How to Properly Install Your Air Operated Diaphragm Pump?

2025.08.17

2025.08.17

Industry News

Industry News

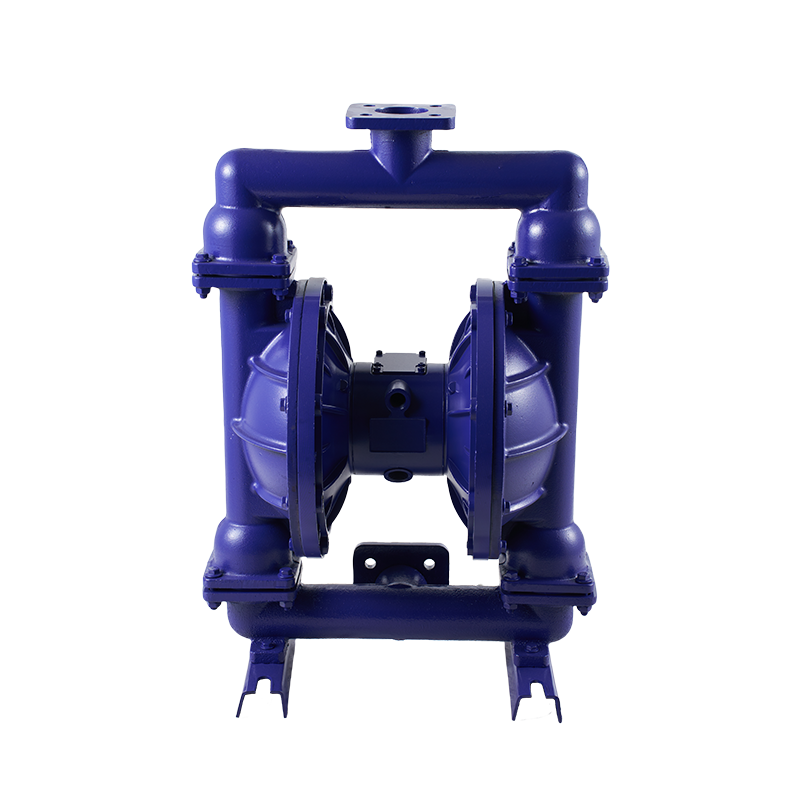

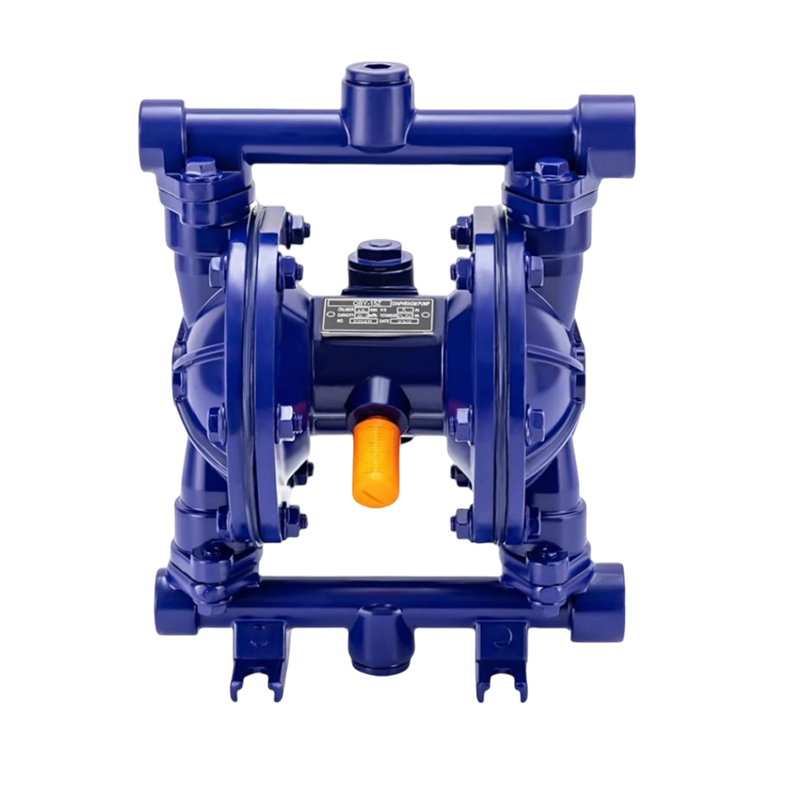

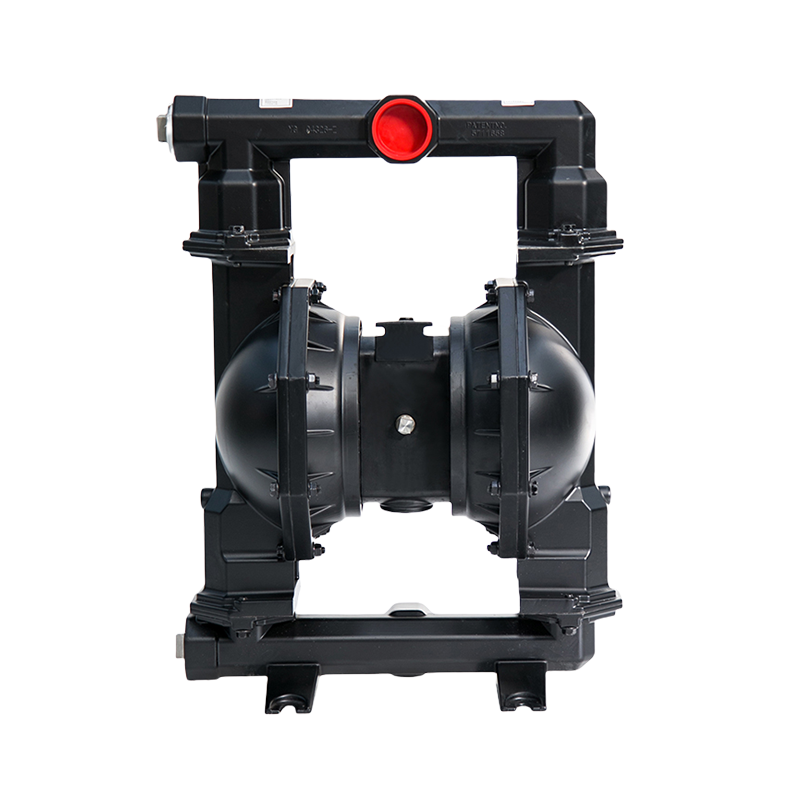

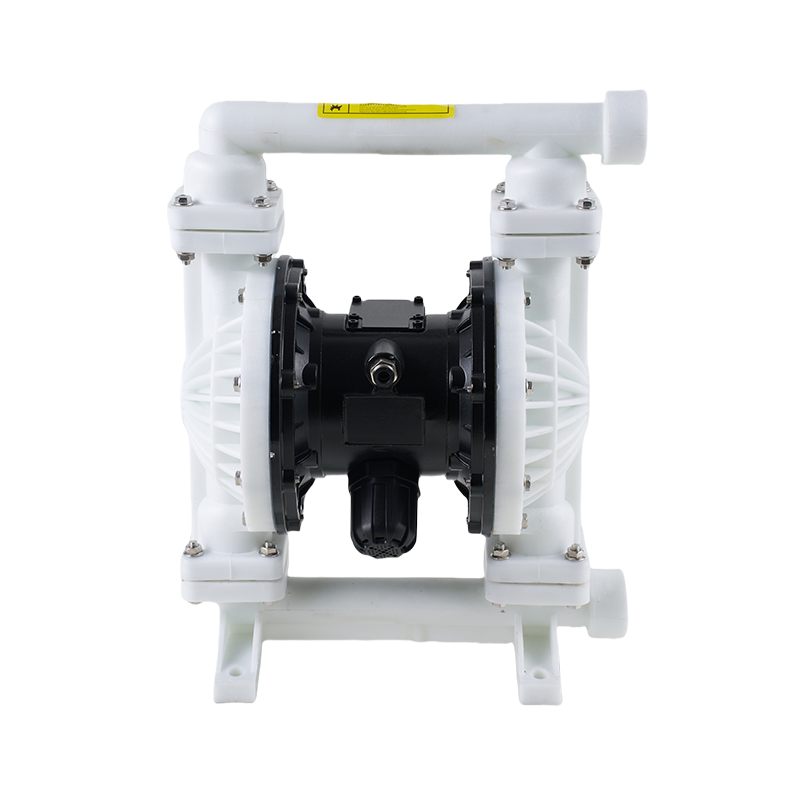

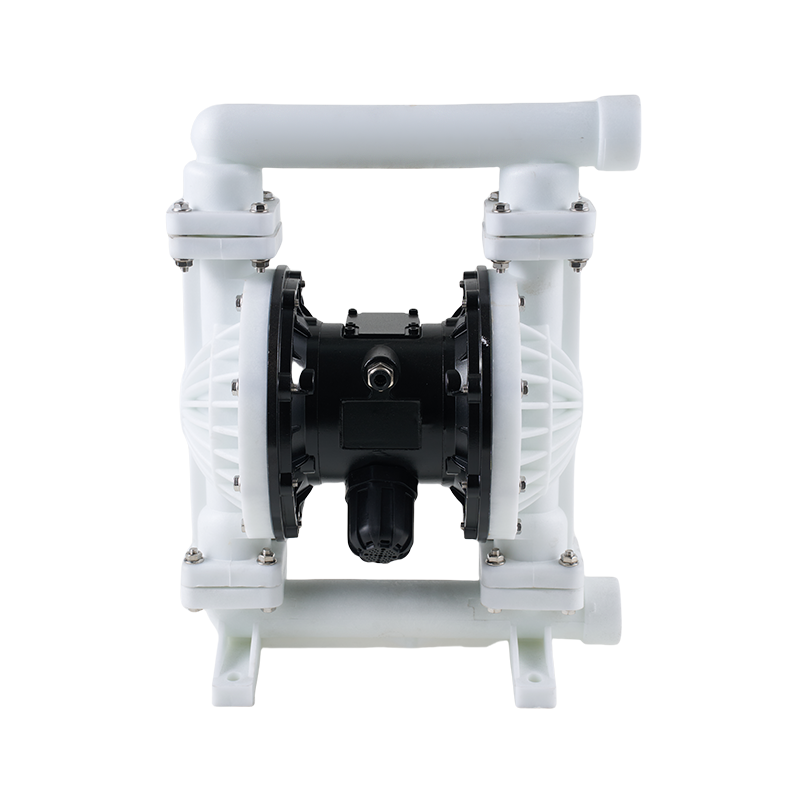

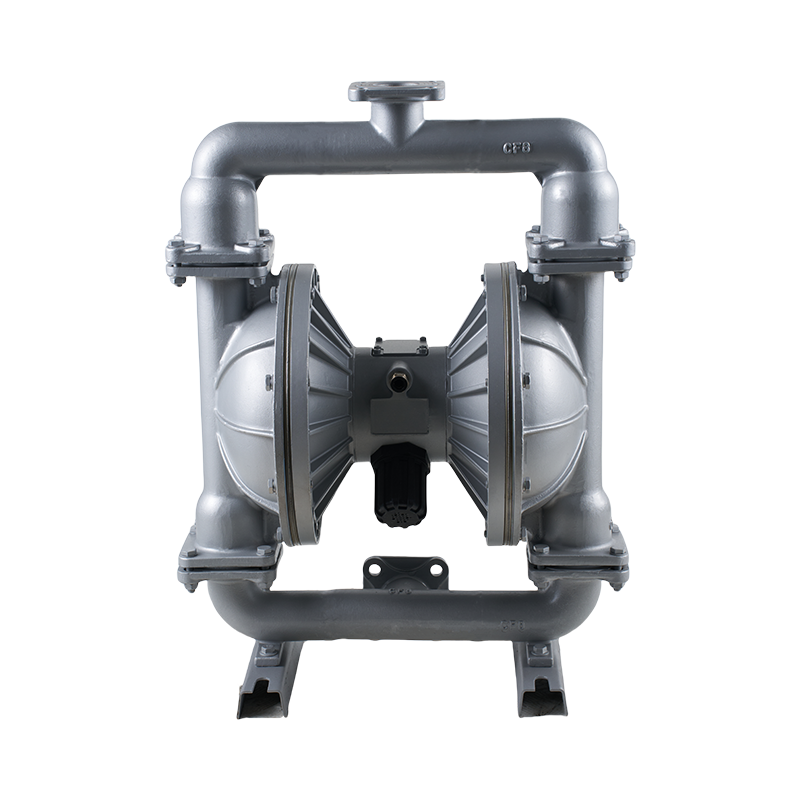

In industrial fluid handling, a correct Diaphragm Pump Installation is critical to achieving efficiency, extending equipment life, and minimizing downtime. Many facilities rely on the expertise of Air Operated Diaphragm Pump Manufacturers to select the right pump and guide proper setup. However, following practices during the Diaphragm Pump Installation process is equally important for long-term performance. This includes not only correct alignment and connection but also the use of appropriate Diaphragm Pump Spare Parts to ensure operational reliability.

A successful Diaphragm Pump Installation begins with preparation. The installation area should be clean, stable, and free from debris that could interfere with operation. Air Operated Diaphragm Pump Manufacturers often recommend selecting a location with