Troubleshooting Common Issues in Sludge Diaphragm Pumps

2025.08.18

2025.08.18

Industry News

Industry News

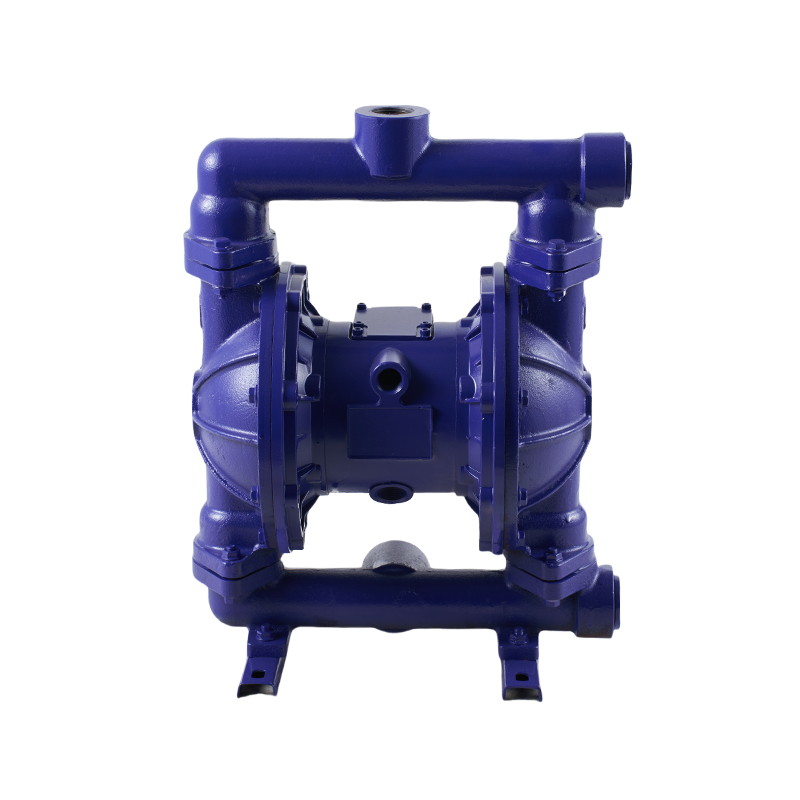

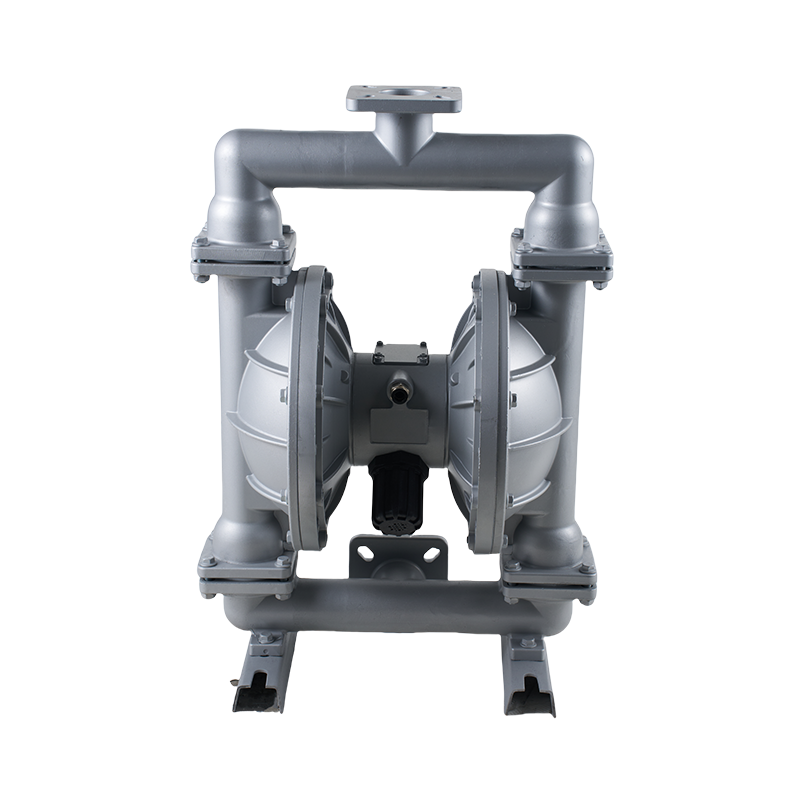

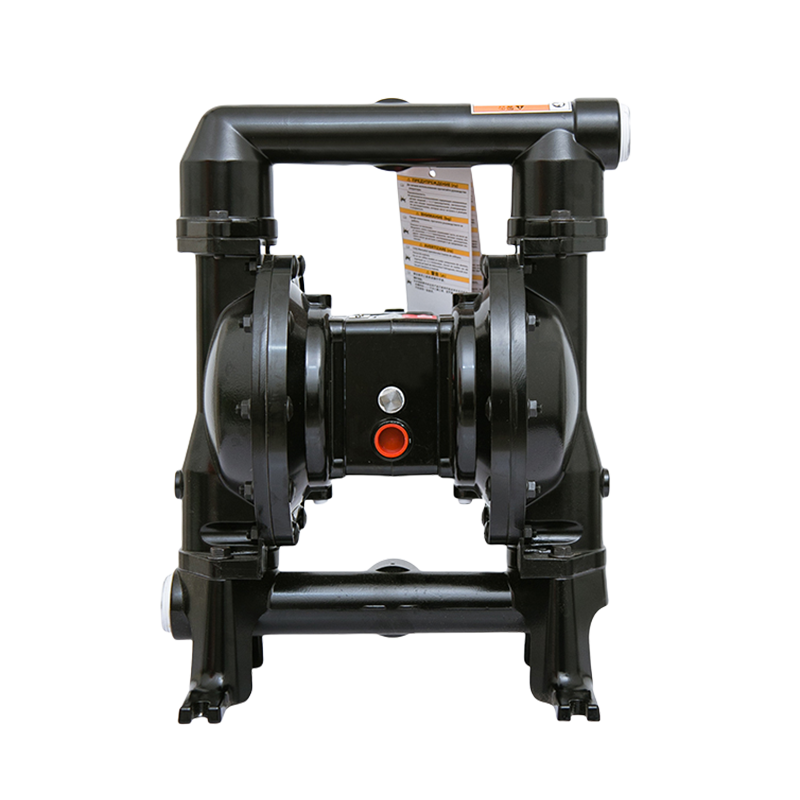

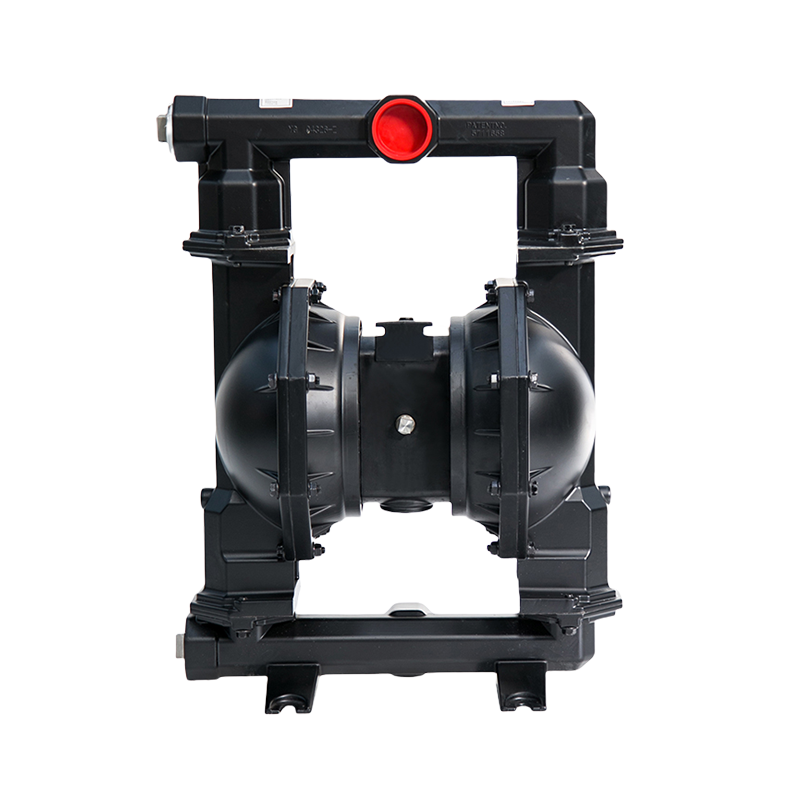

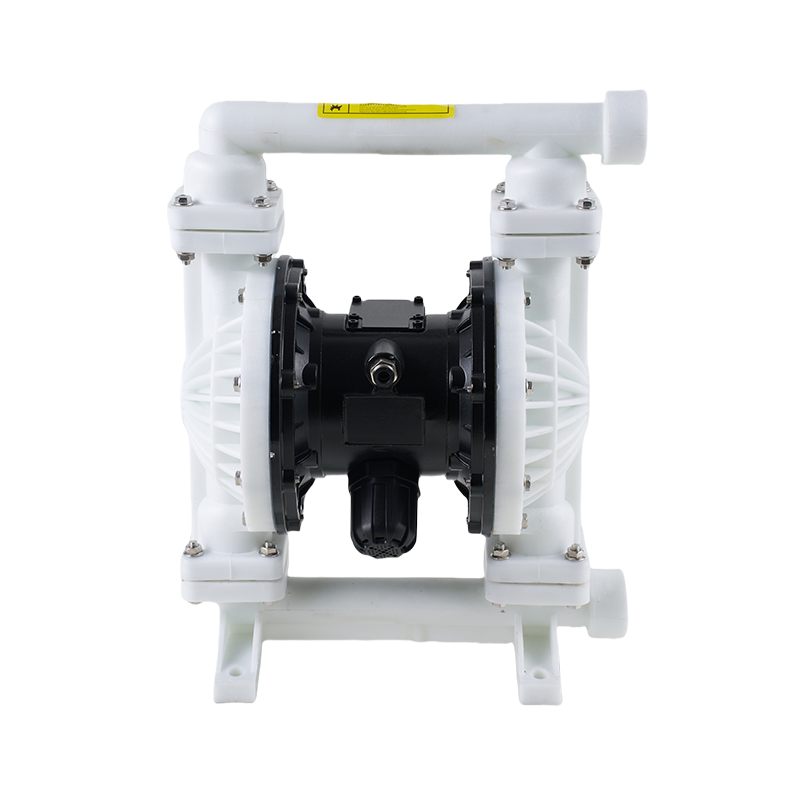

