How Diaphragm Pumps Ensure Safe and Efficient Chemical Transfer?

2025.08.17

2025.08.17

Industry News

Industry News

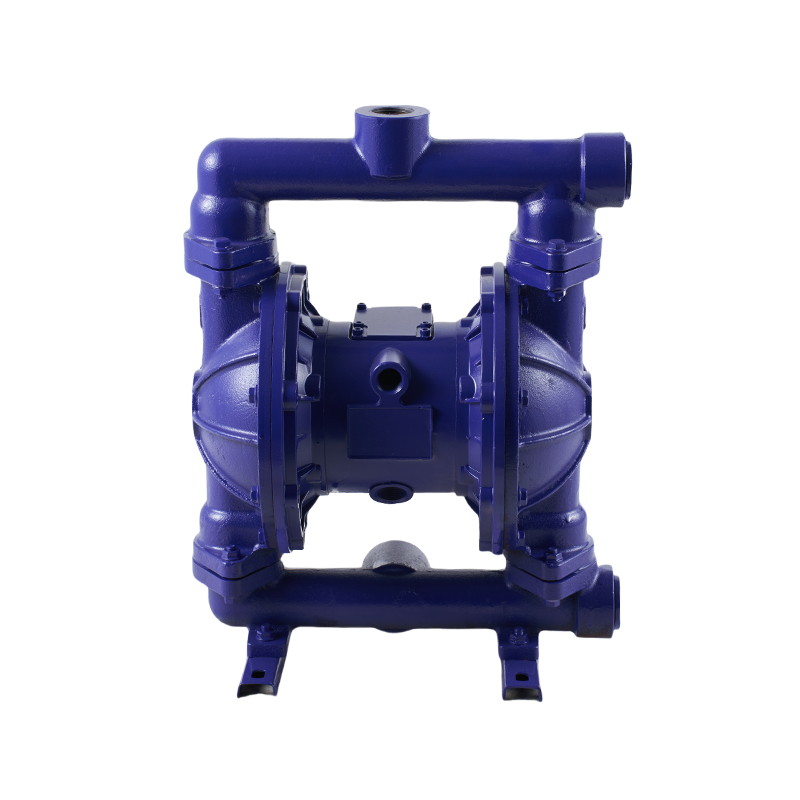

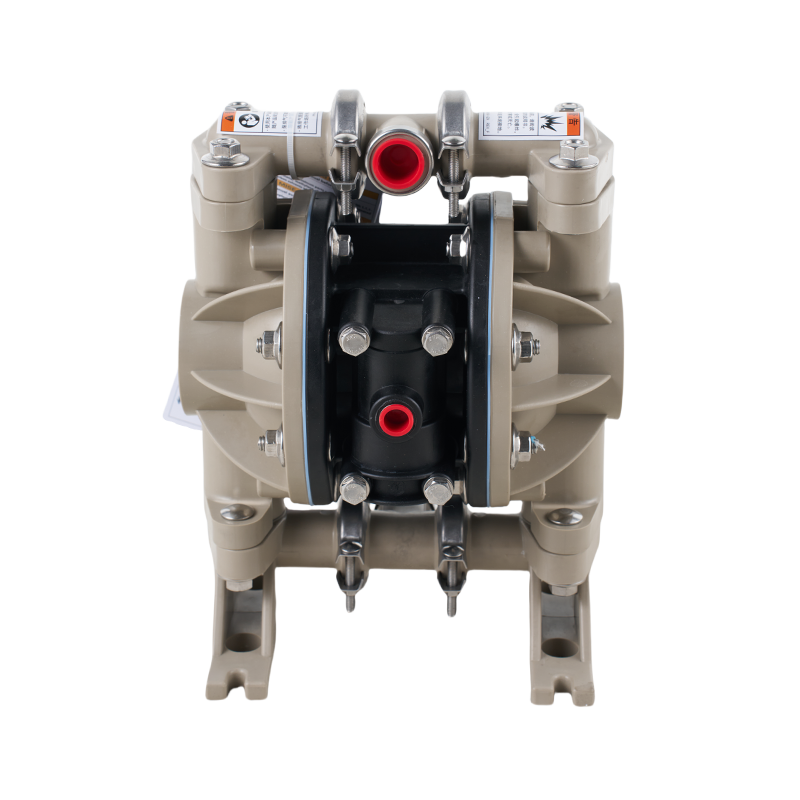

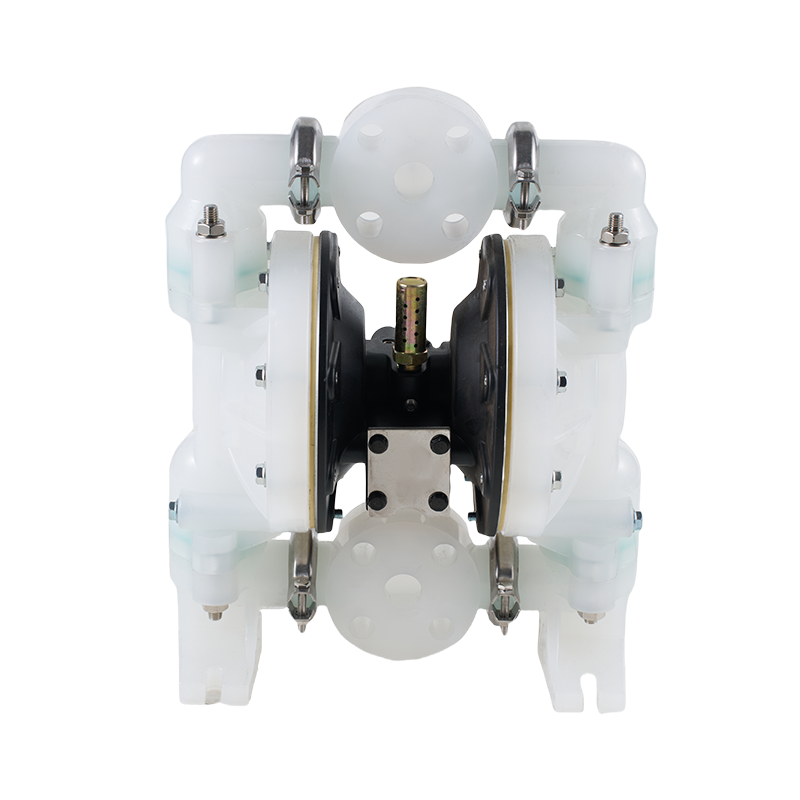

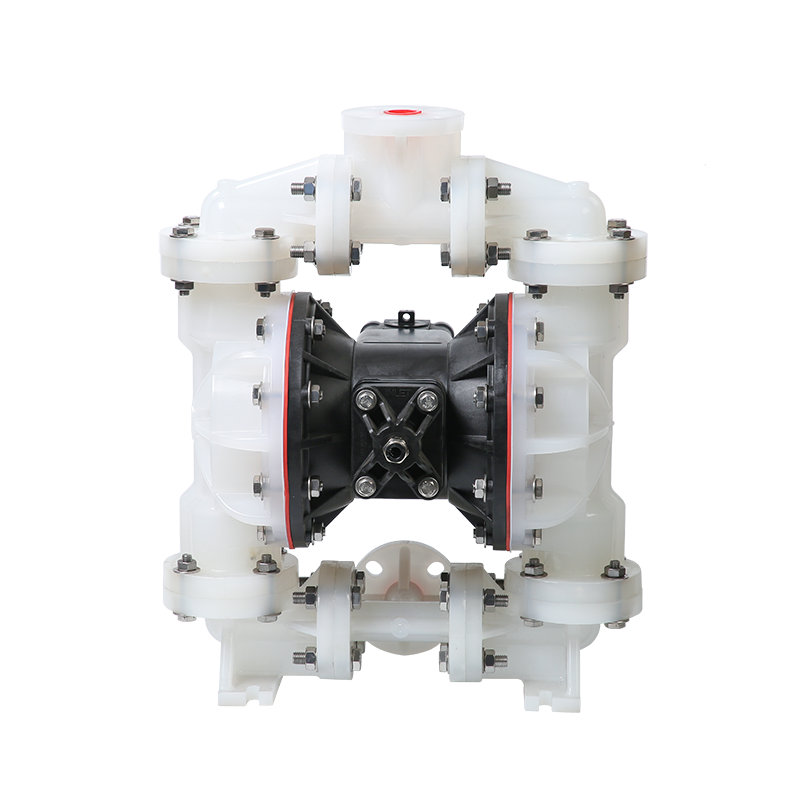

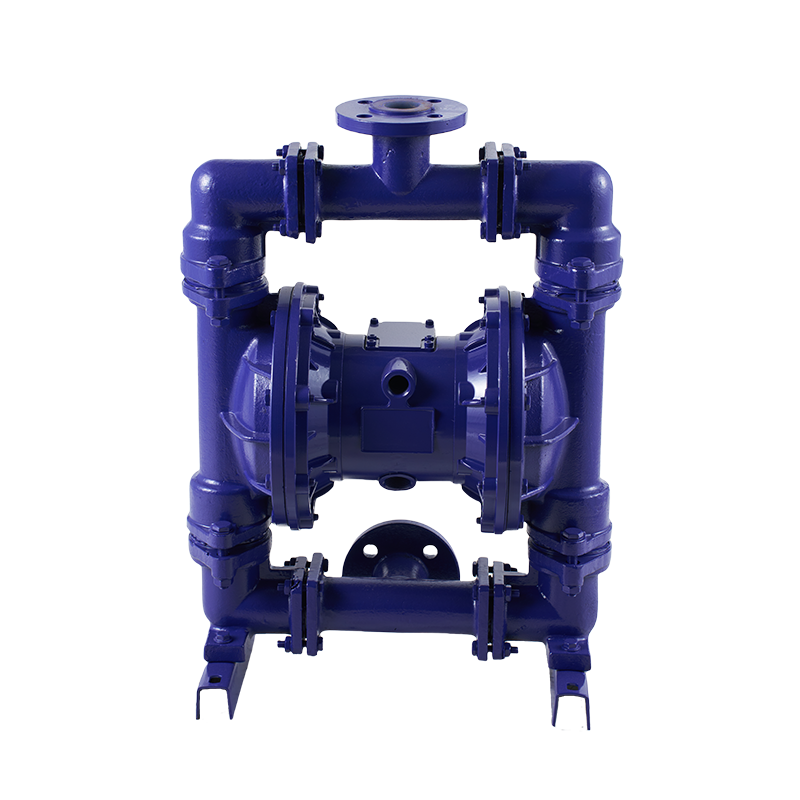

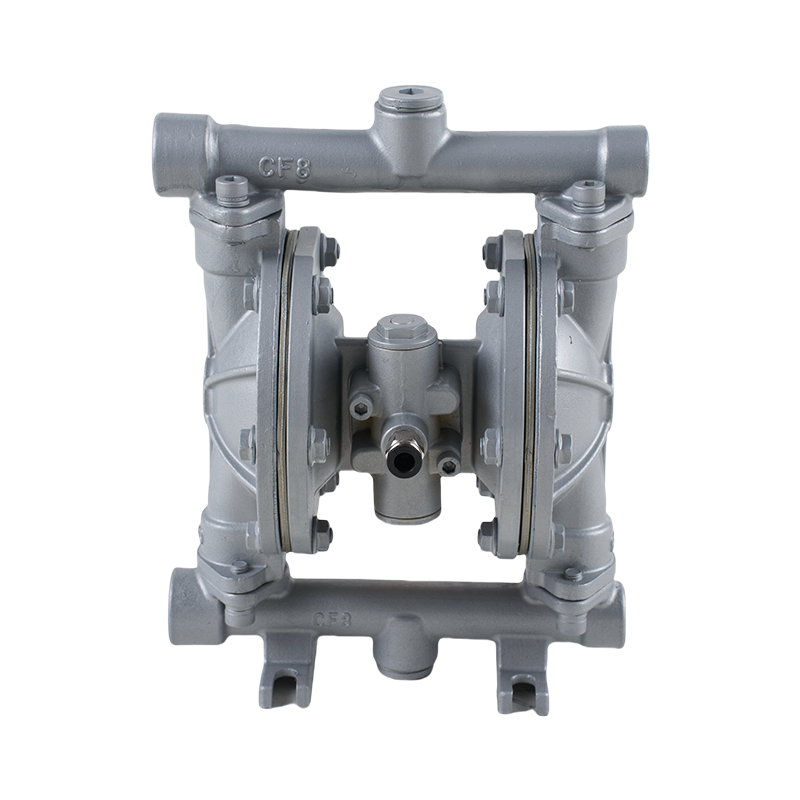

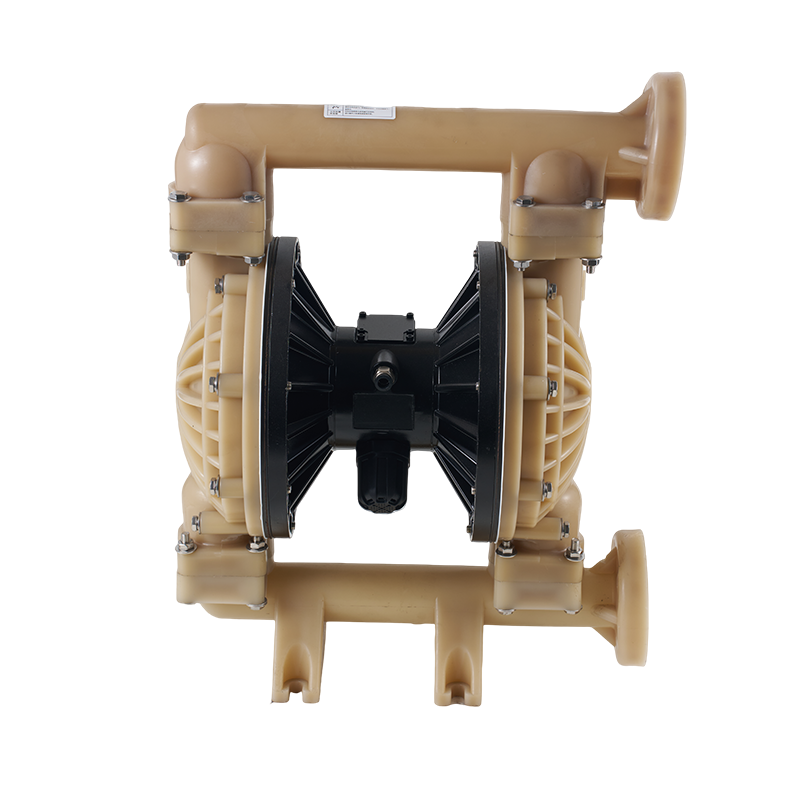

In the realm of industrial operations, the safe and efficient transfer of chemicals is a critical task that demands specialized equipment. Traditional pumps often fall short when handling corrosive, hazardous, or highly viscous chemicals, to potential safety risks, environmental contamination, and operational inefficiencies. This is where Diaphragm Pumps, particularly Air Operated Diaphragm Pump For Chemicals, have emerged as a reliable solution. These pumps are specifically designed to handle a wide range of chemicals while ensuring safety, efficiency, and minimal downtime.

Diaphragm Pumps operate on a principle that involves the use of a flexible diaphragm to create a positive displacement action. This mechanism is what sets them apart from other types of pumps. The diaphragm moves back and forth, creating a suction and discharge action that efficiently transfers the chemical fluid. This design not only ensures a consistent flow rate but also minimizes the risk of leaks and spills, which are common issues with traditional pumps.

