When to use a diaphragm pump?

2025.03.03

2025.03.03

Industry News

Industry News

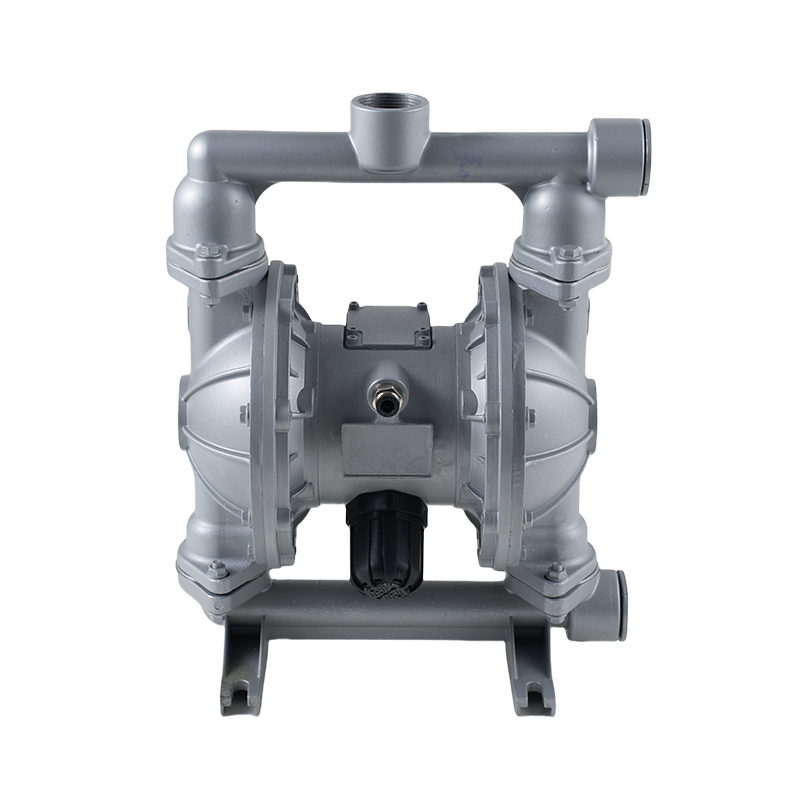

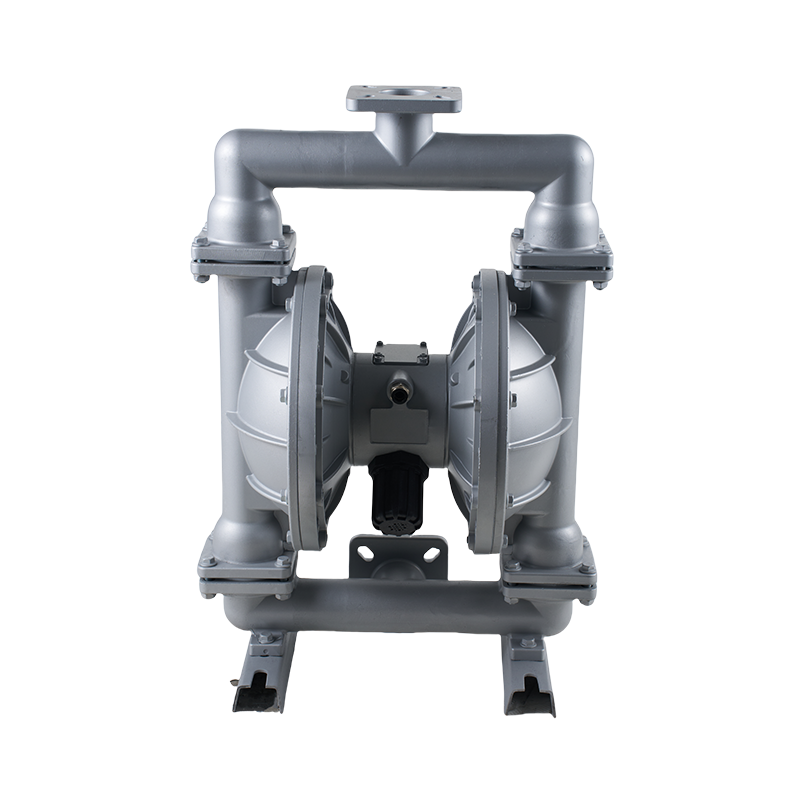

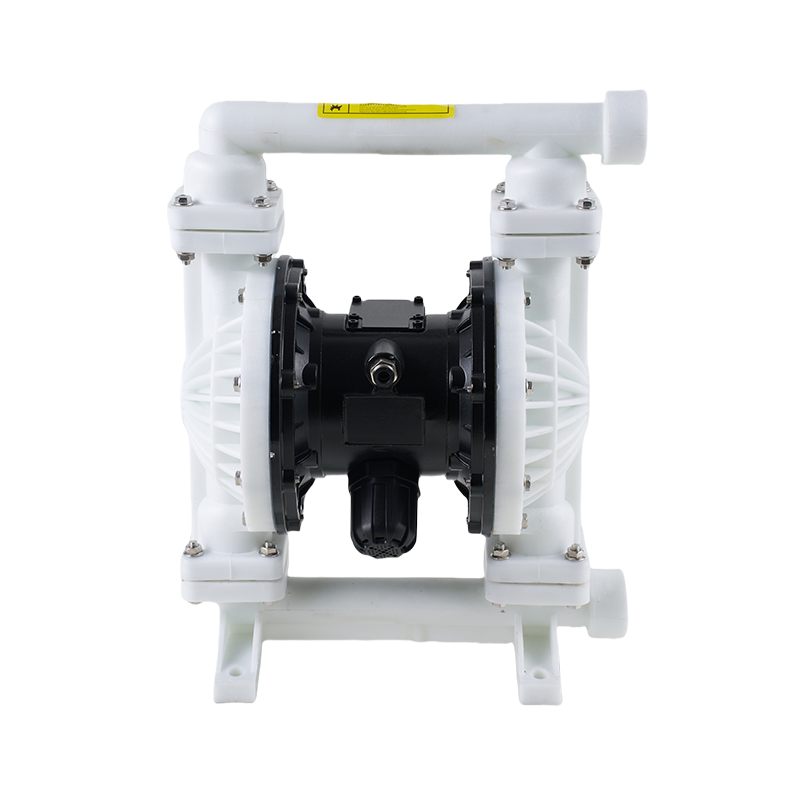

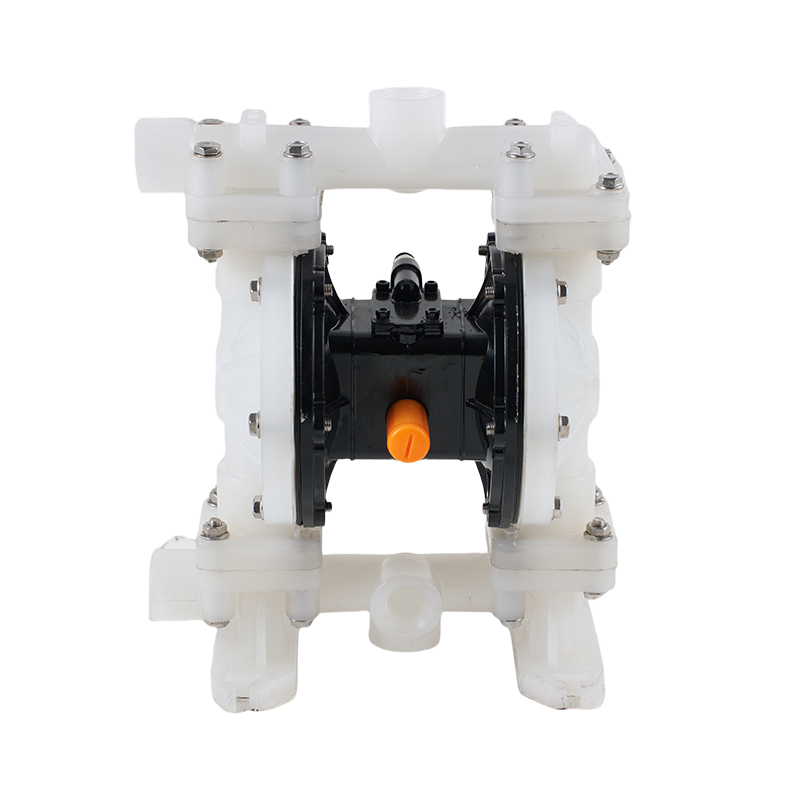

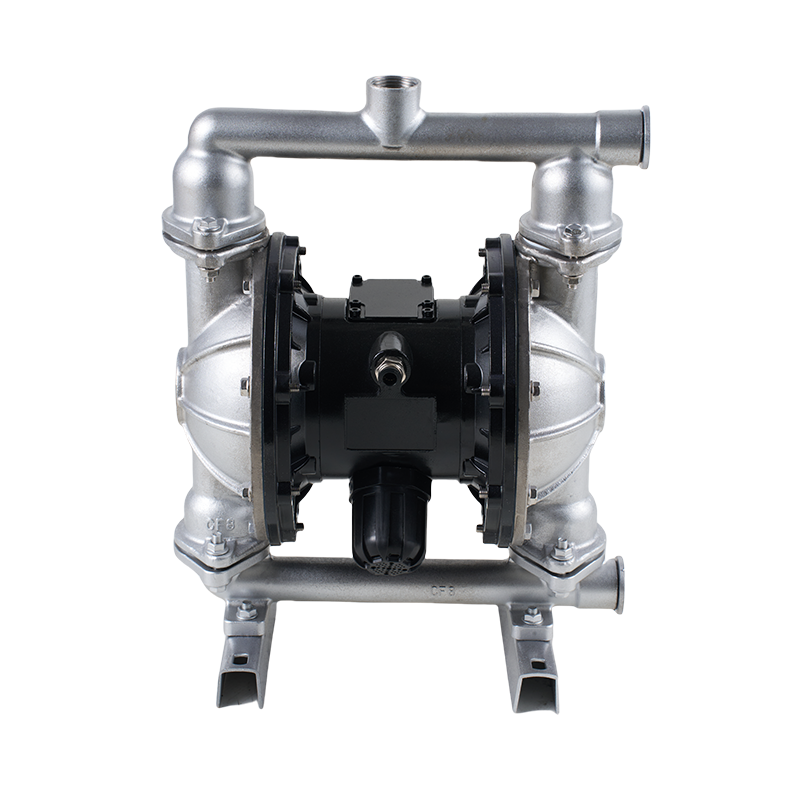

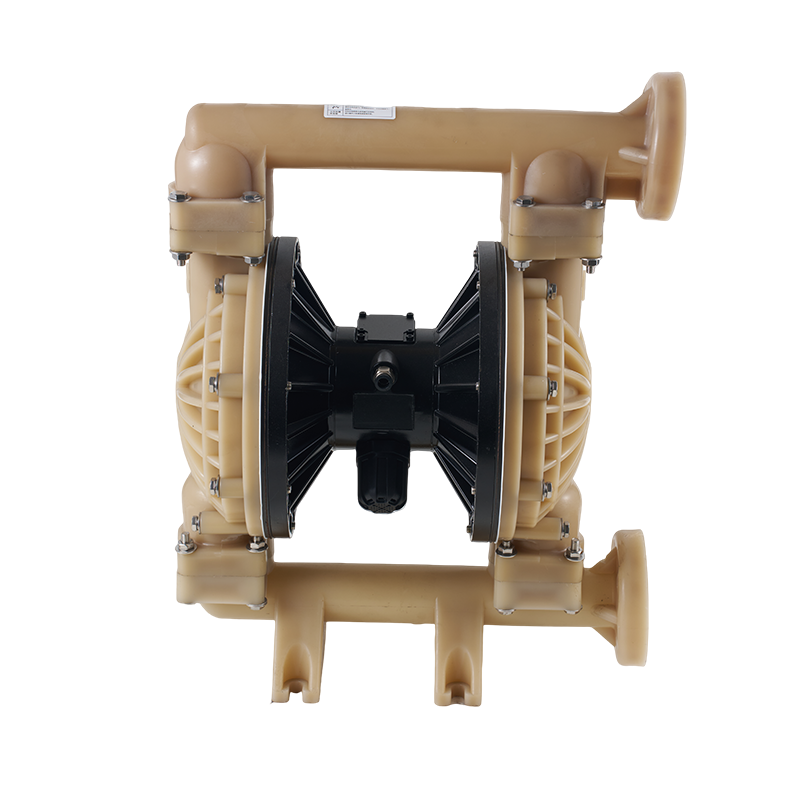

Diaphragm pumps are versatile and widely used in various industries due to their unique ability to handle a broad range of fluids, including corrosive, viscous, and abrasive materials. Knowing when to use a diaphragm pump is essential for selecting the right equipment to improve efficiency and reduce maintenance costs. In this article, we will explore the typical applications and industries where diaphragm pumps, including the Sump Pump Diaphragm and Diaphragm Mud Pump, are effective. Additionally, we will discuss the role of Air Operated Double Diaphragm Pump Manufacturers in supplying these crucial components.

