5 Key Advantages of Using Diaphragm Pumps for Slurry Applications

2025.08.17

2025.08.17

Industry News

Industry News

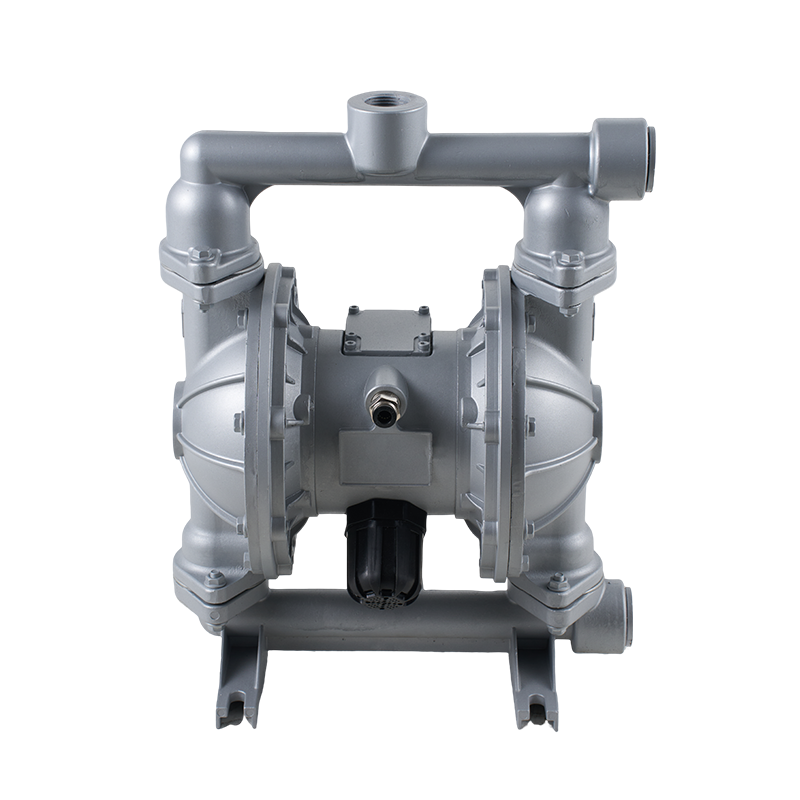

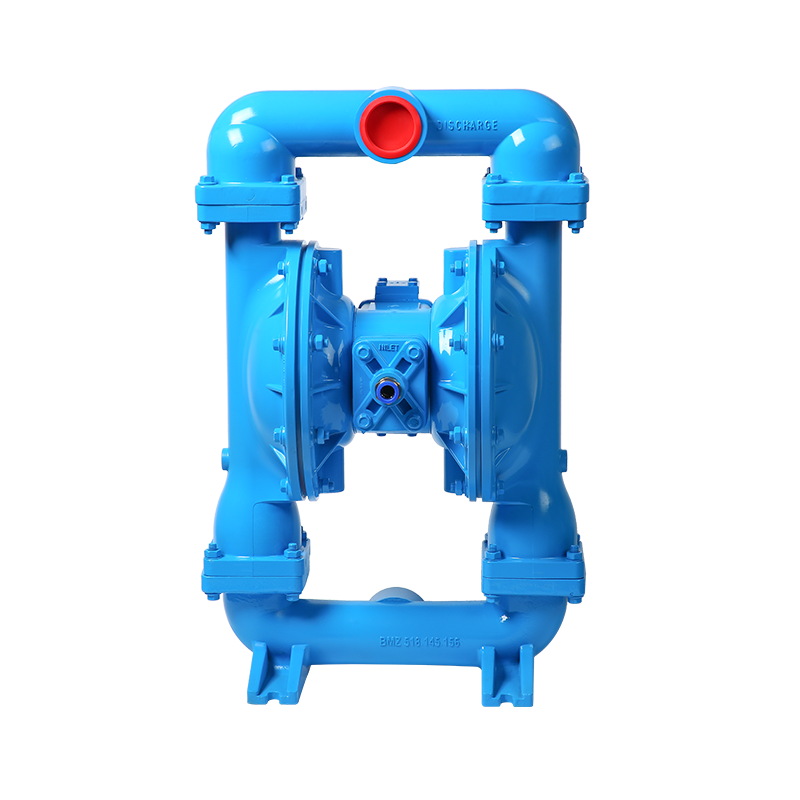

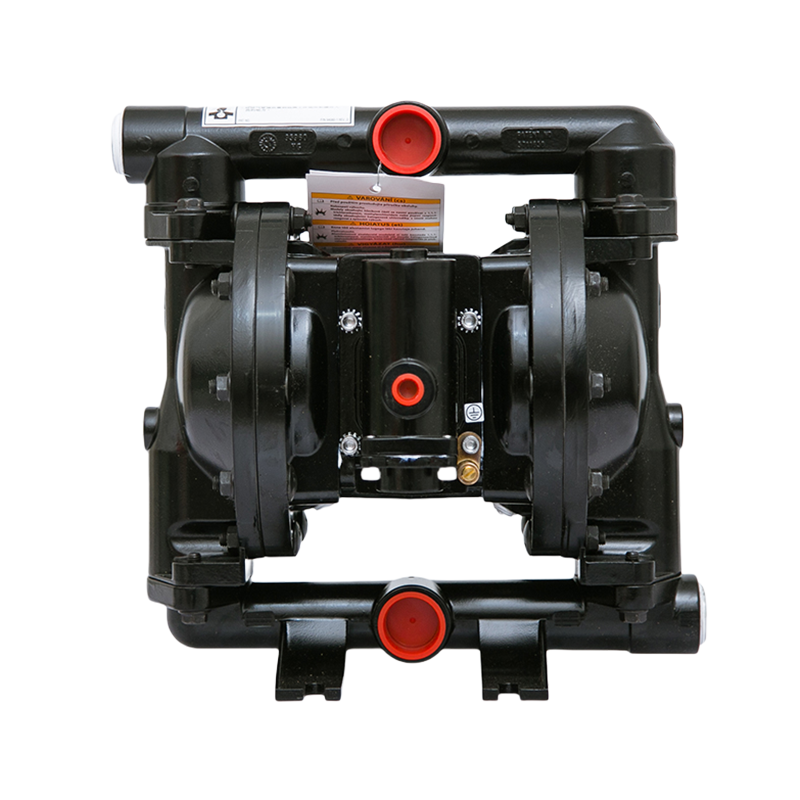

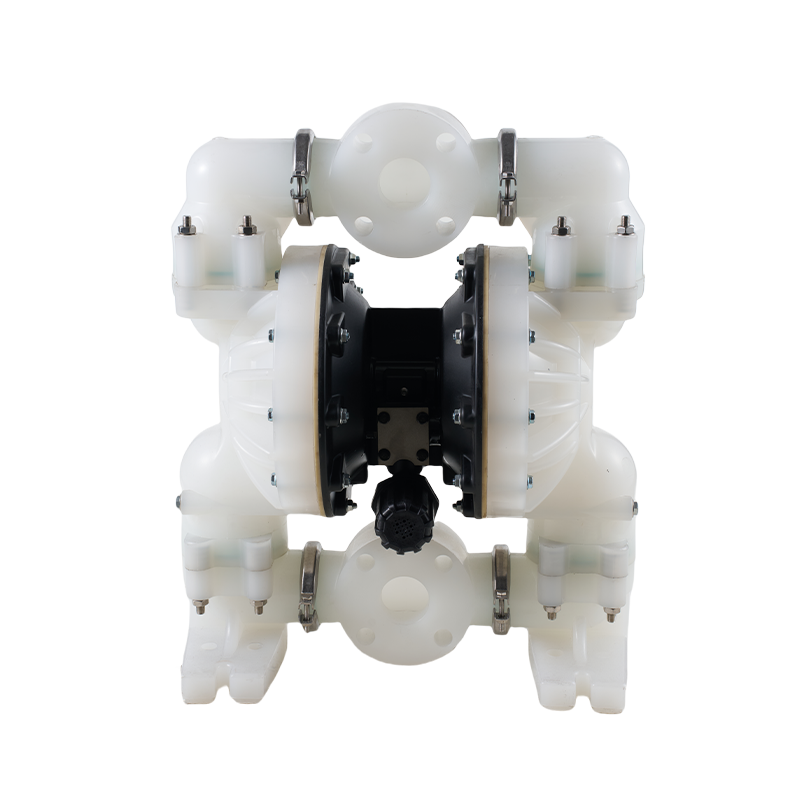

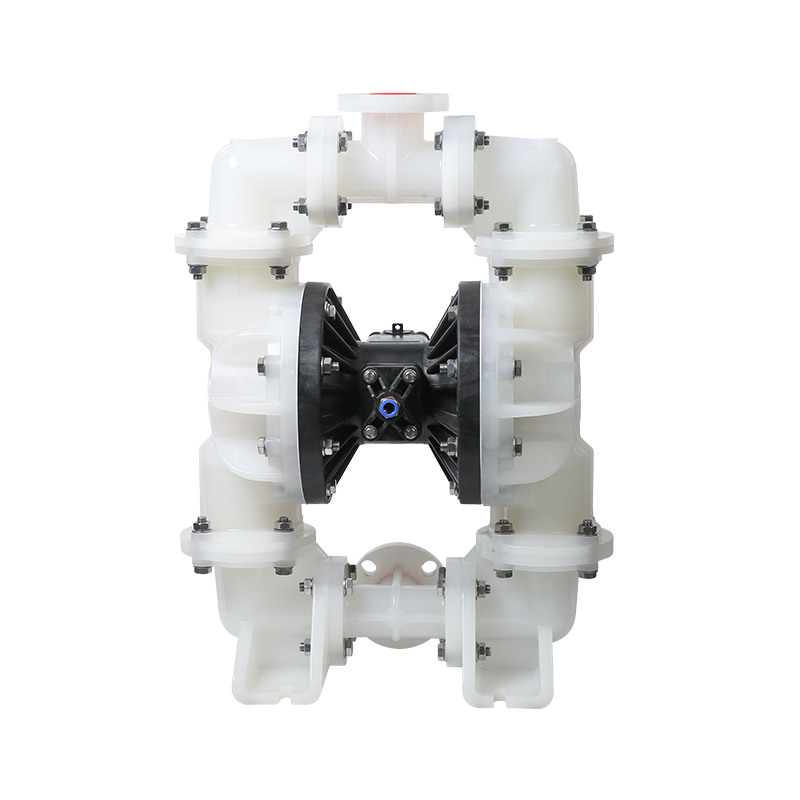

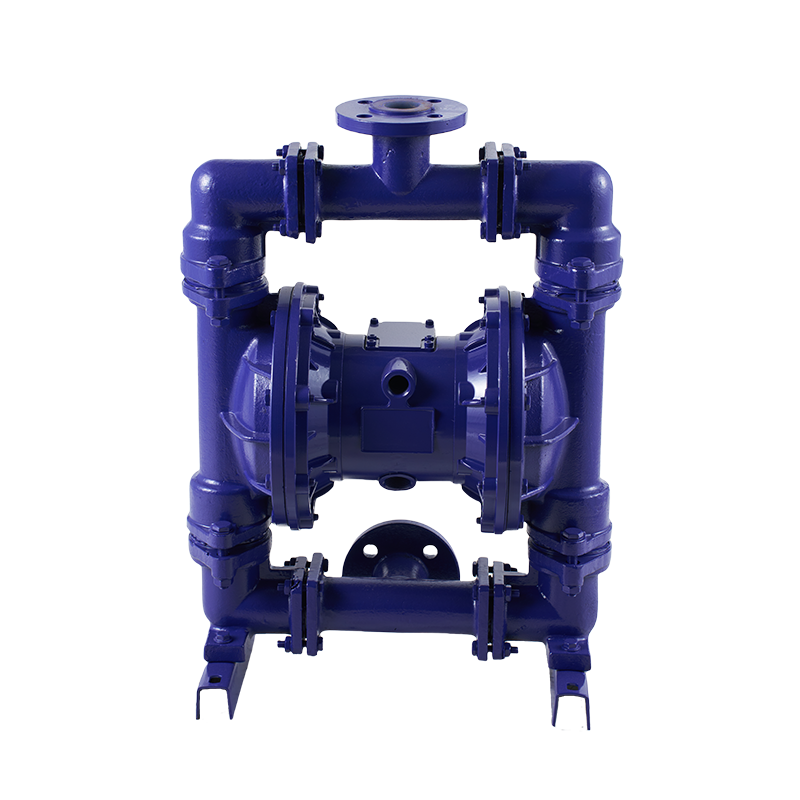

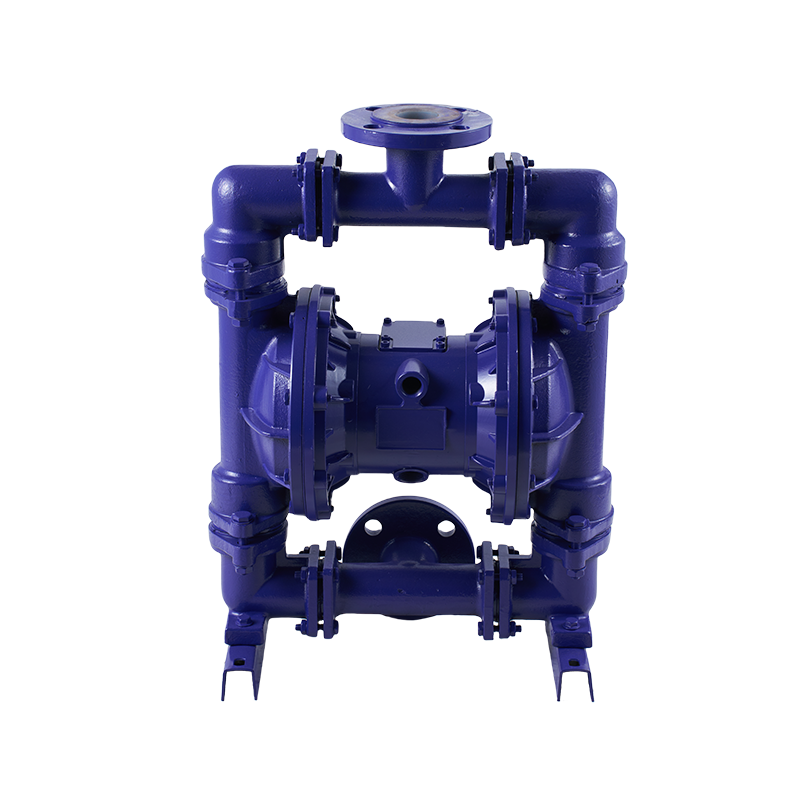

In many industrial operations, handling abrasive, viscous, or particulate-laden fluids requires equipment that can withstand challenging conditions. Among the reliable solutions is the Diaphragm Pump for Slurry, a versatile pumping system capable of moving thick mixtures without compromising flow efficiency. Whether used in mining, wastewater treatment, or manufacturing, the Diaphragm Pump Chemical and slurry-handling models deliver consistent performance with minimal wear. Understanding the benefits of these pumps, along with proper Diaphragm Pump Maintenance, is key to ensuring long-term operational efficiency.

1. Handling of Abrasive Materials

The primary advantage of a Diaphragm Pump For Slurry lies in its ability to transport abrasive and solid-containing fluids without damage to critical components. The pumping mechanism relies on flexible diaphragms that create