How Diaphragm Pumps Enhance Wastewater Treatment Efficiency?

2025.08.18

2025.08.18

Industry News

Industry News

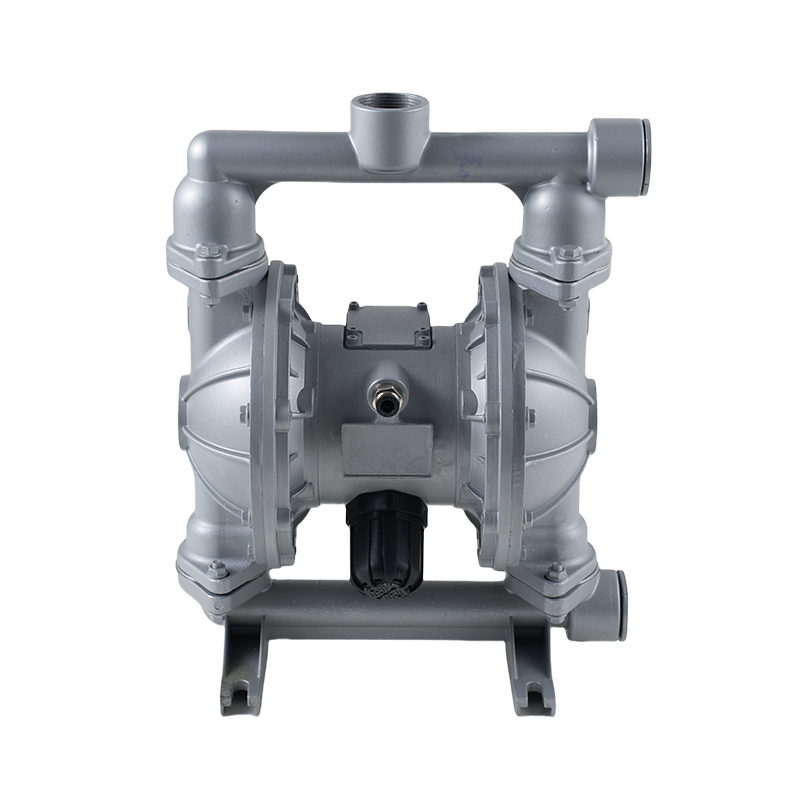

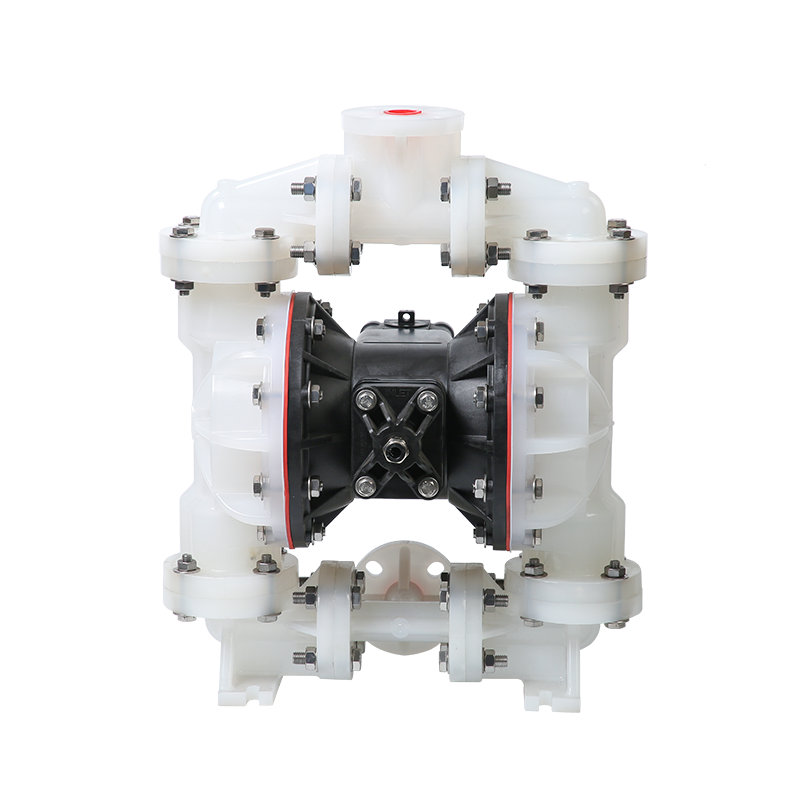

In the modern era of environmental consciousness, the efficiency and effectiveness of wastewater treatment processes have become critical concerns for municipalities and industries alike. One of the significant advancements in this field has been the integration of diaphragm pumps, specifically designed to handle the complex and often challenging demands of wastewater treatment. These pumps, known as diaphragm pumps for wastewater treatment, sludge transfer diaphragm pumps, and air operated water pumps, have revolutionized the way wastewater is processed, transferred, and treated. This article explores how these innovative pumps enhance wastewater treatment efficiency and contribute to more sustainable and effective water management practices.

