Choosing the Right Chemical Pump Diaphragm for Acids, Solvents, and Caustics

2025.08.17

2025.08.17

Industry News

Industry News

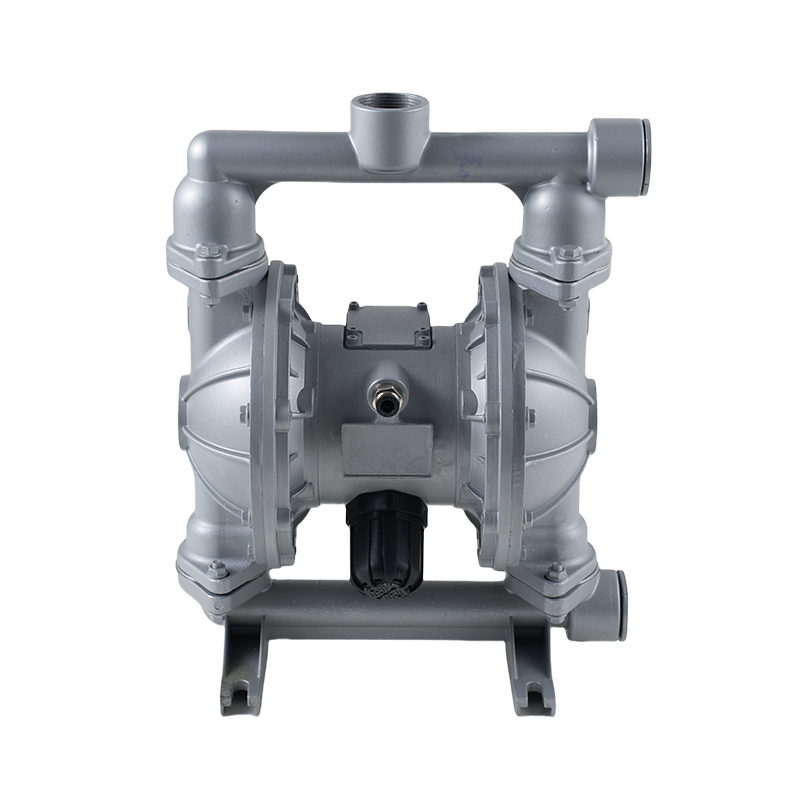

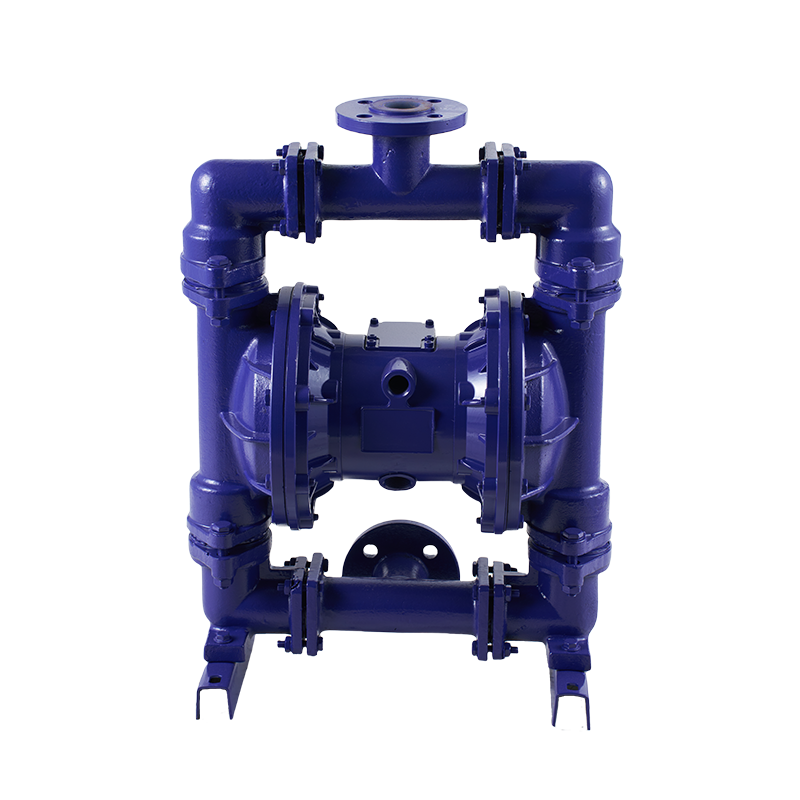

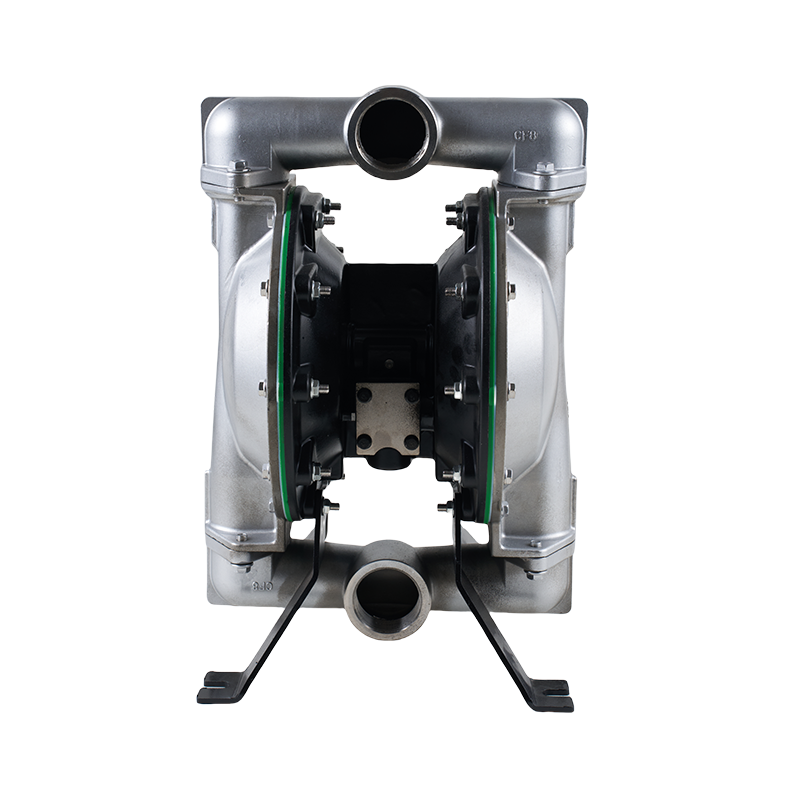

In the chemical processing industry, selecting the appropriate pump for handling corrosive substances such as acids, solvents, and caustics is crucial. The wrong choice can equipment failure, safety hazards, and costly downtime. One of the reliable and versatile options available today is the Chemical Pump Diaphragm. This type of pump is specifically designed to handle aggressive chemicals with ease and efficiency, making it a popular choice among industry professionals.

When it comes to handling corrosive chemicals, the Chemical Pump Diaphragm stands out due to its unique design and construction. Unlike traditional centrifugal pumps, which rely on impellers and seals that can degrade quickly when exposed to harsh