How Does a Diaphragm Chemical Pump Prevent Leakage and Corrosion?

2025.08.17

2025.08.17

Industry News

Industry News

In the chemical processing industry, the prevention of leakage and corrosion is of ut importance. Not only do these issues pose significant safety risks, but they alsoto costly equipment failures and downtime. One of the more effective solutions for handling aggressive chemicals while minimizing these risks is the Diaphragm Chemical Pump. This innovative technology has revolutionized the way industries manage corrosive fluids, ensuring both safety and efficiency.

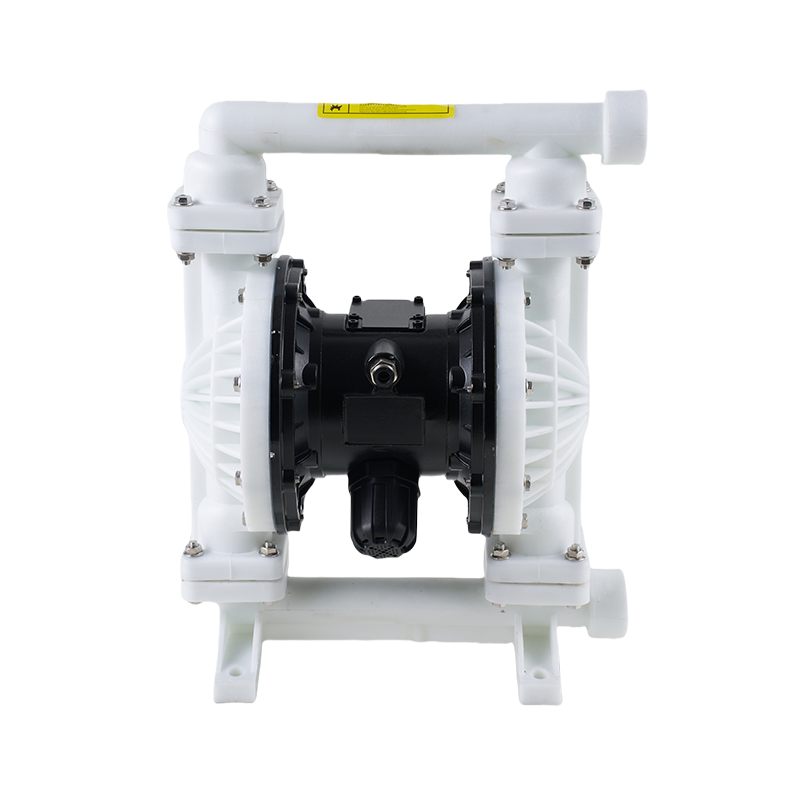

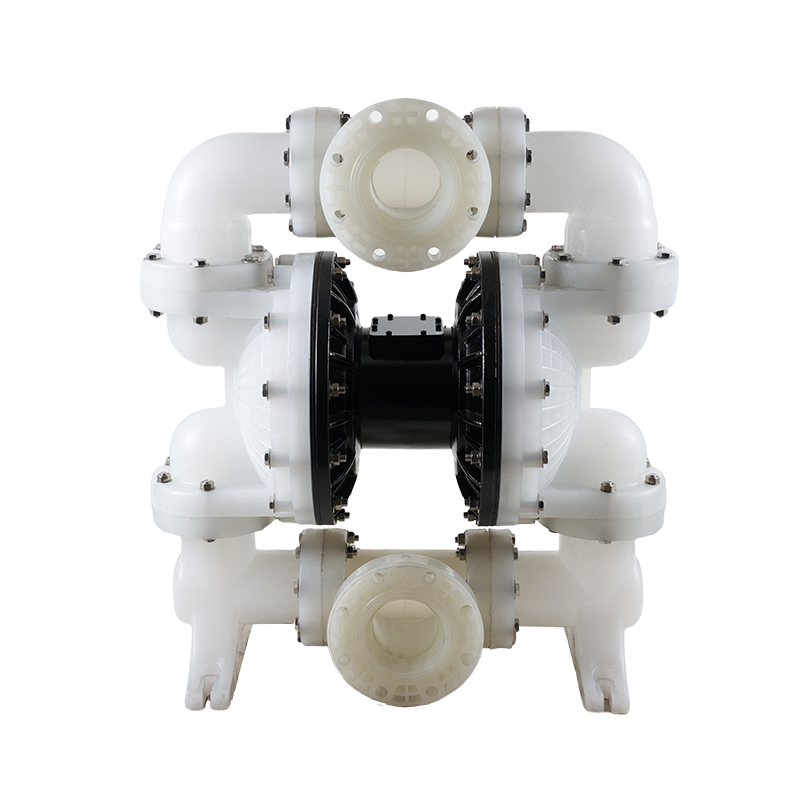

The Diaphragm Chemical Pump operates on a principle that inherently reduces the risk of leakage and corrosion. Unlike traditional centrifugal pumps that rely on mechanical seals and moving parts, the Diaphragm Chemical Pump uses a flexible diaphragm to create a positive displacement action. This design eliminates the need for seals that can wear out or fail over time, significantly reducing the likelihood of chemical leaks.

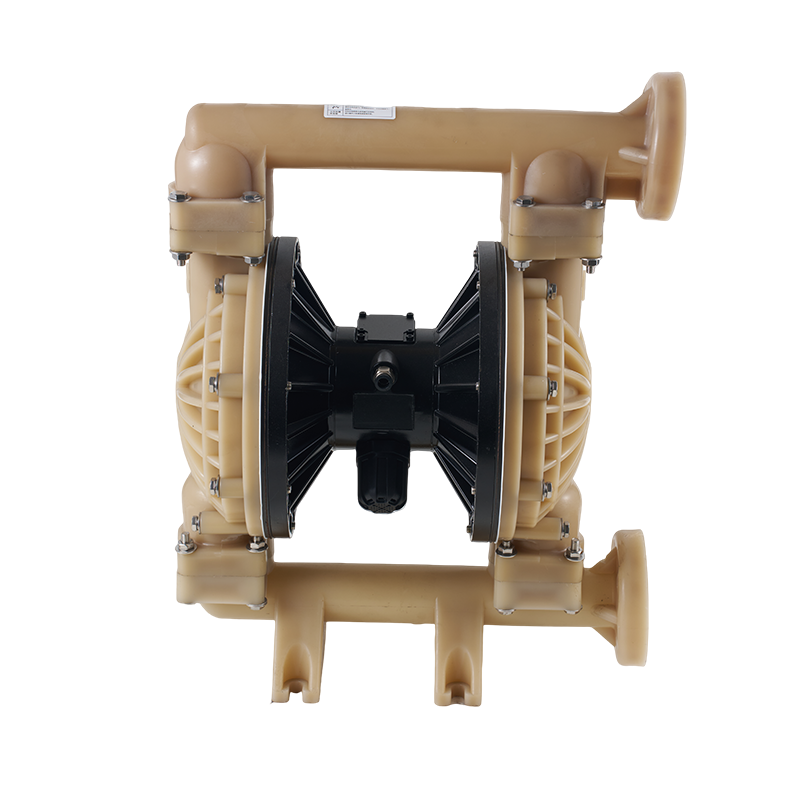

The diaphragm itself is made from highly durable and chemically resistant materials such as PTFE (Polytetrafluoroethylene) or other advanced fluoropolymers. These materials are specifically chosen for their ability to withstand the corrosive effects of acids, solvents, and caustics. The flexible diaphragm moves back and forth, creating a suction and discharge action that efficiently transfers the chemical fluid without direct contact with the pump's internal components.

One of the primary concerns in chemical processing is the prevention of leaks. Leaks canto environmental contamination, safety hazards, and regulatory violations. The Diaphragm Chemical Pump addresses this concern through its unique working mechanism. The diaphragm creates a sealed chamber that isolates the chemical fluid from the pump's mechanical components. This design ensures that even if the diaphragm wears out over time, the risk of a catastrophic leak is minimized.

Moreover, the Diaphragm Chemical Pump is capable of self-priming, which means it can start operating even when the fluid level is low. This feature is particularly useful in applications where the chemical supply may be intermittent. The self-priming capability ensures that the pump can operate efficiently without the need for additional priming mechanisms, which can be prone to failure and leaks.

Corrosion is another major challenge in chemical processing. Traditional pumps often suffer from corrosion due to prolonged exposure to harsh chemicals, to equipment degradation and failure. The Diaphragm Chemical Pump, however, is designed to withstand these challenges. The diaphragm and other critical components are made from materials that are highly resistant to chemical attack. For example, PTFE-lined diaphragms can withstand the corrosive effects of strong acids like hydrochloric acid, sulfuric acid, and nitric acid, as well as harsh solvents like acetone and toluene.

