How Air Diaphragm Pump Manufacturers Tackle High Viscosity Challenges?

2025.08.18

2025.08.18

Industry News

Industry News

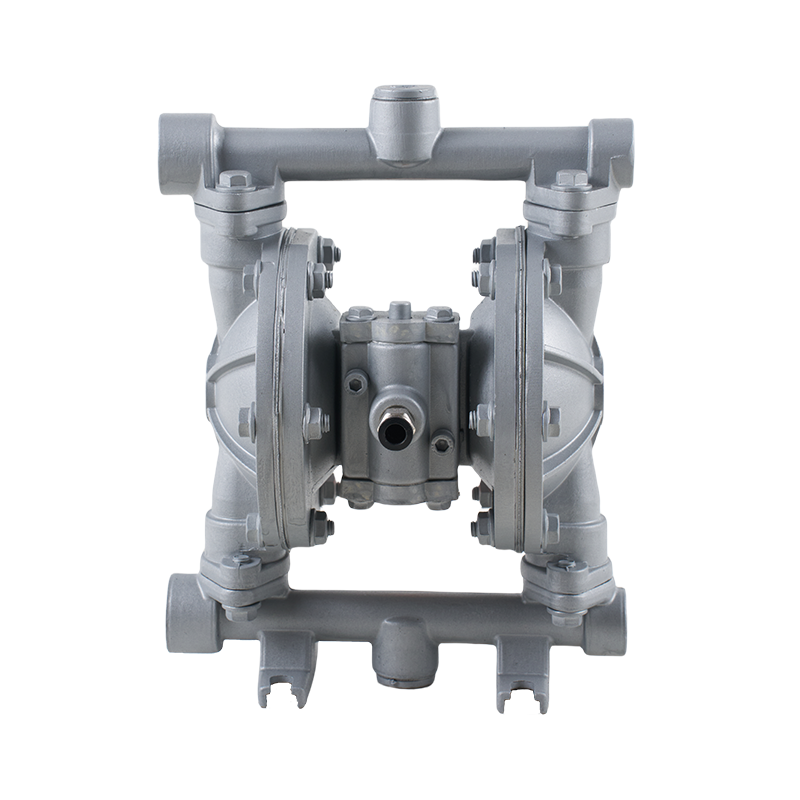

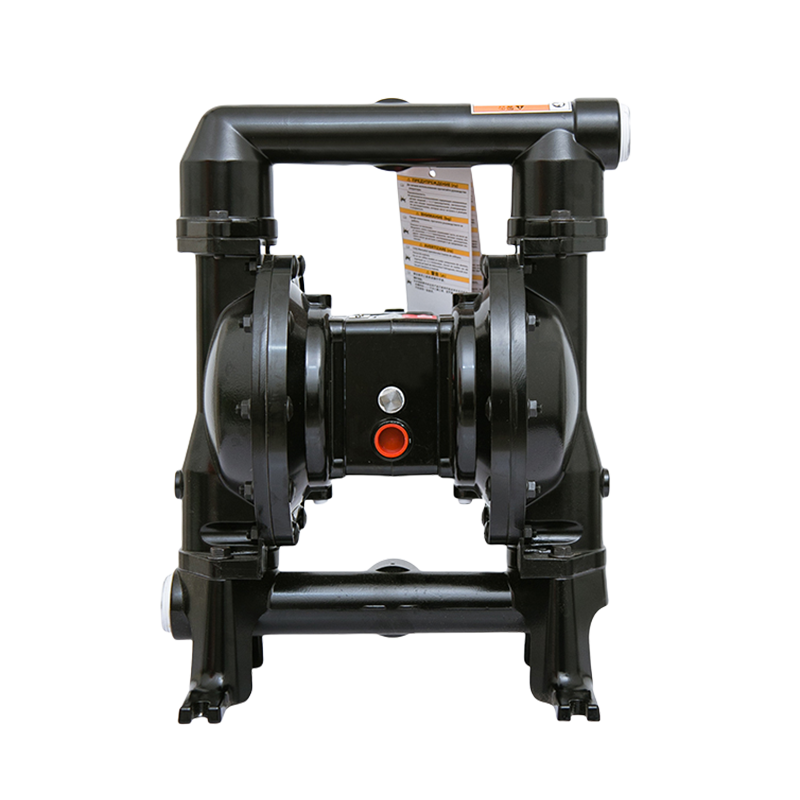

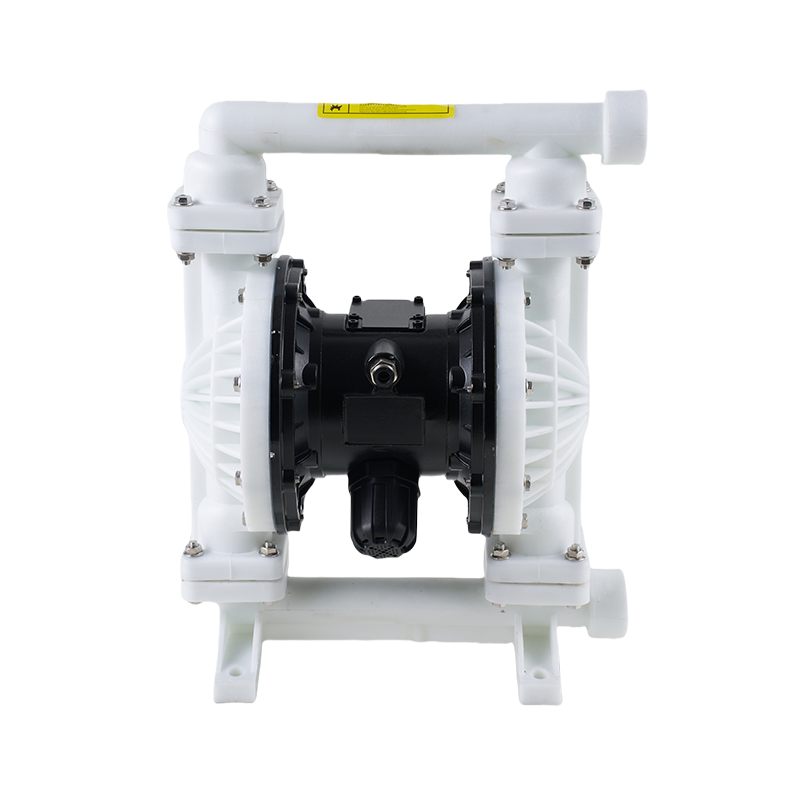

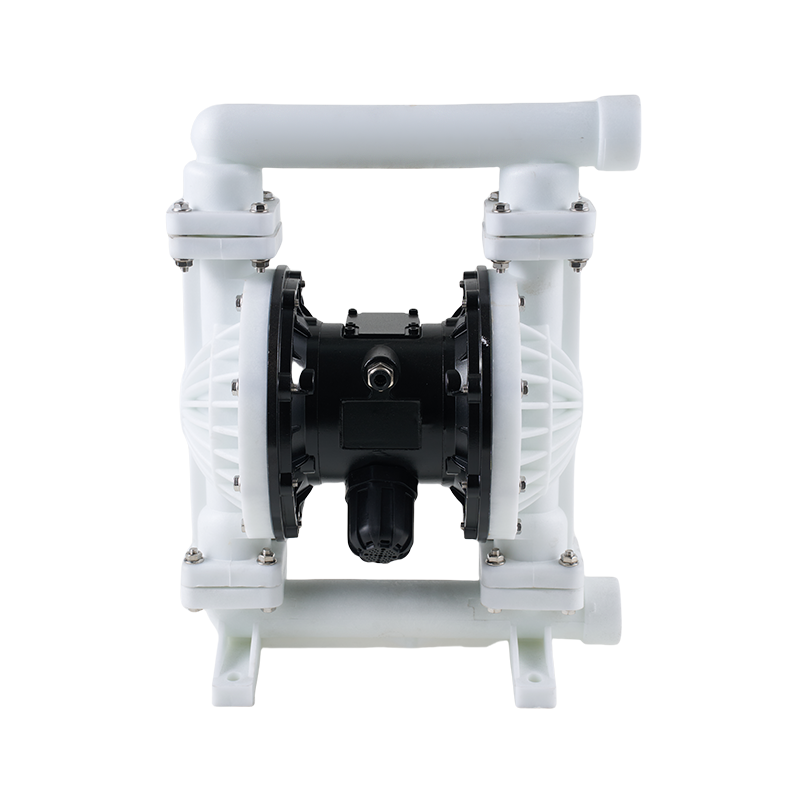

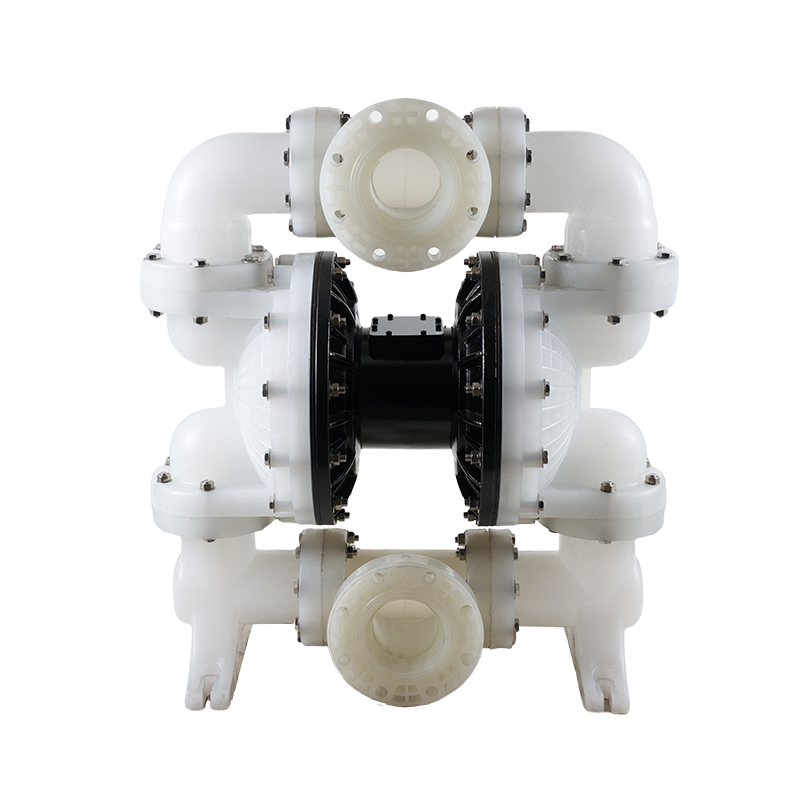

In the ever-evolving industrial landscape, the demand for efficient fluid transfer solutions continues to rise. Among the myriad of pumping technologies available, air diaphragm pumps have emerged as a versatile and reliable choice for a wide range of applications. However, when it comes to handling high-viscosity fluids, air diaphragm pump manufacturers face a unique set of challenges. This article delves into the innovative strategies and advancements employed by these manufacturers to tackle the complexities associated with high-viscosity pumping.

High-viscosity fluids, such as slurries, pastes, and thick oils, pose significant challenges for conventional pumping systems. These fluids tend to exhibit non-Newtonian behavior, meaning their flow characteristics change under different shear rates. Traditional pumps often struggle to maintain consistent flow rates and may suffer from increased wear and tear due to the sheer effort required to move such viscous materials. Air diaphragm pumps, however, have proven to be particularly well-suited for these demanding applications, thanks to their unique design and operational principles.

One of the primary advantages of air diaphragm pumps is their ability to handle a wide range of viscosities without significant modifications. Unlike centrifugal pumps, which rely on rotational speed to generate flow, air diaphragm pumps use a positive displacement mechanism. This allows them to maintain a relatively constant flow rate regardless of the fluid's viscosity. High-viscosity fluids can be pumped with ease, as the diaphragm's reciprocating motion creates a suction and discharge action that effectively moves the material through the pump.

