Corrosive Diaphragm Pumps vs. Traditional Pumps: Which is Better for Industrial Use?

2025.08.18

2025.08.18

Industry News

Industry News

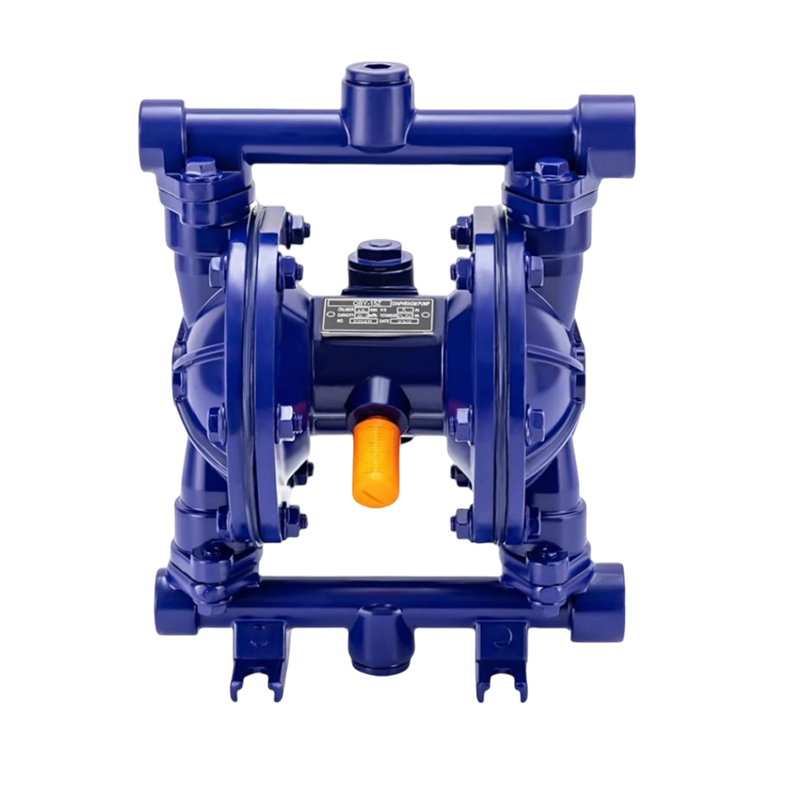

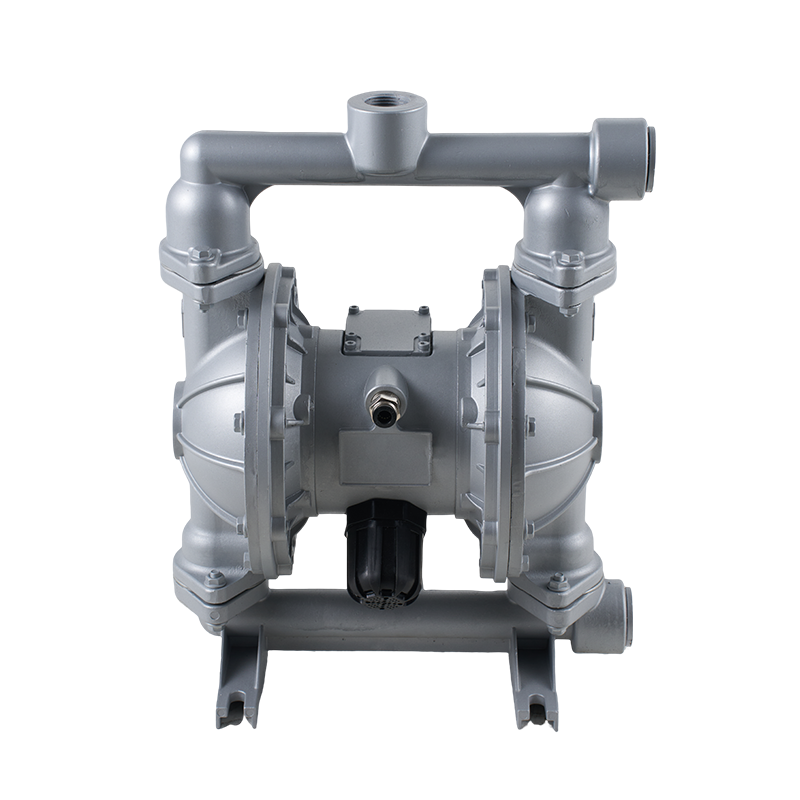

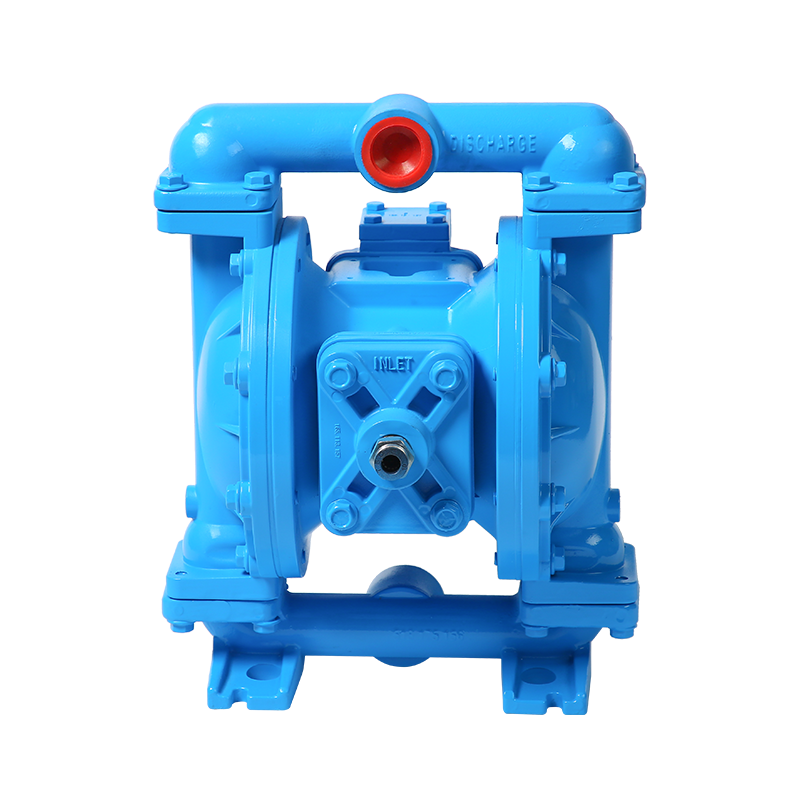

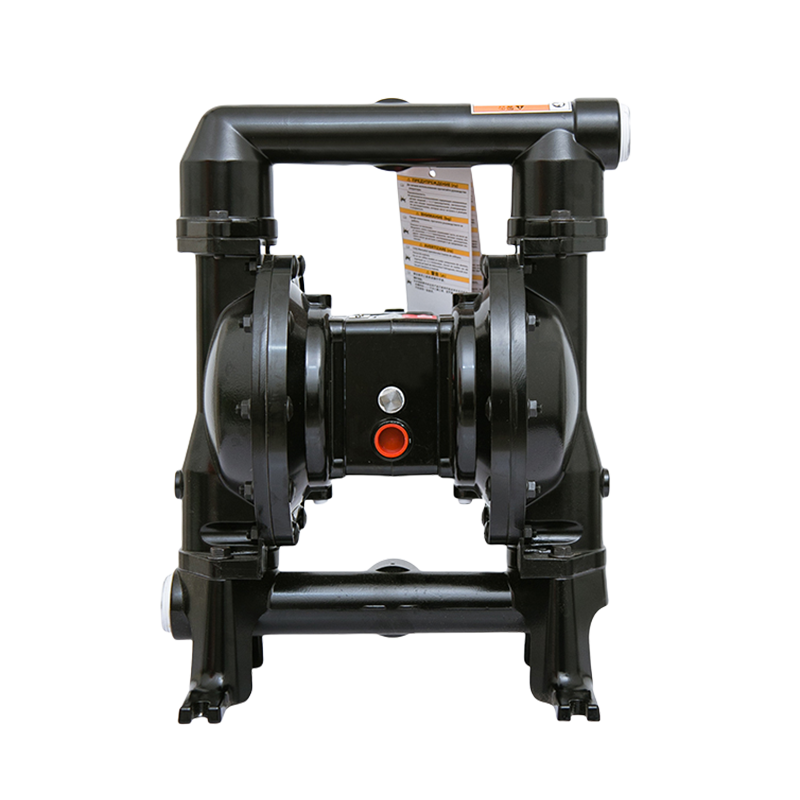

In many sectors, from chemical processing to wastewater treatment, the choice of pumping technology directly affects efficiency, safety, and long-term reliability. Among the available options, Corrosive Diaphragm Pumps are increasingly being compared with traditional pump designs to determine which is more suitable for demanding industrial environments.