Ceramics Industry

In the ceramics industry, diaphragm pumps are often used for slip and slurry transfer as well as wastewater handling. The Sump Pump Diaphragm plays a critical role here, ensuring smooth transfer of thick, abrasive ceramic slips without clogging or damage to the pump. The diaphragm's flexibility and chemical resistance help manage the harsh conditions in ceramic processing. Diaphragm Mud Pump variants are also applied for slurry pumping due to their robust design and ability to handle solids-laden fluids.

Chemical Processing

Chemical processing involves pumping aggressive and corrosive materials such as acids and solvents. This is a prime example of when to use a diaphragm pump. The Air Operated Double Diaphragm Pump Manufacturers provide pumps with chemical-resistant diaphragms designed to withstand harsh substances without degradation. The Sump Pump Diaphragm and Diaphragm Mud Pump are tailored for chemical transfer, offering leak-free, safe handling of hazardous liquids, which is critical for maintaining plant safety and compliance.

Food and Beverage Industry

In food and beverage processing, hygiene and contamination prevention are paramount. Diaphragm pumps are ideal for ingredient transfer due to their gentle pumping action and ability to handle viscous fluids, suspensions, and shear-sensitive products. The Sump Pump Diaphragm used here is made from FDA-compliant materials to ensure food safety. Many Air Operated Double Diaphragm Pump Manufacturers specialize in producing sanitary pumps suitable for food-grade applications, making diaphragm pumps the go-to choice for transferring syrups, sauces, and beverages.

Printing, Packaging, Pulp, and Paper

Industries such as printing, packaging, pulp, and paper rely on diaphragm pumps for transferring inks, glues, solvents, and adhesives. The Diaphragm Mud Pump is particularly valuable in this sector because of its ability to handle viscous and abrasive fluids without clogging or damage. The Sump Pump Diaphragm helps maintain consistent flow rates for ink and adhesive application processes, ensuring product quality. Collaboration with trusted Air Operated Double Diaphragm Pump Manufacturers guarantees pumps that meet specific viscosity and chemical compatibility requirements.

Other Applications

Besides the industries mentioned, diaphragm pumps are widely used for wastewater treatment, mining, oil and gas, and pharmaceutical production. The Diaphragm Mud Pump is especially popular in mining operations for slurry and mud transfer, thanks to its rugged construction and solids-handling capability. Similarly, the Sump Pump Diaphragm finds use in sump pumping applications where removal of wastewater and slurries is needed. The expertise of Air Operated Double Diaphragm Pump Manufacturers ensures pumps are customized to meet the specific environmental and operational challenges of these applications.

Why Choose Diaphragm Pumps?

Diaphragm pumps provide several advantages, including:

Ability to handle abrasive, corrosive, and viscous fluids

Self-priming and dry-run capability

Leak-free operation due to hermetically sealed diaphragm

Low shear pumping, suitable for delicate fluids

Easy maintenance and long service life

When faced with demanding fluid transfer tasks, such as slurry handling in ceramics or chemical transfer in harsh environments, selecting the correct diaphragm pump model from reputable Air Operated Double Diaphragm Pump Manufacturers is critical. The choice between a Sump Pump Diaphragm or a Diaphragm Mud Pump depends on the application specifics like fluid type, flow rate, and environmental conditions.

Knowing when to use a diaphragm pump can significantly enhance operational efficiency and reduce downtime across various industries. Whether you need a Sump Pump Diaphragm for wastewater management, a Diaphragm Mud Pump for slurry and abrasive fluid handling, or rely on trusted Air Operated Double Diaphragm Pump Manufacturers to supply tailored solutions, diaphragm pumps offer unmatched versatility and reliability. From ceramics and chemical processing to food and beverage and printing, diaphragm pumps are the trusted choice for challenging pumping applications.

English

English русский

русский Español

Español عربى

عربى