The Benefits of Using Diaphragm Pumps for Paint Transfer in Industrial Settings

2025.08.18

2025.08.18

Industry News

Industry News

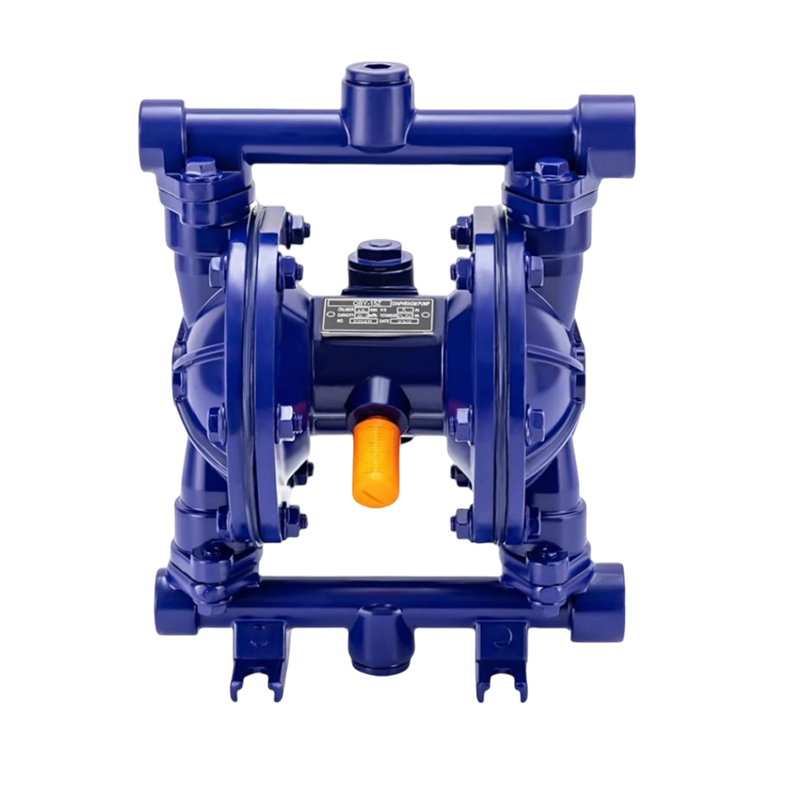

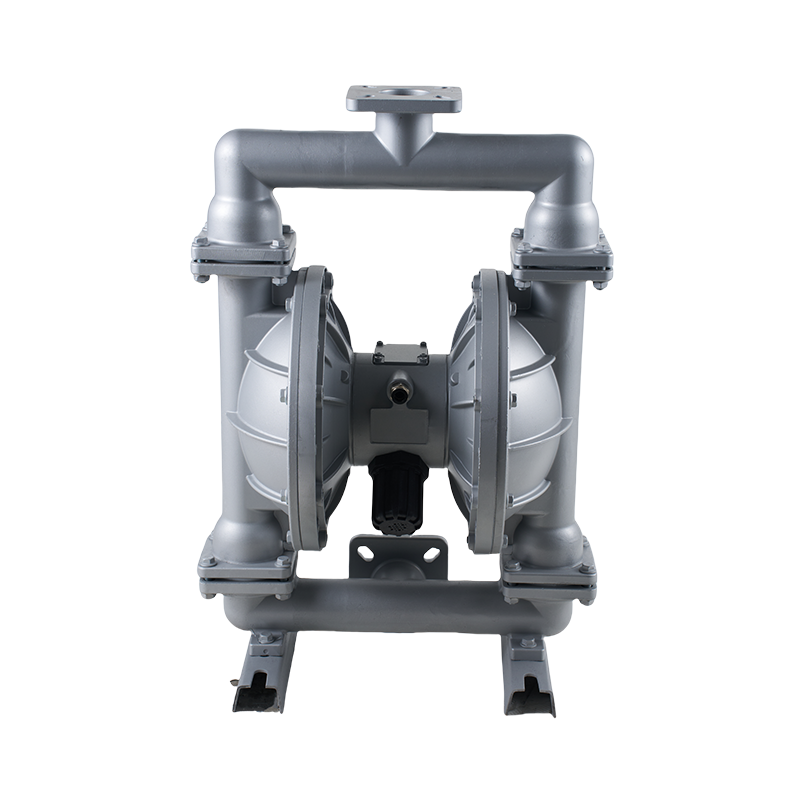

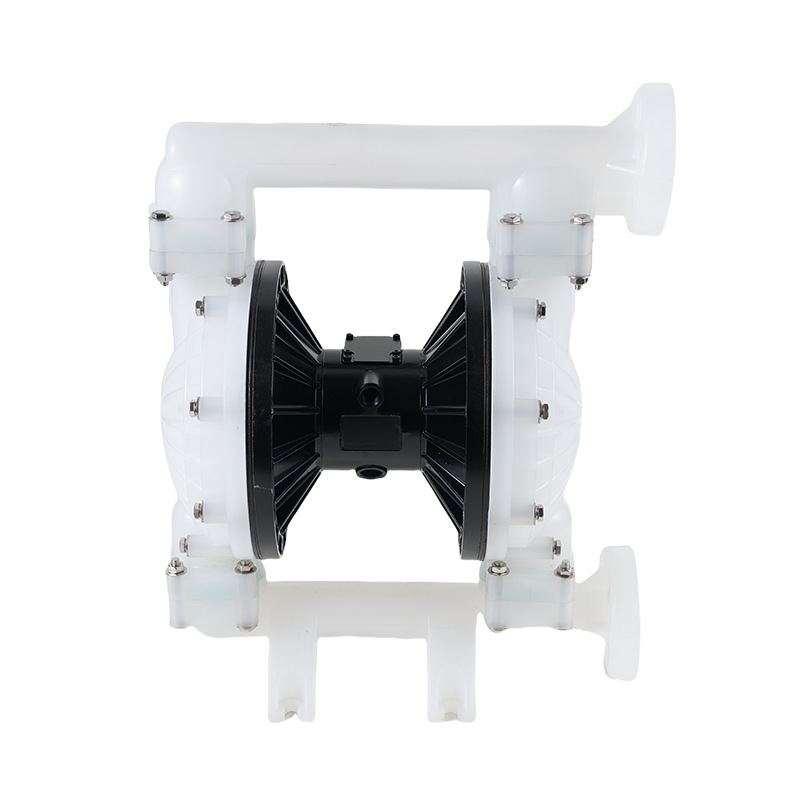

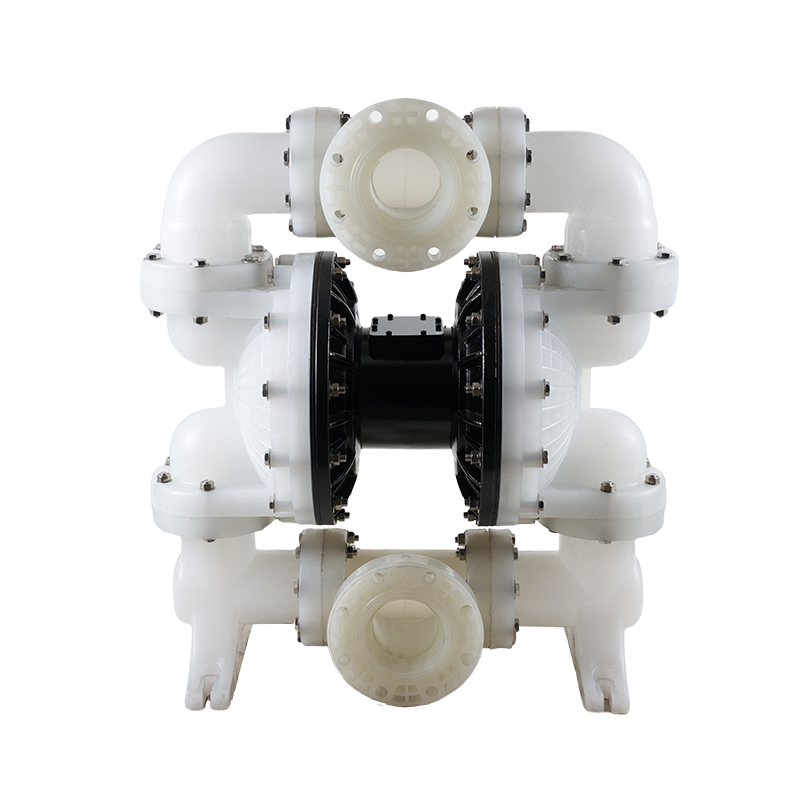

In the dynamic landscape of industrial manufacturing, the efficient and reliable transfer of materials is crucial for maintaining productivity and ensuring high-quality output. One such material that requires precise handling is paint. Diaphragm pumps have emerged as a choice for paint transfer applications, offering a host of benefits that make them indispensable in industrial settings.

