5 Things You Need to Know About Double Diaphragm Pump Operation

2025.08.17

2025.08.17

Industry News

Industry News

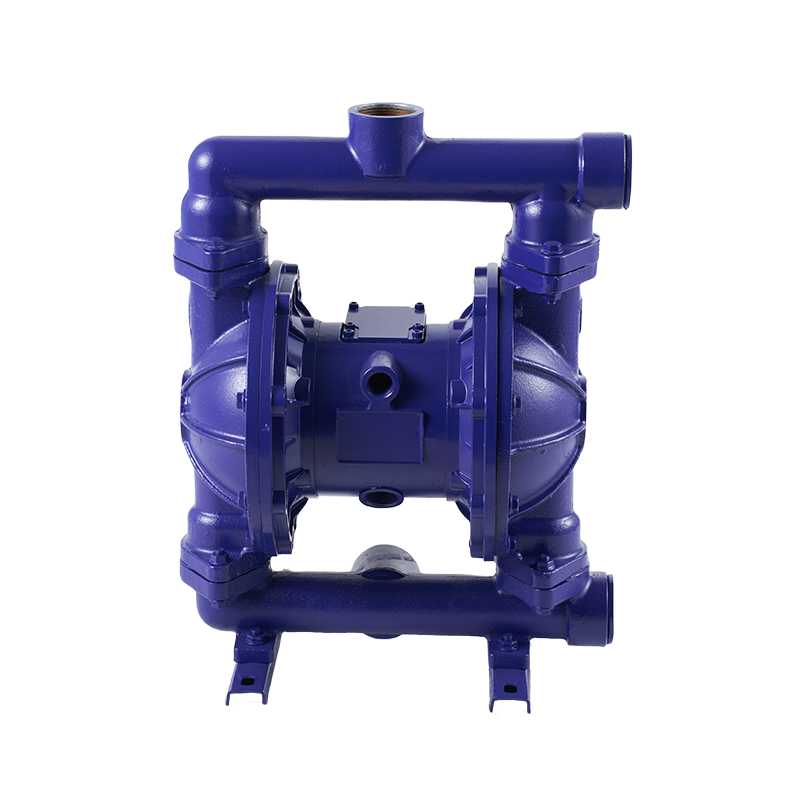

In the world of fluid transfer and industrial applications, the double diaphragm pump has emerged as a versatile and reliable solution. Whether you are involved in manufacturing, chemical processing, or even wastewater management, understanding the intricacies of double diaphragm pump operation is crucial. Here are five key things you need to know about these remarkable devices.