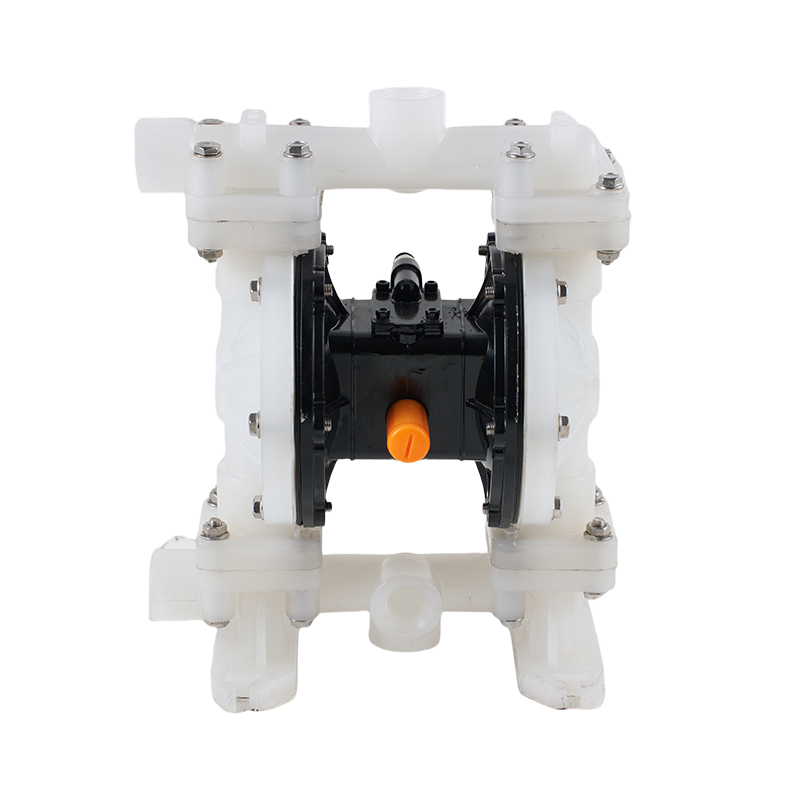

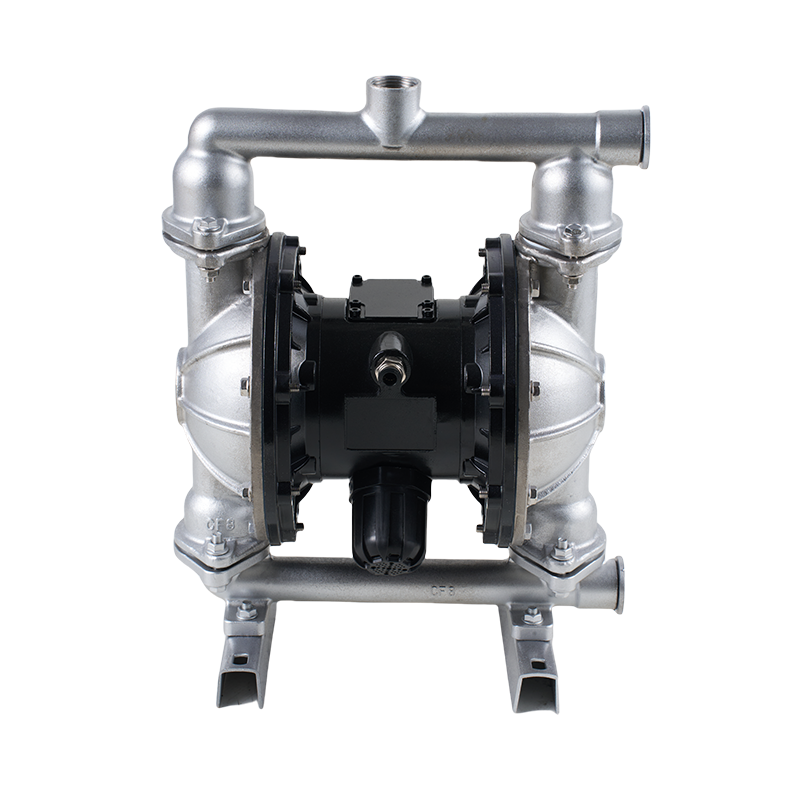

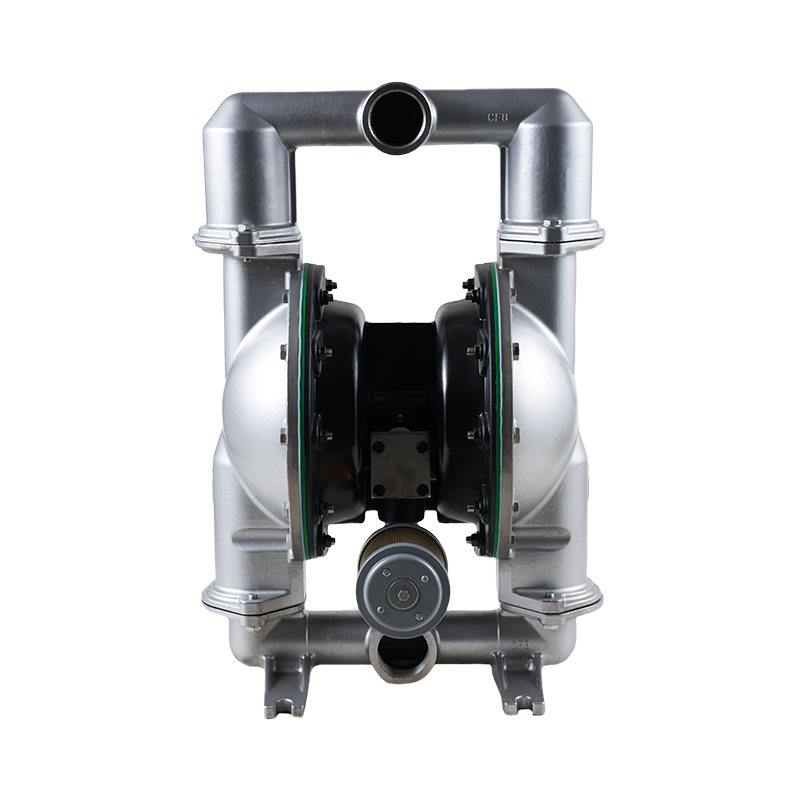

Air diaphragm pump manufacturers have been at the forefront of innovation, continuously enhancing their products to better address the challenges posed by high-viscosity fluids. One notable advancement is the development of specialized diaphragm materials. These materials are designed to withstand the mechanical stresses associated with pumping viscous fluids while maintaining flexibility and durability. By using advanced polymer composites and elastomers, manufacturers have been able to extend the service life of their pumps, reducing maintenance costs and downtime for end-users.

Another critical aspect of tackling high-viscosity challenges is optimizing the pump's internal geometry. High-viscosity fluids require a larger pumping chamber and wider passages to minimize resistance and ensure smooth flow. Air diaphragm pump manufacturers have redesigned their pump internals to accommodate these requirements. Wider ball valves and larger-diameter diaphragms are now common features in pumps designed for viscous applications. These modifications not only improve flow efficiency but also reduce the risk of clogging, a common issue when dealing with thick fluids.

In addition to material and design improvements, air diaphragm pump manufacturers are also focusing on enhancing the control systems of their pumps. High-viscosity fluids often require precise control over flow rates and pressures to prevent overpressurization and ensure consistent output. Modern air diaphragm pumps are equipped with advanced pressure-relief valves and flow-control mechanisms that can be easily adjusted to match the specific requirements of the application. This level of control is particularly important in industries such as chemical processing, pharmaceuticals, and food manufacturing, where precise fluid handling is crucial.

