The Benefits of Air Operated Single and Double Diaphragm Pumps in Real-World Applications

2025.08.18

2025.08.18

Industry News

Industry News

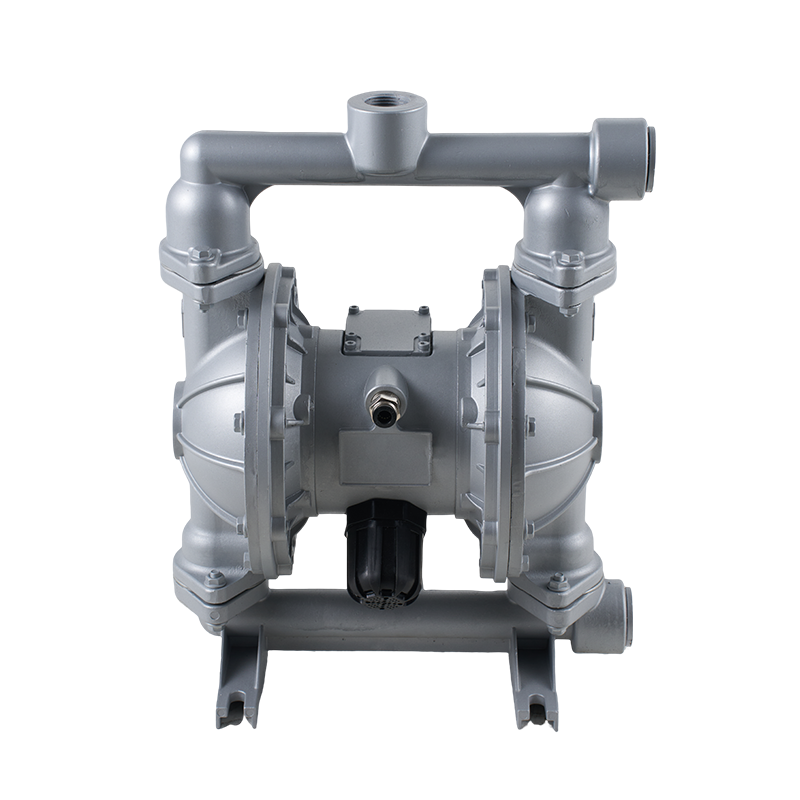

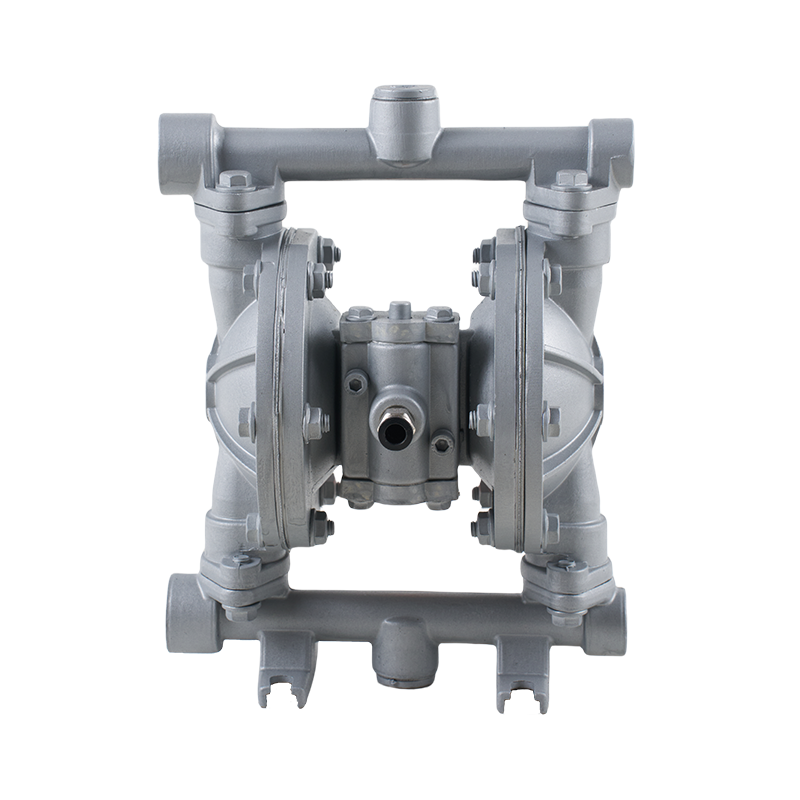

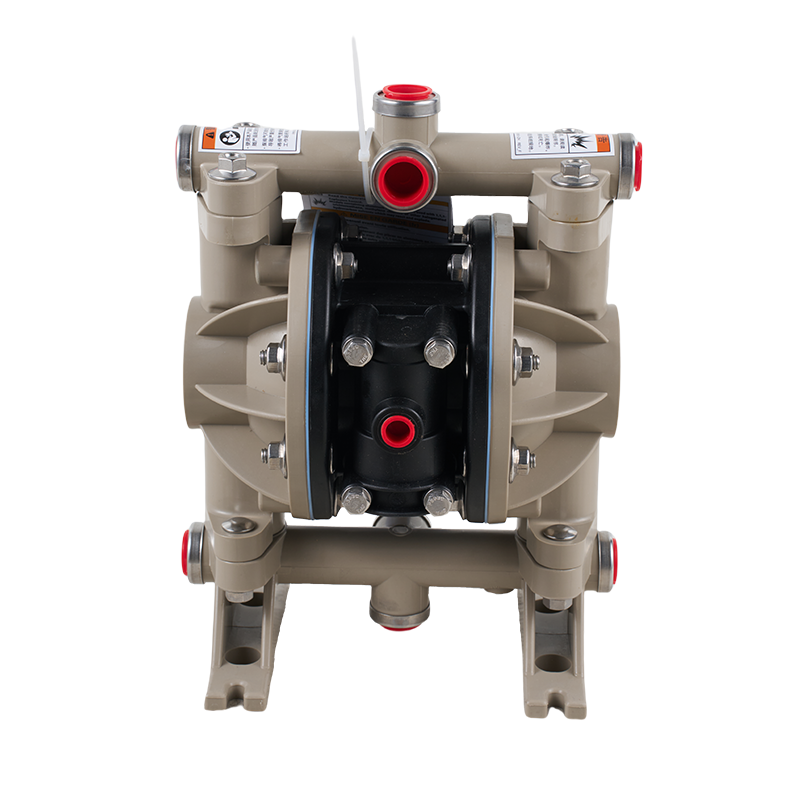

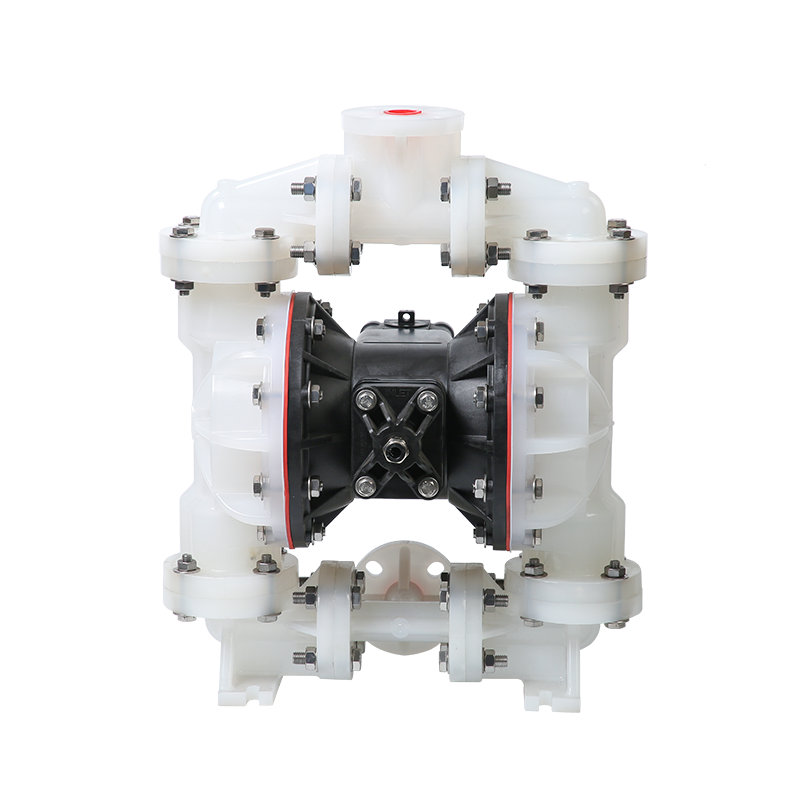

In industrial fluid handling, the Air Operated Single Diaphragm Pump and the Air Driven Double Diaphragm Pump have earned a solid reputation for reliability, versatility, and adaptability. Both pump types offer unique strengths, making them valuable in a wide range of real-world applications, from chemical transfer to food processing and construction. Understanding their benefits will help operators select the right pump for their specific needs.

