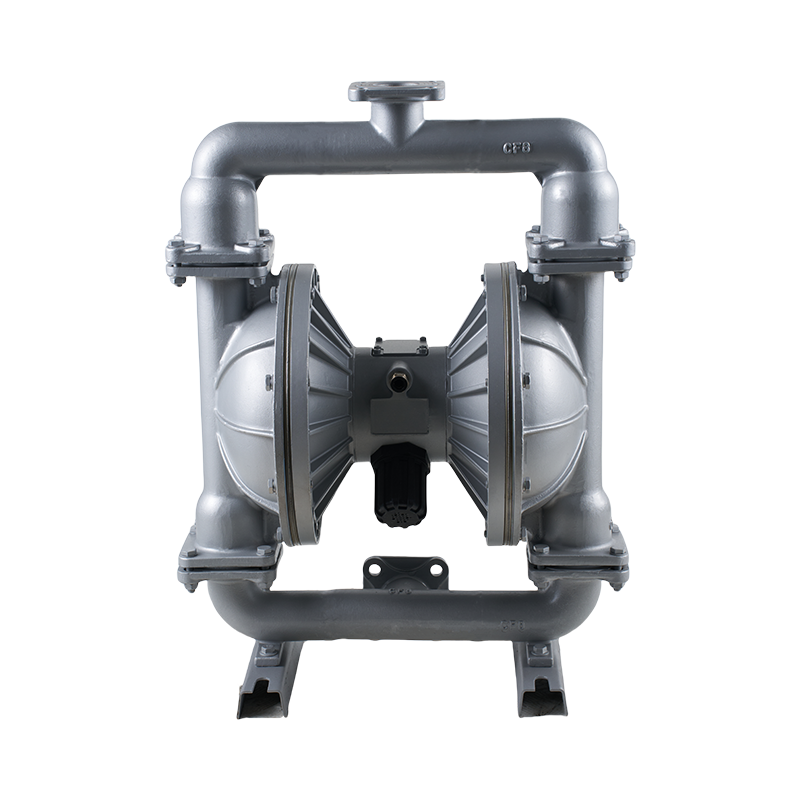

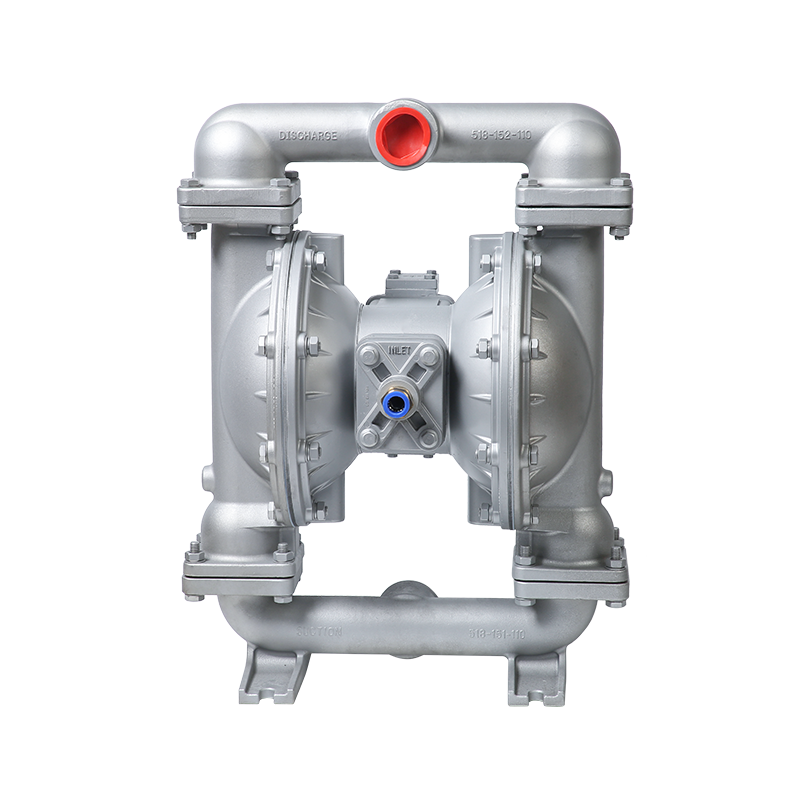

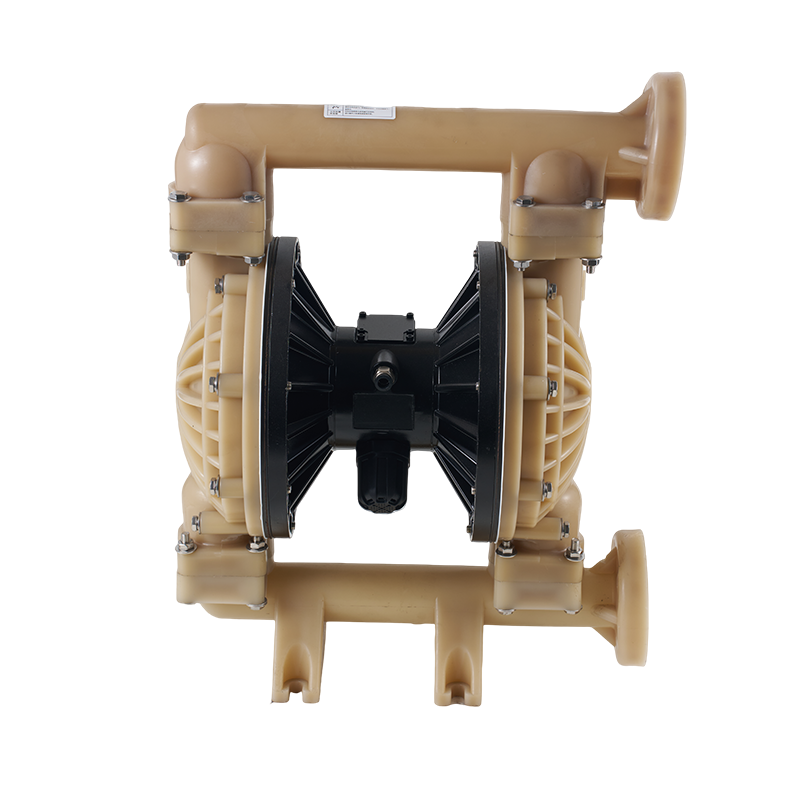

A Customized Diaphragm Pump plays a critical role in industries where precise fluid handling is essential. Unlike standard pumps, these units are tailored for specific applications, whether chemical processing, food production, or wastewater management. Companies often face challenges with fluid viscosity, abrasiveness, or chemical reactivity, and a customized solution can mitigate these issues efficiently.

Advantages of Working with a Customized Diaphragm Pump Factory

Selecting a Customized Diaphragm Pump Factory in China allows access to specialized expertise and production capabilities. Chinese factories focus on high-quality pneumatic diaphragm pumps and double diaphragm pumps, ensuring consistency across large production runs. Many factories offer competitive pricing, broad material options, and customization services, making them attractive for businesses needing reliable pump solutions.

These factories also prioritize technology and skilled technicians, which enhances pump durability and operational performance. For applications involving aggressive or abrasive fluids, working with a Customized Diaphragm Pump Factory ensures that the pump's construction materials and design are appropriate for the intended process.

