How to Choose the Right Air Actuated Diaphragm Pump for Your Application?

2025.08.18

2025.08.18

Industry News

Industry News

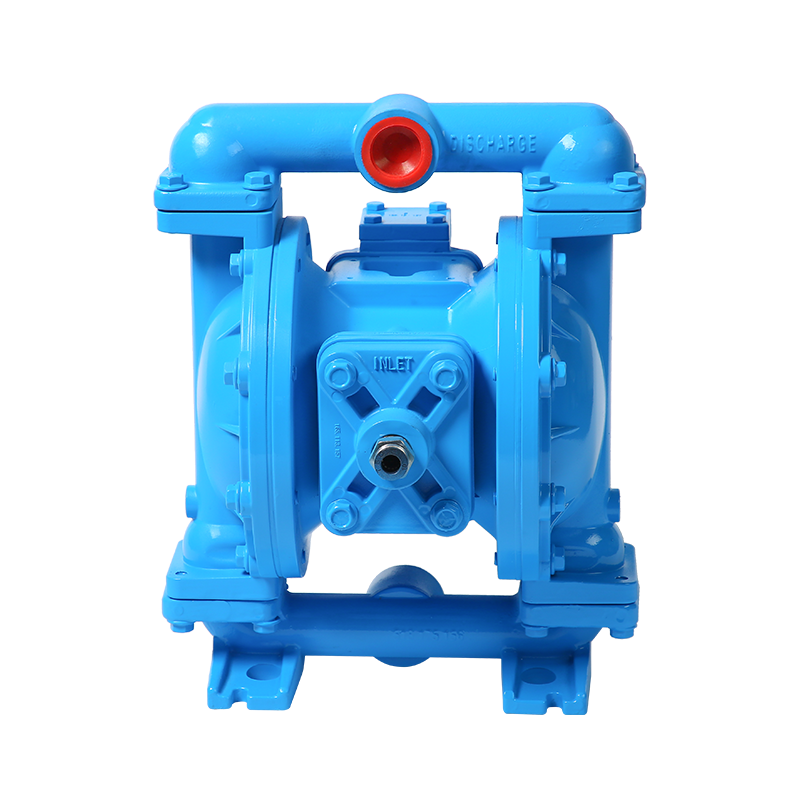

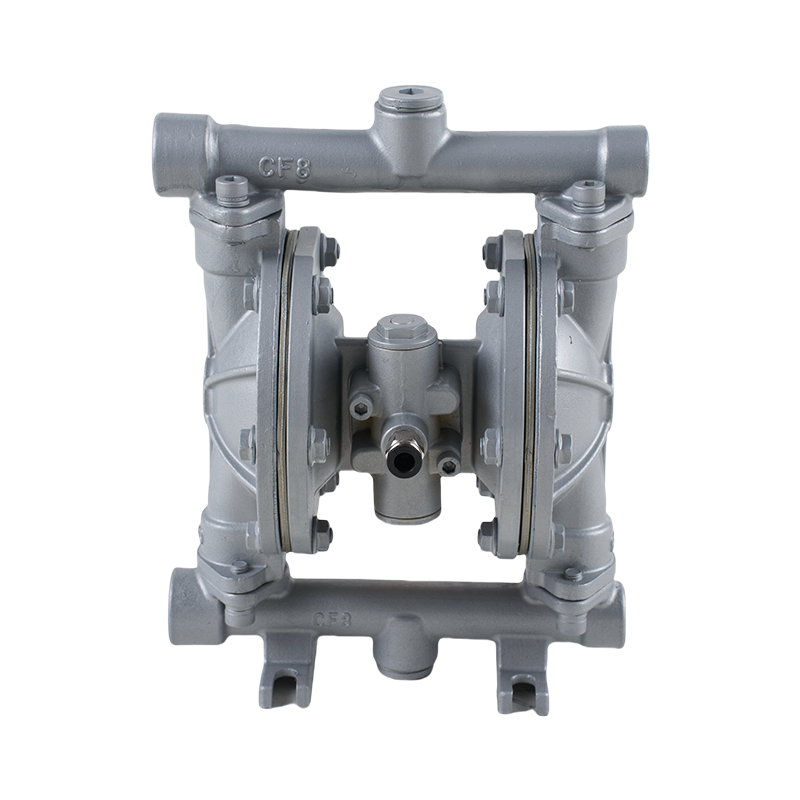

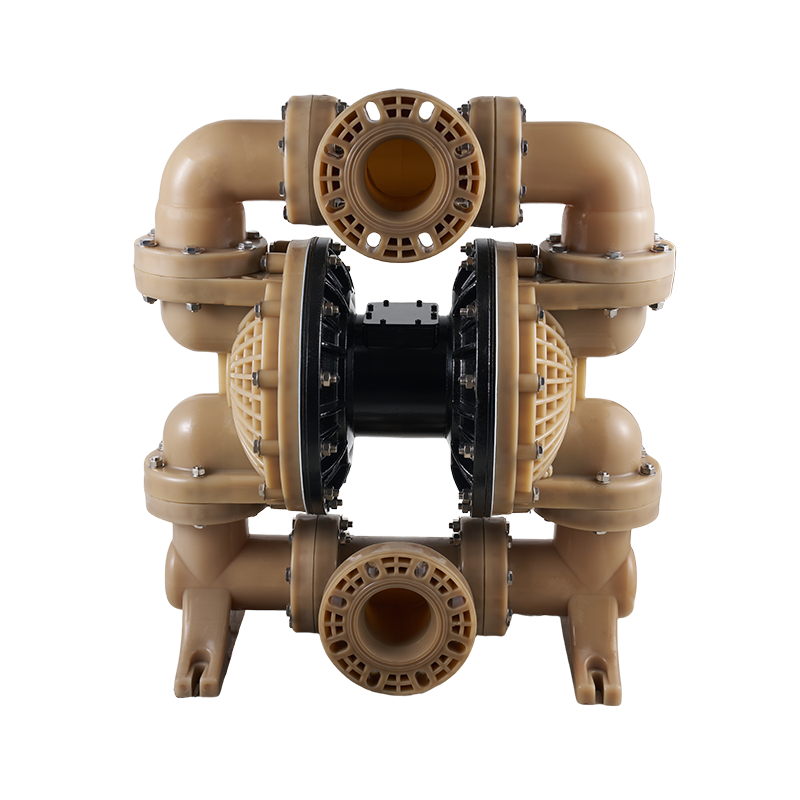

Selecting the right pump for an industrial or commercial process is a critical decision that affects efficiency, product quality, and maintenance costs. Among the many options available, the Air Actuated Diaphragm Pump has become a popular choice due to its versatility and durability. Whether handling chemicals, viscous fluids, or delicate products, understanding the essential features of an Air Actuated Diaphragm Pump will help you make the right decision.

An Air Actuated Diaphragm Pump operates using compressed air instead of electricity, making it suitable for environments where electrical equipment might pose risks. This design allows the pump to handle corrosive, abrasive, or temperature-sensitive fluids without damaging the motor. The ability to run dry without damage is another significant advantage, giving the Air Actuated Diaphragm Pump an edge in processes where flow conditions may change unexpectedly.