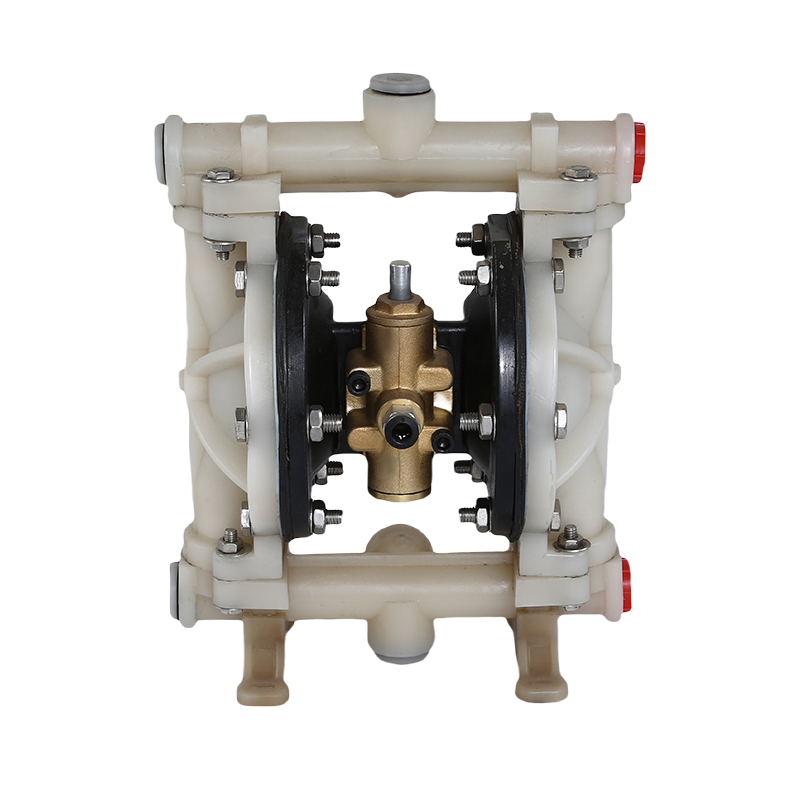

The Air Operated Single Diaphragm Pump is well-known for its straightforward design. With a single diaphragm driven by compressed air, this pump type is ideal for low-to-medium flow rates where consistent output and simple maintenance are priorities. The Air Operated Single Diaphragm Pump can handle a variety of fluids, including light slurries, viscous liquids, and even fluids with suspended solids. Its ability to run dry without damage is a valuable feature in industries where intermittent flow is common.