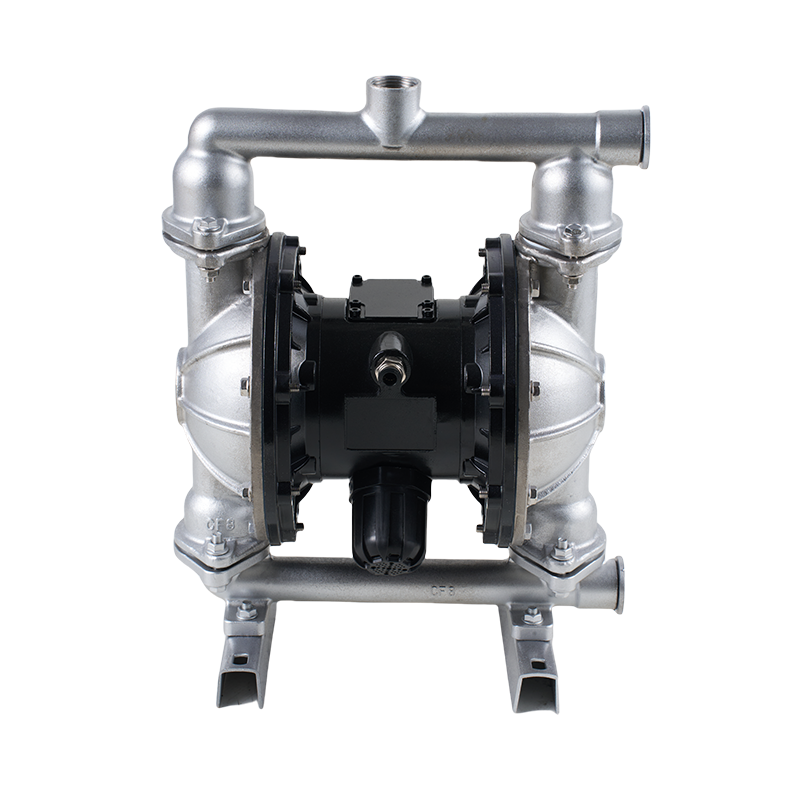

In the realm of industrial fluid transfer, sludge diaphragm pumps have emerged as indispensable tools for handling a wide array of challenging applications. These robust machines are specifically designed to move viscous, abrasive, and even hazardous materials with ease. However, like any mechanical equipment, sludge diaphragm pumps can encounter operational issues that may hinder their efficiency and reliability. This article delves into the common problems faced by operators of sludge diaphragm pumps and provides practical troubleshooting tips to ensure smooth and uninterrupted operation.

