Choosing the Right Industrial Diaphragm Pump: A Guide to Pneumatic Diaphragms and Their Uses

2025.08.17

2025.08.17

Industry News

Industry News

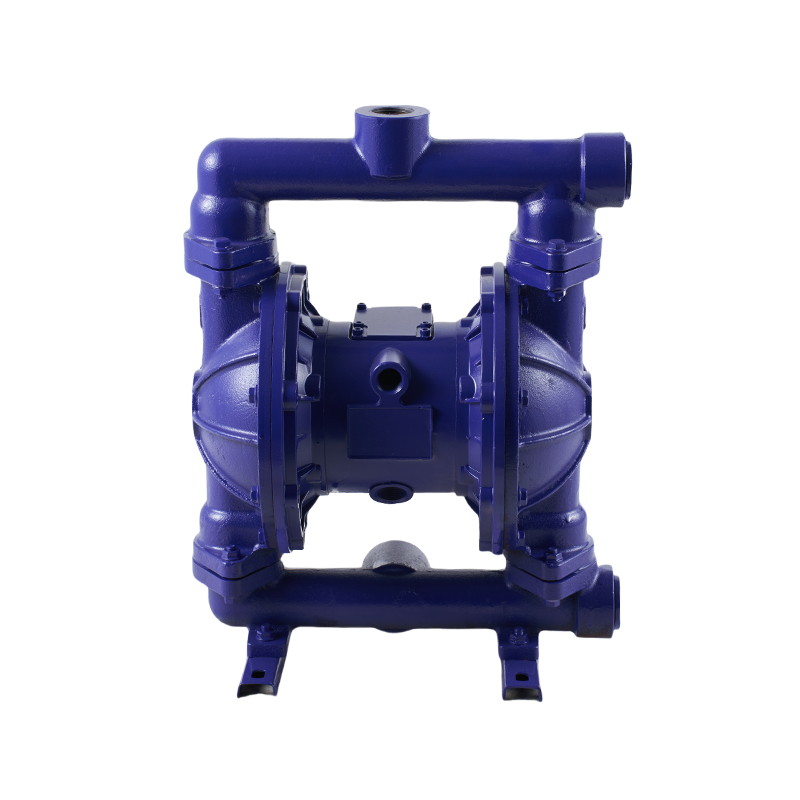

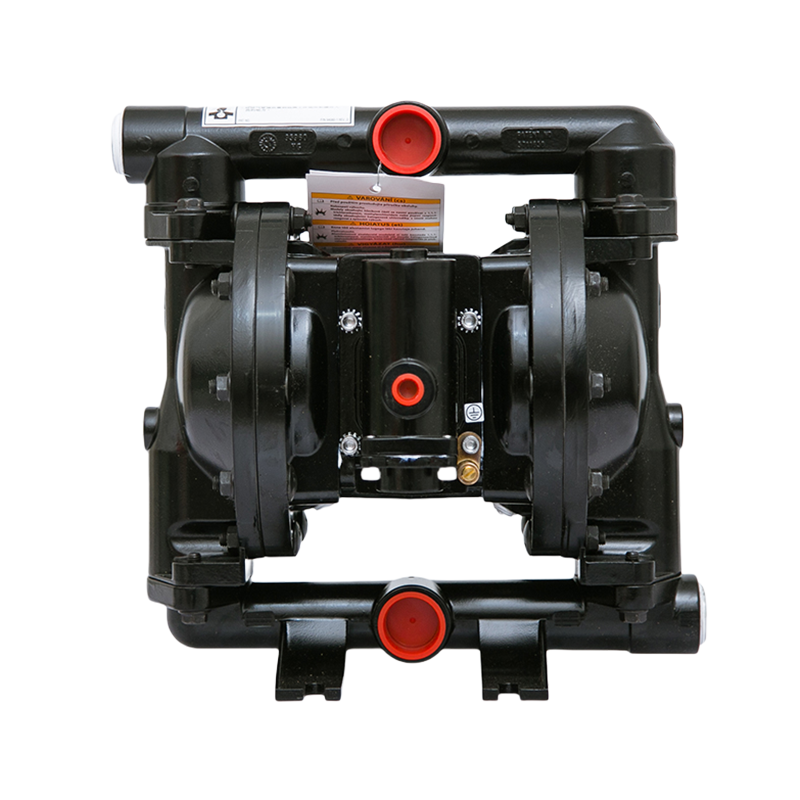

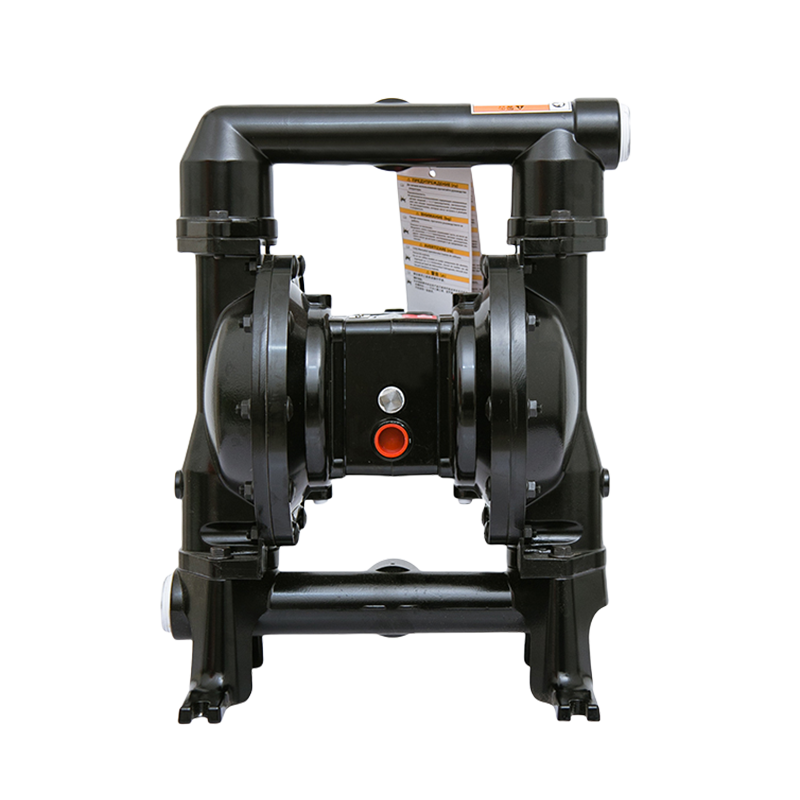

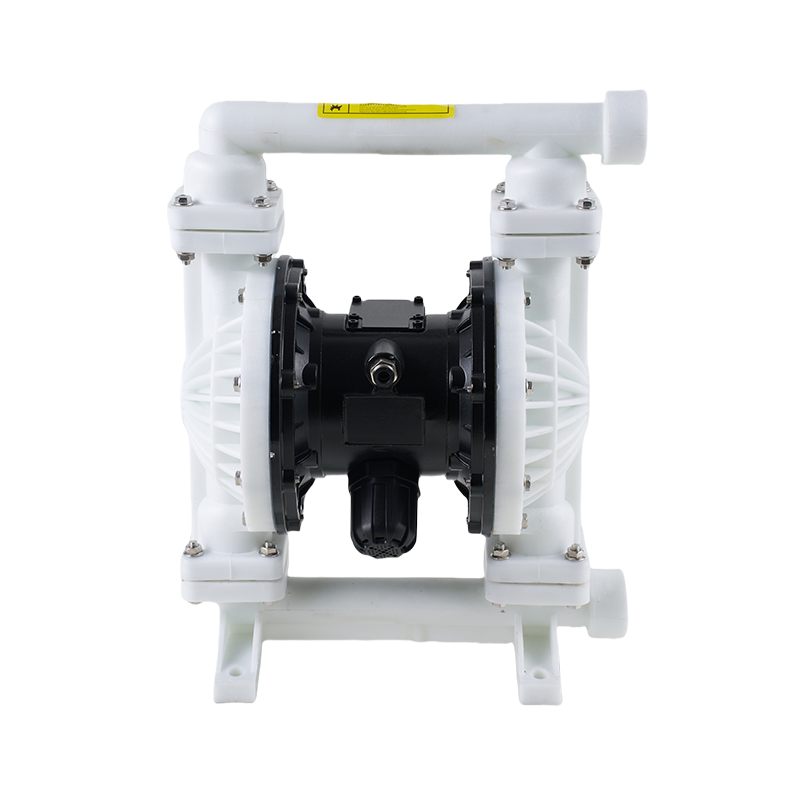

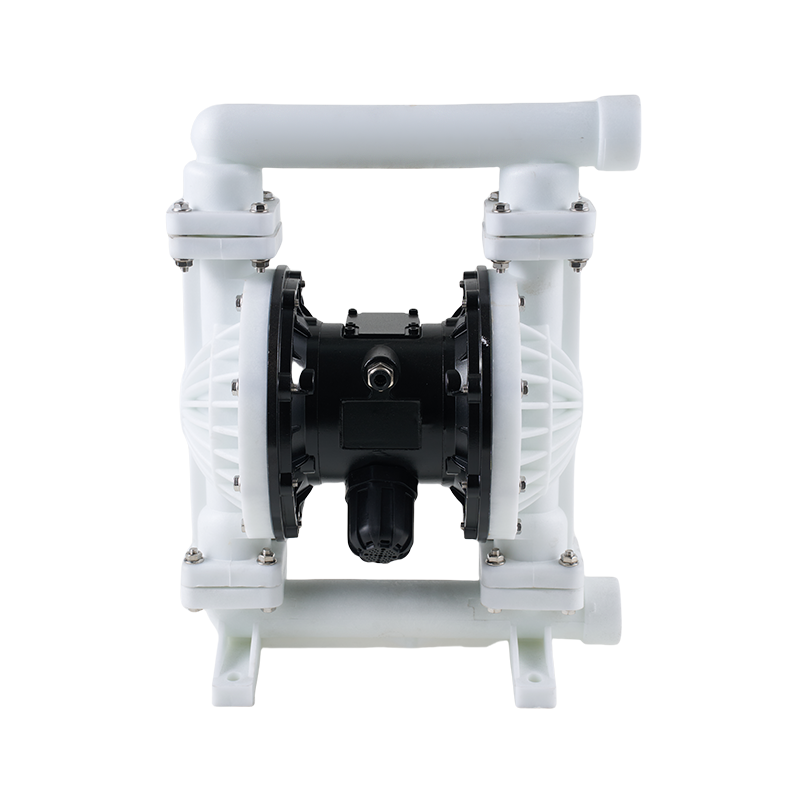

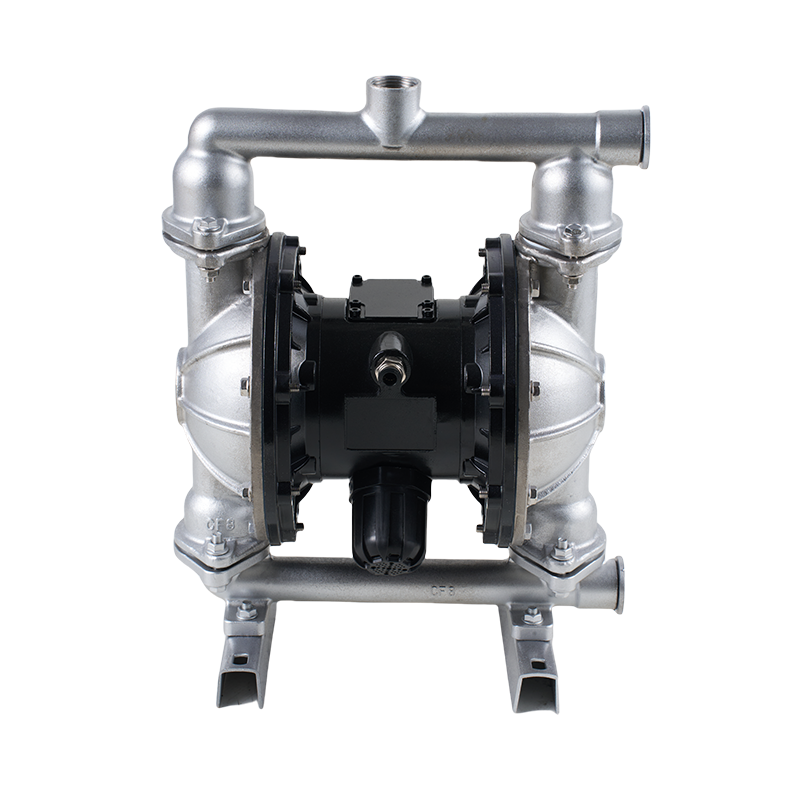

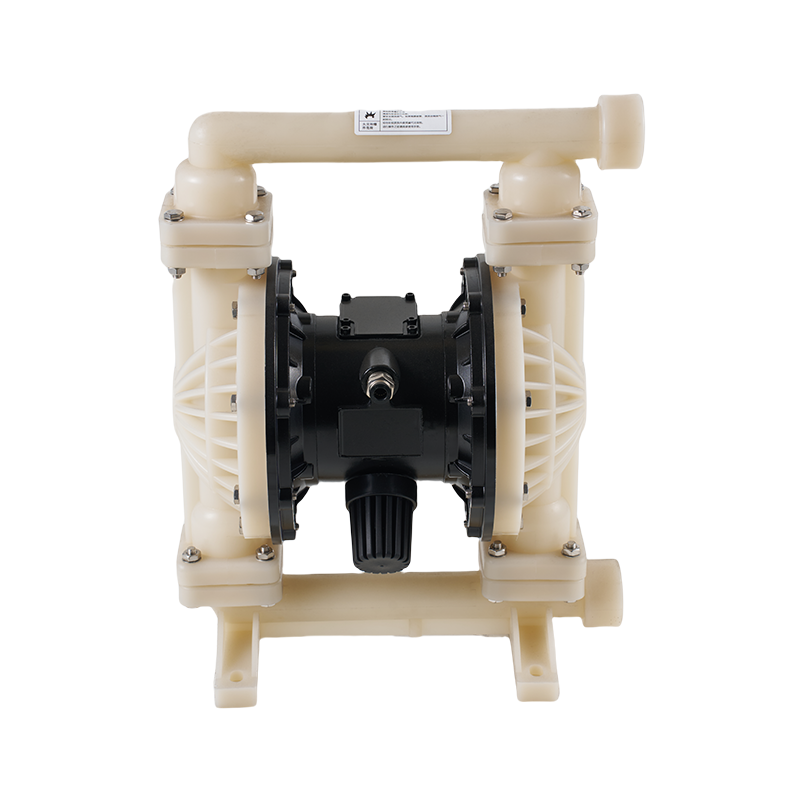

In today's manufacturing and processing industries, the Industrial Diaphragm Pump plays a vital role in moving fluids efficiently, safely, and with minimal maintenance requirements. As businesses across chemical production, food processing, pharmaceuticals, and mining seek reliable solutions for their pumping needs, understanding the range of Diaphragm Pump Uses becomes increasingly important. Among the different configurations available, the Pneumatic Pump Diaphragm has gained significant attention due to its versatility and operational efficiency.

An Industrial Diaphragm Pump operates using flexible diaphragms that create a reciprocating motion to displace liquids. This mechanism allows for consistent flow rates, the handling of various viscosities, and