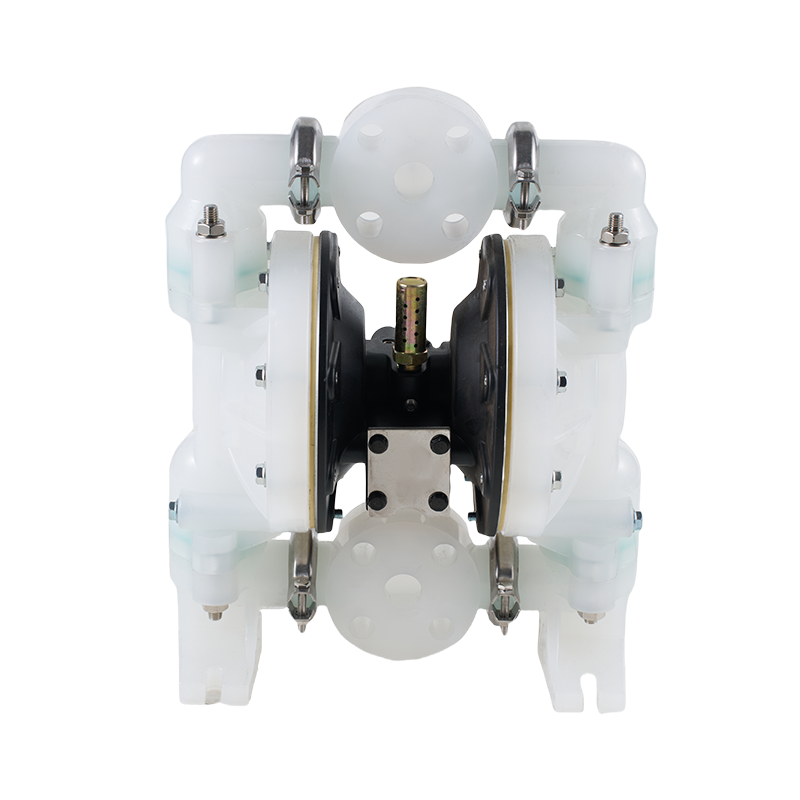

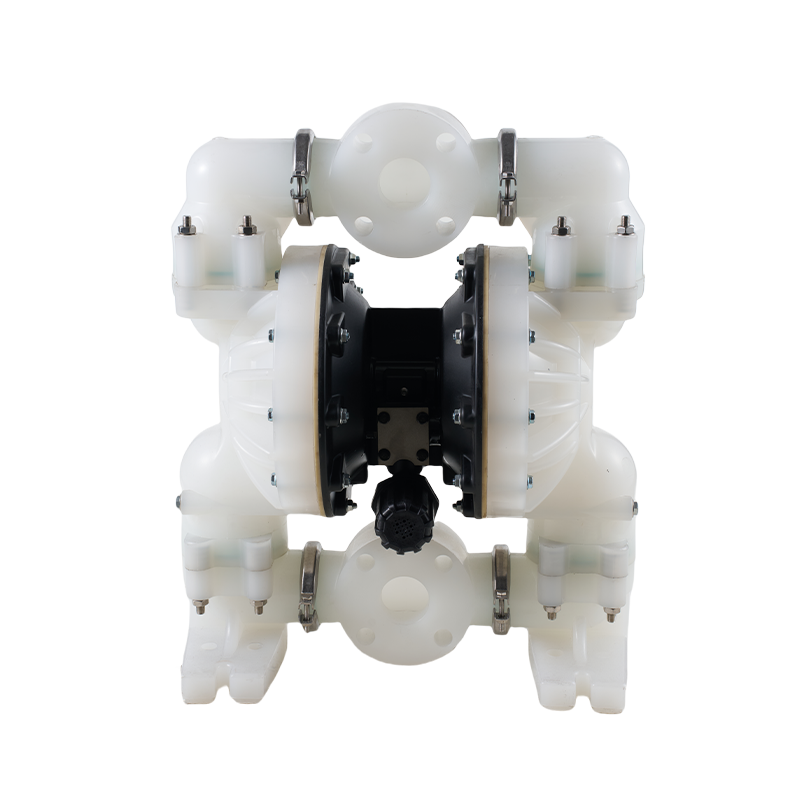

1. The Basic Principle of Operation

A double diaphragm pump, also known as a double diaphragm pump, operates on a simple yet efficient principle. It uses two flexible diaphragms that act as the primary moving parts. These diaphragms are synchronized to create a reciprocating motion, which draws fluid into the pump and then expels it. The process begins when one diaphragm moves outward, creating a vacuum that draws fluid into the corresponding chamber. Simultaneously, the other diaphragm moves inward, compressing the fluid and forcing it out through the discharge port. This alternating action ensures continuous flow, making the double diaphragm pump highly effective for a wide range of applications.

One of the key advantages of this design is that the fluid being pumped never comes into contact with the mechanical components of the pump. This feature is particularly important when handling corrosive or abrasive materials, as it minimizes wear and tear on the pump and reduces the risk of contamination.