The Role of Diaphragm Pumps in Wastewater Treatment

Diaphragm pumps for wastewater treatment are specifically engineered to handle the unique challenges posed by wastewater. Unlike traditional pumps, which may struggle with viscous or abrasive materials, diaphragm pumps are designed to transfer sludge, wastewater, and other challenging fluids with ease. Their operation is based on a positive displacement mechanism, which uses a flexible diaphragm to create suction and pressure, allowing for the efficient movement of fluids. This makes them ideal for use in wastewater treatment plants, where they can handle everything from raw sewage to treated effluent.

Handling Sludge Transfer with Precision

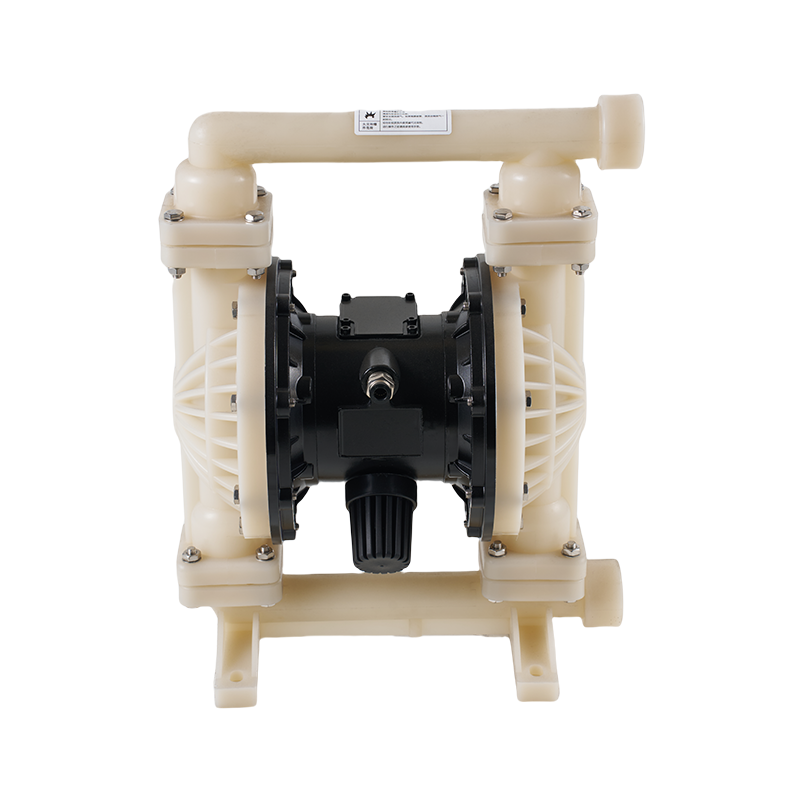

One of the critical applications of diaphragm pumps in wastewater treatment is the transfer of sludge. Sludge, a byproduct of the wastewater treatment process, is often thick, viscous, and abrasive, making it difficult to handle with conventional pumps. Sludge transfer diaphragm pumps, however, are specifically designed to move this challenging material efficiently. Their ability to handle high viscosity fluids without clogging or losing efficiency makes them indispensable in the sludge management process.

These pumps are also highly versatile, capable of operating at various flow rates and pressures, depending on the specific requirements of the treatment plant. This flexibility allows operators to optimize the sludge transfer process, ensuring that sludge is moved quickly and efficiently from one part of the plant to another. Additionally, the self-priming nature of diaphragm pumps means they can handle intermittent flow and varying sludge concentrations without the need for additional priming mechanisms.

