Cast Iron Pneumatic Diaphragm Pumps vs. Plastic Models: Which One Suits Your Needs?

2025.08.17

2025.08.17

Industry News

Industry News

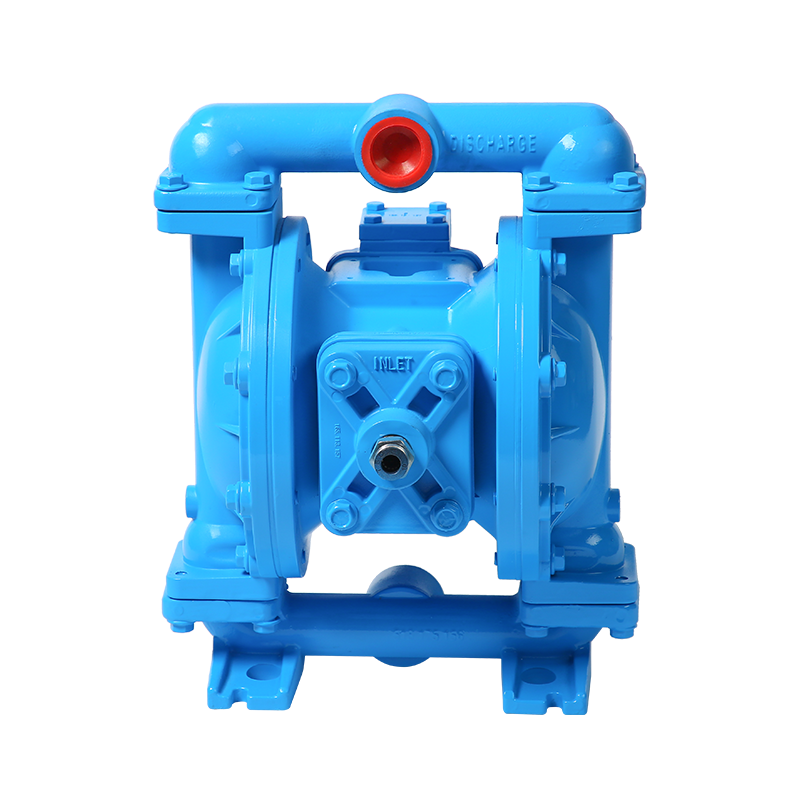

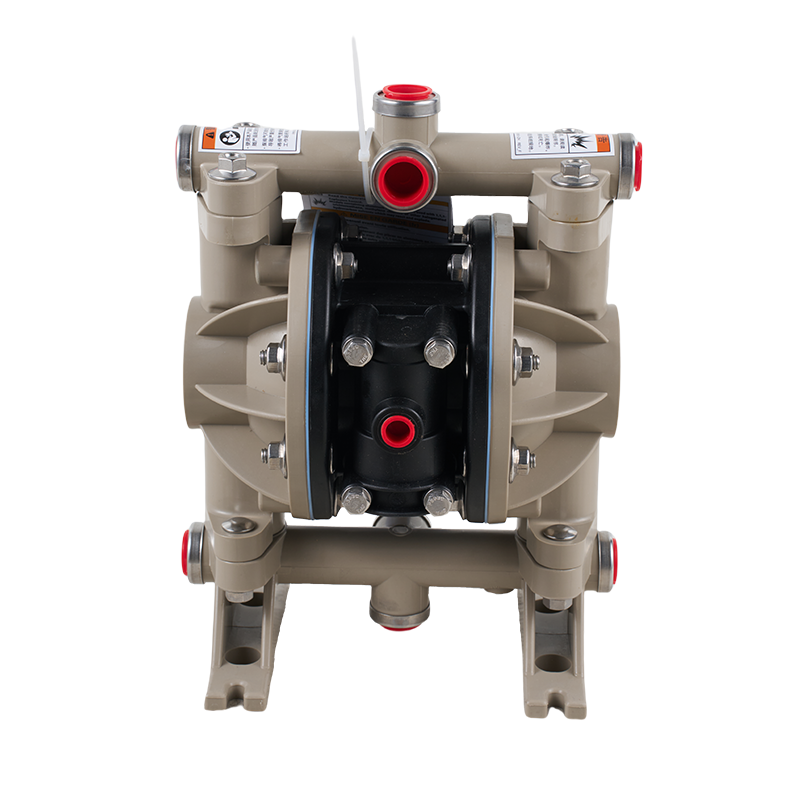

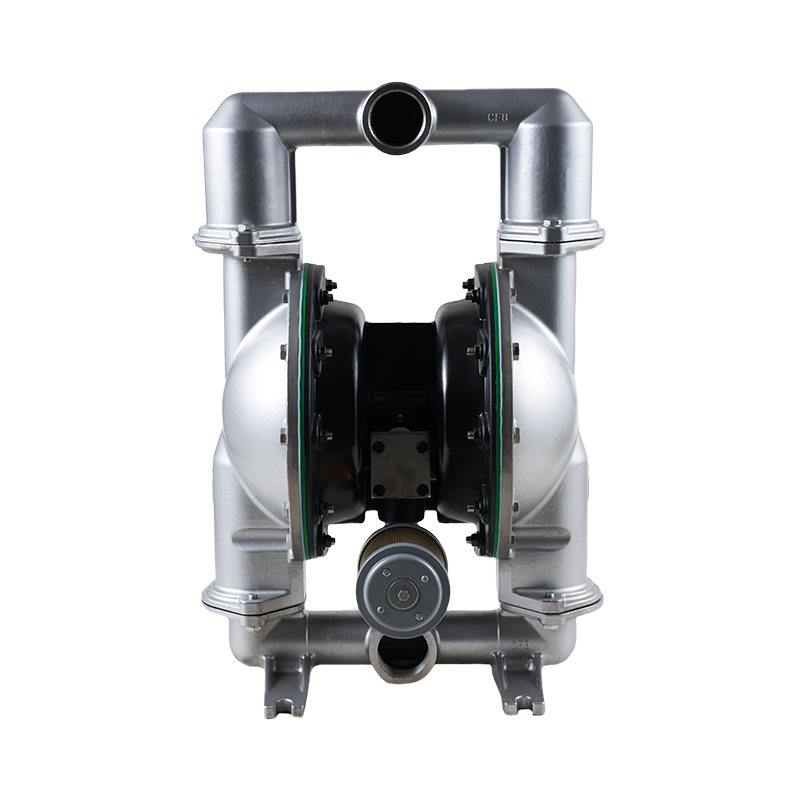

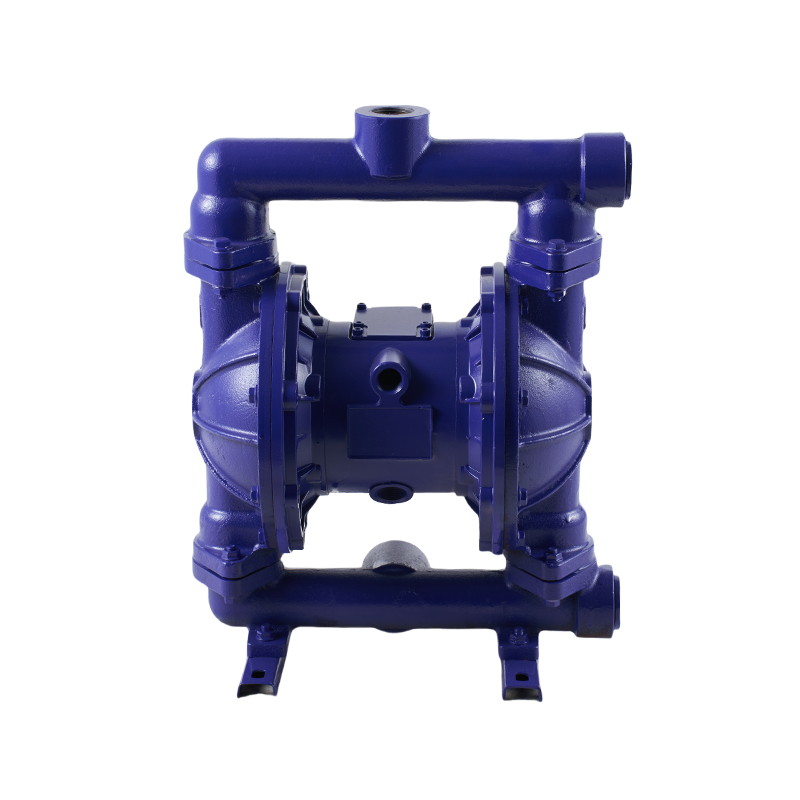

In industrial fluid handling, choosing between a Metal Diaphragm Pump and a plastic-bodied model is a decision that can significantly influence performance, durability, and maintenance costs. While plastic pumps offer corrosion resistance and lighter weight, the robust construction of a Double Diaphragm Pneumatic Pump made from cast iron or other metals is often preferred in demanding applications. One example is the 22 GPM Cast Iron Pneumatic Diaphragm Pump, a model designed to deliver steady flow rates while withstanding tough operating environments.

A Metal Diaphragm Pump offers notable advantages in industries where abrasion, temperatures, and mechanical stress are common. Cast iron, in particular, provides structural strength, allowing the pump to handle viscous liquids, slurries, and even some abrasive chemicals. The 22 GPM Cast Iron Pneumatic Diaphragm Pump combines this durability with the efficient, low-shear pumping action of a Double Diaphragm Pneumatic Pump, making it suitable for applications such as wastewater processing, mining, and heavy-duty manufacturing.

