How Do Diaphragm Slurry Pumps Handle Abrasive Materials with Ease?

2025.08.18

2025.08.18

Industry News

Industry News

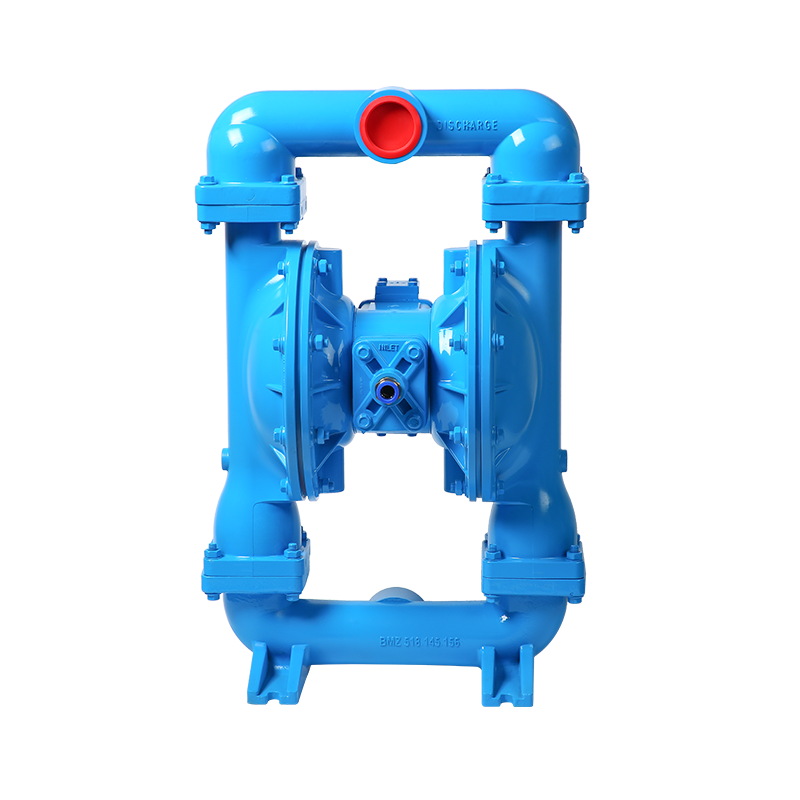

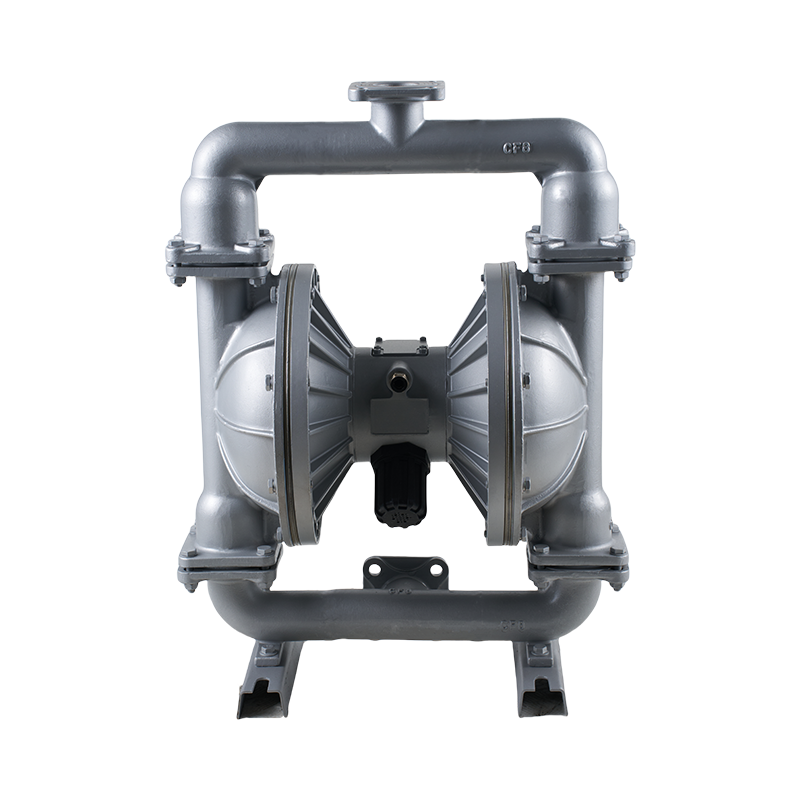

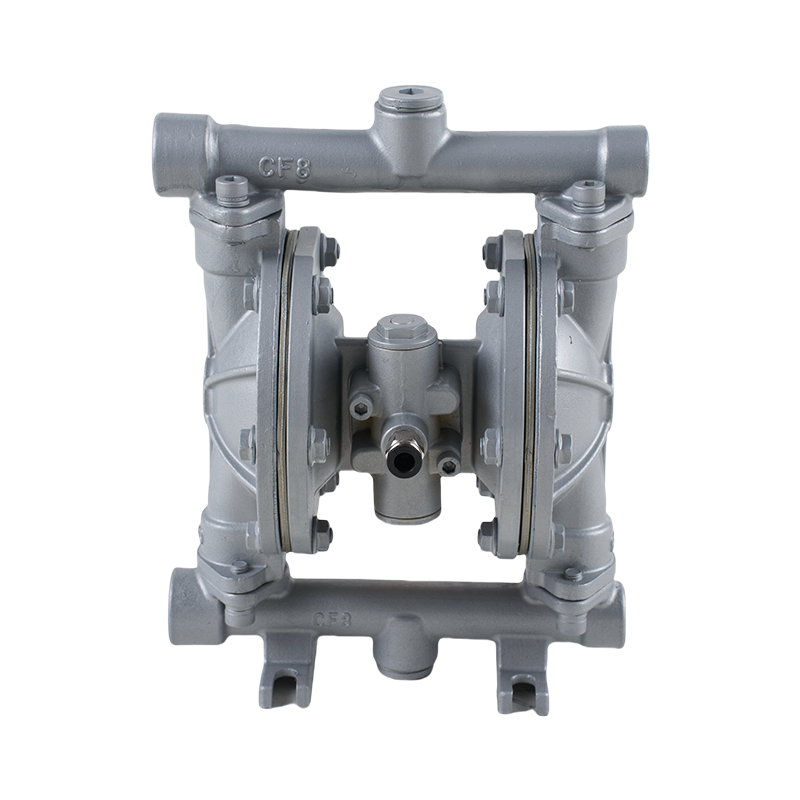

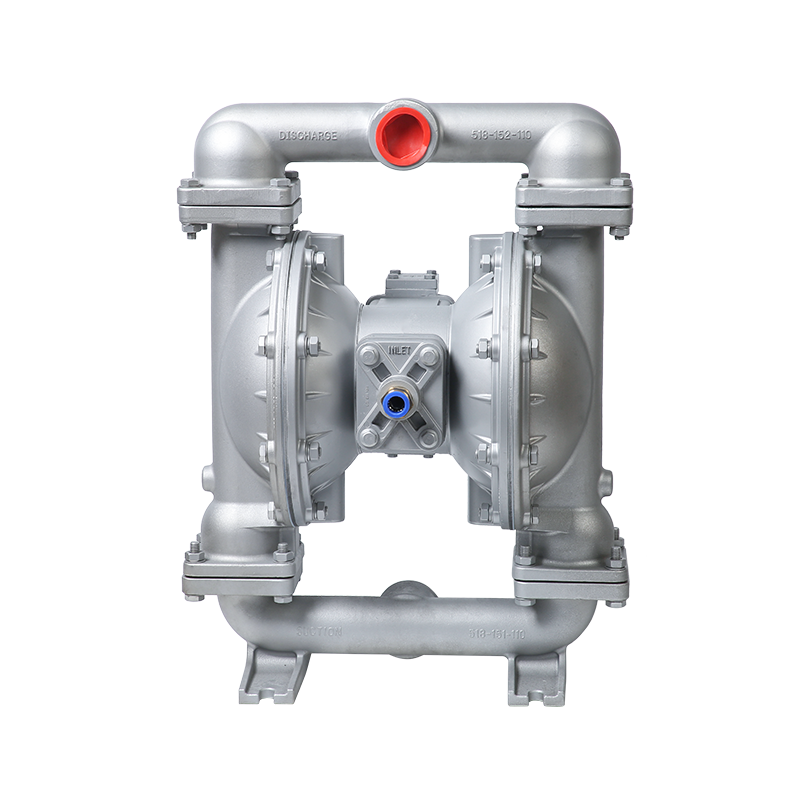

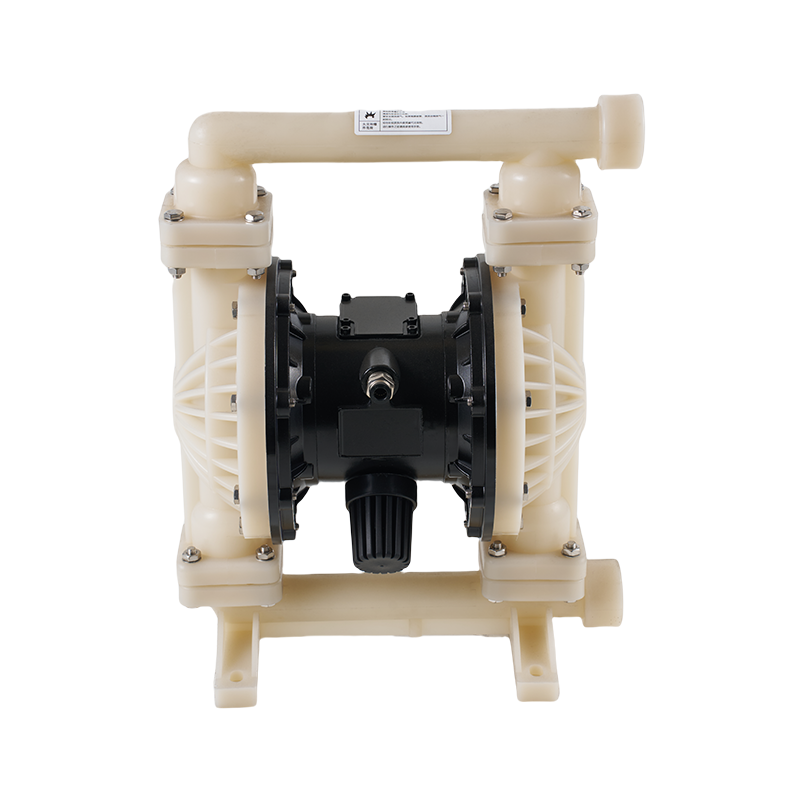

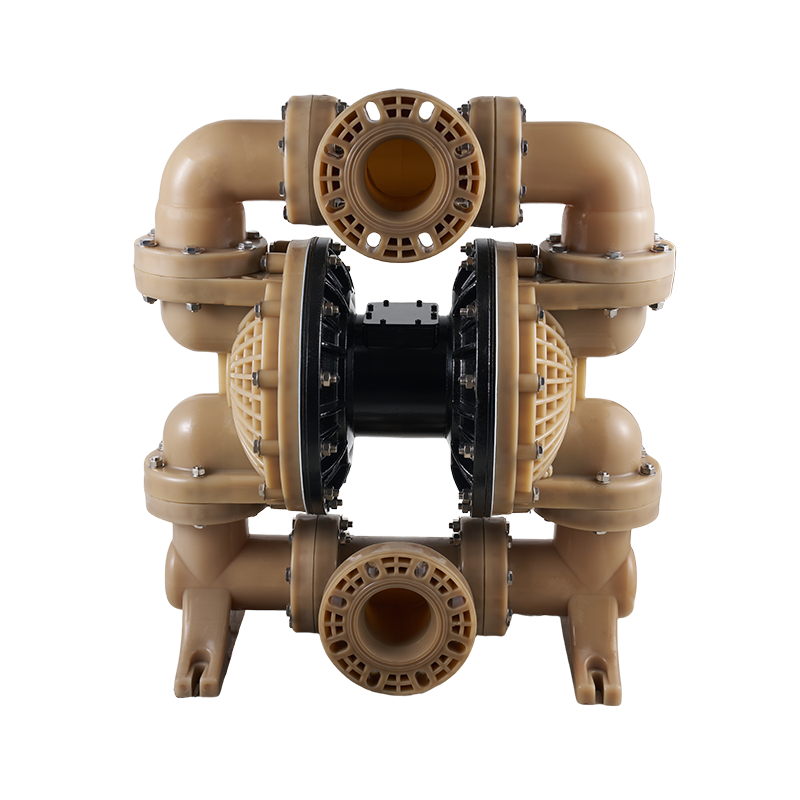

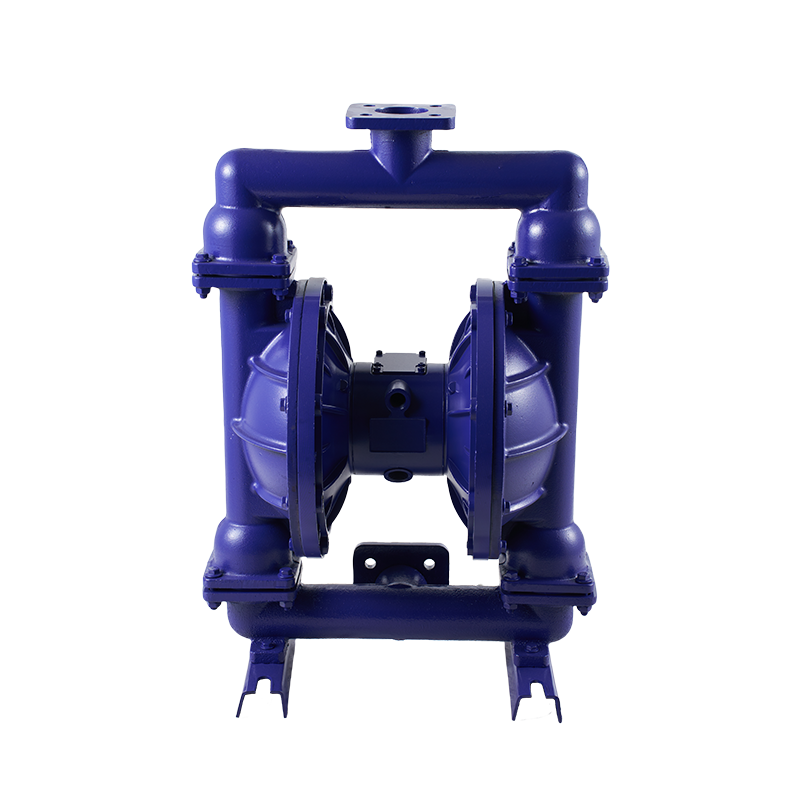

In the world of industrial pumping, handling abrasive materials is a formidable challenge. However, diaphragm slurry pumps have emerged as a reliable solution, demonstrating remarkable capabilities in managing these harsh substances. These pumps are specifically designed to transport abrasive slurries, tailings, and other challenging materials with ease, making them indispensable in various industries such as mining, mineral processing, and wastewater treatment.

Diaphragm slurry pumps are engineered to withstand the rigors of abrasive materials. Unlike traditional centrifugal pumps, which can suffer from rapid wear and tear when handling abrasive slurries, diaphragm pumps utilize a flexible diaphragm to create a positive displacement action. This mechanism ensures that the abrasive materials are moved efficiently without causing excessive wear to the pump's internal components. The diaphragm acts as a barrier, preventing direct contact between the abrasive slurry and the pump's vital parts, thereby extending the pump's service life.