a displacement action, minimizing direct contact between moving parts and the slurry. Similarly, the Diaphragm Pump Chemical is designed to handle corrosive or reactive fluids without leakage, making it a preferred choice in environments where safety and material integrity are essential. With regular Diaphragm Pump Maintenance, the pump can operate reliably even in harsh conditions.

2. Versatility Across Industries

A Diaphragm Pump For Slurry is not limited to a single application; it can be used in mineral processing, drilling mud transfer, and even food waste handling. Likewise, a Diaphragm Pump Chemical finds applications in transporting acids, solvents, and other aggressive liquids. This versatility allows industries to standardize equipment and reduce spare part inventories. However, to sustain this adaptability, a structured Diaphragm Pump Maintenance schedule is vital, ensuring performance across various fluid types.

3. Self-Priming and Dry-Running Capability

One of the valuable features of the Diaphragm Pump For Slurry is its self-priming capability, allowing it to start pumping without pre-filling. This reduces downtime during installation or after cleaning cycles. The Diaphragm Pump Chemical also benefits from the same operational flexibility, especially in setups where fluid levels fluctuate. Regular Diaphragm Pump Maintenance ensures seals, diaphragms, and valves remain in good condition, enabling these features to function without interruption.

4. Low Shear Pumping for Sensitive Materials

When dealing with fragile or shear-sensitive materials, the Diaphragm Pump For Slurry maintains fluid integrity by using a gentle pumping action. The Diaphragm Pump Chemical design also minimizes shear, which is crucial for handling emulsions, polymers, or biologically active fluids. A consistent Diaphragm Pump Maintenance program helps retain these performance characteristics by preventing wear-induced turbulence or mechanical stress within the pump chamber.

5. Easy Maintenance and Long Service Life

The Diaphragm Pump For Slurry is constructed for durability, but like any industrial equipment, it requires upkeep. Fortunately, its straightforward design makes Diaphragm Pump Maintenance relatively simple, involving inspections of diaphragms, valves, and seals. The Diaphragm Pump Chemical similarly benefits from this ease of servicing, allowing rapid part replacement without specialized tools. By adhering to proper Diaphragm Pump Maintenance procedures, operators can extend service life and reduce unplanned downtime, ensuring a consistent return on investment.

Operational Insights and Practices

Selecting between a Diaphragm Pump For Slurry and a Diaphragm Pump Chemical often depends on the nature of the fluid being handled. In many facilities, both pump types are used in parallel, with the slurry version handling abrasive materials and the chemical version transporting reactive or hazardous liquids. Regardless of application, scheduled Diaphragm Pump Maintenance is essential. This includes monitoring diaphragm condition, checking for valve wear, and cleaning internal passages to prevent blockages.

The Diaphragm Pump For Slurry offers multiple advantages in industries that demand durability, efficiency, and flexibility. Its ability to handle abrasive, viscous, and particulate-rich fluids makes it a dependable choice. When combined with the capabilities of the Diaphragm Pump Chemical, businesses can cover a wide range of pumping requirements with a unified technology base. Consistent Diaphragm Pump Maintenance ensures that these systems operate at peak performance, reducing costs and enhancing process reliability. By understanding and applying these benefits, operators can make informed decisions that improve productivity and safeguard equipment investment.

English

English русский

русский Español

Español عربى

عربى