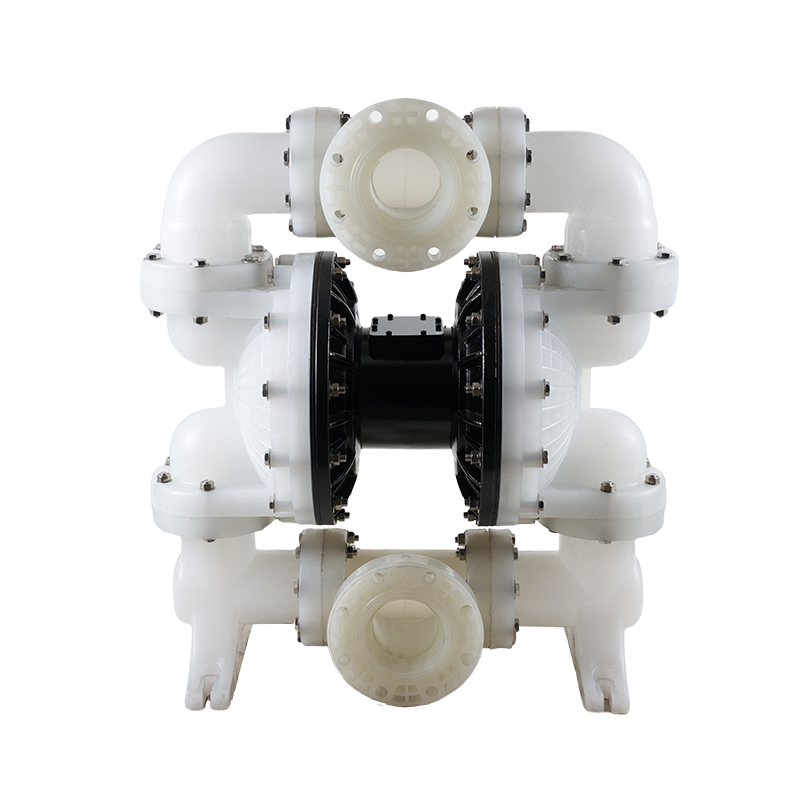

In contrast, plastic-bodied Double Diaphragm Pneumatic Pump models are often selected for chemical transfer tasks involving highly corrosive fluids. While a Metal Diaphragm Pump may excel in mechanical strength, certain acids and solvents can degrade metal over time. Here, engineered plastics like polypropylene or PVDF provide longer life expectancy. However, these materials typically cannot match the structural resilience of a 22GPM Cast Iron Pneumatic Diaphragm Pump in applications involving high mechanical wear or elevated temperatures.

Flow rate is another consideration when comparing pump types. The 22 GPM Cast Iron Pneumatic Diaphragm Pump is designed for medium-volume transfer, delivering a consistent 22 gallons per minute under certain conditions. For many industrial processes, this rate balances throughput with control, making it a versatile choice. While some plastic Double Diaphragm Pneumatic Pump models can achieve similar flow rates, they may require more frequent maintenance if used with abrasive or high-temperature media, conditions where a Metal Diaphragm Pump typically performs better.

Weight and portability also influence selection. A plastic Double Diaphragm Pneumatic Pump is generally lighter, which can be advantageous for mobile setups or temporary installations. The 22 GPM Cast Iron Pneumatic Diaphragm Pump, being a Metal Diaphragm Pump, is heavier but offers greater stability during operation, reducing vibration and movement that can cause wear to hoses and fittings over time.

Maintenance requirements vary as well. A Metal Diaphragm Pump, such as the 22 GPM Cast Iron Pneumatic Diaphragm Pump, is relatively easy to service, with straightforward access to diaphragms, valves, and seals. Many operators find that a Double Diaphragm Pneumatic Pump made from metal can go longer between major servicing intervals, especially in non-corrosive applications. Plastic pumps, while corrosion-resistant, may require earlier component replacement if subjected to physical impacts or abrasive fluids.

Cost is often a deciding factor. While a 22 GPM Cast Iron Pneumatic Diaphragm Pump may have a higher initial purchase price than a plastic equivalent, its long-term operational lifespan and lower frequency of repairs can make it more cost-effective in the long run. A plastic Double Diaphragm Pneumatic Pump can be more economical upfront, but frequent exposure to harsh mechanical conditions may shorten its service life, making a Metal Diaphragm Pump the better investment for certain industries.

The choice between a Metal Diaphragm Pump and a plastic-bodied Double Diaphragm Pneumatic Pump depends on the nature of the fluids being pumped, the operating environment, and long-term cost considerations. The 22 GPM Cast Iron Pneumatic Diaphragm Pump stands out for its durability, consistent performance, and ability to handle challenging media, making it well-suited to demanding industrial operations. For lighter-duty or highly corrosive chemical applications, a plastic pump may be more appropriate. By carefully evaluating your specific needs, you can select a pump type that delivers both reliability and value over its operational life.

English

English русский

русский Español

Español عربى

عربى