Need to Move Sludge, Debris, or Wastewater? Try an Air Operated Trash Pump

2025.08.17

2025.08.17

Industry News

Industry News

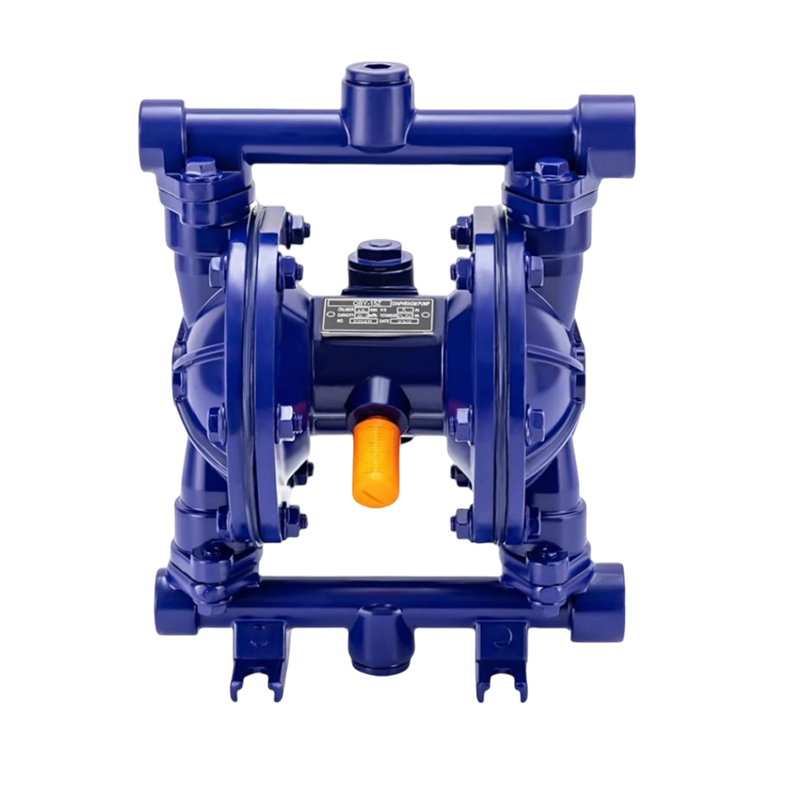

Efficient wastewater and debris management is a constant challenge in industries ranging from construction to municipal services. When faced with the need to remove sludge, sediment, or large solids from a work site, traditional pumping solutions often struggle with clogging or performance drops. In such cases, an Air-Operated Trash Pump provides a reliable and versatile solution.

