Double Diaphragm Pump Manufacturers Innovate to Meet Industry Demands

2025.08.18

2025.08.18

Industry News

Industry News

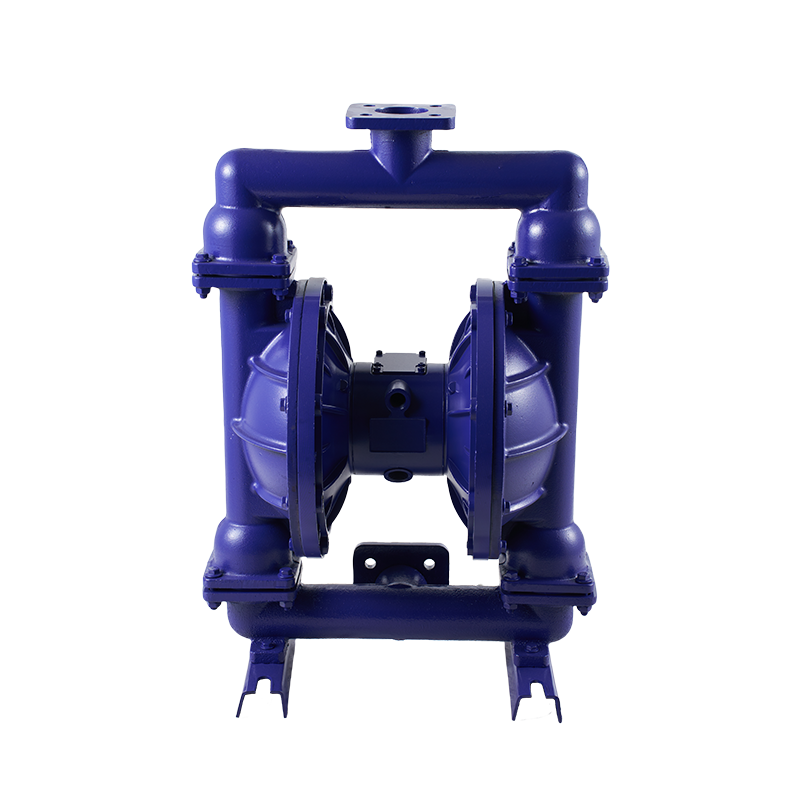

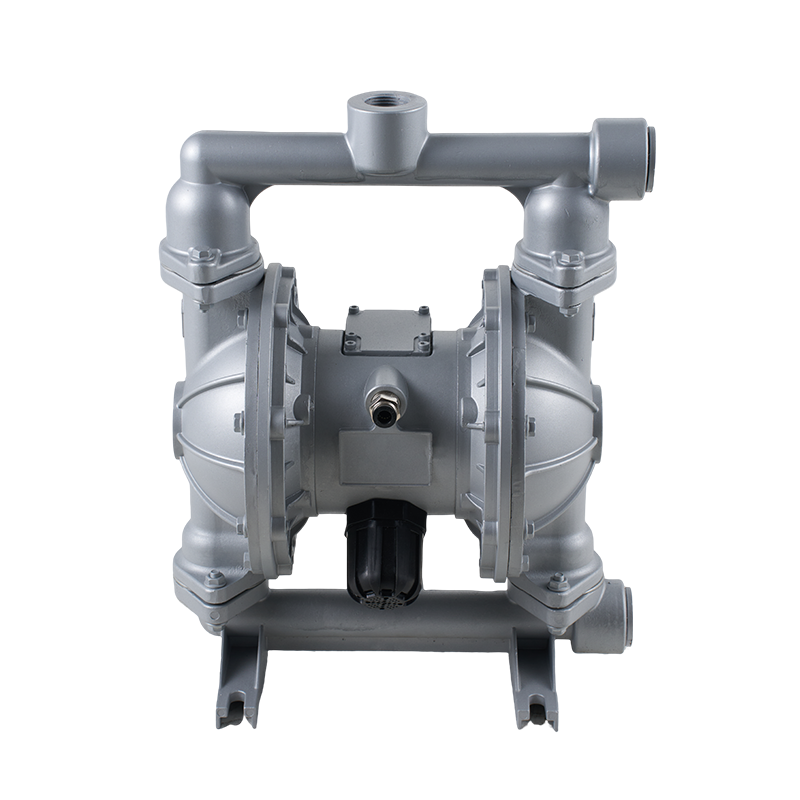

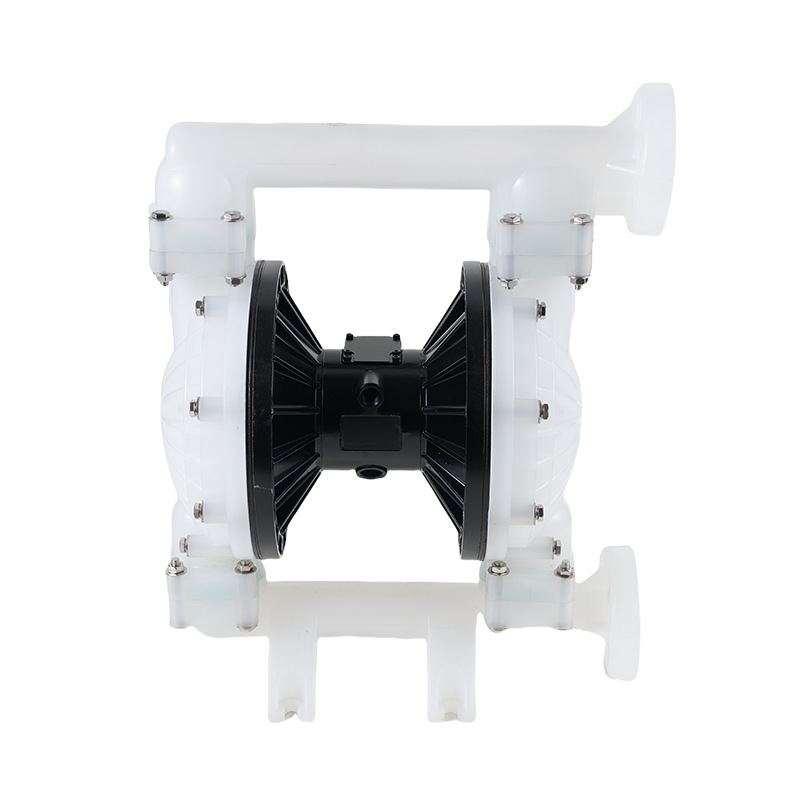

