How Diaphragm Pumps for Corrosive Fluids are Transforming the Chemical Industry?

2025.08.18

2025.08.18

Industry News

Industry News

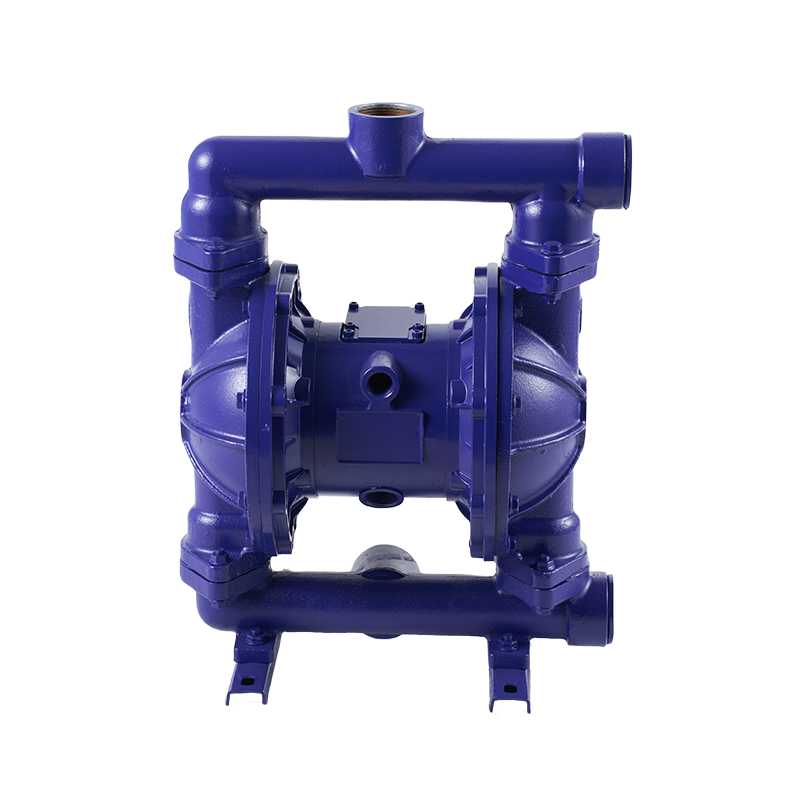

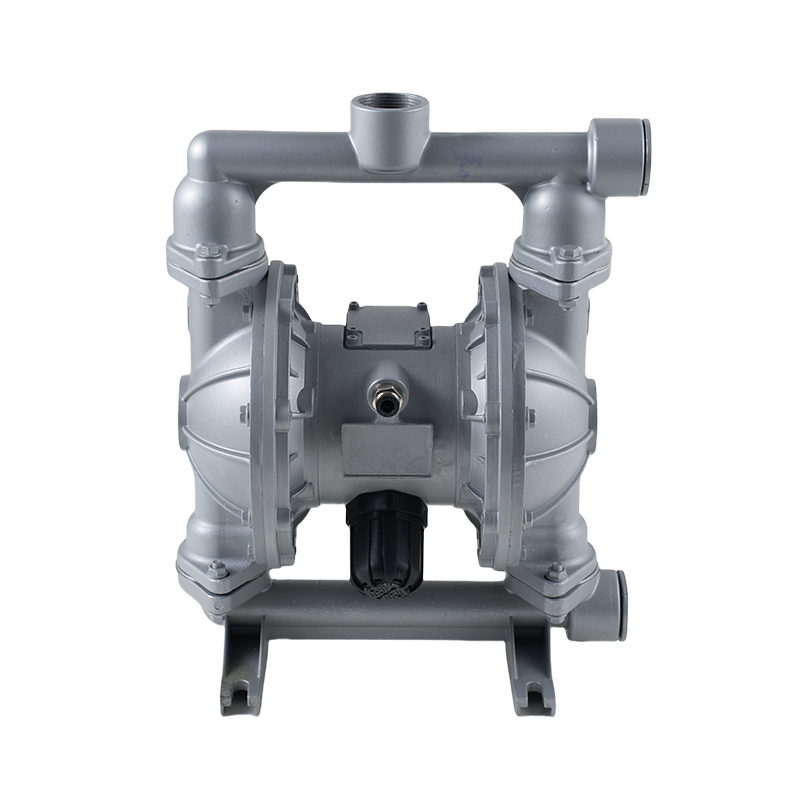

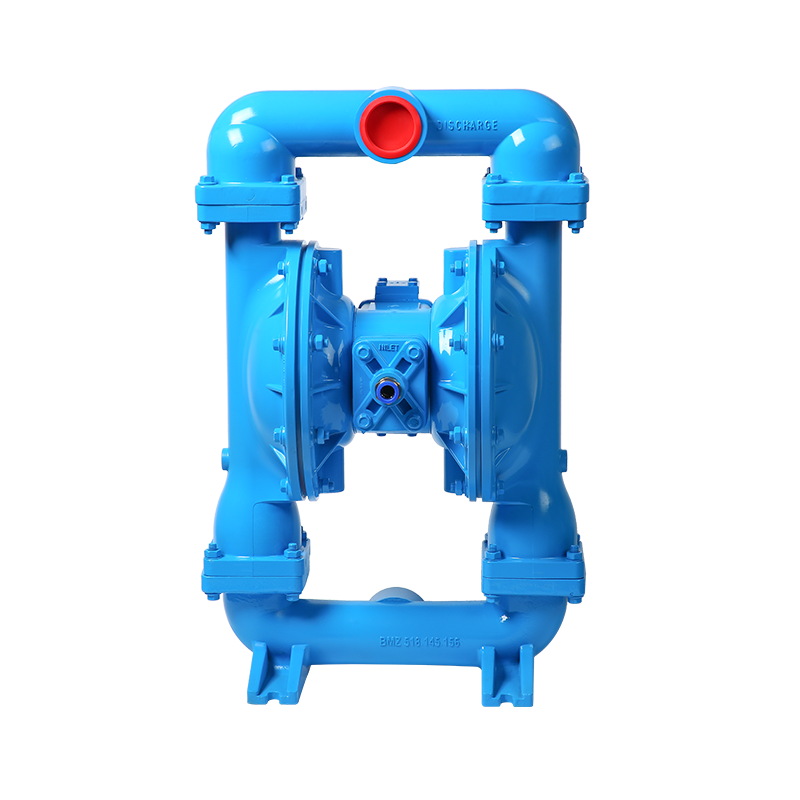

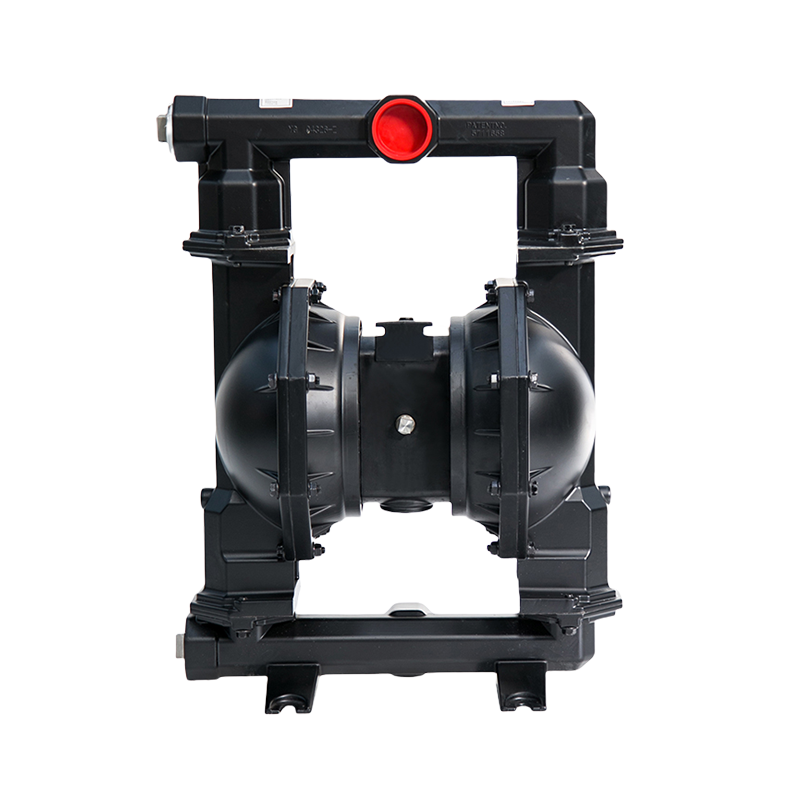

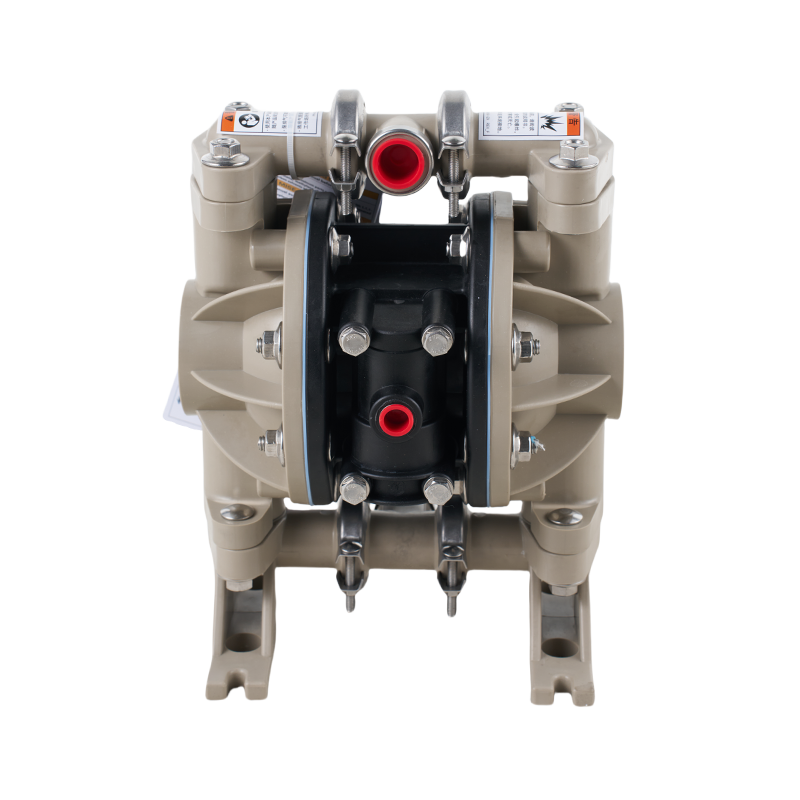

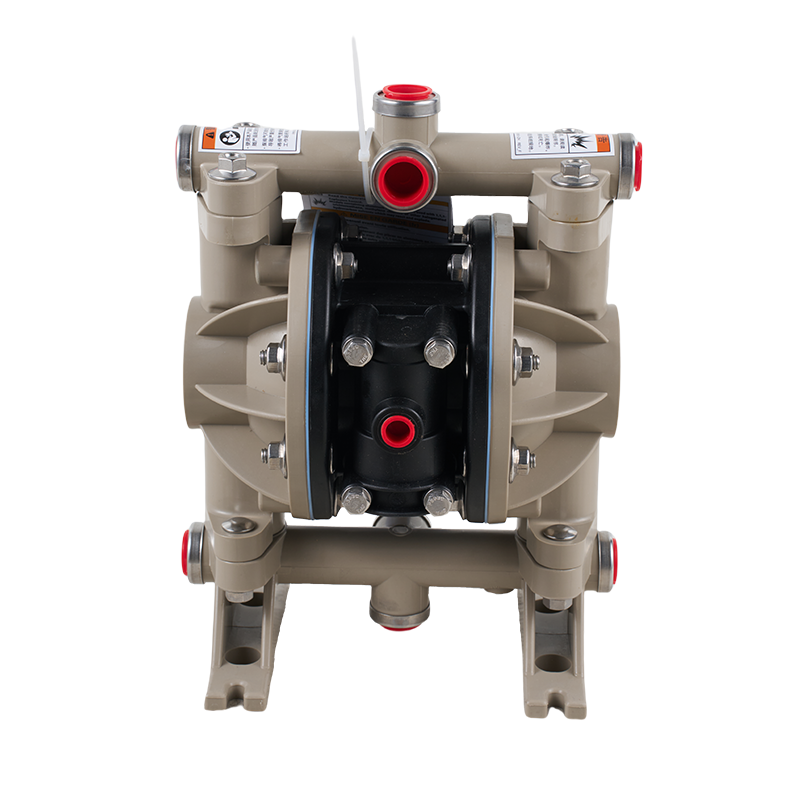

In recent years, the chemical industry has been undergoing a significant shift in how it handles aggressive and reactive substances. One of the key drivers behind this change is the growing adoption of diaphragm pumps for corrosive fluids. Designed to safely transfer challenging liquids such as acids, solvents, and abrasive mixtures, these pumps have proven to be a dependable solution for facilities seeking efficiency, safety, and long-term durability.

Diaphragm pumps for corrosive fluids operate by using a flexible membrane that moves back and forth to create a pumping action. This design ensures that the liquid being transferred never comes into contact with moving mechanical parts, reducing wear and the risk of leakage. In the chemical sector, where even small leaks can cause operational delays or equipment damage, this separation is a critical advantage.