2. Versatility in Applications

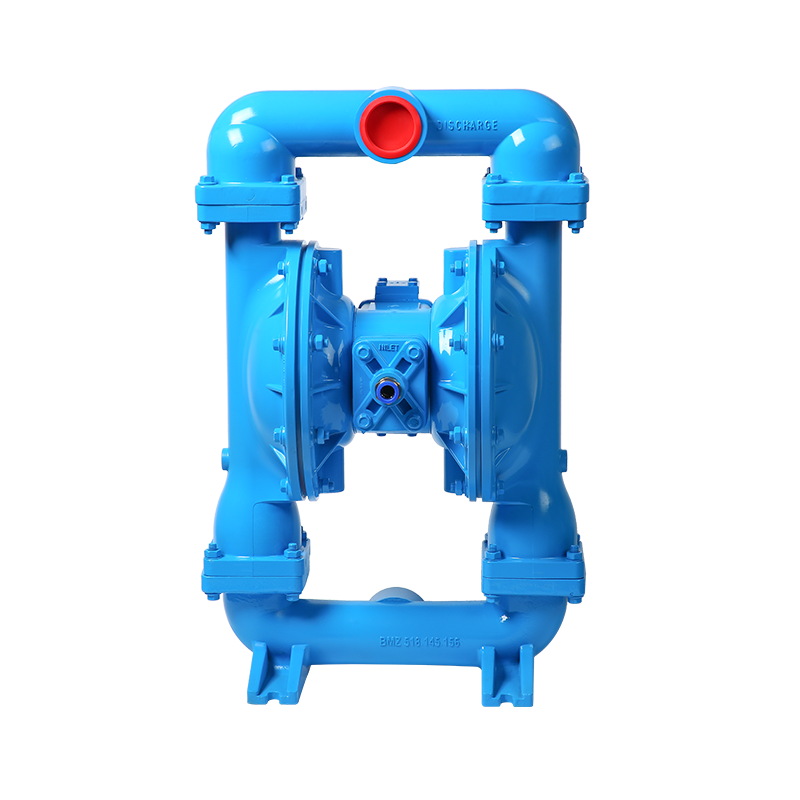

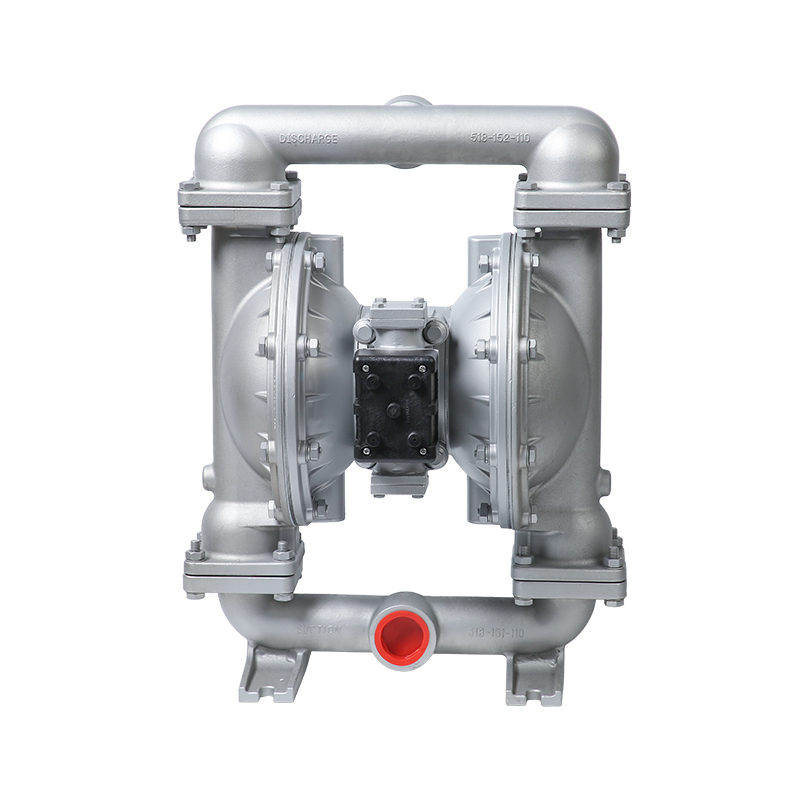

The double diaphragm pump is renowned for its versatility. It can handle a variety of fluids, including those with high viscosity, solid content, and even corrosive properties. This makes it ideal for use in industries such as chemical processing, pharmaceuticals, mining, and food and beverage production.

For example, in the chemical industry, double diaphragm pumps are often used to transfer corrosive acids and bases. Their ability to handle abrasive materials also makes them suitable for applications in the mining sector, where they can transfer slurry without clogging. In the food and beverage industry, these pumps are used to transfer products like syrups and sauces, ensuring that the fluid remains uncontaminated.

3. Maintenance and Longevity

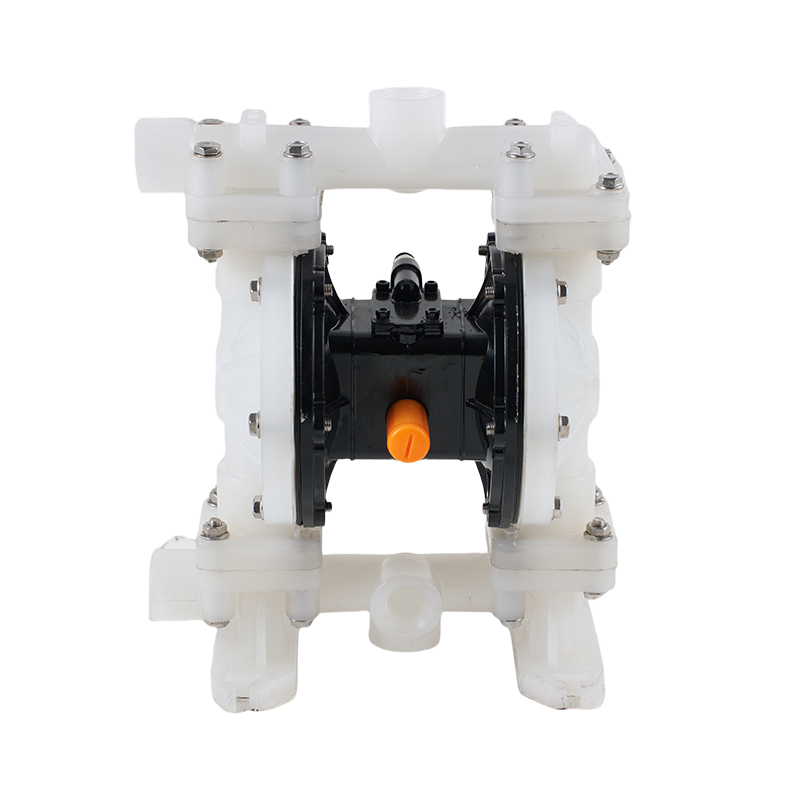

When it comes to maintenance, double diaphragm pumps are relatively low-maintenance devices. The key to their longevity lies in the simplicity of their design. Since the fluid does not come into contact with the mechanical components, there is less wear and tear on the pump. However, regular inspection and replacement of the diaphragms are essential to ensureperformance.