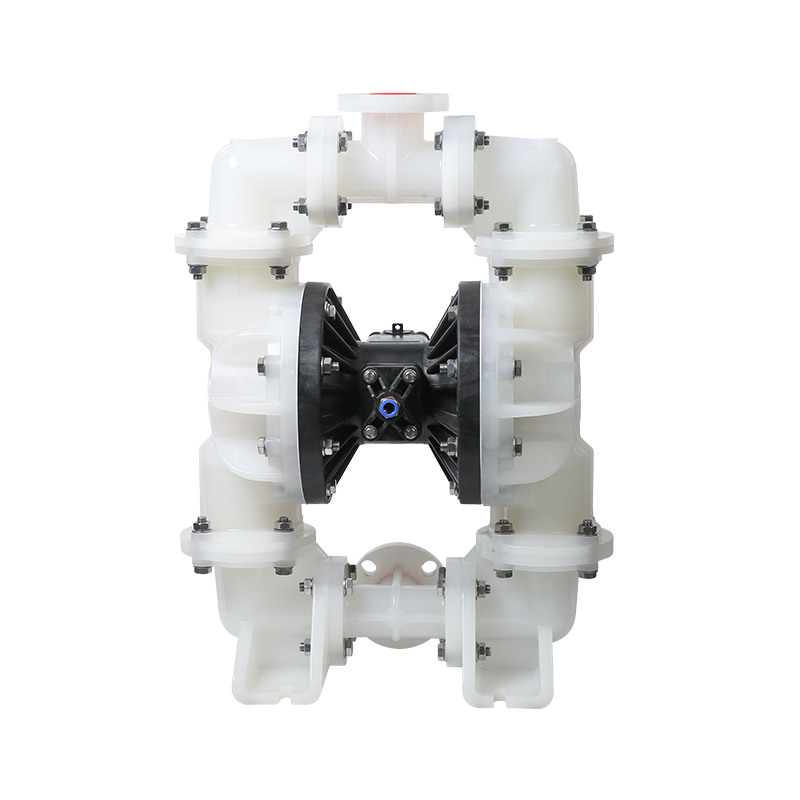

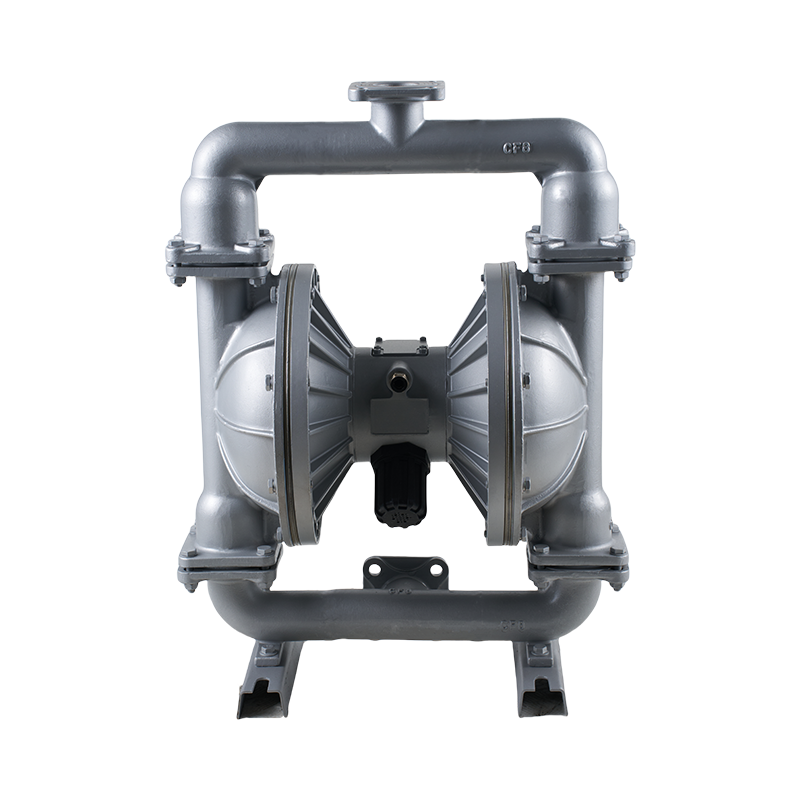

In contrast, the Air Driven Double Diaphragm Pump uses two diaphragms that operate in tandem, delivering smoother flow and greater volume capacity. This makes the Air Driven Double Diaphragm Pump a preferred choice in operations where higher throughput is required, such as large-scale water treatment, bulk chemical transfer, and construction site dewatering. The double diaphragm configuration also helps reduce pulsation, which can be critical for applications requiring steady pressure.

One of the key advantages of both the Air Operated Single Diaphragm Pump and the Air Driven Double Diaphragm Pump is their compatibility with a wide range of fluids. They can handle corrosive chemicals, abrasive slurries, oils, and even food-grade materials. In sanitary environments, these pumps can be fitted with food-grade diaphragms and components to meet hygiene standards. Their air-powered design also eliminates the risk of electrical hazards, making them suitable for explosive or wet environments.

Maintenance is another area where these pumps excel. The Air Operated Single Diaphragm Pump has fewer moving parts, which simplifies inspection and repairs. Likewise, the Air Driven Double Diaphragm Pump offers easy diaphragm replacement and minimal downtime when serviced correctly. This ease of maintenance ensures that both pump types remain cost-effective over their operational lifespan.

Energy efficiency has also improved in recent years. Many Air Driven Double Diaphragm Pumps now feature advanced air valve systems that optimize air consumption without compromising performance. Similarly, updated Air Operated Single Diaphragm Pumps are designed to maximize output per unit of air, which can result in noticeable cost savings over time.

In real-world applications, the choice between an Air Operated Single Diaphragm Pump and an Air Driven Double Diaphragm Pump often comes down to flow requirements and system design. Smaller operations or processes that require controlled, moderate flow rates may find the Air Operated Single Diaphragm Pump to be the fit. In contrast, large-scale projects with high-volume needs often benefit from the capacity and smoother performance of the Air Driven Double Diaphragm Pump.

From construction sites pumping muddy water to factories transferring chemicals, these pumps prove their value daily. Their durability, adaptability, and ease of maintenance make them indispensable across industries. Choosing between them involves assessing operational needs, budget considerations, and the specific properties of the fluid being moved.

Both the Air Operated Single Diaphragm Pump and the Air Driven Double Diaphragm Pump bring significant benefits to real-world applications. By understanding their differences and strengths, operators can ensure they select the efficient and reliable solution for their particular process. With proper selection and maintenance, these pumps deliver consistent performance and long-term value in a wide variety of industrial settings.

English

English русский

русский Español

Español عربى

عربى