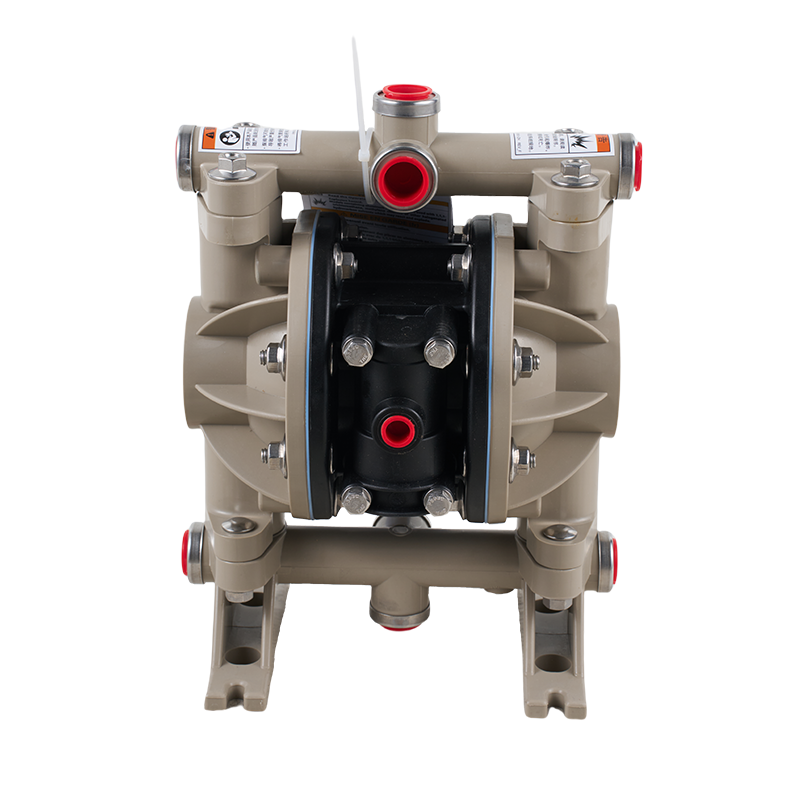

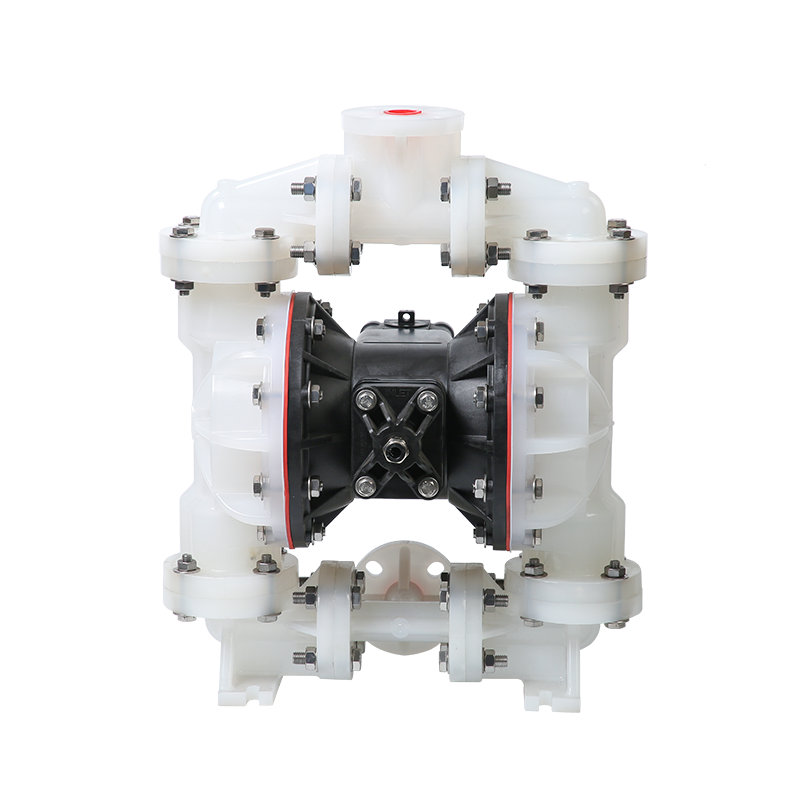

An Air Operated Trash Pump works by using compressed air to drive a diaphragm mechanism, enabling it to handle liquids with high solid content. Unlike centrifugal pumps, it does not rely on fast-spinning impellers that can become blocked by debris. This makes it ideal for pumping contaminated water, industrial waste, or construction runoff. These pumps are also capable of running dry without damage, which reduces the risk of downtime on site.