One specialized variation, the chemistry diaphragm pump, has gained notable attention for laboratory and industrial use. This type of pump is often constructed from materials such as PTFE, PVDF, or other corrosion-resistant polymers. By combining chemical compatibility with a robust pumping mechanism, the chemistry diaphragm pump can handle a wide range of fluids without compromising performance. From research laboratories to large-scale chemical manufacturing plants, these pumps are now a preferred choice for handling sensitive or hazardous liquids.

A prime example of their application is in the transfer of hydrochloric acid, one of the commonly used yet highly corrosive substances in the chemical industry. Traditional pumping systems often suffer from premature wear when exposed to hydrochloric acid, to costly replacements and downtime. However, a diaphragm pump for hydrochloric acid is specifically designed to resist such degradation. With the right material selection for the pump head, valves, and diaphragms, these pumps can deliver consistent performance while maintaining safety standards.

The advantages of using diaphragm pumps for corrosive fluids extend beyond chemical compatibility. They are also valued for their self-priming capabilities, ability to run dry without damage, and precise flow control. In processes where dosing accuracy is essential—such as in blending chemicals for pharmaceutical or specialty material production—these features help maintain product quality and process reliability.

In addition, the maintenance requirements for a chemistry diaphragm pump are generally lower compared to other pump types. Since the pumped fluid does not interact with internal components, there is less mechanical wear, reducing the frequency and cost of repairs. This benefit becomes even more evident when handling substances like hydrochloric acid, where equipment longevity directly impacts operational costs.

The adoption of diaphragm pumps for hydrochloric acid has also played a role in enhancing workplace safety. By minimizing the potential for leaks and spills, these pumps reduce the risk of chemical exposure for workers. In a sector where safety protocols are paramount, the ability of these pumps to provide secure fluid handling contributes to overall operational stability.

Industry analysts note that the demand for diaphragm pumps for corrosive fluids is likely to grow further as environmental and safety regulations become more stringent. Many companies are replacing older pumping systems with modern diaphragm models to meet compliance requirements while improving efficiency. For the chemical industry, this shift is not just about meeting regulations—it is about building a more reliable and sustainable operational framework.

The emergence of diaphragm pumps for corrosive fluids has transformed fluid handling in the chemical industry. Whether it is the laboratory-focused chemistry diaphragm pump or the industrial-grade diaphragm pump for hydrochloric acid, these innovations are enabling companies to handle challenging substances with greater safety, efficiency, and cost-effectiveness. As technology advances and materials science continues to improve, these pumps will likely play an even larger role in shaping the future of chemical processing.

English

English русский

русский Español

Español عربى

عربى