Ensuring Reliable Water Transfer

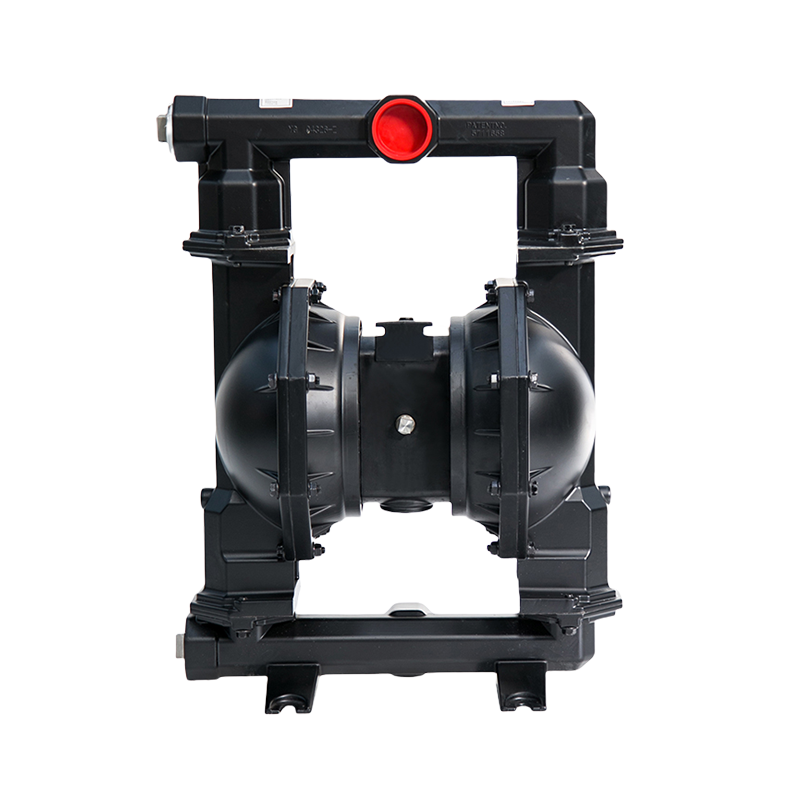

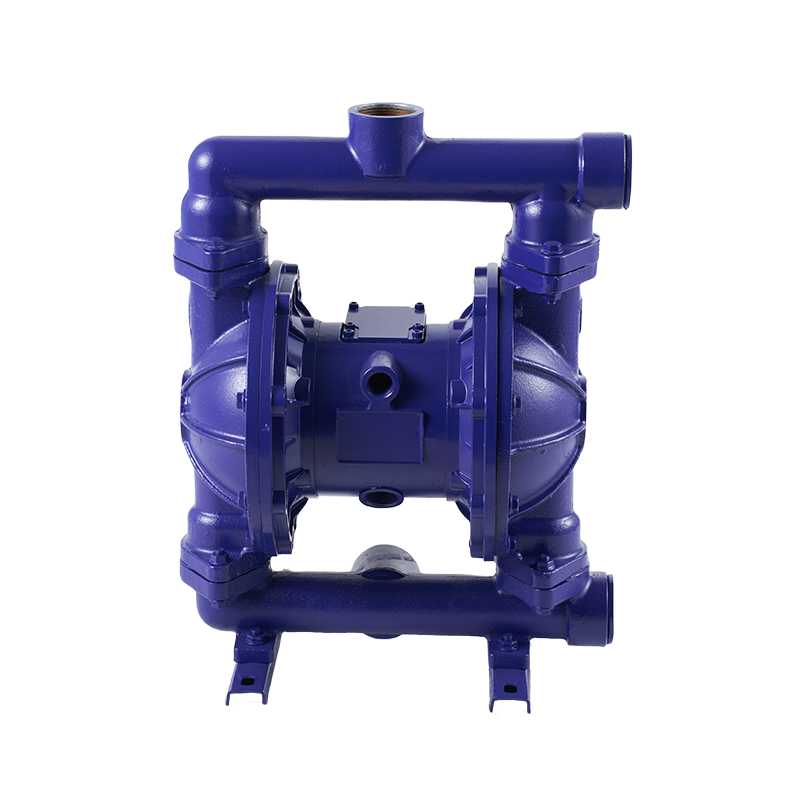

Air operated water pumps, another type of diaphragm pump, play a crucial role in the overall wastewater treatment process. These pumps are powered by compressed air, which provides a reliable and efficient means of transferring water and wastewater through the treatment plant. Unlike electric pumps, which can be prone to failure in wet environments, air operated water pumps are highly reliable and require minimal maintenance.

