Understanding the Mechanics of Stainless Steel Double Diaphragm Pumps

2025.08.17

2025.08.17

Industry News

Industry News

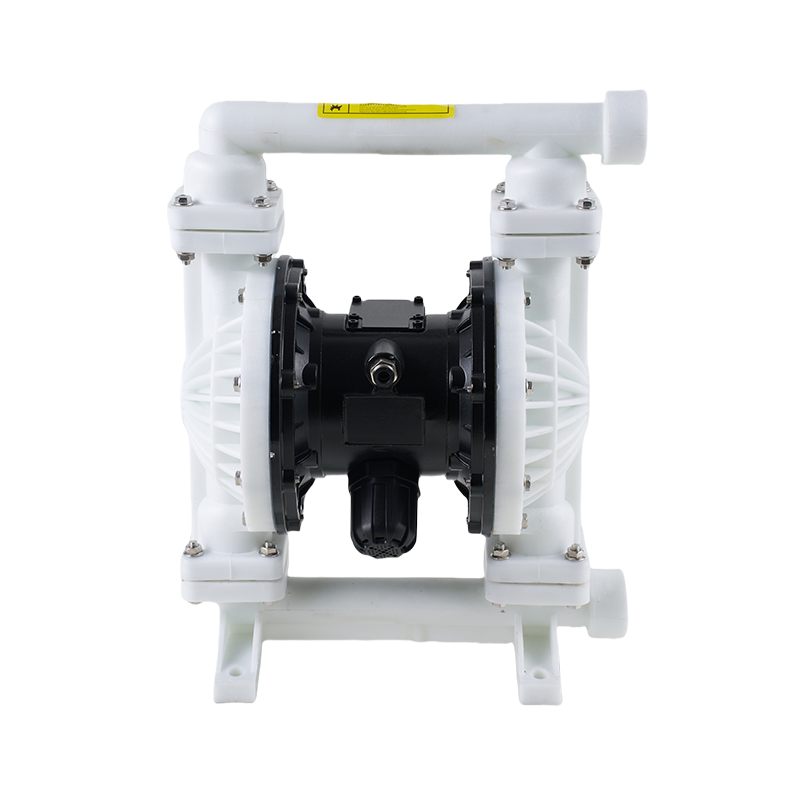

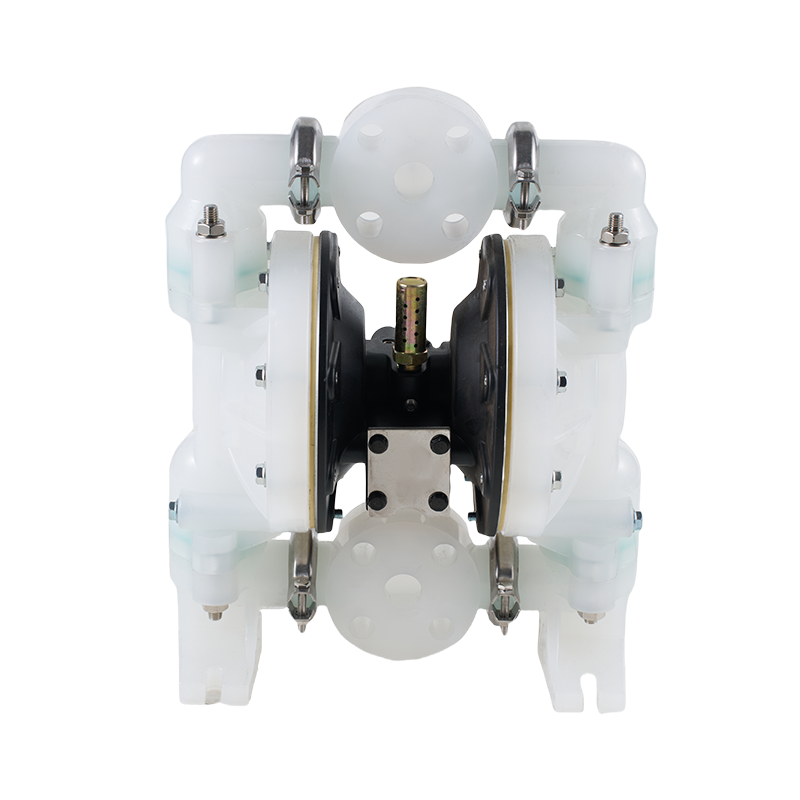

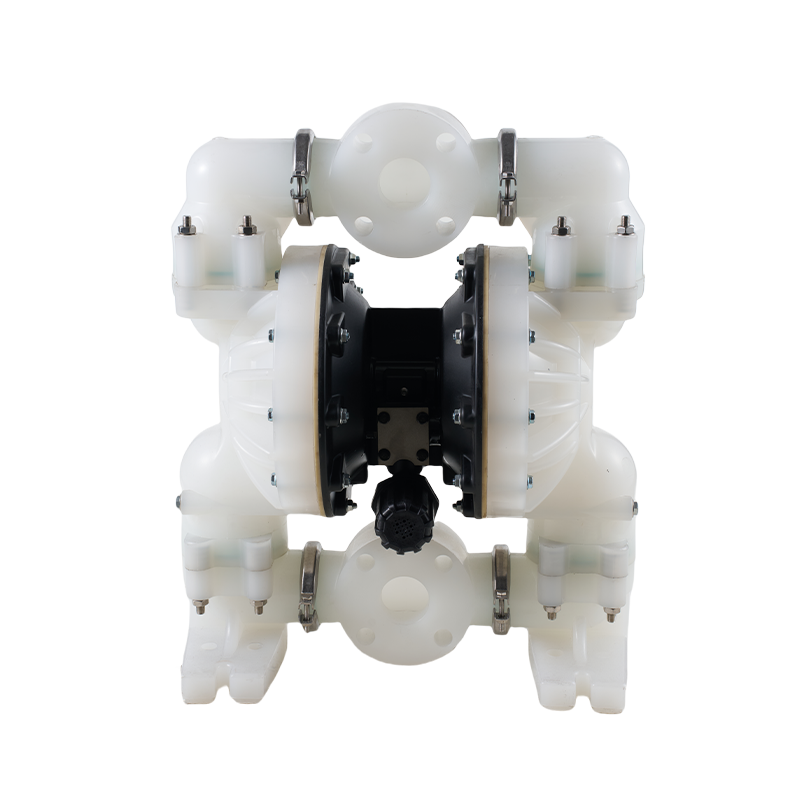

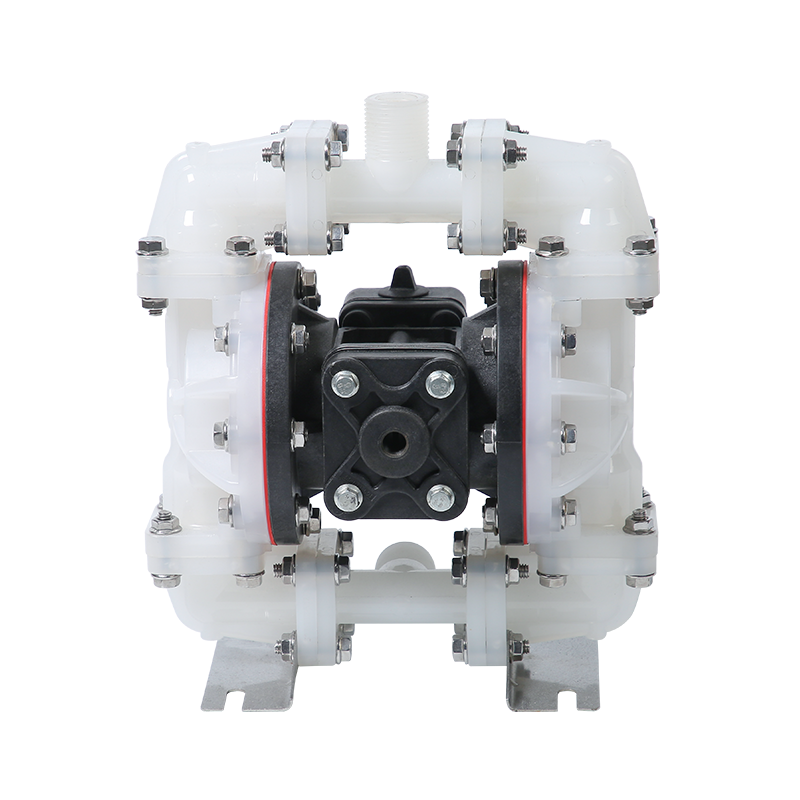

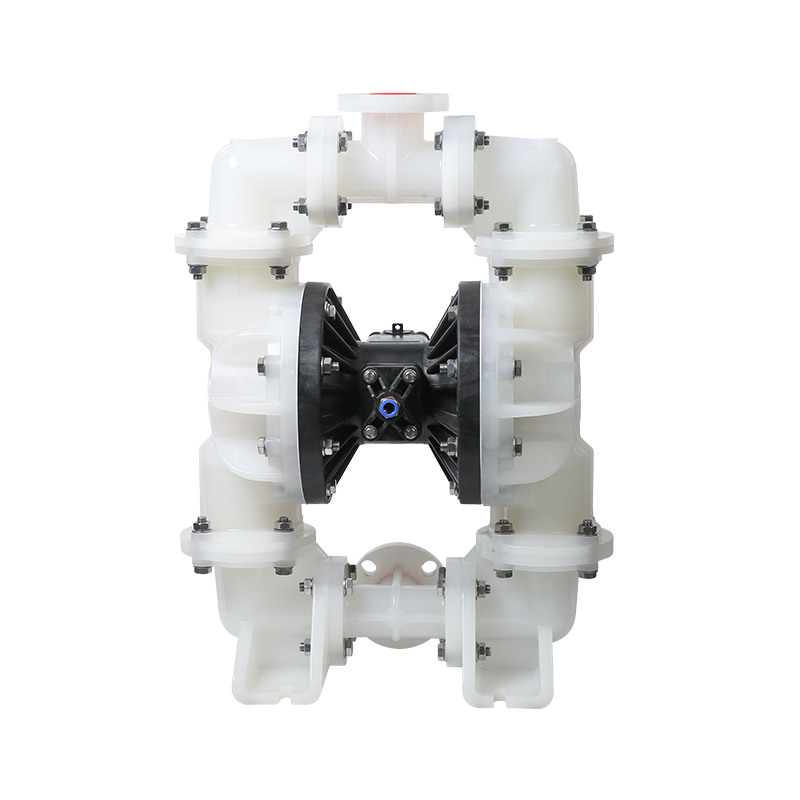

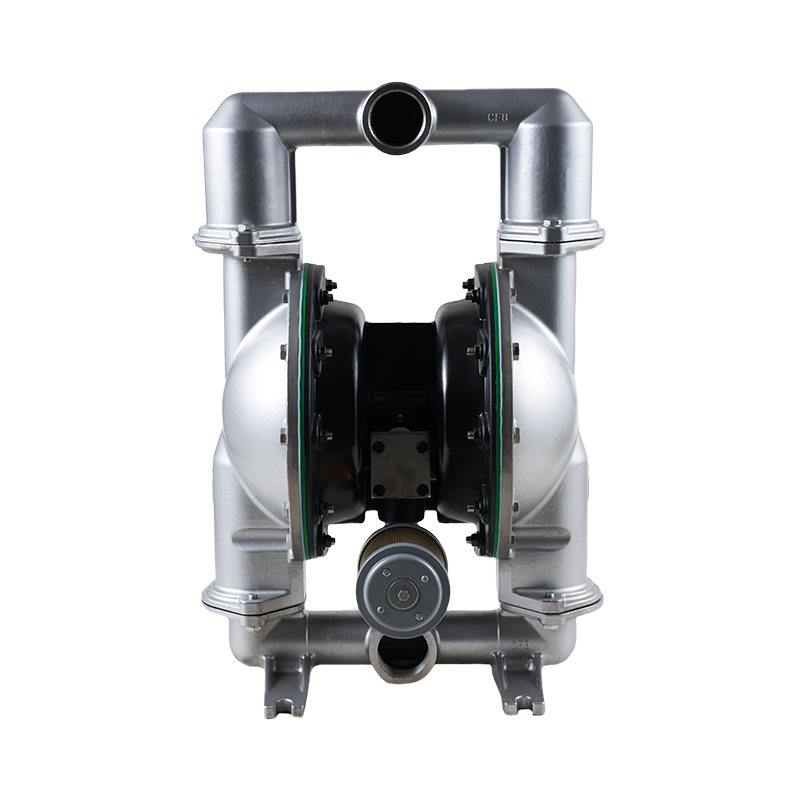

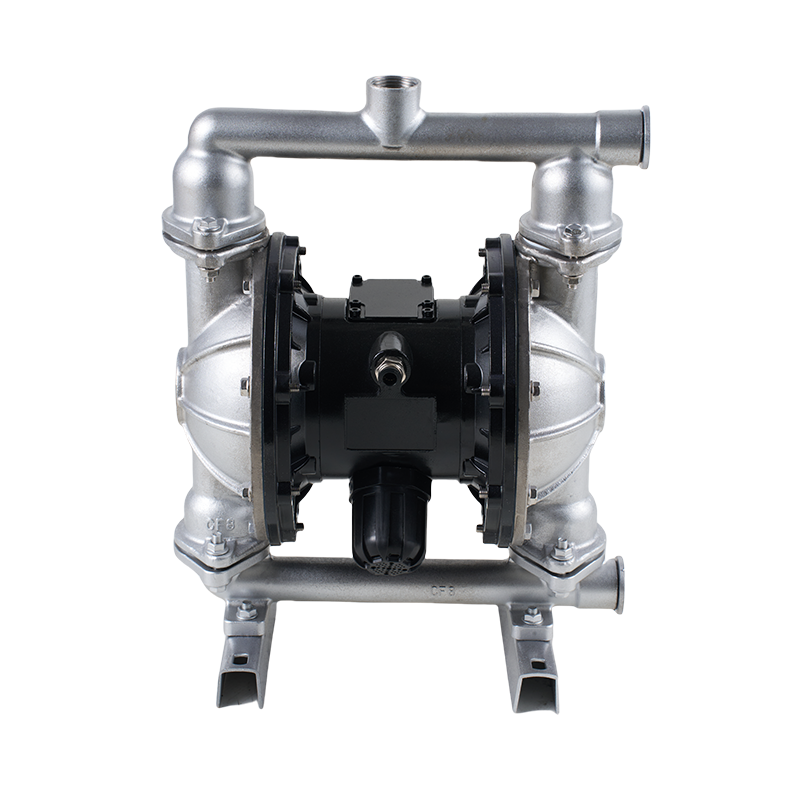

In modern industrial processes, the stainless steel double diaphragm pump has become a widely adopted solution for handling liquids with precision and reliability. Known for its versatility, this pump type combines the corrosion resistance of stainless steel with the proven pumping action of a double diaphragm system. As industries ranging from chemical manufacturing to food processing continue to demand efficient and sanitary transfer systems, understanding the mechanics of the double diaphragm vacuum pump and the broader category of diaphragm pump stainless steel models becomes essential for engineers and plant operators alike.

