10 Features to Look for in a High-Quality Diaphragm Pump

2025.08.17

2025.08.17

Industry News

Industry News

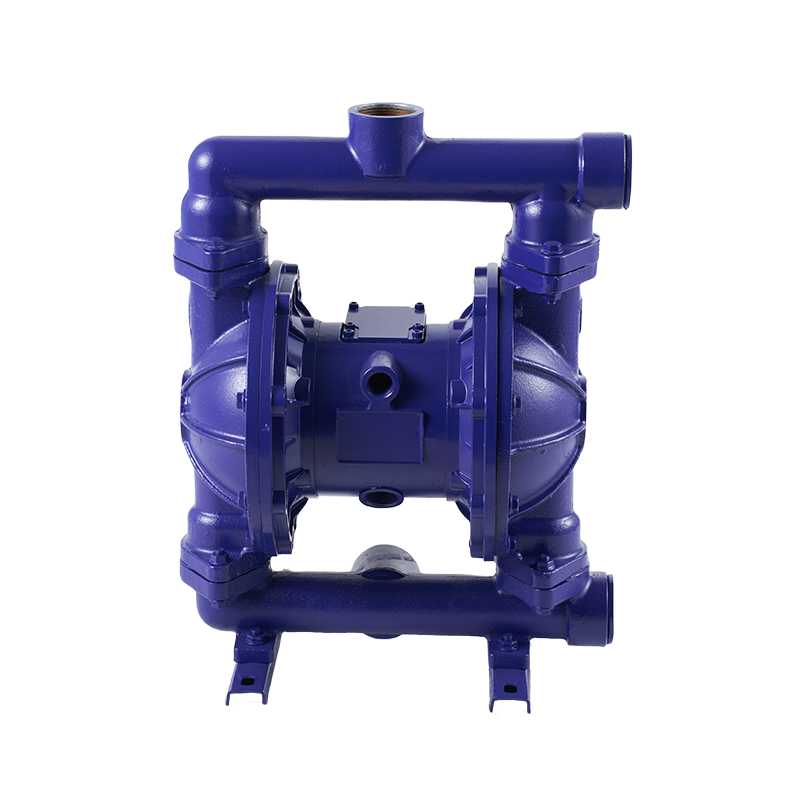

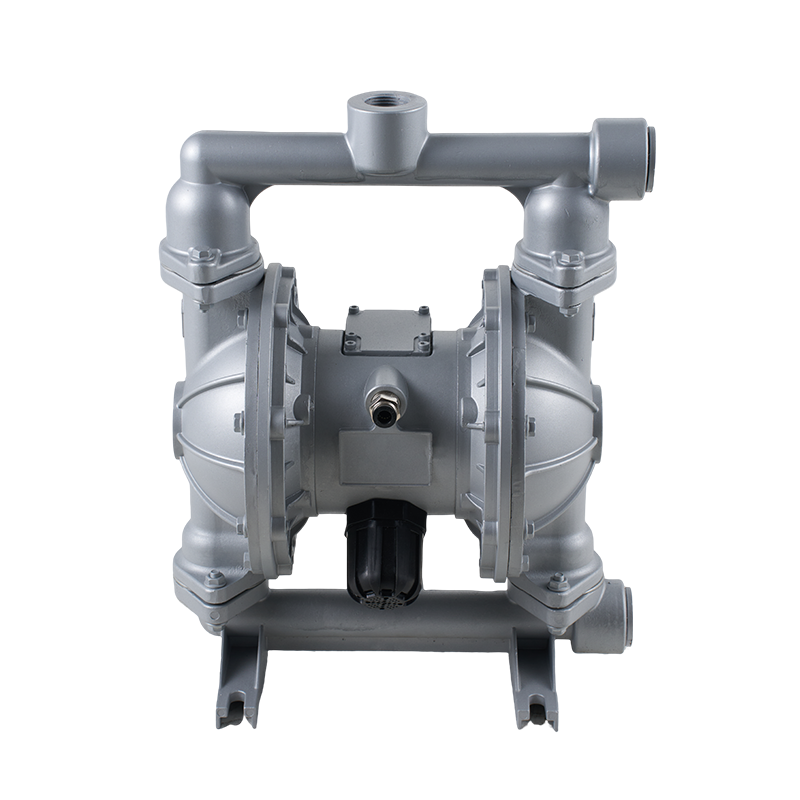

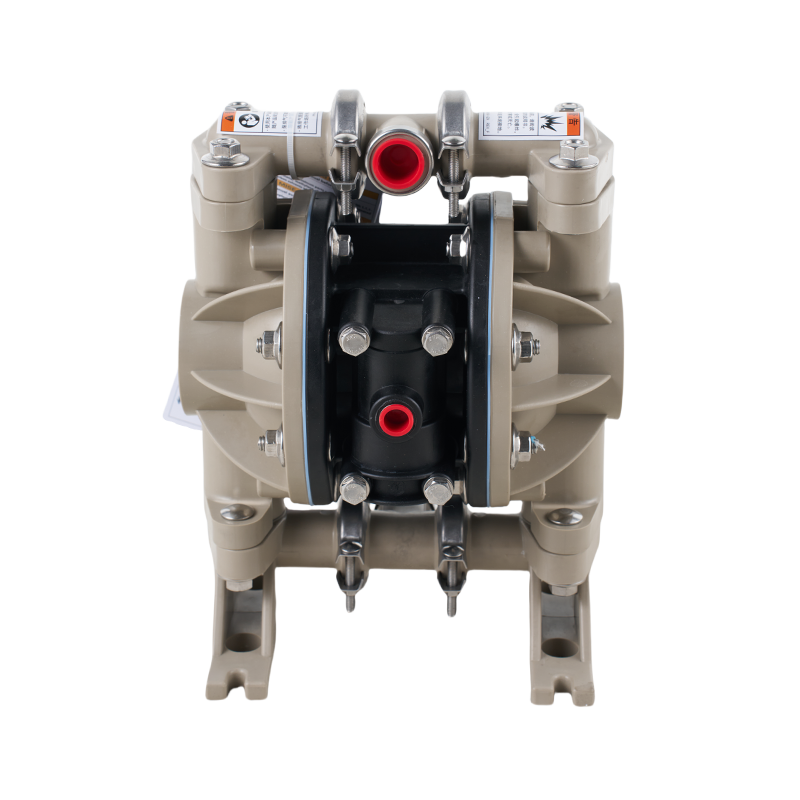

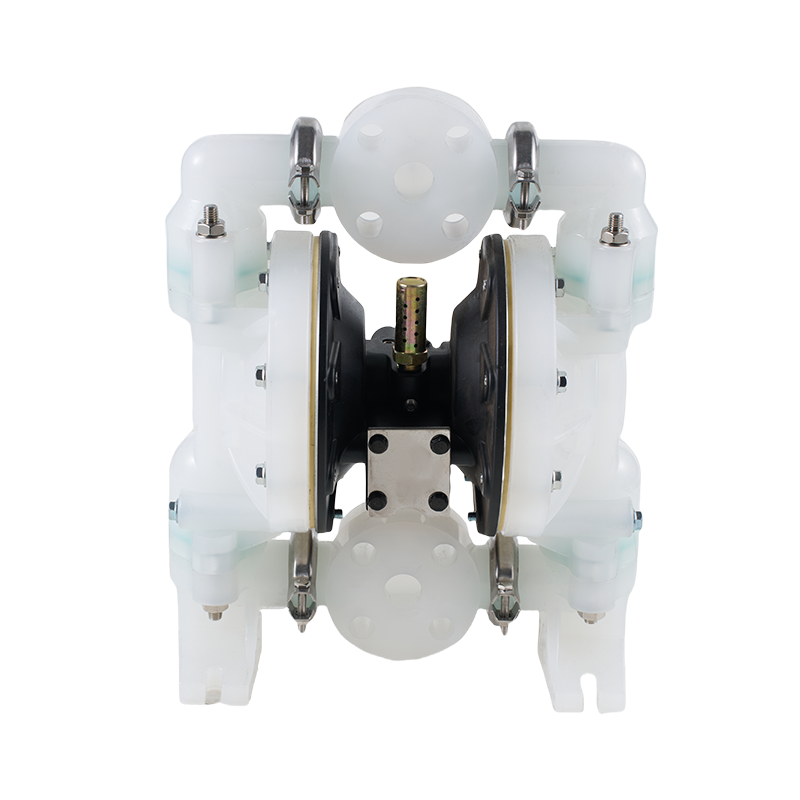

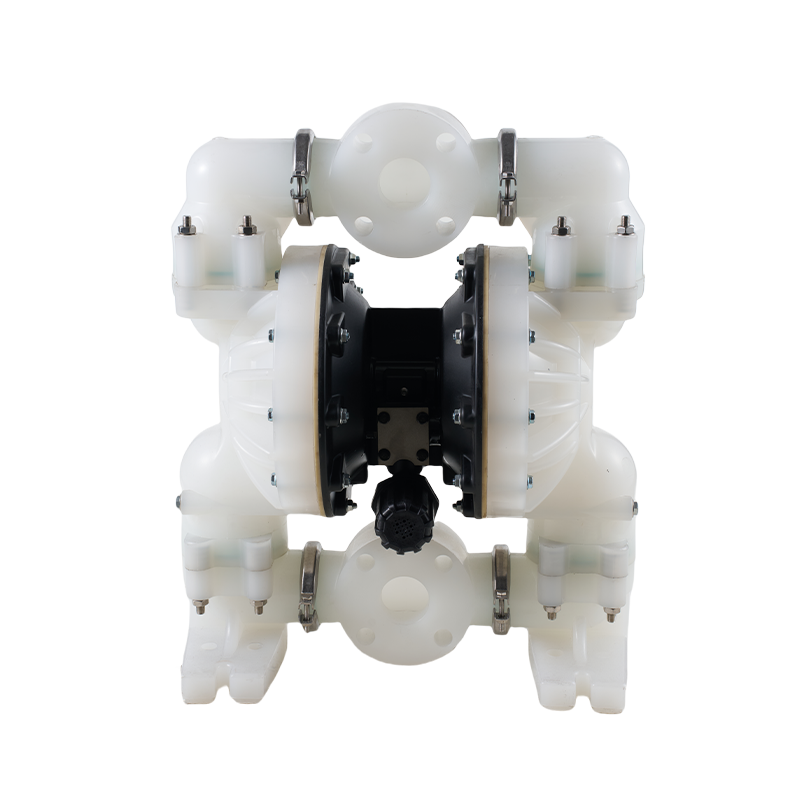

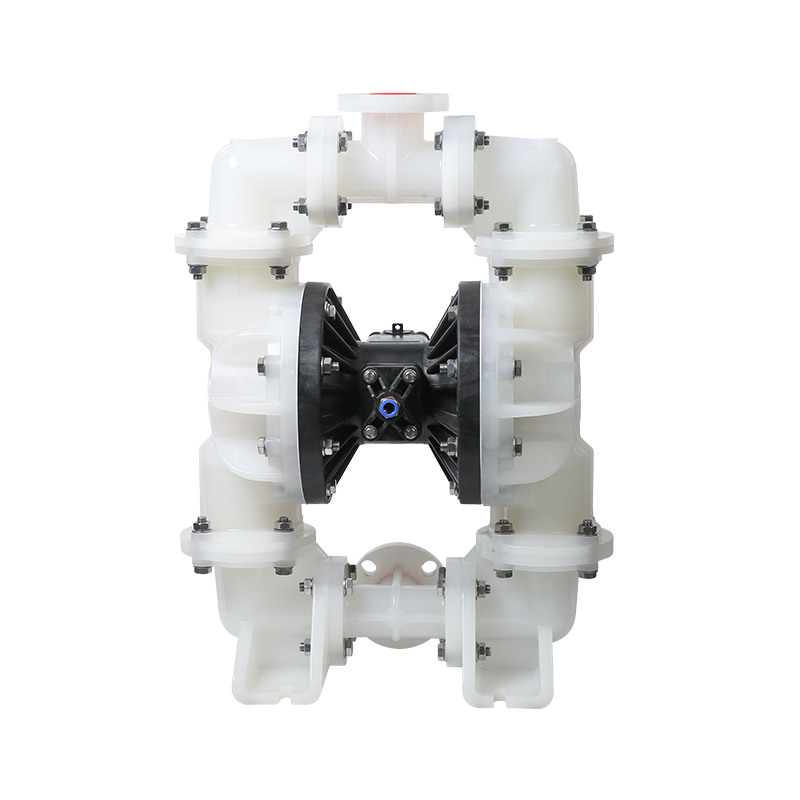

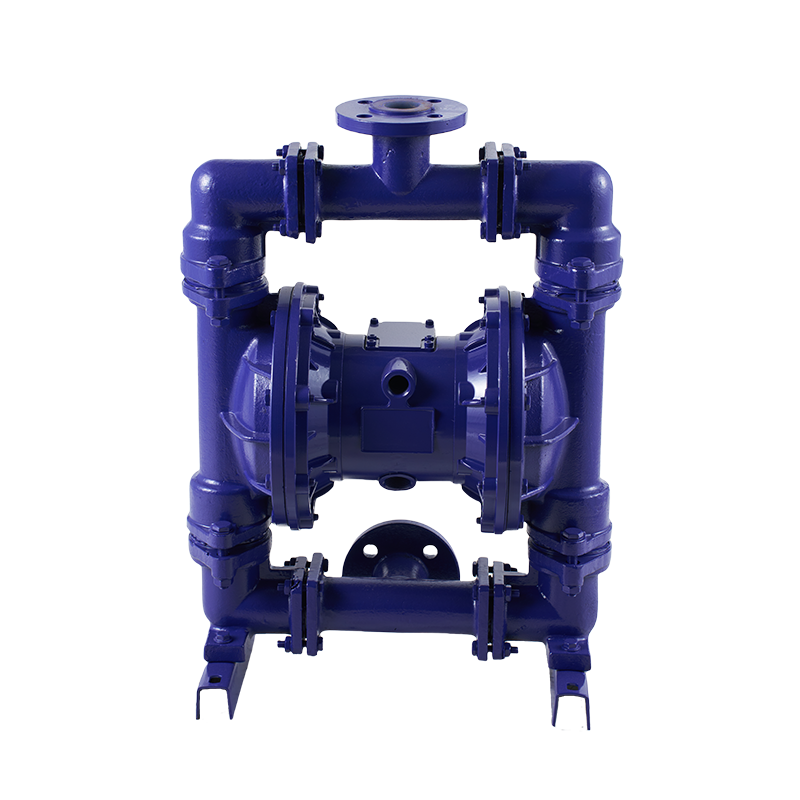

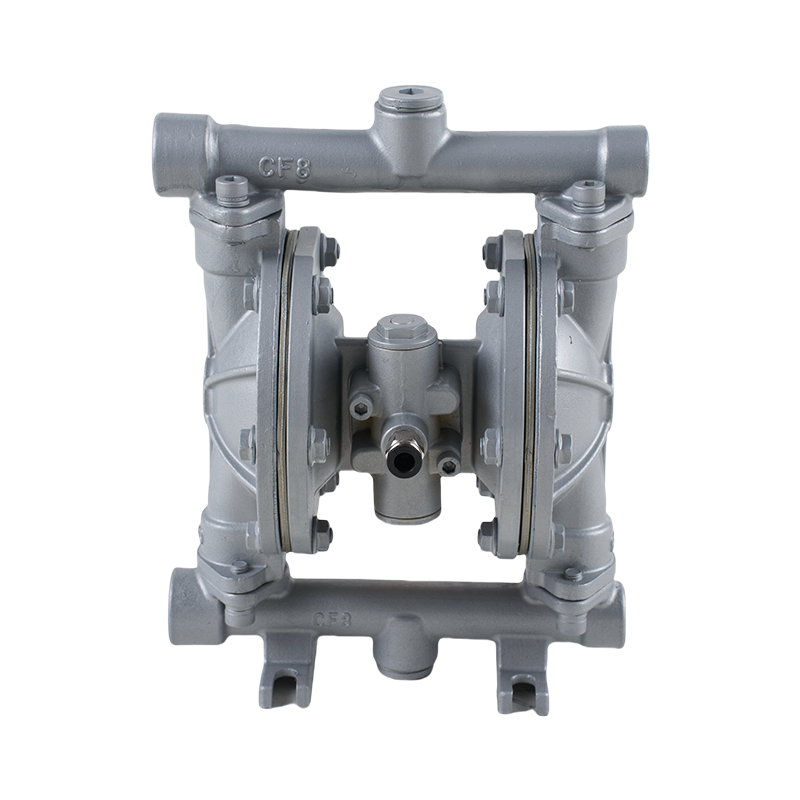

When selecting a diaphragm pump for industrial or commercial use, understanding the key features that distinguish a high-quality model is essential. Whether you are considering a Duplex Diaphragm Pump, a Silent Diaphragm Pump, or simply seeking a High Quality Diaphragm Pump to meet your specific needs, being aware of these characteristics will help ensure reliable performance and long service life.