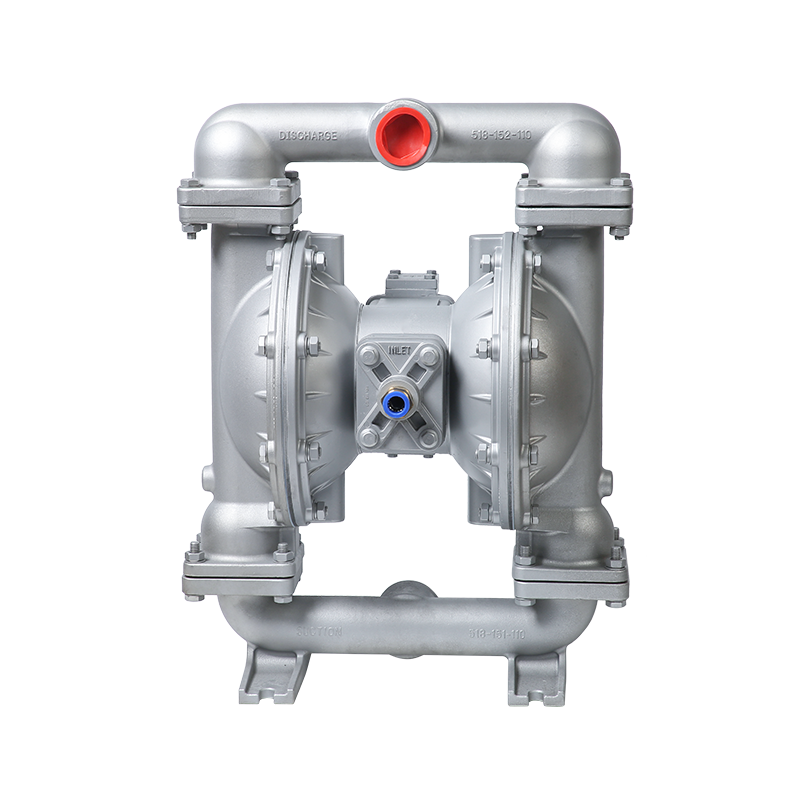

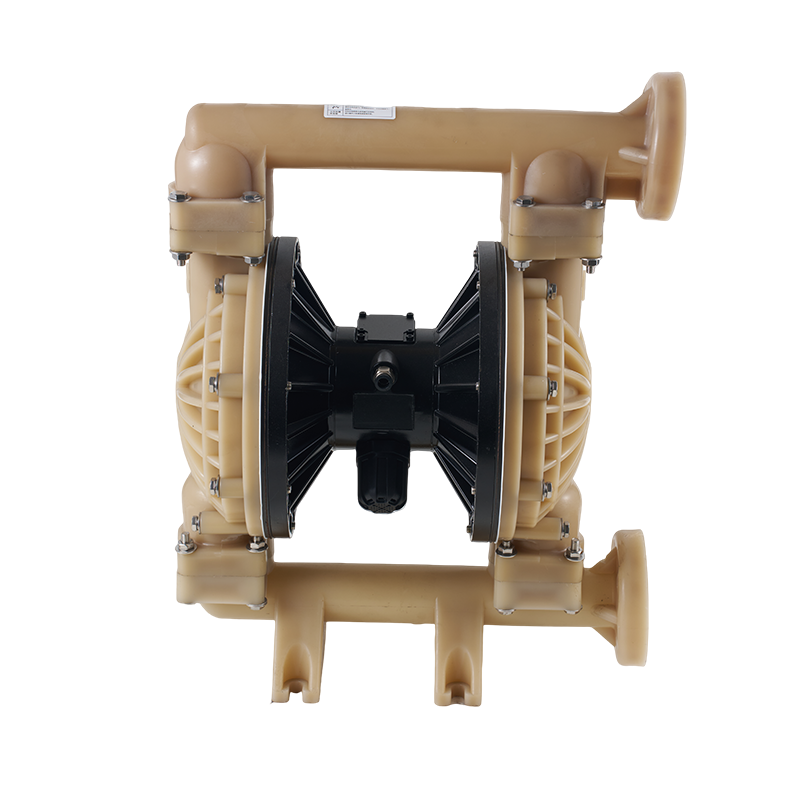

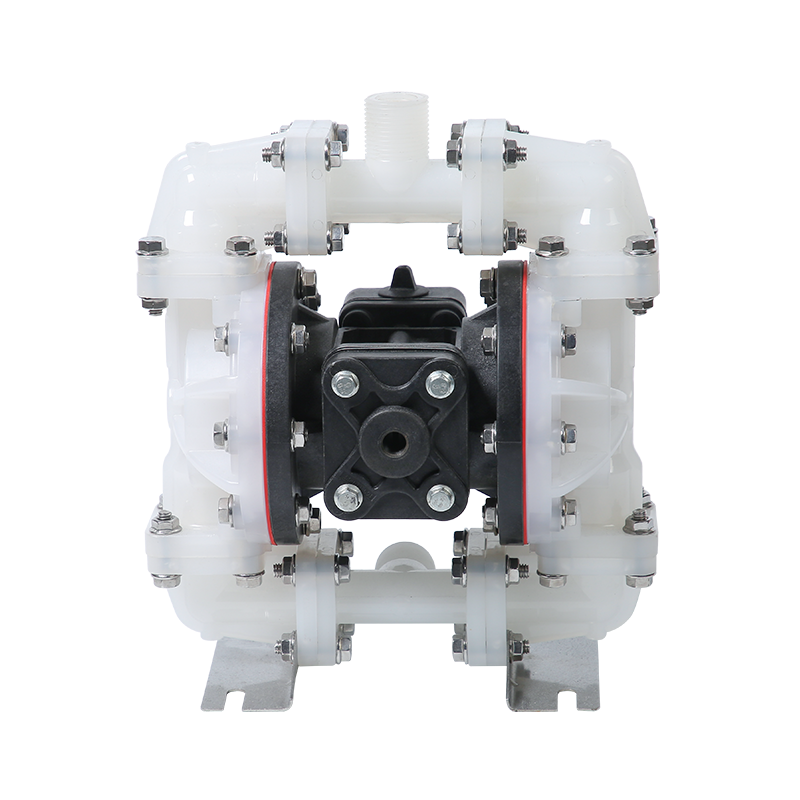

Diaphragm pumps are particularly well-suited for paint transfer due to their unique design and operational principles. These pumps utilize a flexible diaphragm that creates a vacuum and pressure differential to move fluids. This mechanism ensures that paint is transferred smoothly and consistently, without the risk of agitation or degradation that can occur with other types of pumps. The diaphragm pump's ability to handle viscous fluids like paint without compromising on performance makes it a preferred choice for many industries.

One of the primary advantages of using diaphragm pumps for paint transfer is their versatility. These pumps can handle a wide range of paint viscosities, from thin water-based paints to thick, high-viscosity coatings. This versatility is particularly important in industrial settings where different types of paints may be used for various applications. Whether it is a delicate automotive paint job or a robust industrial coating, diaphragm pumps can accommodate the specific requirements of each process.

Another significant benefit of diaphragm pumps is their ability to provide precise control over the paint transfer process. The pumps can be easily adjusted to deliver the exact amount of paint needed, ensuring consistent application and reducing waste. This level of control is essential in industries where the quality of the paint job is critical to the final product. For example, in the automotive industry, where a flawless finish is paramount, diaphragm pumps can help achieve the desired results by providing accurate and reliable paint transfer.

Diaphragm pumps are also known for their durability and low maintenance requirements. The design of these pumps minimizes the risk of wear and tear, ensuring long-term reliability. Unlike other types of pumps that may require frequent maintenance or replacement of parts, diaphragm pumps can operate for extended periods with minimal downtime. This durability not only saves time and resources but also reduces the overall cost of ownership, making diaphragm pumps a cost-effective solution for paint transfer in industrial settings.