Rising Demand in Industrial Applications

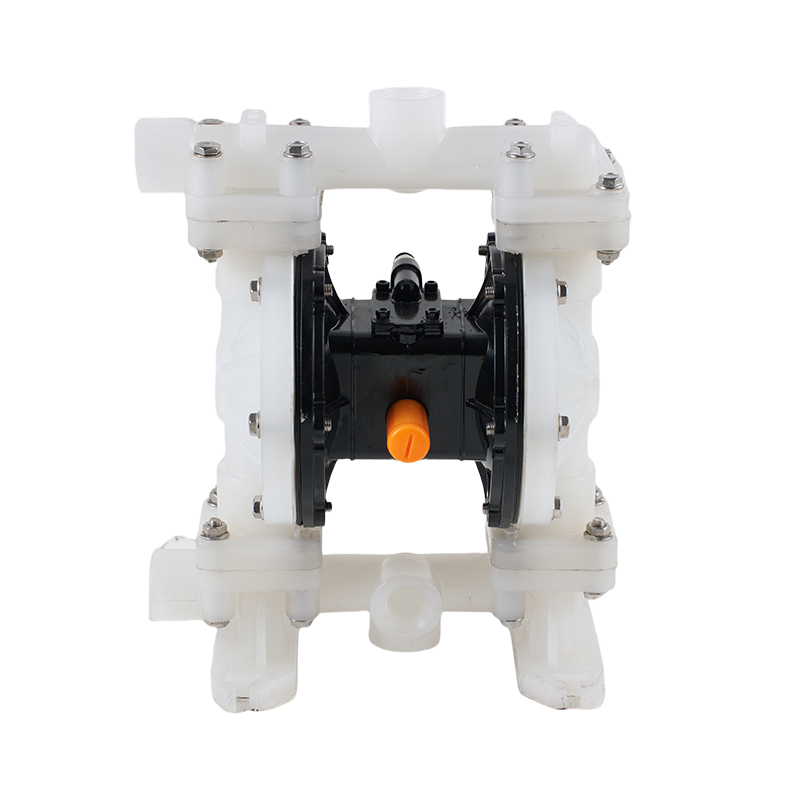

Industrial operations often require equipment that can handle aggressive chemicals and abrasive fluids. Industrial Diaphragm Pumps have become a reliable choice because they provide stable performance under challenging conditions. Unlike standard models, Corrosive Diaphragm Pumps are specifically engineered to handle acids, alkalis, and other substances that would quickly damage traditional pumps. This makes them highly valuable in sectors such as pharmaceuticals, water treatment, and mining.

Safety and Reliability in Conveying Corrosive Materials

When conveying hazardous liquids, safety is always a top concern. Diaphragm Pumps For Conveying Corrosive Materials are designed with non-metallic or coated internal components to resist chemical attack. This ensures that leaks and breakdowns are less likely, helping operators maintain safe working environments. Traditional pumps, while effective in some general applications, often require additional protection when exposed to aggressive fluids, adding to maintenance costs and downtime.

Energy and Maintenance Considerations

Energy efficiency and reduced downtime are important for plant managers seeking long-term value. Corrosive Diaphragm Pumps typically require less frequent maintenance because their design reduces direct contact between moving parts and corrosive fluids. In contrast, traditional pumps often need regular servicing to replace seals, bearings, and other components. For companies aiming to minimize operational interruptions, Industrial Diaphragm Pumps provide a clear advantage.

Adaptability Across Industries

One of the strongest points in favor of Diaphragm Pumps is their adaptability. They are suitable for handling liquids of varying viscosity, solids-laden slurries, and corrosive chemicals. Whether in chemical manufacturing, food processing, or environmental protection projects, Diaphragm Pumps For Conveying Corrosive Materials provide reliable transfer solutions. Traditional pumps remain useful in standard water supply or low-risk applications, but for industries dealing with aggressive media, Corrosive Diaphragm Pumps often deliver more consistent performance.

Market analysts expect the demand for Industrial Diaphragm Pumps to continue growing as industries face stricter safety and environmental regulations. Companies are recognizing that investing in Diaphragm Pumps For Conveying Corrosive Materials not only reduces risks but also extends equipment lifespan. While traditional pumps will continue to serve in basic applications, the shift toward Corrosive Diaphragm Pumps is becoming more evident across multiple sectors.

The decision between Corrosive Diaphragm Pumps and traditional pumps depends on the specific needs of each operation. For industries dealing with aggressive chemicals, Diaphragm Pumps For Conveying Corrosive Materials offer significant advantages in safety, durability, and cost-effectiveness. As industrial requirements evolve, Industrial Diaphragm Pumps are expected to play a greater role in supporting efficient and secure operations.

English

English русский

русский Español

Español عربى

عربى