the ability to move both clean and abrasive fluids. When powered by compressed air, the system is referred to as a Pneumatic Pump Diaphragm, a design well-suited to environments where electricity use is limited or where intrinsic safety is a priority.

The diversity of Diaphragm Pump Uses means that these pumps can be found in sectors as varied as water treatment, oil and gas, beverage manufacturing, and slurry handling. For example, in a chemical plant, an Industrial Diaphragm Pump can transfer corrosive acids without the risk of leakage. In food production, a Pneumatic Pump Diaphragm can move sauces or syrups without altering their consistency, thanks to the pump's low-shear operation. This adaptability is one of the reasons the list of Diaphragm Pump Uses continues to grow across industries.

When selecting an Industrial Diaphragm Pump, material compatibility is a key consideration. The diaphragms themselves may be made from PTFE, rubber, or other specialized materials, depending on the fluid's chemical properties. In a Pneumatic Pump Diaphragm system, the choice of material directly affects durability and efficiency. Understanding Diaphragm Pump Uses in your specific operation will help in selecting the right diaphragm composition, ensuring longevity and consistent performance.

Another benefit of the Industrial Diaphragm Pump is its self-priming capability. This makes it particularly suitable for applications where suction lift is required. A Pneumatic Pump Diaphragm can also run dry without damage, which adds to its appeal in processes that involve intermittent flow. This characteristic is important in many Diaphragm Pump Uses, especially in industries where operational interruptions are frequent or unavoidable.

Maintenance requirements for an Industrial Diaphragm Pump are relatively straightforward. There are no complex seals or rotating shafts in contact with the pumped fluid, which reduces wear and simplifies servicing. In the case of a Pneumatic Pump Diaphragm, the absence of an electric motor means fewer moving parts and a lower risk of electrical failure. These features align with many Diaphragm Pump Uses in remote or hazardous locations where ease of repair is essential.

Energy considerations also influence pump selection. While an Industrial Diaphragm Pump driven by air requires a compressed air source, it offers energy efficiency in intermittent duty cycles. A Pneumatic Pump Diaphragm is often chosen for operations that demand flexibility, portability, and safe handling of flammable or volatile fluids. The wide range of Diaphragm Pump Uses ensures that these systems can be tailored to balance performance with operational costs.

Choosing the right pump involves consultation with experienced suppliers and reviewing performance specifications. Manufacturers of the Industrial Diaphragm Pump often guide the selection of the Pneumatic Pump Diaphragm setup for a given process. By matching pump capacity, materials, and operating conditions to actual Diaphragm Pump Uses, businesses can ensure smooth, reliable operations while minimizing downtime.

The Industrial Diaphragm Pump remains a trusted solution in modern industry, valued for its durability, adaptability, and ease of maintenance. The Pneumatic Pump Diaphragm variant further expands its versatility, making it suitable for countless Diaphragm Pump Uses. With proper selection, installation, and care, these pumps can provide years of dependable service, supporting productivity across a broad range of applications.

English

English русский

русский Español

Español عربى

عربى