One of the key advantages of air operated water pumps is their ability to handle solids-laden water without clogging. This is particularly important in wastewater treatment plants, where the water often contains a variety of solid particles and debris. The positive displacement mechanism of these pumps ensures that even thick, solids-laden water can be transferred efficiently, reducing the risk of blockages and downtime.

Enhancing Energy Efficiency

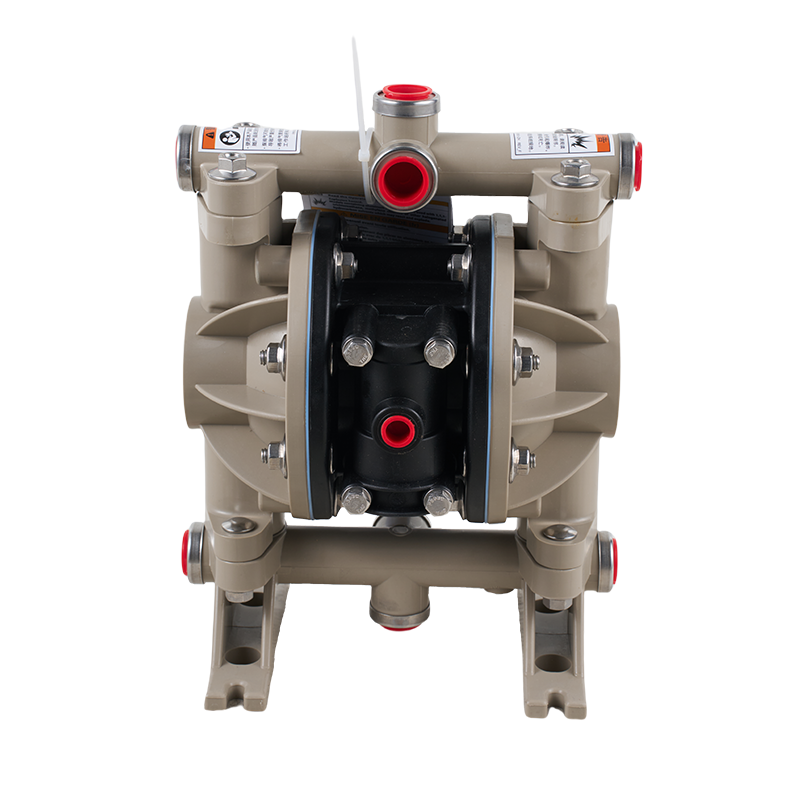

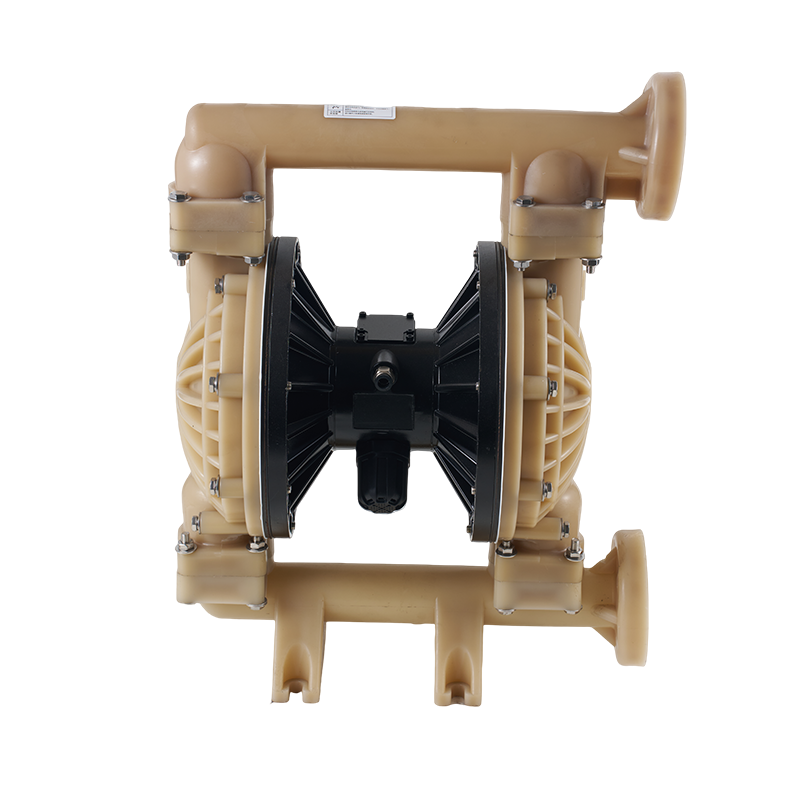

Diaphragm pumps are not only effective at handling challenging fluids but also offer significant energy savings compared to traditional pumping solutions. Their operation is highly efficient, with minimal energy loss during the pumping process. This is particularly important in wastewater treatment plants, where energy consumption can be a significant operational cost.