chemicals, the Chemical Pump Diaphragm uses a flexible diaphragm to create a positive displacement action. This design eliminates the need for mechanical seals, reducing the risk of leaks and chemical exposure. The diaphragm itself is made from materials that are highly resistant to acids, solvents, and caustics, ensuring long-term durability and reliability.

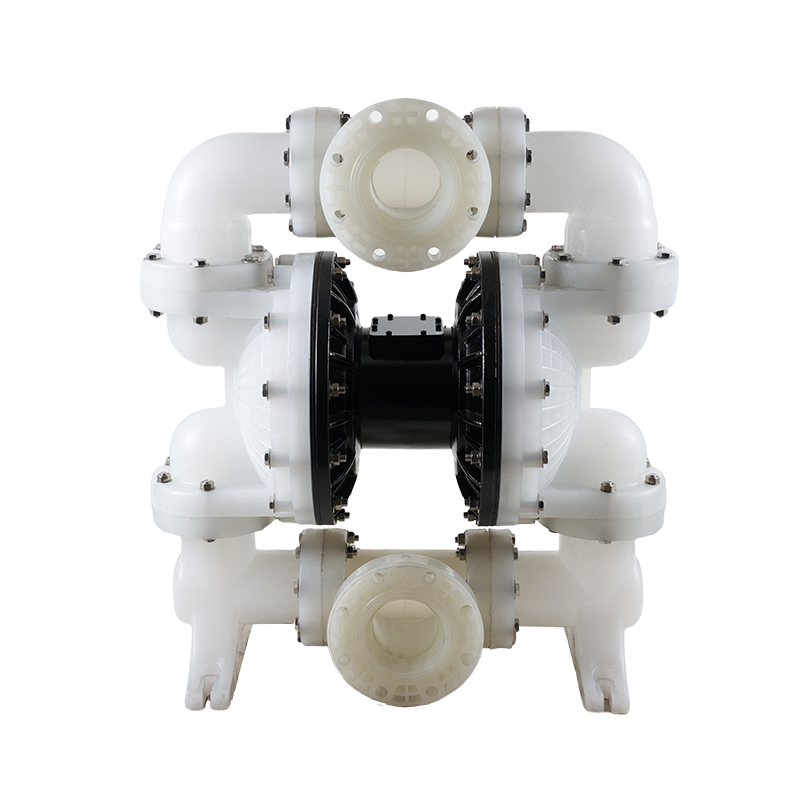

One of the key factors to consider when choosing a Chemical Pump Diaphragm is the material of the diaphragm. High-quality diaphragms are often made from advanced materials such as PTFE (Polytetrafluoroethylene) or other fluoropolymer-based compounds. These materials offer chemical resistance, allowing the pump to handle a wide range of corrosive substances without degradation. For example, PTFE-lined diaphragms can withstand the corrosive effects of strong acids like hydrochloric acid, sulfuric acid, and nitric acid, as well as harsh solvents like acetone and toluene.