Material Selection and Fluid Compatibility

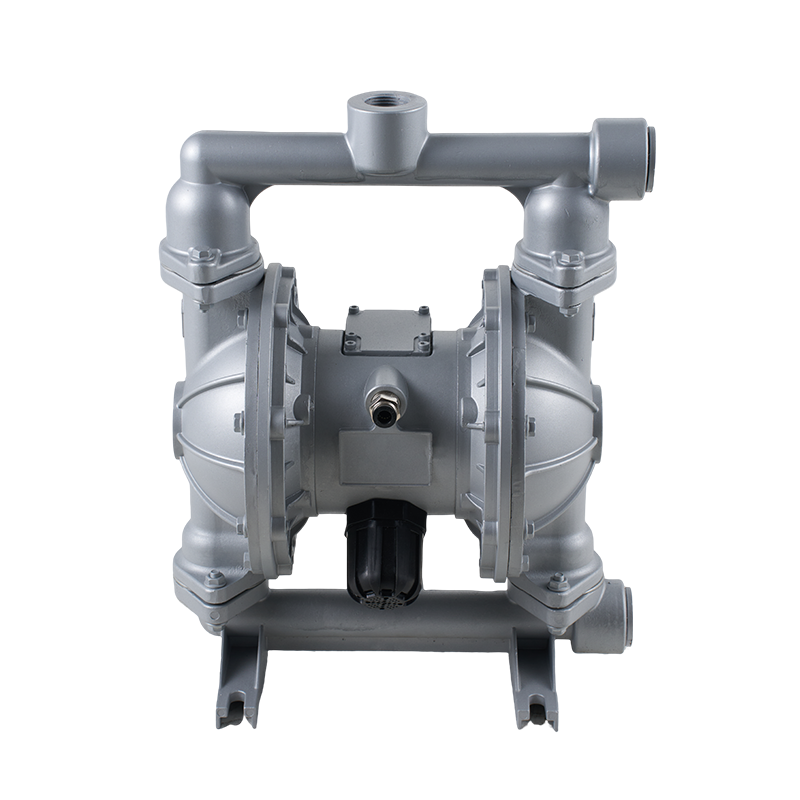

One of the many common concerns is whether a pump can handle specific fluids safely. Customized Diaphragm Pumps are available in materials such as PTFE, stainless steel, or polypropylene, each suited for different chemical or thermal conditions. A Customized Diaphragm Pump Factory can recommend good materials for your application, whether the fluid is corrosive, abrasive, or contains solids. Proper material selection reduces downtime and maintenance costs.

Performance and Efficiency Benefits

Customized pumps allow businesses to optimize flow rate, pressure, and pumping efficiency. Unlike off-the-shelf options, these pumps are designed around the exact requirements of the operation. A Customized Diaphragm Pump can deliver consistent output, handle challenging fluids, and reduce energy consumption, all of which contribute to operational efficiency.

Double diaphragm pumps produced by specialized Chinese factories are particularly suited for handling viscous or solid-laden fluids gently without causing damage. Partnering with a Customized Diaphragm Pump Factory ensures that the pump design aligns with industrial goals, improving both reliability and long-term performance.

Maintenance and Reliability Considerations

Maintenance is a key concern for industrial pumps. A Customized Diaphragm Pump can be engineered for easier maintenance with fewer downtime interruptions. Factories typically offer technical guidance on installation, operation, and maintenance schedules. Knowing that the pump is supported by a professional Customized Diaphragm Pump Factory provides peace of mind for long-term operations.

Regular inspection of diaphragms, valves, and connections ensures the pump performs as intended. By choosing a factory that emphasizes quality and support, businesses can reduce operational disruptions and avoid unexpected failures.

Delivery and After-Sales Support

Speed and reliability of delivery are critical when integrating pumps into production lines. A Customized Diaphragm Pump Factory can provide timely delivery schedules, often with logistics experience for international shipments. After-sales support is equally important, as manufacturers offer troubleshooting, spare parts, and guidance to maintain pump efficiency.

A Customized Diaphragm Pump is more than just a fluid-handling tool—it's a tailored solution for efficiency, reliability, and cost management. Choosing a Customized Diaphragm Pump Factory in China gives access to technical expertise, diverse material options, and competitive pricing. From material compatibility to performance optimization and after-sales support, these factories provide solutions that fit industrial needs and minimize operational headaches.

English

English русский

русский Español

Español عربى

عربى