Applications in Industrial Wastewater Management

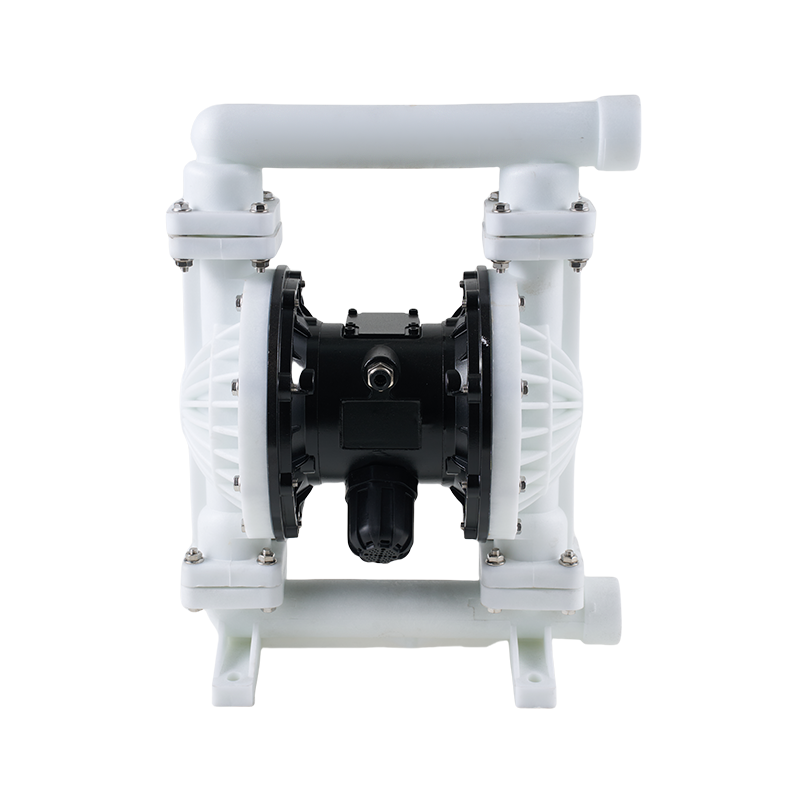

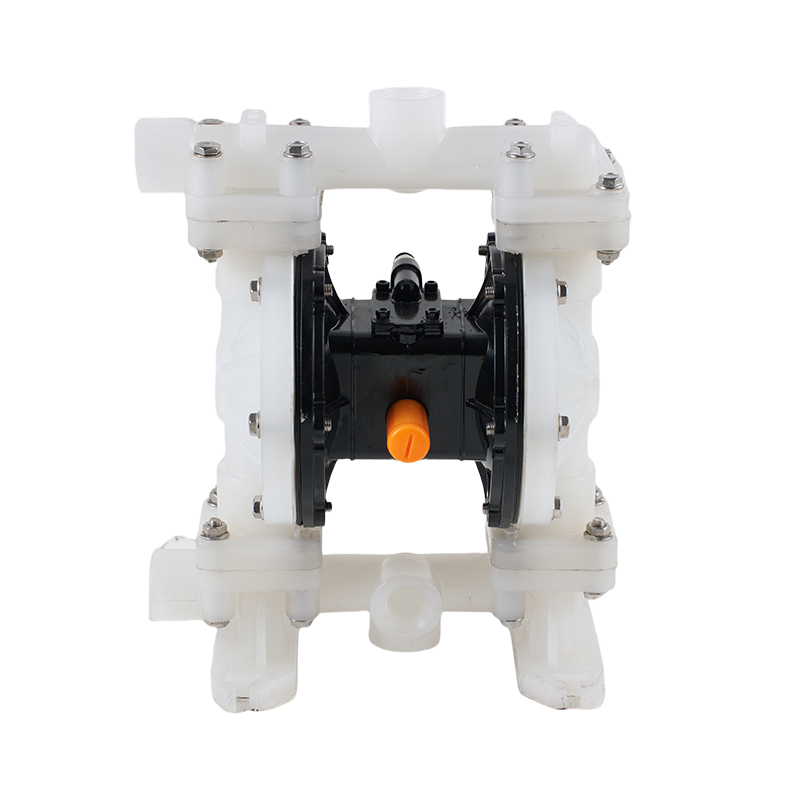

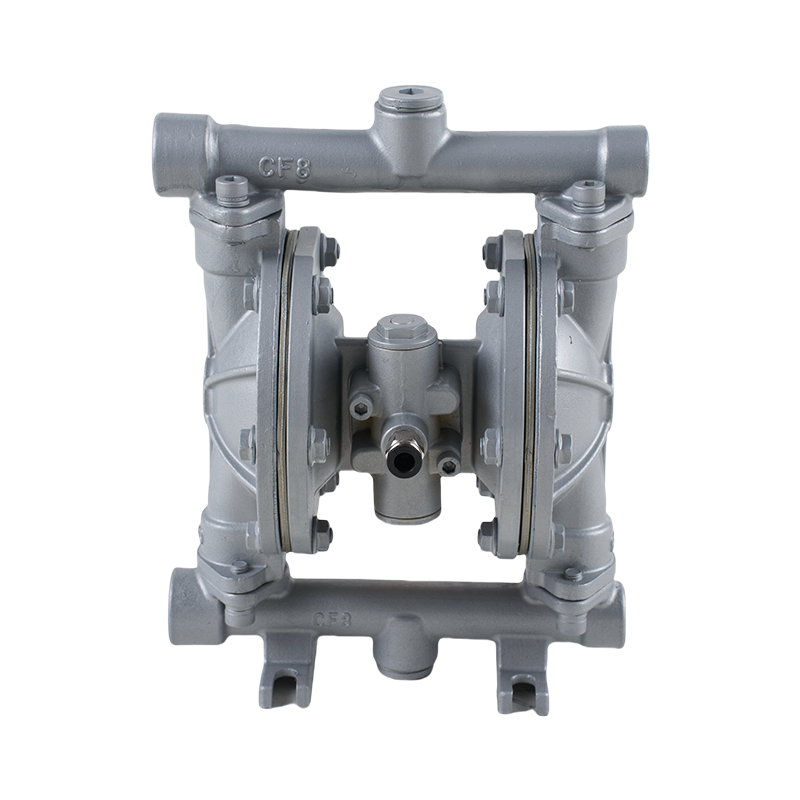

Many industrial facilities generate wastewater containing not only liquids but also suspended solids, fibrous materials, and sediments. An Air Operated Trash Pump can easily manage this mixture without clogging, ensuring consistent flow rates. It is frequently paired with Membrane Diaphragm Pump technology, which uses a flexible membrane to separate the pumped liquid from the driving mechanism. This design provides a strong seal, protecting internal components and extending service life.

A Membrane Diaphragm Pump offers similar benefits to an Air Operated Trash Pump in terms of debris handling, but its precision makes it suitable for controlled transfer processes. These pumps are often used in chemical handling, food processing, wastewater, and environmental remediation. When the need is specifically to manage liquids containing sludge or gravel, however, the Air Operated Trash Pump is the more robust choice.

Role in the Medical Sector

While heavy-duty trash pumps are designed for industrial and municipal work, the diaphragm pumping principle is equally valuable in the medical field. Medical Diaphragm Pumps are smaller, precision-engineered devices that provide controlled, contamination-free fluid transfer in applications like laboratory equipment, dialysis machines, and medical suction systems. Unlike industrial trash pumps, Medical Diaphragm Pumps are designed for low-noise operation, minimal pulsation, and precise dosing.

Interestingly, the core technology of the Medical Diaphragm Pump—the use of flexible diaphragms driven mechanically or pneumatically—mirrors the operational principles of larger Membrane Diaphragm Pumps used in wastewater management. Both rely on the diaphragm's ability to create a sealed chamber for clean and reliable pumping. The main difference lies in the pump's size, construction materials, and intended application.

Advantages of Air Operated Systems