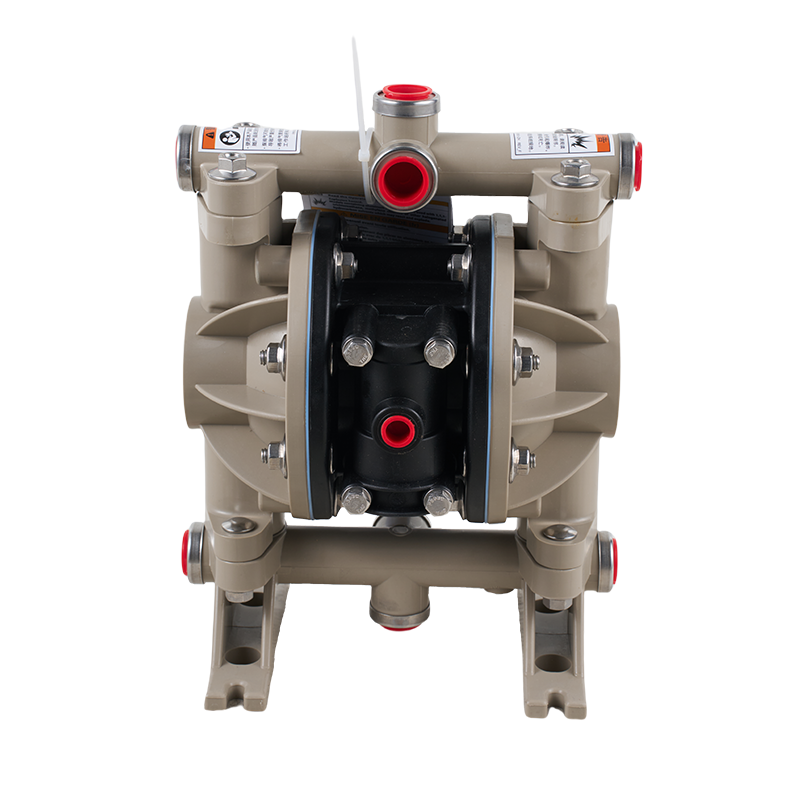

Another important consideration is the size and capacity of the pump. In many chemical processing applications, the Small Line Double Diaphragm Pump is an ideal choice. These compact pumps are designed for low-volume applications, making themfor transferring small quantities of chemicals or for use in laboratory settings. Despite their small size, Small Line Double Diaphragm Pumps are highly efficient and can handle a wide range of viscosities. Their compact design also makes them easy to install and maintain, even in tight spaces.

When selecting a Chemical Pump Diaphragm, it is essential to choose a reputable supplier. The quality of the pump and its components can vary significantly between manufacturers, so it is important to work with a trusted Air Operated Diaphragm Pump supplier. Reputable suppliers will offer a wide range of pump sizes and configurations, as well as high-quality diaphragms made from durable and chemically resistant materials. They will also provide detailed technical specifications and support to help you choose the right pump for your specific application.

One of the major advantages of the Chemical Pump Diaphragm is its ability to self-prime. This means that the pump can start operating even when the chemical level is low, without the need for a separate priming mechanism. This feature is particularly useful in applications where the chemical supply may be intermittent, such as in batch processing or transfer operations. The self-priming capability ensures that the pump can operate efficiently and reliably, reducing downtime and increasing overall productivity.

Another important feature of the Chemical Pump Diaphragm is its ability to handle abrasive materials. In many chemical processing applications, the chemicals being transferred may contain solid particles or abrasive substances. The flexible diaphragm design of the pump allows it to handle these materials without significant wear and tear on the internal components. This makes the Chemical Pump Diaphragm an ideal choice for applications involving slurries, suspensions, or other abrasive mixtures.

The Chemical Pump Diaphragm also offers control over flow rates and pressures. This is particularly important in applications where precise dosing or metering of chemicals is required. The pump can be easily adjusted to meet the specific needs of the application, ensuring accurate and consistent chemical transfer. This level of control is essential in industries such as pharmaceuticals, where the precise mixing of chemicals is critical to the production process.

In addition to its technical advantages, the Chemical Pump Diaphragm is also known for its low - maintenance requirements. Unlike other types of pumps that require frequent servicing and part replacements, the Chemical Pump Diaphragm has fewer moving parts. This reduces the likelihood of mechanical failures and lowers maintenance costs. In industries where downtime can be costly, the reliability and durability of the Chemical Pump Diaphragm make it a valuable asset.

Choosing the right Chemical Pump Diaphragm for handling acids, solvents, and caustics is essential for ensuring safe and efficient chemical processing operations. The unique design and construction of the Chemical Pump Diaphragm, combined with its self-priming capability, ability to handle abrasive materials, and low - maintenance requirements, make it an ideal choice for a wide range of applications. By working with a reputable Air Operated Diaphragm Pump Suppliers and selecting a high-quality Small Line Double Diaphragm Pump, you can ensure that your chemical processing operations run smoothly and reliably. Whether you are transferring small quantities of chemicals in a laboratory setting or handling large-scale industrial applications, the Chemical Pump Diaphragm is a proven and reliable solution.

English

English русский

русский Español

Español عربى

عربى