Diaphragm Pumps Transforming Mining Operations with Viscous and Abrasive Fluids

2025.08.18

2025.08.18

Industry News

Industry News

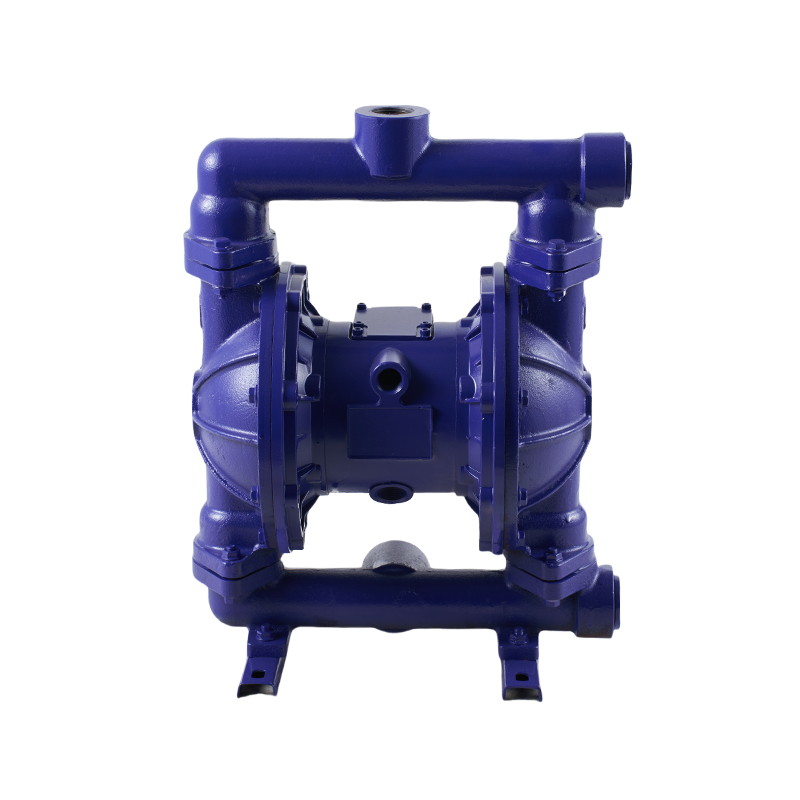

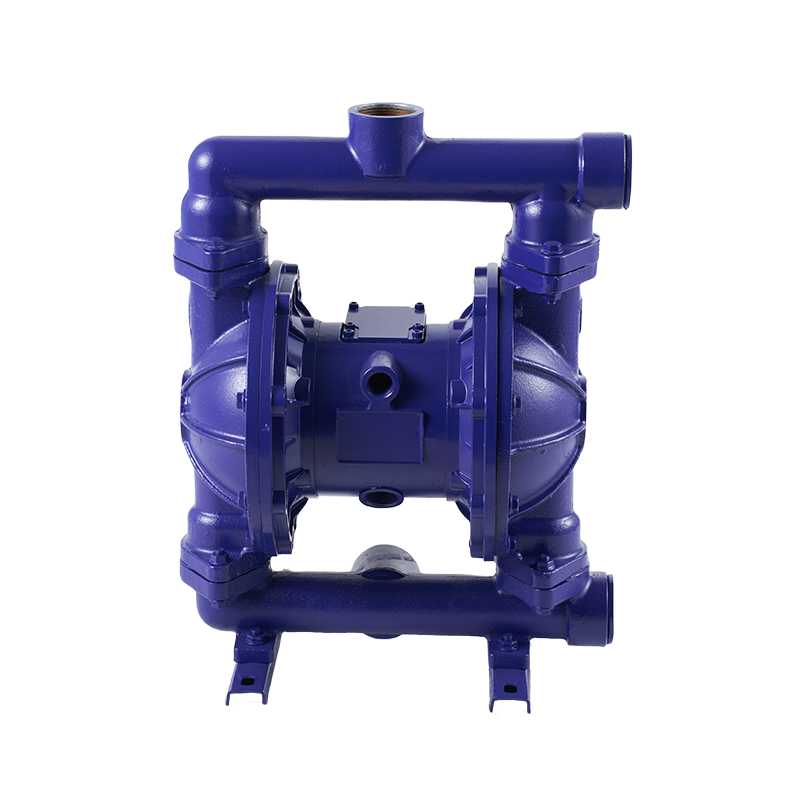

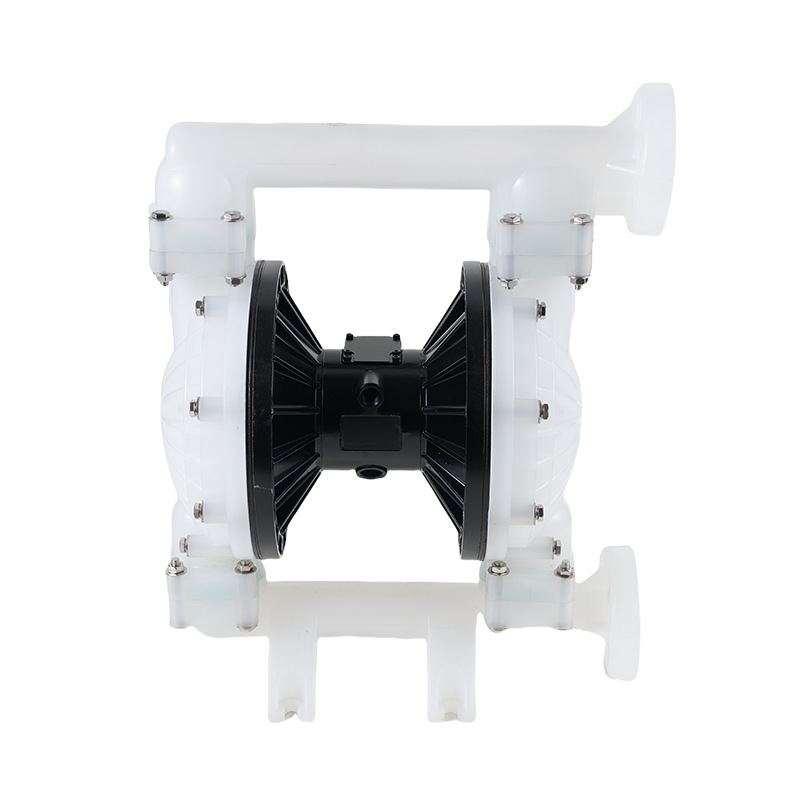

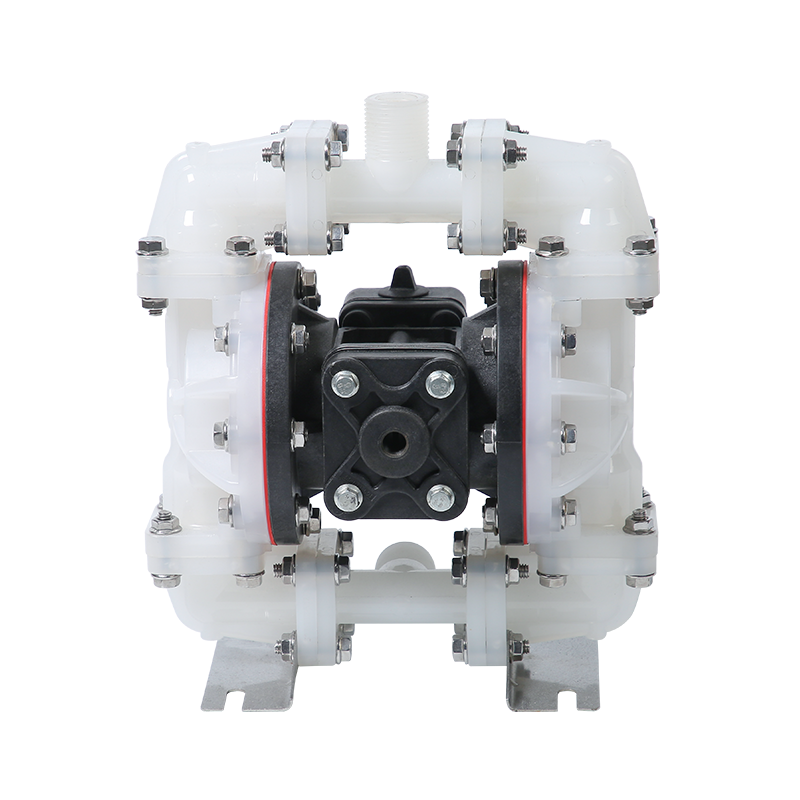

As mining companies strive to improve efficiency and reduce downtime, the use of specialized solutions such as the diaphragm pump for viscous fluids, the mining diaphragm pump, and the diaphragm pump for abrasive fluids has grown significantly.

The diaphragm pump for viscous fluids offers a practical answer to one of the persistent challenges: the movement of thick slurries, concentrated mineral mixtures, and other dense substances. Unlike centrifugal pumps, which often lose efficiency or suffer mechanical wear when dealing with heavy materials, diaphragm pumps rely on a flexible membrane to displace the fluid. This method ensures consistent flow rates and minimal shear, preserving the quality of the material being transported. In operations where viscous concentrates need to be moved over long distances, these pumps provide a dependable and low-maintenance solution.

Equally important in the mining sector is the mining diaphragm pump, designed to operate under demanding field conditions. Dust, temperature fluctuations, and irregular power supplies can quickly compromise standard pumping systems. However, mining diaphragm pumps are engineered to deliver stable performance even in remote, rugged environments. They are