1. Durable Construction Materials

A High Quality Diaphragm Pump is built using materials that resist corrosion and wear. Pumps made from stainless steel, reinforced plastics, or specialized alloys tend to provide enhanced durability. This is especially important for a Duplex Diaphragm Pump, which often handles more demanding or abrasive fluids.

2. Efficient Fluid Handling

Efficiency in fluid handling is critical. A High Quality Diaphragm Pump should provide steady flow rates and maintain consistent pressure under varying conditions. The design of the diaphragm and valves in a Silent Diaphragm Pump often contributes to this efficiency by minimizing fluid pulsation and turbulence.

3. Leak-Free Performance

One hallmark of a reliable diaphragm pump is its ability to operate without leaks. A Duplex Diaphragm Pump, with its dual-diaphragm system, typically offers improved sealing capabilities, reducing the risk of leakage and contamination. This feature is vital in many industries, including pharmaceuticals and food processing.

4. Low Noise Operation

Noise levels are a significant concern in many working environments. A Silent Diaphragm Pump is specifically designed to minimize operational noise. This is achieved through advanced engineering of the pump chamber and damping mechanisms, making the pump suitable for settings where quiet operation is preferred.

5. Easy Maintenance and Serviceability

Maintenance ease is a major factor for operational continuity. High Quality Diaphragm Pumps usually feature modular designs that allow for quick access to diaphragms, valves, and other internal parts. A Duplex Diaphragm Pump often simplifies maintenance by enabling one side to operate while the other is serviced.