The use of compressed air to power diaphragm pumps also provides additional benefits. Compressed air systems can be easily integrated into existing plant infrastructure, and the pumps themselves are highly reliable, reducing the need for frequent maintenance and repairs. This translates to lower operational costs and a more sustainable wastewater treatment process.

Reducing Maintenance and Downtime

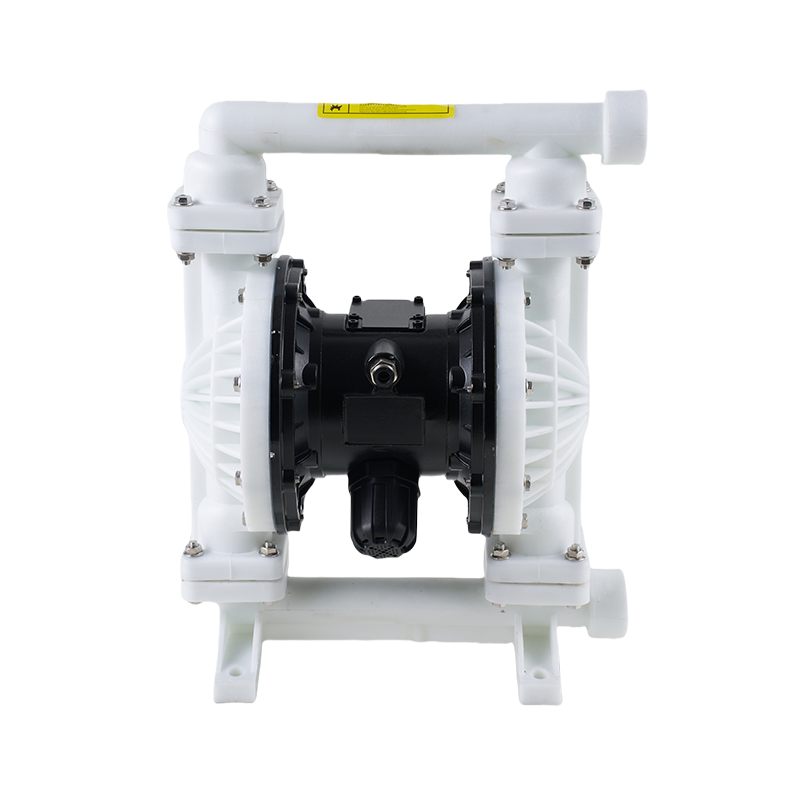

One of the significant advantages of diaphragm pumps for wastewater treatment is their low maintenance requirements. These pumps are designed to handle harsh operating conditions, including abrasive and corrosive materials, without significant wear and tear. This means that they require fewer repairs and replacements, reducing downtime and maintenance costs.

The self-priming nature of diaphragm pumps also contributes to their reliability. Unlike other types of pumps, which may require regular priming to function effectively, diaphragm pumps can operate without the need for additional priming mechanisms. This reduces the risk of operational errors and ensures that the pumps are always ready to function when needed.

Ensuring Environmental Compliance

In addition to their operational benefits, diaphragm pumps also contribute to environmental compliance in wastewater treatment plants. Their ability to handle hazardous and corrosive materials without leakage or spillage ensures that wastewater treatment processes meet the strictest environmental standards. This is particularly important in an era of increasing environmental regulation, where compliance with wastewater discharge standards is critical.

Diaphragm pumps for wastewater treatment, sludge transfer diaphragm pumps, and air operated water pumps have become essential tools in modern wastewater treatment plants. Their ability to handle challenging fluids, provide reliable and efficient operation, and reduce maintenance and downtime makes them indispensable in the wastewater treatment process. By integrating these innovative pumps into their operations, municipalities and industries can enhance their wastewater treatment efficiency, reduce operational costs, and ensure compliance with environmental regulations. As we continue to face growing environmental challenges, the role of diaphragm pumps in wastewater treatment will only become more critical in the years to come.

English

English русский

русский Español

Español عربى

عربى