commonly deployed for dewatering tasks, transferring mineral slurries, and managing waste streams. With proper selection and maintenance, a mining diaphragm pump can offer years of reliable service, reducing the need for frequent replacements or costly repairs.

When it comes to handling harsh, particle-laden liquids, the diaphragm pump for abrasive fluids stands out as a critical tool. Mining processes often involve fluids containing sand, crushed rock, and other abrasive particles that can cause severe wear in ordinary pumps. The design of the diaphragm pump for abrasive fluids minimizes direct contact between moving parts and the material being pumped, significantly reducing wear rates. This extends the operational lifespan of the pump while maintaining consistent throughput.

The combined benefits of these specialized pumps are transforming the way mining operations approach fluid management. A diaphragm pump for viscous fluids enables the smooth transfer of thick mixtures without excessive energy consumption. The mining diaphragm pump provides rugged reliability in challenging conditions, while the diaphragm pump for abrasive fluids ensures long-term durability when working with highly abrasive slurries. By integrating these solutions into their operations, mining companies can improve efficiency, reduce downtime, and extend equipment lifespans.

Industry experts note that the versatility of diaphragm pumps also adds to their value. A single unit can often handle both viscous and abrasive fluids with minimal modification, making it possible for operators to adapt quickly to changing process requirements. This flexibility is particularly important in mining, where ore composition, moisture content, and production demands can shift from week to week. The ability to use the same mining diaphragm pump for multiple fluid types reduces the need for additional equipment and simplifies maintenance routines.

As the mining sector continues to adopt more sustainable and cost-efficient practices, the role of the diaphragm pump for viscous fluids, the mining diaphragm pump, and the diaphragm pump for abrasive fluids is expected to expand. Innovations in diaphragm materials, pump geometry, and drive systems are further enhancing their performance, enabling them to handle even more challenging applications. From underground operations to open-pit sites, these pumps are proving to be a reliable backbone of fluid transfer systems in modern mining.

Diaphragm pumps are not just supporting mining operations—they are reshaping them. Whether moving thick mineral slurries, coping with abrasive mixtures, or operating in demanding conditions, the diaphragm pump for viscous fluids, the mining diaphragm pump, and the diaphragm pump for abrasive fluids are setting new benchmarks for durability, efficiency, and adaptability. With their proven performance and ongoing technological advancements, these pumps are well-positioned to remain at the forefront of mining fluid management for years to come.

English

English русский

русский Español

Español عربى

عربى