Sludge diaphragm pumps, also known as air driven diaphragm pumps or simply sludge pumps, operate on a principle that leverages compressed air to drive the pumping mechanism. The diaphragm within the pump alternates between suction and discharge strokes, creating a positive displacement action that efficiently moves sludge and other challenging fluids. These pumps are particularly favored in industries such as wastewater treatment, chemical processing, and mining, where the ability to handle thick, corrosive, and abrasive materials is crucial.

Common Issues and Solutions

1. Insufficient Flow Rate

One of the frequent complaints from operators of sludge diaphragm pumps is an insufficient flow rate. This issue can arise from several factors. Clogged inlet or outlet valves can restrict the passage of fluid, reducing efficiency. To address this, operators should regularly inspect and clean the valves, ensuring that no debris or sludge buildup is obstructing the flow. Additionally, the air supply to the pump must be checked. An inadequate air pressure or a faulty air regulator can significantly impact the performance of an air driven diaphragm pump. Ensuring that the air pressure is within the recommended range and that the regulator is functioning correctly can often resolve flow rate issues.

2. Diaphragm Damage

The diaphragm is the heart of a sludge diaphragm pump, and its condition directly affects the pump's performance. Over time, diaphragms can wear out or become damaged due to prolonged exposure to abrasive materials or corrosive chemicals. Signs of diaphragm damage include leaks, reduced pumping efficiency, and irregular fluid delivery. Regular inspection of the diaphragm is essential. If damage is detected, prompt replacement is necessary to prevent further complications. Many manufacturers offer durable and chemically resistant diaphragms specifically designed for sludge diaphragm pumps, which can extend the life of the pump and enhance its reliability.

3. Air Locks and Stalling

Air locks can occur when air becomes trapped within the pump chamber, preventing the diaphragm from moving properly. This canto stalls or complete cessation of the pumping action. To prevent air locks, operators should ensure that the pump is properly primed before starting. In some cases, installing a vent valve can help release trapped air and maintain smooth operation. Additionally, checking the air inlet and outlet lines for blockages or kinks can help prevent air from becoming trapped within the system. Proper maintenance of the air driven mechanism is crucial in avoiding such issues.

4. Chemical Compatibility

When using sludge diaphragm pumps to transfer chemicals, it is vital to ensure that all components of the pump are compatible with the specific chemicals being handled. Incompatible materials can to corrosion, swelling, or degradation of pump parts, resulting in leaks, reduced efficiency, and potential safety hazards. Operators should consult the pump's technical documentation and chemical compatibility charts to verify that the pump's materials are suitable for the intended application. If necessary, upgrading to pumps with more chemically resistant components, such as those made from stainless steel or specialized plastics, can significantly enhance the pump's longevity and performance.

5. Excessive Noise and Vibration

Excessive noise and vibration in a sludge diaphragm pump can indicate underlying mechanical issues. Loose or misaligned components, worn bearings, or an unbalanced air supply can all contribute to these problems. Regular maintenance checks should include inspecting all fasteners and securing any loose parts. Additionally, ensuring that the pump is properly mounted and aligned can help minimize vibration. If the issue persists, it may be necessary to consult with a service technician to diagnose and repair any deeper mechanical problems. In some cases, installing vibration dampeners or using flexible hoses can also help reduce noise and vibration levels.

6. Inconsistent Performance

Inconsistent performance in a sludge diaphragm pump can be frustrating for operators. This issue can stem from a variety of causes, including fluctuating air pressure, clogged filters, or worn internal components. Monitoring the air pressure and ensuring a consistent supply is crucial. Regularly cleaning or replacing air filters can help maintain airflow. Additionally, inspecting internal components such as valves, seals, and the diaphragm itself can identify any wear or damage that may be causing inconsistent performance. Timely maintenance and replacement of worn parts can restore the pump to its operating condition.

Sludge diaphragm pumps are powerful and versatile tools, but they require proper care and attention to ensure their longevity and efficiency. By understanding the common issues that can arise and implementing the appropriate troubleshooting measures, operators can minimize downtime and maximize the performance of their sludge diaphragm pumps. Regular maintenance, careful monitoring, and prompt action when problems arise are key to maintaining a reliable and efficient pumping system. Whether handling wastewater, chemicals, or other challenging materials, a well-maintained sludge diaphragm pump can provide years of reliable service in even the demanding industrial environments.

English

English русский

русский Español

Español عربى

عربى