In addition to their durability, diaphragm pumps offer safety features. They are designed to prevent leaks and spills, which is particularly important when handling paint. Paint spills can not only be costly to clean up but can also pose environmental and health risks. Diaphragm pumps' leak-proof design ensures that paint is transferred safely and efficiently, minimizing the risk of accidents and environmental contamination.

Furthermore, diaphragm pumps are capable of handling abrasive and corrosive materials, making them ideal for use with certain types of paint and coatings. Some industrial paints contain abrasive particles or corrosive chemicals that can damage other types of pumps. However, diaphragm pumps are constructed with materials that can withstand these harsh conditions, ensuring reliable performance and longevity.

The efficiency of diaphragm pumps is another key advantage. These pumps can transfer paint at high flow rates, significantly speeding up the production process. In industrial settings where time is of the essence, the ability to transfer paint quickly and efficiently can increase productivity and reduce times. This efficiency is particularly beneficial in large-scale manufacturing operations, where even a small improvement in the paint transfer process can result in substantial time and cost savings.

Moreover, diaphragm pumps are designed to be energy-efficient. They require less power to operate compared to other types of pumps, resulting in lower energy consumption and reduced operating costs. In an era where sustainability and energy efficiency are increasingly important, diaphragm pumps offer a solution that aligns with these goals. By reducing energy usage, industrial facilities can lower their carbon footprint and contribute to a more sustainable future.

Diaphragm pumps offer numerous benefits for paint transfer in industrial settings. Their versatility, precision, durability, safety features, efficiency, and energy efficiency make them an ideal choice for handling paint and other viscous materials. As industries continue to seek ways to improve productivity, reduce costs, and enhance sustainability, diaphragm pumps are poised to play a crucial role in the future of paint transfer operations. By investing in diaphragm pumps, industrial facilities can ensure reliable, efficient, and high-quality paint transfer processes that meet the demands of modern manufacturing.

English

English русский

русский Español

Español عربى

عربى