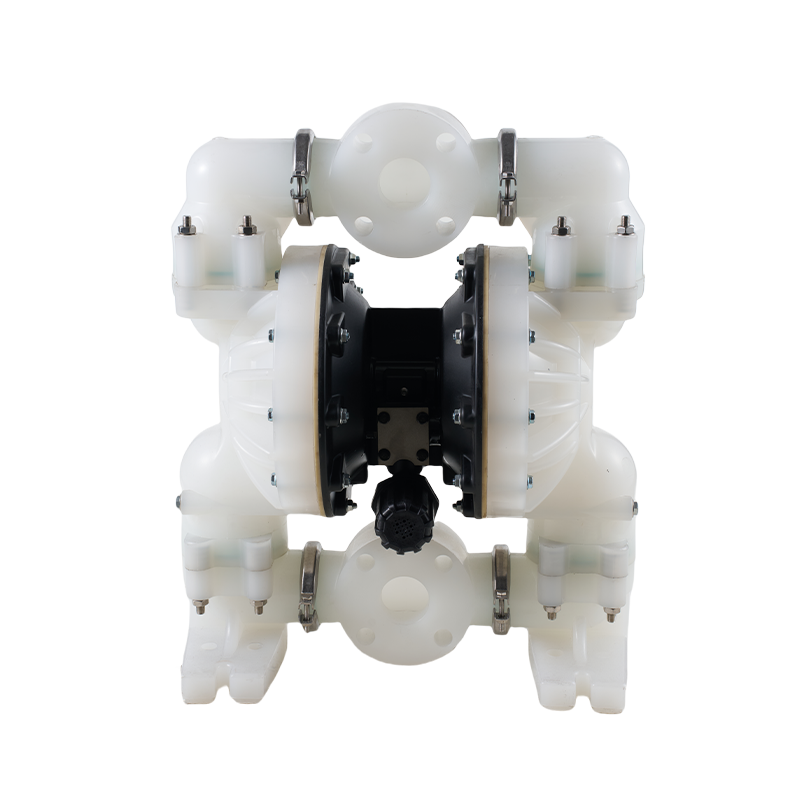

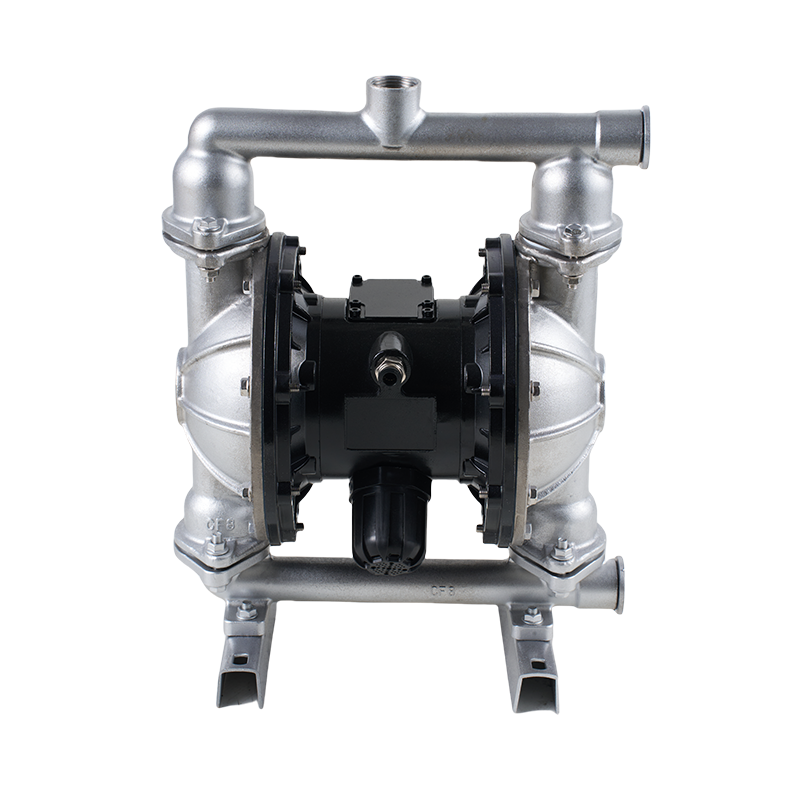

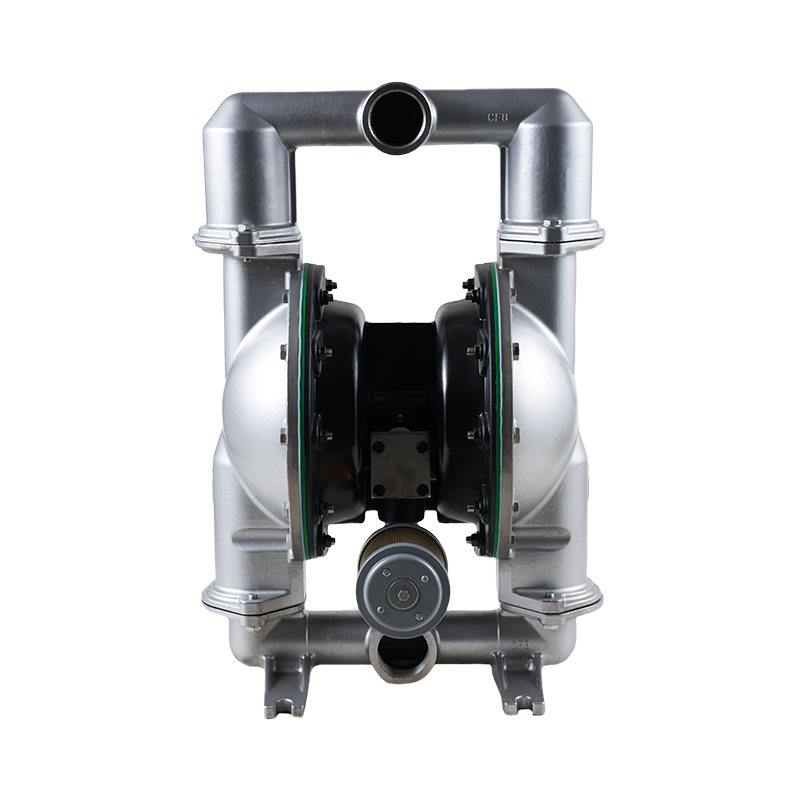

Pneumatic diaphragm pumps, particularly double diaphragm pumps, have emerged as indispensable tools across various sectors, from chemical processing and pharmaceuticals to mining and wastewater management. As a result, double diaphragm pump manufacturers are at the forefront of innovation, striving to meet the ever-growing and increasingly complex needs of industries worldwide.

