Innovations in Slurry Diaphragm Pump Design Boost Efficiency and Durability

2025.08.17

2025.08.17

Industry News

Industry News

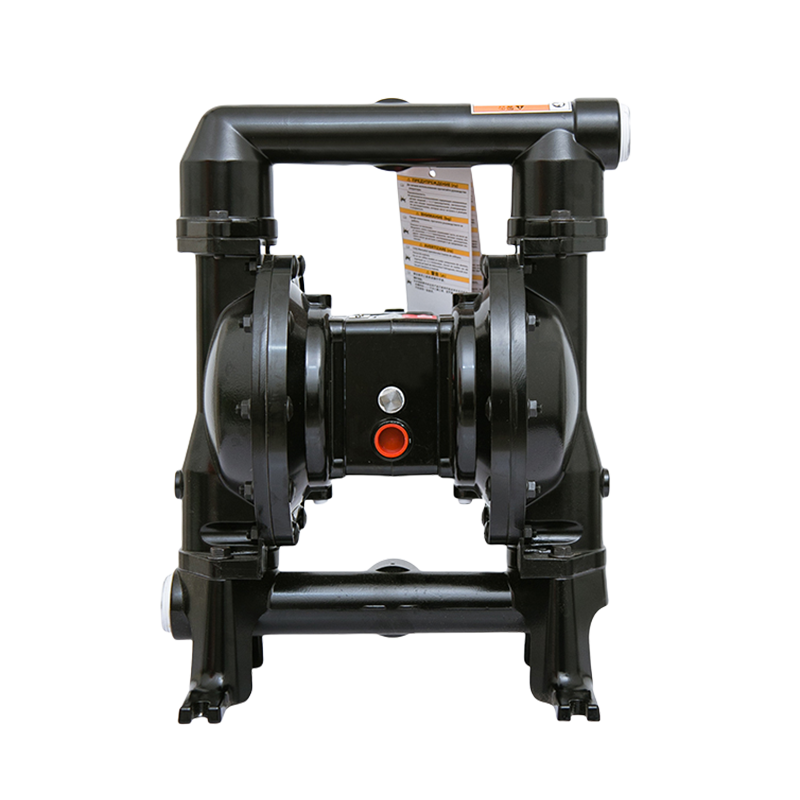

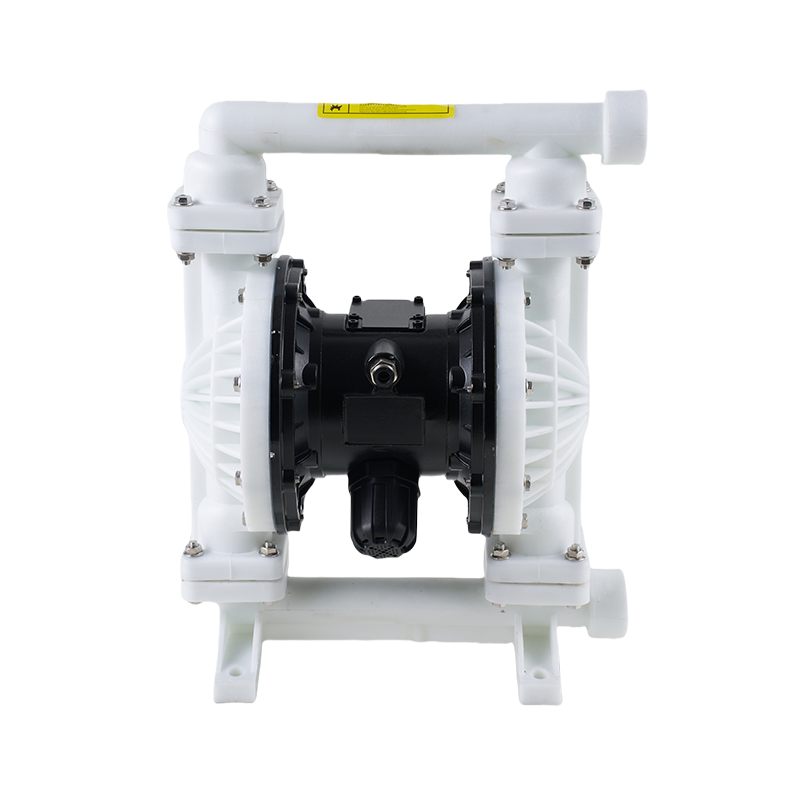

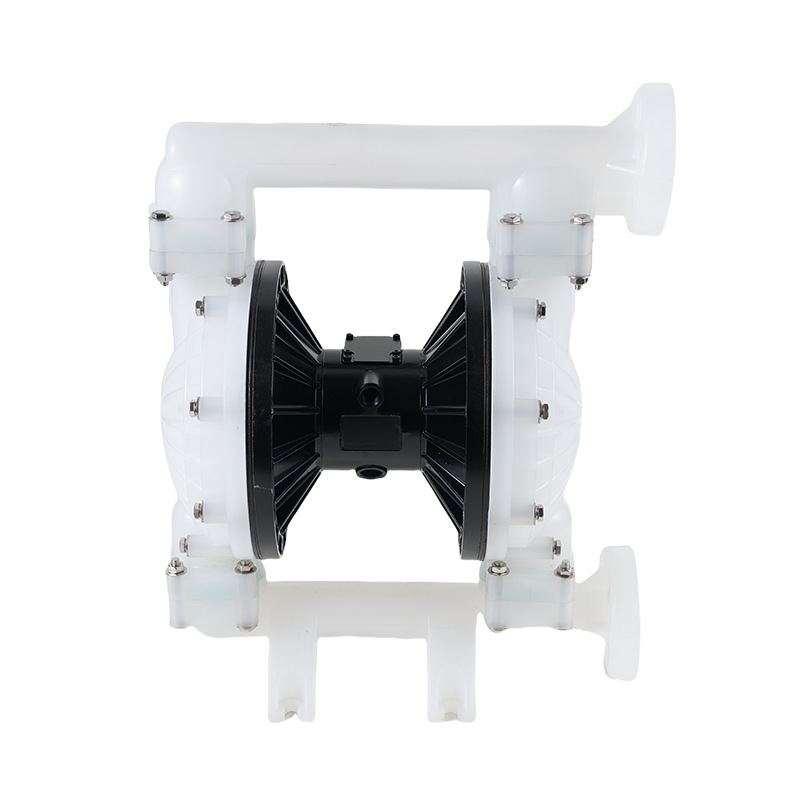

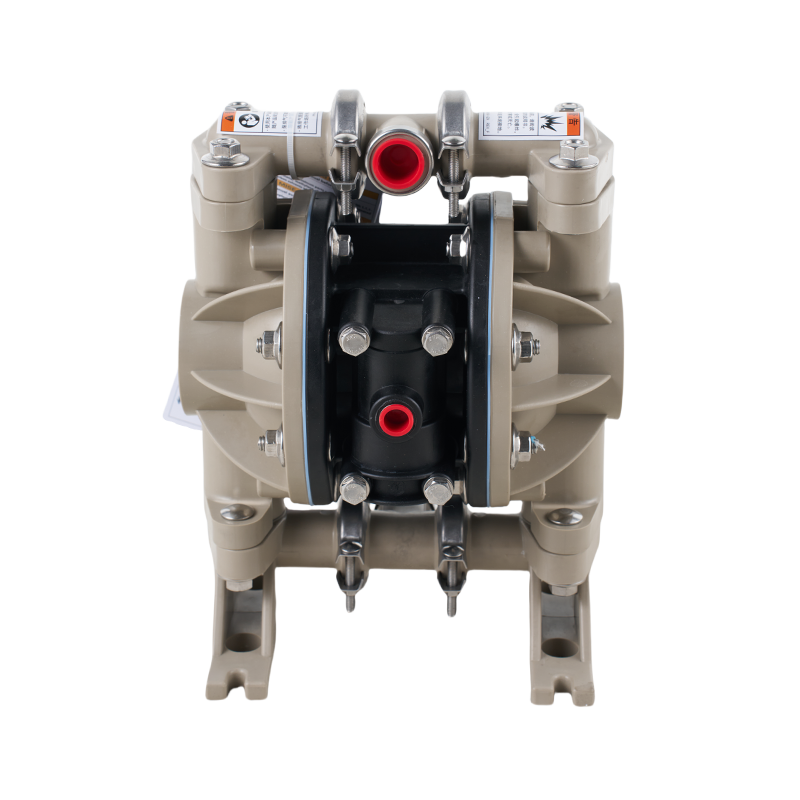

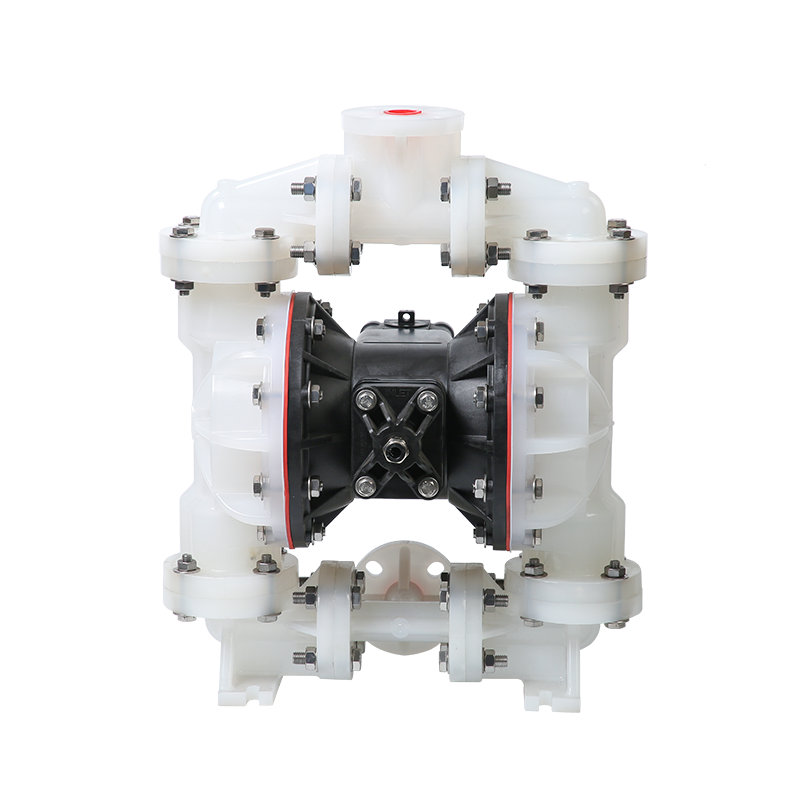

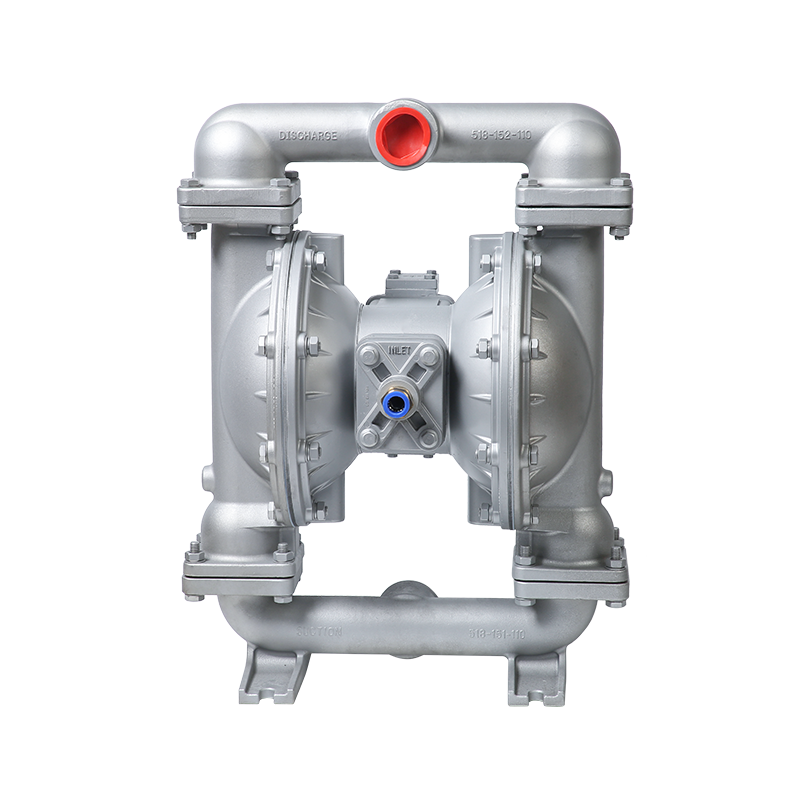

In industrial sectors where handling abrasive and viscous fluids is common, the role of a slurry diaphragm pump is indispensable. Recent advancements in diaphragm pump design have significantly enhanced the efficiency and durability of these pumps, making them more reliable and cost-effective for a wide range of applications. This article explores the latest innovations that are shaping the future of slurry diaphragm pumps and how they contribute to improved operational performance.

A slurry diaphragm pump is specifically engineered to manage fluids containing solid particles, often abrasive. Traditional pumps faced challenges such as rapid wear and frequent maintenance, primarily due to the harsh conditions imposed by slurries. However, modern slurry diaphragm pump designs incorporate novel materials and engineering solutions that address these issues effectively.