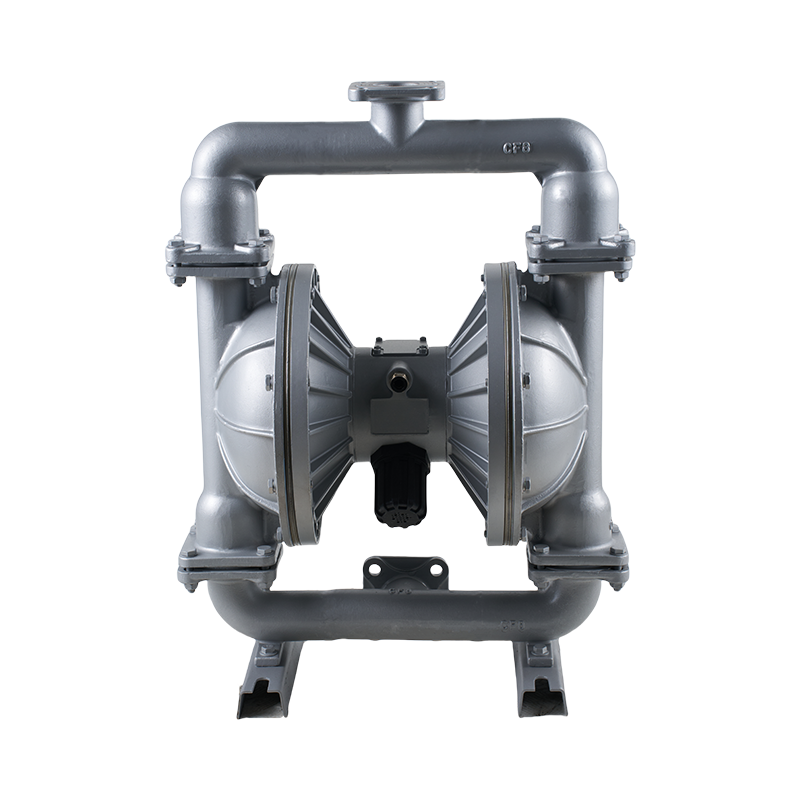

The pump's construction also plays a crucial role in preventing corrosion. Many Diaphragm Chemical Pumps are built with stainless steel or other corrosion-resistant materials for the pump body and other components. This ensures that the entire system remains durable and reliable, even in aggressive chemical environments.

The Diaphragm Chemical Pump is not only effective in preventing leakage and corrosion but also highly versatile. It can handle a wide range of chemical fluids, from low-viscosity liquids to high-viscosity slurries. This makes it an ideal choice for various industrial applications, including chemical processing, pharmaceutical manufacturing, and wastewater treatment.

The pump's ability to handle high-solids content without clogging is another significant advantage. This feature is particularly useful in applications where the chemical fluid contains abrasive particles or solid impurities. The flexible diaphragm design allows the pump to transfer these materials without significant wear and tear on the internal components.

In addition to its safety and reliability, the Diaphragm Chemical Pump is also known for its low - maintenance requirements. Unlike other types of pumps that require frequent servicing and part replacements, the Diaphragm Chemical Pump has fewer moving parts. This reduces the likelihood of mechanical failures and lowers maintenance costs. In industries where downtime can be costly, the reliability and durability of the Diaphragm Chemical Pump make it a valuable asset.

Moreover, the Diaphragm Chemical Pump is energy-efficient. It operates on compressed air, which means it uses less energy compared to electric or diesel-powered pumps. This not only reduces operating costs but also makes the pump more environmentally friendly. In an era where sustainability is a key concern, the energy efficiency of the Diaphragm Chemical Pump is a major selling point.

The Diaphragm Chemical Pump is a game-changing technology in the chemical processing industry. Its unique design and construction make it highly effective in preventing leakage and corrosion, ensuring safe and efficient chemical transfer. By using flexible diaphragms made from chemically resistant materials and eliminating the need for mechanical seals, the Diaphragm Chemical Pump offers unparalleled reliability and durability.

Whether you are transferring corrosive acids, volatile solvents, or abrasive slurries, the Diaphragm Chemical Pump is an ideal solution. Its versatility, low - maintenance requirements, and energy efficiency make it a valuable asset in any industrial setting. By choosing the right Diaphragm Chemical Pump, you can significantly reduce the risks associated with chemical processing and ensure a safer, more efficient operation.

English

English русский

русский Español

Español عربى

عربى