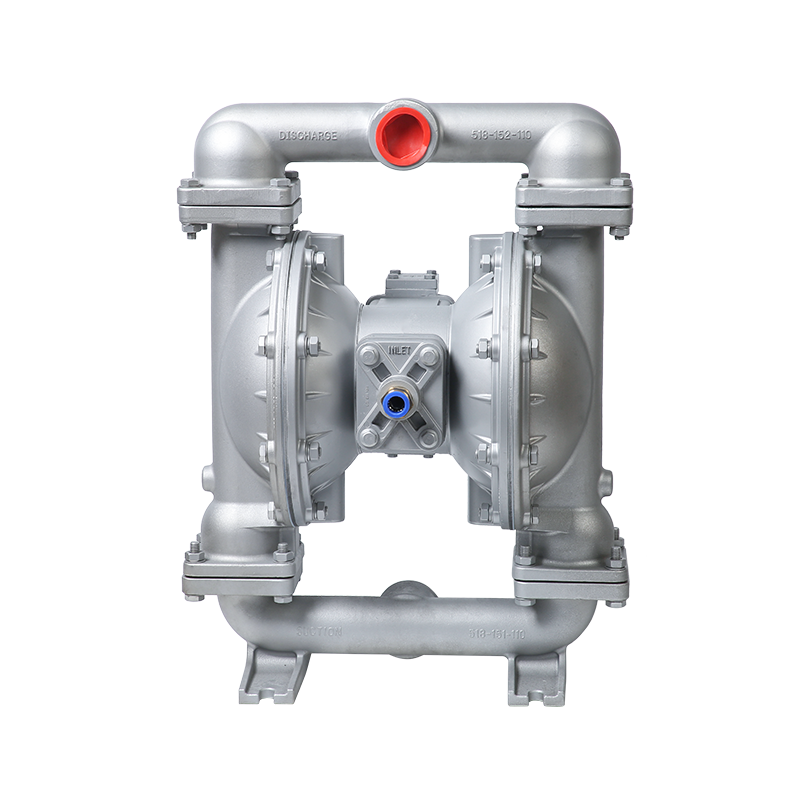

Double diaphragm pumps, known for their ability to handle a wide range of fluids, including corrosive, abrasive, and viscous materials, have long been a staple in industrial operations. These pumps operate by using compressed air to drive two flexible diaphragms, which alternately draw in and expel fluid. This unique mechanism ensures that the fluid never comes into contact with the mechanical parts of the pump, minimizing the risk of contamination and wear. Pneumatic diaphragm pump suppliers have long recognized the value of this technology, but it is the continuous innovation by double diaphragm pump manufacturers that is driving the industry forward.

One of the key areas of innovation for double diaphragm pump manufacturers is the development of more energy-efficient models. As industries increasingly focus on sustainability and reducing their carbon footprints, manufacturers are exploring ways to optimize the air consumption of their pumps without compromising performance. New designs and materials are being employed to improve the efficiency of the air-driven mechanism, resulting in significant energy savings over the life of the pump. This not only benefits the environment but also reduces operational costs for end-users, making double diaphragm pumps an even more attractive option.