One of the key improvements in diaphragm pump design is the use of advanced elastomers and composite materials for the diaphragms themselves. These materials offer enhanced resistance to abrasion and chemical degradation, significantly extending the service life of the pump. The improved diaphragm materials ensure consistent performance even under continuous operation, reducing downtime and maintenance costs.

In addition to materials, innovations in the pump's internal structure have been crucial. Modern slurry diaphragm pumps feature optimized flow paths that minimize turbulence and wear. This refined flow design not only improves pumping efficiency but also reduces the energy consumption required to move slurry materials. Energy efficiency is becoming an important consideration for industries aiming to reduce operational costs and environmental impact, making these design improvements highly valuable.

Another notable innovation in slurry diaphragm pump design is the modular construction approach. This design allows for easier disassembly and maintenance without the need for specialized tools or excessive downtime. By simplifying the maintenance process, operators can address wear-related issues quickly, keeping the pump in working condition for longer periods.

Furthermore, advancements in sealing technology have played a significant role in enhancing slurry diaphragm pump durability. Effective sealing is critical to prevent leakage of abrasive slurry materials, which can cause both environmental hazards and equipment damage. Modern designs incorporate more robust sealing systems that withstand harsh conditions while maintaining tight seals, thus ensuring operational safety and reliability.

Automation and monitoring features have also been integrated into recent slurry diaphragm pump designs. Sensors capable of tracking parameters such as pressure, temperature, and diaphragm wear enable predictive maintenance. This technology helps avoid unexpected failures by alerting operators to potential issues before they escalate. The inclusion of smart monitoring systems aligns with the industry trend toward digitalization and Industry 4.0. providing users with greater control and insight into pump performance.

Industries ranging from mining and chemical processing to wastewater treatment benefit from these innovations in slurry diaphragm pump design. The ability to efficiently handle abrasive, viscous fluids while maintaining low maintenance requirements translates to higher productivity and lower operating costs. Companies are increasingly prioritizing pumps that deliver both durability and efficiency, and the latest slurry diaphragm pump models meet these demands effectively.

In conclusion, the evolution of slurry diaphragm pump design is marked by significant improvements in materials, internal structure, sealing technology, and smart monitoring capabilities. These innovations collectively boost the efficiency and durability of slurry diaphragm pumps, ensuring they meet the rigorous demands of modern industrial applications. As industries continue to face challenges related to abrasive slurry handling, the advancements in slurry diaphragm pump technology promise to deliver reliable, efficient, and sustainable solutions well into the future.

By embracing these new design features, companies can enhance their operational workflows, reduce downtime, and achieve better overall performance. The continued focus on innovation in slurry diaphragm pump design ensures that this critical equipment remains at the forefront of industrial fluid handling technology.

English

English русский

русский Español

Español عربى

عربى