One of the key advantages of diaphragm slurry pumps is their ability to handle high concentrations of solids. In industries like mining, where tailings often contain a significant amount of abrasive particles, these pumps can operate without clogging or losing efficiency. The unique design of the diaphragm allows for a consistent flow rate, even when the slurry is thick and viscous. This makes diaphragm pumps for tailings an ideal choice for applications where the material being pumped is highly abrasive and difficult to manage.

Moreover, diaphragm slurry pumps offer unparalleled versatility. They can handle a wide range of materials, from fine powders to coarse slurries, making them suitable for various industrial processes. In addition to their ability to transport abrasive materials, these pumps can also handle corrosive substances, thanks to their construction from durable materials such as stainless steel and other corrosion-resistant alloys. This versatility ensures that diaphragm slurry pumps can meet the diverse needs of different industries, providing a reliable and efficient pumping solution.

Safety is another critical aspect of diaphragm slurry pumps. In environments where there is a risk of explosion due to the presence of flammable gases or dust, explosion-proof diaphragm pumps are available. These pumps are designed to meet stringent safety standards, ensuring that they can operate safely in hazardous areas. The explosion-proof diaphragm pump is equipped with special features such as flameproof enclosures and spark-resistant materials, which prevent the ignition of flammable substances. This makes them an essential tool in industries like chemical processing and oil and gas, where safety is of importance.

The maintenance requirements of diaphragm slurry pumps are also relatively low compared to other types of pumps. The diaphragm itself is the only moving part that comes into contact with the abrasive material, reducing the number of components that need regular replacement. This not only lowers maintenance costs but also minimizes downtime, ensuring that industrial operations can continue smoothly. Additionally, the diaphragm can be easily replaced when worn out, without the need for extensive disassembly of the pump.

In terms of efficiency, diaphragm slurry pumps are designed to deliver consistent performance. The positive displacement action ensures that the pump can maintain a steady flow rate, even when the pressure varies. This is particularly important when handling abrasive materials, as fluctuations in flow rate can to uneven wear and reduced efficiency. The ability to maintain a constant flow rate also makes diaphragm slurry pumps suitable for applications where precise control over the pumping process is required.

The environmental impact of diaphragm slurry pumps is also worth noting. These pumps are designed to minimize the release of abrasive materials into the environment. The enclosed design of the pump ensures that the slurry is contained within the pump's chamber, reducing the risk of spillage and contamination. This is particularly important in industries where environmental regulations are strict and the safe handling of abrasive materials is a priority.

Diaphragm slurry pumps have proven to be highly effective in handling abrasive materials. Their unique design, versatility, safety features, and low maintenance requirements make them an ideal choice for a wide range of industrial applications. Whether it is transporting tailings in the mining industry, handling corrosive slurries in chemical processing, or ensuring safe operations in hazardous environments, diaphragm slurry pumps offer a reliable and efficient solution. As industries continue to face the challenges of handling abrasive materials, diaphragm slurry pumps will undoubtedly remain a crucial component in ensuring smooth and efficient operations.

English

English русский

русский Español

Español عربى

عربى