6. Versatility in Applications

A reliable diaphragm pump should be versatile enough to handle different fluids, including aggressive chemicals, slurries, and viscous liquids. Both the Silent Diaphragm Pump and Duplex Diaphragm Pump variants are popular choices in diverse industries due to their adaptability and resistance to various media.

7. Energy Efficiency

Reducing energy consumption is a growing priority. High Quality Diaphragm Pumps tend to be designed with energy-saving features such as optimized air or hydraulic drive systems. This not only lowers operating costs but also reduces environmental impact.

8. Safe and Stable Operation

Safety is paramount when dealing with pumps, especially when pumping hazardous substances. The design of a Duplex Diaphragm Pump inherently provides redundancy, which adds an extra layer of safety by preventing sudden failures. Similarly, Silent Diaphragm Pumps often incorporate features that ensure stable operation under fluctuating pressure conditions.

9. Compact and Lightweight Design

Space and weight considerations are important in many installations. A High Quality Diaphragm Pump generally balances robustness with a compact footprint. Silent Diaphragm Pumps often excel in this regard, making them suitable for confined spaces or mobile applications.

10. Proven Track Record and Support

Finally, the reputation of the manufacturer and the availability of customer support can influence the overall satisfaction with a diaphragm pump. Choosing a well-established supplier of Duplex Diaphragm Pumps or Silent Diaphragm Pumps ensures access to technical assistance, spare parts, and warranty coverage.

English

English русский

русский Español

Español عربى

عربى