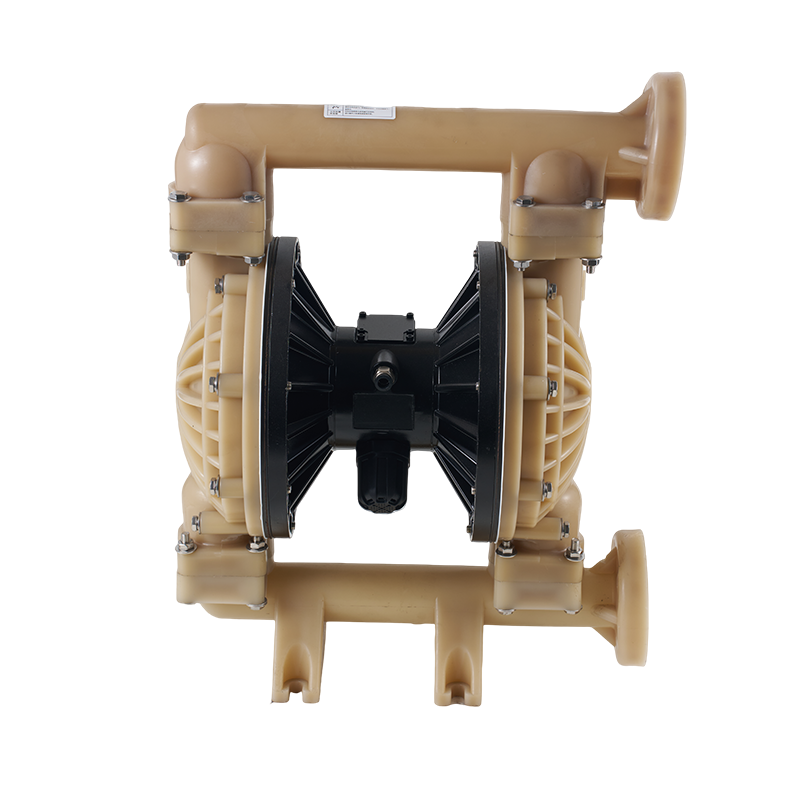

Another critical area of focus for double diaphragm pump manufacturers is improving the durability and reliability of their products. Industrial applications often involve harsh operating conditions, including exposure to corrosive chemicals, temperatures, and abrasive materials. To address these challenges, manufacturers are investing in advanced materials and manufacturing processes. For example, the use of high-performance polymers and composites is becoming more common, offering enhanced resistance to chemical attack and wear. Additionally, improved sealing technologies are being developed to prevent leaks and ensure the long-term integrity of the pump.

Pneumatic diaphragm pump suppliers are also benefiting from the innovations of double diaphragm pump manufacturers. With the introduction of smarter, more user-friendly designs, suppliers are able to offer a wider range of solutions to meet the diverse needs of their customers. For instance, some manufacturers are incorporating advanced monitoring and control systems into their pumps. These systems allow operators to remotely monitor the performance of the pump, receive alerts for potential issues, and adjust operating parameters in real time. This level of control not only improves the efficiency of the pumping process but also enhances safety and reduces downtime.

The ability to handle a wide variety of fluids is a hallmark of double diaphragm pumps, and manufacturers are constantly expanding this capability. Research and development efforts are focused on optimizing the pump's performance with different types of fluids, including those with high viscosity or containing solid particles. This versatility makes double diaphragm pumps suitable for a broader range of applications, from transferring thick slurries in mining operations to pumping delicate pharmaceuticals. Pneumatic diaphragm pump suppliers are well-positioned to capitalize on this versatility, offering customized solutions to meet the specific requirements of their clients.

In addition to technical innovations, double diaphragm pump manufacturers are also placing a strong emphasis on customer service and support. They understand that the success of their products depends not only on their performance but also on the ease with which customers can integrate and maintain them. As a result, many manufacturers are offering comprehensive training programs, technical assistance, and after-sales support. This holistic approach ensures that customers can make their double diaphragm pumps, their return on investment.

The global market for pneumatic diaphragm pumps is highly competitive, with numerous manufacturers vying for market share. However, it is those who can innovate and adapt to the changing needs of the industry that will ultimately succeed. Double diaphragm pump manufacturers are the way to continuously push the boundaries of what is possible with this technology. Through their efforts, they are not only meeting the current demands of the industry but also laying the groundwork for future advancements.

The ongoing innovation by double diaphragm pump manufacturers is a testament to their commitment to excellence and their ability to respond to the evolving needs of the industrial sector. From improving energy efficiency and durability to enhancing versatility and customer support, these manufacturers are ensuring that pneumatic diaphragm pumps remain a vital component of modern industrial operations. As industries continue to face new challenges and opportunities, the role of double diaphragm pump manufacturers will be more important than ever in driving progress and ensuring that the right pumping solutions are available to meet the demands of tomorrow.

English

English русский

русский Español

Español عربى

عربى