A double diaphragm vacuum pump operates on a simple yet highly effective principle: two flexible diaphragms move back and forth, driven by air or mechanical actuation, to create a vacuum that draws liquid into one chamber while simultaneously pushing liquid out of the other. This alternating action ensures a continuous, pulseless flow, which is critical in applications that require smooth fluid transfer. When built as a diaphragm pump stainless steel variant, the pump gains the added advantage of resistance to rust, chemical attack, and temperature fluctuations.

The stainless steel double diaphragm pump is particularly valued in environments where hygiene and durability are paramount. In the food and beverage sector, for example, stainless steel construction helps prevent contamination while withstanding frequent cleaning cycles. For operators working in chemical plants, the double diaphragm vacuum pump offers safe handling of corrosive or volatile liquids without risk of metal degradation. This makes the diaphragm pump stainless steel an ideal choice for long-term service under demanding conditions.

Mechanically, a double diaphragm vacuum pump uses check valves to control the flow direction. As the diaphragms move, one chamber fills while the other empties, with the check valves ensuring that fluid only flows forward. The robust design of the stainless steel double diaphragm pump allows it to handle viscous fluids, abrasive slurries, or liquids containing solids. This capability gives the diaphragm pump stainless steel a clear advantage over certain centrifugal pumps that may struggle with such materials.

Maintenance is another area where the double diaphragm vacuum pump excels. With no rotating seals and minimal contact between moving parts and the fluid, wear and tear are reduced. The stainless steel double diaphragm pump is also easy to disassemble for cleaning or inspection, making it suitable for industries with strict compliance requirements. Furthermore, the diaphragm pump stainless steel design is compatible with various diaphragm materials, enabling customization for specific chemical or temperature resistance needs.

Energy efficiency is an additional benefit. A well-configured double diaphragm vacuum pump can operate effectively with modest air or power input, reducing operational costs. When built as a stainless steel double diaphragm pump, it not only offers mechanical efficiency but also a long operational lifespan, which helps lower replacement expenses. The adaptability of the diaphragm pump stainless steel design means it can be integrated into both fixed installations and mobile transfer systems.

Looking ahead, advancements in manufacturing and materials are likely to further improve the performance of the double diaphragm vacuum pump. Enhanced diaphragm formulations, precision-machined stainless steel components, and improved valve designs will keep the stainless steel double diaphragm pump at the forefront of fluid handling solutions. In many sectors, the stainless steel diaphragm pump remains a reliable, versatile, and cost-effective choice for applications that require a balance of strength, cleanliness, and operational stability.

By understanding how a double diaphragm vacuum pump functions and recognizing the benefits of stainless steel construction, operators can make informed decisions that enhance both process efficiency and product quality. The stainless steel double diaphragm pump continues to play an important role in industrial operations, and the diaphragm pump stainless steel category is expected to see steady adoption as industries prioritize durability, hygiene, and precision in their pumping systems.

English

English русский

русский Español

Español عربى

عربى