adequate ventilation and easy access for maintenance. Positioning the pump correctly allows technicians to inspect and replace Diaphragm Pump Spare Parts without unnecessary disassembly, saving both time and labor costs.

During Diaphragm Pump Installation, it is essential to connect air supply lines according to the specifications provided by Air Operated Diaphragm Pump Manufacturers. Proper air pressure ensures the pump operates efficiently without placing excessive strain on diaphragms or valves. Overpressurizing the pump can cause premature wear, making it necessary to replace Diaphragm Pump Spare Parts more frequently. Likewise, underpressurizing can reduce pumping efficiency, to slower transfer rates.

The inlet and outlet piping setup is another key element of a correct Diaphragm Pump Installation. Piping should be aligned to avoid stress on the pump's ports, as misalignment can damage connections and increase the need for Diaphragm Pump Spare Parts replacement. Air Operated Diaphragm Pump Manufacturers typically suggest flexible connections to absorb vibration and accommodate slight movement during operation. This not only protects the pump but also minimizes strain on connected systems.

Priming is a crucial step during Diaphragm Pump Installation. Although air operated diaphragm pumps are self-priming, ensuring the lines are clear of obstructions before startup helps prevent mechanical issues. Air Operated Diaphragm Pump Manufacturers emphasize checking all seals and fasteners during the initial run to verify there are no leaks. If leaks are detected, replacing the relevant Diaphragm Pump Spare Parts immediately can prevent damage to other components.

Maintenance planning should be integrated into the Diaphragm Pump Installation process. Keeping a stock of essential Diaphragm Pump Spare Parts, such as diaphragms, valve balls, and gaskets, allows for quick repairs without waiting for shipments. Many Air Operated Diaphragm Pump Manufacturers offer spare parts kits designed specifically for their models, ensuring compatibility and reducing the risk of installation errors.

Safety considerations are also part of a correct Diaphragm Pump Installation. Operators should follow the guidelines provided by Air Operated Diaphragm Pump Manufacturers, including grounding procedures for conductive models used in hazardous environments. Using the correct Diaphragm Pump Spare Parts for these setups is critical, as incompatible materials can compromise safety features.

Once the Diaphragm Pump Installation is complete, it is advisable to perform a controlled test run. Air Operated Diaphragm Pump Manufacturers recommend monitoring flow rates, noise levels, and pressure readings during this stage. Any irregularities could indicate a need for adjustments or the replacement of specific Diaphragm Pump Spare Parts. A thorough test ensures the pump is ready for regular operation without risk of early failure.

A proper Diaphragm Pump Installation is more than just connecting pipes and turning on the air supply. It involves careful preparation, adherence to manufacturer guidelines, and the strategic use of Diaphragm Pump Spare Parts. By following the recommendations of trusted Air Operated Diaphragm Pump Manufacturers and establishing a maintenance plan from the start, operators can maximize pump efficiency, extend service life, and minimize downtime. A well-installed pump is an investment in operational stability and long-term cost savings.

English

English русский

русский Español

Español عربى

عربى