Moreover, the energy efficiency of air diaphragm pumps has become a key focus for manufacturers. Handling high-viscosity fluids can be energy-intensive, but recent advancements in pump technology have led to significant improvements in this area. By optimizing the air consumption patterns and incorporating energy-saving features, air diaphragm pumps can now operate more efficiently while maintaining their performance capabilities. This not only reduces operating costs for end-users but also contributes to a more sustainable industrial environment.

The versatility of air diaphragm pumps is another factor that has contributed to their success in high-viscosity applications. These pumps can be easily configured to meet the specific needs of different industries. For example, in the mining sector, air-diaphragm pumps are used to transfer thick slurries from processing plants to tailings dams. In the food industry, they are employed to pump viscous sauces and pastes without compromising the product's quality. The ability to handle both abrasive and shear-sensitive materials makes air diaphragm pumps an ideal choice for a wide range of applications.

Air diaphragm pump manufacturers have made significant strides in addressing the challenges associated with high-viscosity fluids. Through innovative material science, optimized design, advanced control systems, and a focus on energy efficiency, these manufacturers have developed pumps that can handle the demanding viscous applications with ease. As industries continue to evolve and demand more efficient fluid-handling solutions, air diaphragm pumps are well-positioned to meet these needs. Their reliability, versatility, and adaptability make them a preferred choice for tackling high-viscosity challenges in today's dynamic industrial environment.

English

English русский

русский Español

Español عربى

عربى