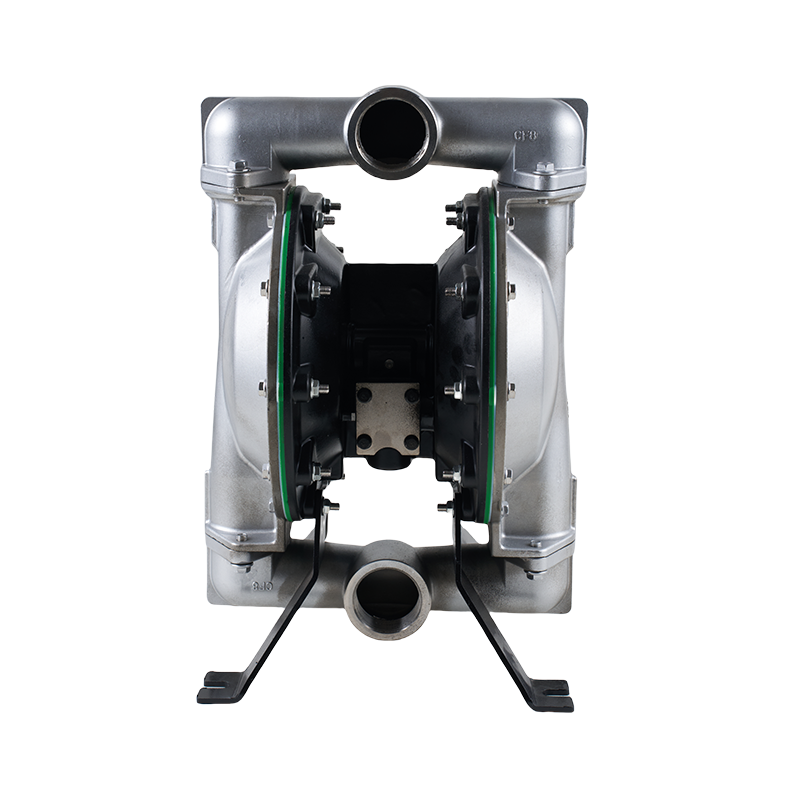

When evaluating an Air Actuated Diaphragm Pump, consider the materials used in the diaphragms and housings. For example, chemical applications may require PTFE diaphragms, while food processing often benefits from stainless steel components. This is where the Sanitary Diaphragm Pump comes into focus. Designed to meet hygiene and safety standards, the Sanitary Diaphragm Pump is ideal for food, beverage, and pharmaceutical applications. Its smooth surfaces, easy disassembly, and clean-in-place compatibility ensure that products remain uncontaminated.

For users who require a different pumping method, the Air Driven Peristaltic Pump offers an alternative. This pump design uses a rotating roller to compress a flexible tube, moving the fluid forward without direct contact with moving metal parts. In situations where shear-sensitive or highly viscous materials need to be transferred, the Air Driven Peristaltic Pump provides gentle handling and precise flow control. While it operates differently from the Air Actuated Diaphragm Pump, both serve valuable roles in industrial operations.

The decision between an Air Actuated Diaphragm Pump, an Air Driven Peristaltic Pump, and a Sanitary Diaphragm Pump depends largely on the type of fluid being transferred, the required flow rate, and the operating environment. For abrasive slurries or chemically aggressive fluids, an Air Actuated Diaphragm Pump offers robust performance. For highly hygienic processes, the Sanitary Diaphragm Pump ensures compliance with regulatory standards. For low-shear and precise dosing, the Air Driven Peristaltic Pump is often the better choice.

Energy efficiency is another factor to weigh. Modern Air Actuated Diaphragm Pumps are designed with advanced air valve systems that minimize air consumption while maintaining output. Likewise, the latest Air Driven Peristaltic Pumps incorporate innovations to reduce energy usage and extend tubing life. In the food and pharmaceutical sectors, Sanitary Diaphragm Pumps are engineered not only for hygiene but also for efficient, reliable performance under frequent cleaning cycles.

Maintenance considerations should not be overlooked. The Air Actuated Diaphragm Pump typically requires diaphragm replacement at set intervals, while the Air Driven Peristaltic Pump needs periodic tubing replacement. The Sanitary Diaphragm Pump, with its quick-release fittings, is designed to minimize downtime during cleaning or parts replacement. Choosing a pump with accessible components and clear maintenance instructions can significantly reduce operational interruptions.

Selecting the right Air Actuated Diaphragm Pump for your application involves assessing fluid characteristics, hygiene requirements, energy consumption, and maintenance needs. Comparing it with alternatives such as the Air Driven Peristaltic Pump and the Sanitary Diaphragm Pump will help ensure you choose the suitable option. With the right pump in place, you can achieve consistent performance, maintain product quality, and optimize operational efficiency across a wide range of applications.

English

English русский

русский Español

Español عربى

عربى