Double diaphragm pumps are designed with easy access to the diaphragms and other critical components. This makes maintenance straightforward and reduces downtime. Additionally, many modern double diaphragm pumps come with features such as leak detection and automatic shut-off, which further enhance their reliability and safety.

4. Energy Efficiency and Cost-Effectiveness

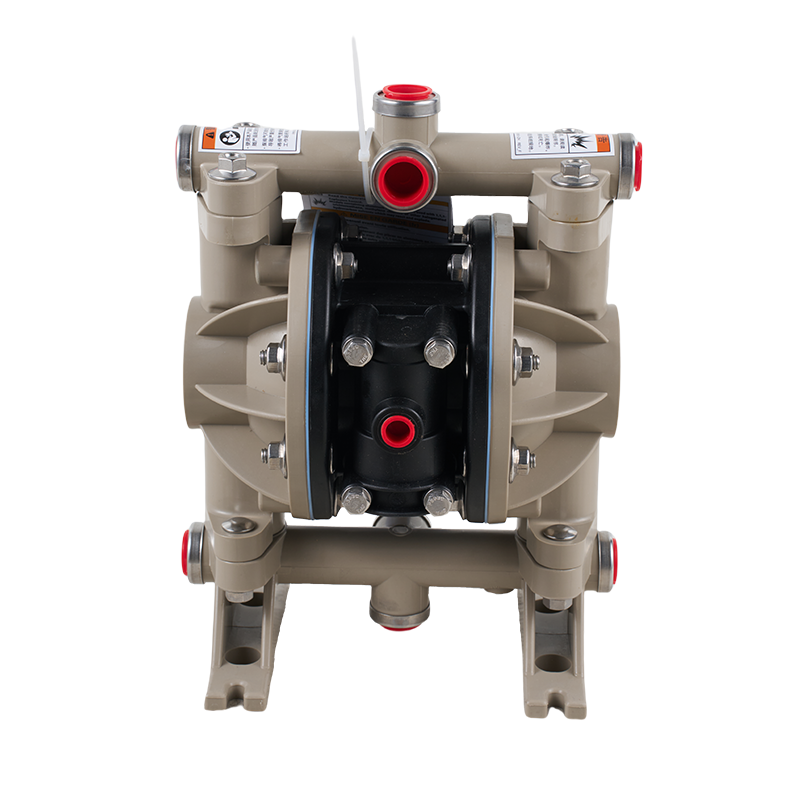

Double diaphragm pumps are known for their energy efficiency. Unlike some other types of pumps that require constant power to maintain flow, double diaphragm pumps only consume energy during the pumping cycle. This intermittent operation canto significant energy savings, especially in applications where the pump is not required to run continuously.

Moreover, the low maintenance requirements and long service life of double diaphragm pumps contribute to their cost-effectiveness. While the initial investment may be higher compared to some other pump types, the overall cost of ownership is often lower due to reduced maintenance and energy costs.

5. Safety and Environmental Considerations

Safety is a paramount concern in any industrial application, and double diaphragm pumps are designed with this in mind. One of the key safety features of these pumps is their ability to handle hazardous fluids without the risk of leakage. The diaphragms act as a barrier, preventing the fluid from coming into contact with the mechanical components and reducing the risk of spills and contamination.

In addition to safety, double diaphragm pumps also offer environmental benefits. Their ability to handle a wide range of fluids, including those with high solids content, means that they can be used in applications such as wastewater treatment and sludge transfer. This helps to minimize environmental impact and ensures compliance with environmental regulations.

The double diaphragm pump is a versatile, reliable, and efficient solution for a wide range of industrial applications. Its unique operating principle ensures continuous flow while minimizing wear and tear on the pump. The low maintenance requirements, energy efficiency, and safety features make it an attractive option for businesses looking to optimize their fluid transfer processes. Whether you are transferring chemicals, slurries, or food products, a double diaphragm pump can provide the performance and reliability you need.

As technology continues to advance, we can expect further improvements in the design and efficiency of double diaphragm pumps. However, one thing remains certain: the double diaphragm pump will continue to play a vital role in the world of industrial fluid transfer for years to come.

English

English русский

русский Español

Español عربى

عربى