One of the primary advantages of an Air Operated Trash Pump is its safety in hazardous environments. Since it is powered by compressed air rather than electricity, there is no risk of sparks, making it suitable for areas where flammable gases or vapors may be present. This safety factor also benefits certain Medical Diaphragm Pump setups in sensitive environments where electrical interference must be minimized.

The Membrane Diaphragm Pump design also contributes to operational safety. By keeping the pumped medium fully separated from moving parts and lubricants, it minimizes contamination risk and equipment wear. This makes it an attractive choice for industries where hygiene and reliability are priorities.

Meeting Modern Environmental Demands

With increasing environmental regulations, industries are under pressure to handle wastewater responsibly. An Air Operated Trash Pump provides a practical solution by allowing quick and effective removal of contaminated water before treatment. Paired with a Membrane Diaphragm Pump for finer transfer operations, the system can handle everything from initial debris removal to final liquid processing.

In healthcare facilities, Medical Diaphragm Pumps play a parallel role in ensuring that fluids are safely and efficiently handled without leaks or contamination. Whether in a treatment plant or a hospital lab, diaphragm-based pumps have proven their versatility and reliability.

When faced with the challenge of moving sludge, debris, or wastewater, an Air Operated Trash Pump is an option. Its ability to handle large solids without clogging, combined with the benefits of Membrane Diaphragm Pump technology, ensures a dependable performance in tough conditions. Meanwhile, Medical Diaphragm Pumps demonstrate how diaphragm pumping principles can be applied across vastly different industries, from construction sites to operating rooms. By choosing the right pump for the right task, organizations can achieve efficient, safe, and long-lasting fluid management.

English

English русский

русский Español

Español عربى

عربى