One of the key advantages of Diaphragm Pumps is their ability to handle a wide range of chemical properties. Whether it's corrosive acids, volatile solvents, or viscous slurries, these pumps can manage them all. The diaphragm itself is made from highly durable and chemically resistant materials such as PTFE (Polytetrafluoroethylene) or other advanced fluoropolymers. These materials are specifically chosen for their ability to withstand the corrosive effects of various chemicals, ensuring long-term durability and reliability.

Safety is a paramount concern in chemical transfer operations, and Diaphragm Pumps are designed with this in mind. Unlike traditional pumps that rely on mechanical seals, which can wear out and fail over time, Diaphragm Pumps use a flexible diaphragm that creates a sealed chamber. This design eliminates the need for seals that can degrade or fail, significantly reducing the risk of chemical leaks and spills. The self-priming capability of these pumps further enhances safety by allowing them to operate efficiently even when the chemical level is low, without the need for additional priming mechanisms that could fail.

Efficiency is another hallmark of Diaphragm Pumps. These pumps are capable of handling high-solids content without clogging, making them ideal for transferring abrasive materials or slurries. The positive displacement action ensures a consistent flow rate, even with varying fluid viscosities. This is particularly important in applications where precise dosing or metering of chemicals is required, such as in pharmaceutical or food processing industries.

The ability of Diaphragm Pumps to run dry without damage is another significant advantage. In many chemical transfer operations, the supply of chemicals may be intermittent. Traditional pumps can be damaged if they run dry, but Diaphragm Pumps can operate safely without the risk of mechanical failure. This ensures continuous operation and reduces downtime to increase productivity.

Diaphragm Pumps are known for their low - maintenance requirements. Unlike other types of pumps that require frequent servicing and part replacements, Diaphragm Pumps have fewer moving parts. This reduces the likelihood of mechanical failures and lowers maintenance costs. In industries where downtime can be costly, the reliability and durability of Diaphragm Pumps make them a valuable asset.

Moreover, Diaphragm Pumps are energy-efficient. They operate on compressed air, which means they use less energy compared to electric or diesel-powered pumps. This not only reduces operating costs but also makes the pump more environmentally friendly. In an era where sustainability is a key concern, the energy efficiency of Diaphragm Pumps is a major selling point.

The versatility of Diaphragm Pumps makes them suitable for a wide range of applications. From transferring corrosive acids in chemical processing plants to handling viscous slurries in mining operations, these pumps can handle it all. They are also commonly used in the pharmaceutical industry for transferring sensitive chemicals that require precise control and in the food and beverage industry for transferring ingredients without contamination.

Diaphragm Pumps, particularlyAir Operated Diaphragm Pump For Chemicals, are a game-changing solution for the safe and efficient transfer of chemicals. Their unique design and construction make them highly effective in preventing leaks and spills, ensuring safety and reliability in chemical processing operations. The ability to handle a wide range of chemical properties, low - maintenance requirements, and energy efficiency further enhances their value in industrial applications.

Whether you are transferring corrosive acids, volatile solvents, or viscous slurries, Diaphragm Pumps offer a reliable and efficient solution. By choosing the right Diaphragm Pump for your chemical transfer needs, you can significantly reduce operational risks, lower maintenance costs, and ensure a more productive and sustainable operation.

English

English русский

русский Español

Español عربى

عربى