How Diaphragm Sump Pumps Enhance Industrial Wastewater Management?

2025.08.18

2025.08.18

Industry News

Industry News

In the complex landscape of modern industrial operations, effective wastewater management is not just a regulatory necessity but a cornerstone of sustainable practices. One of the innovative and reliable solutions in this domain is the diaphragm sump pump. These pumps have revolutionized the way industries handle wastewater, offering unparalleled efficiency, durability, and adaptability.

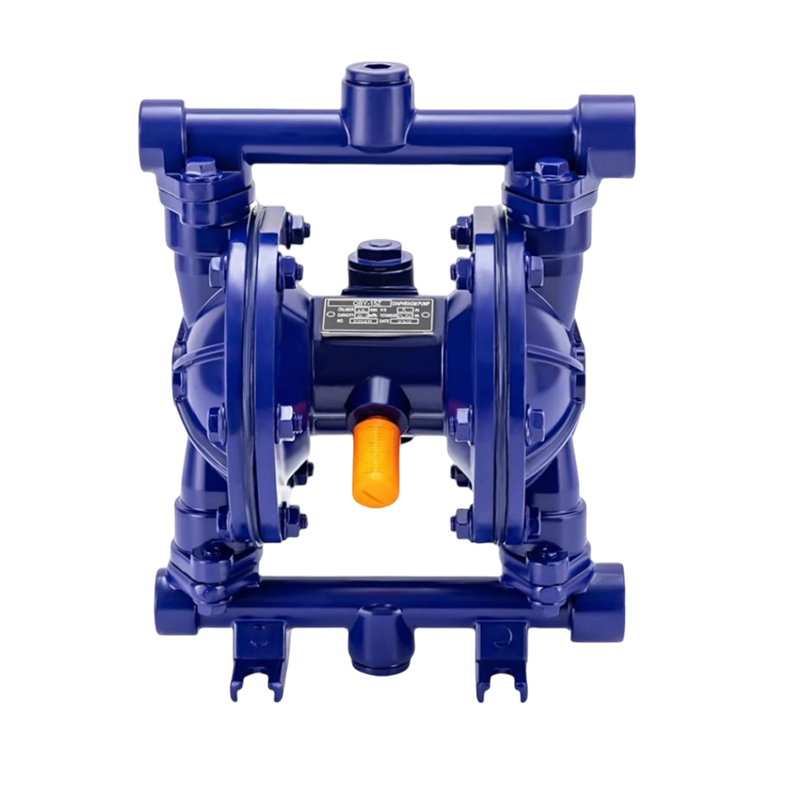

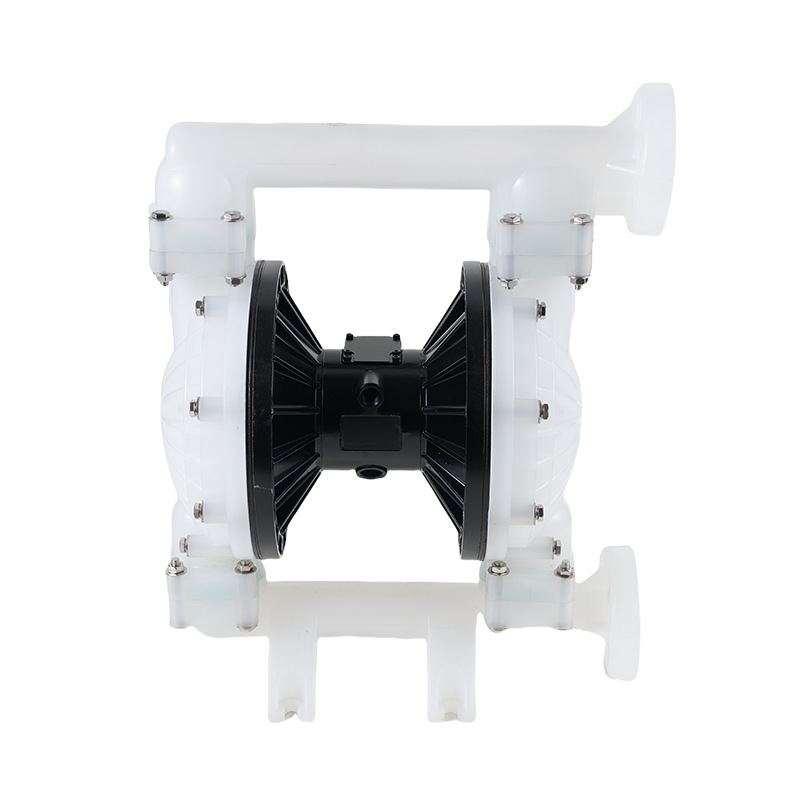

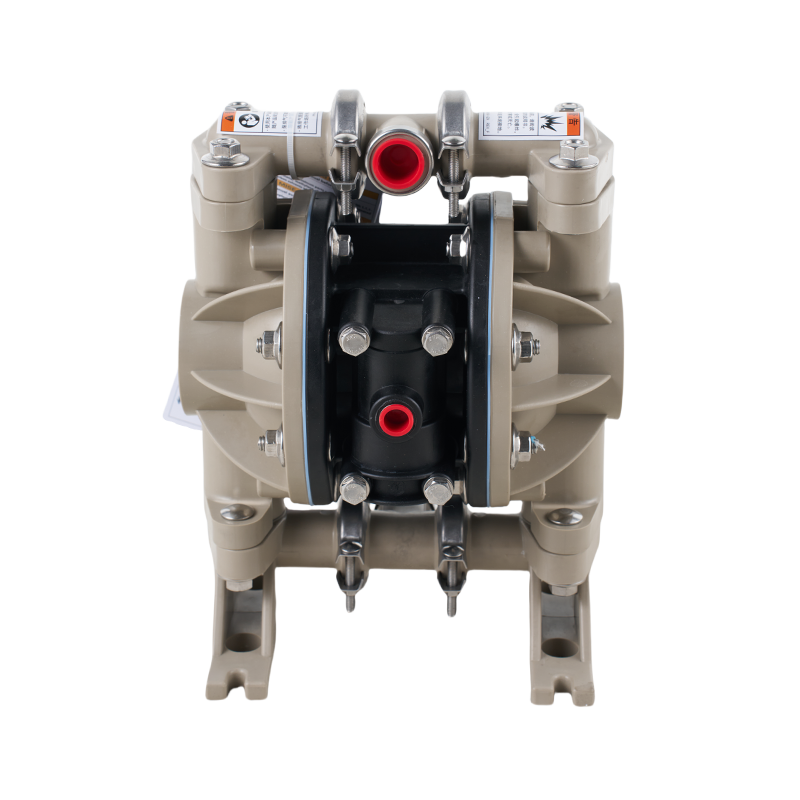

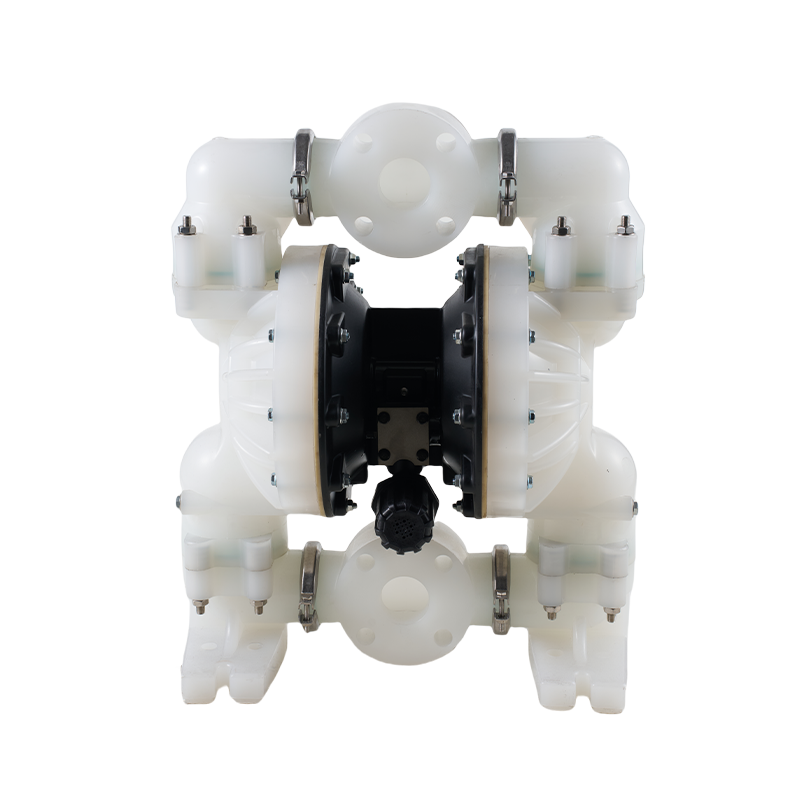

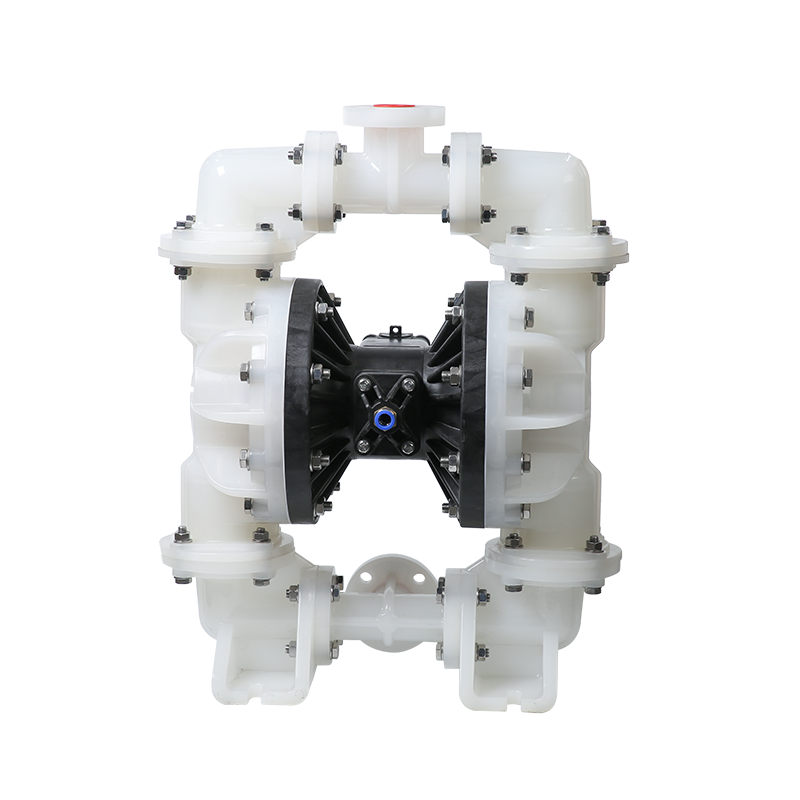

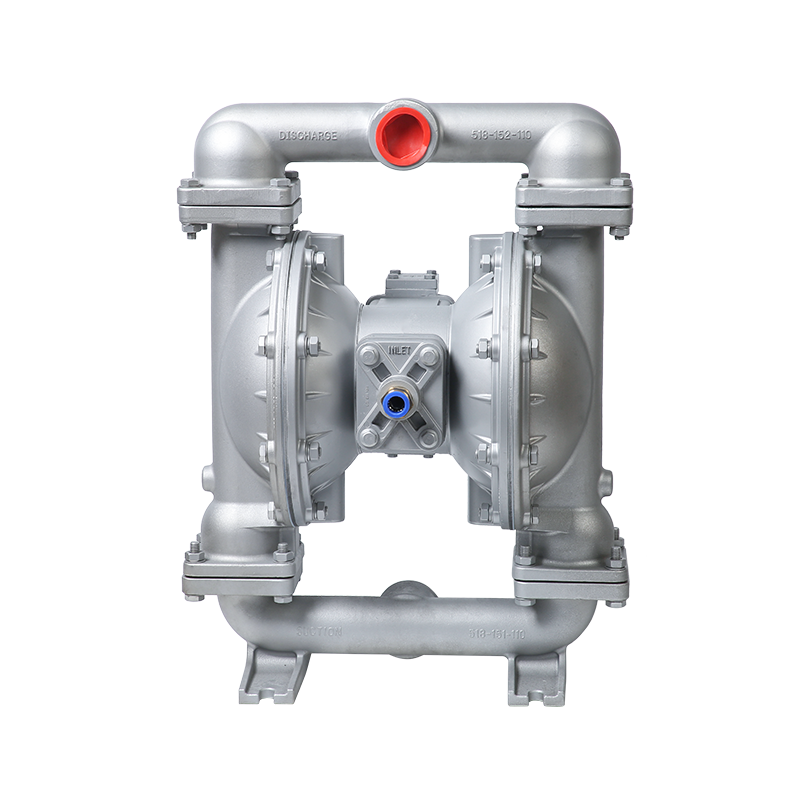

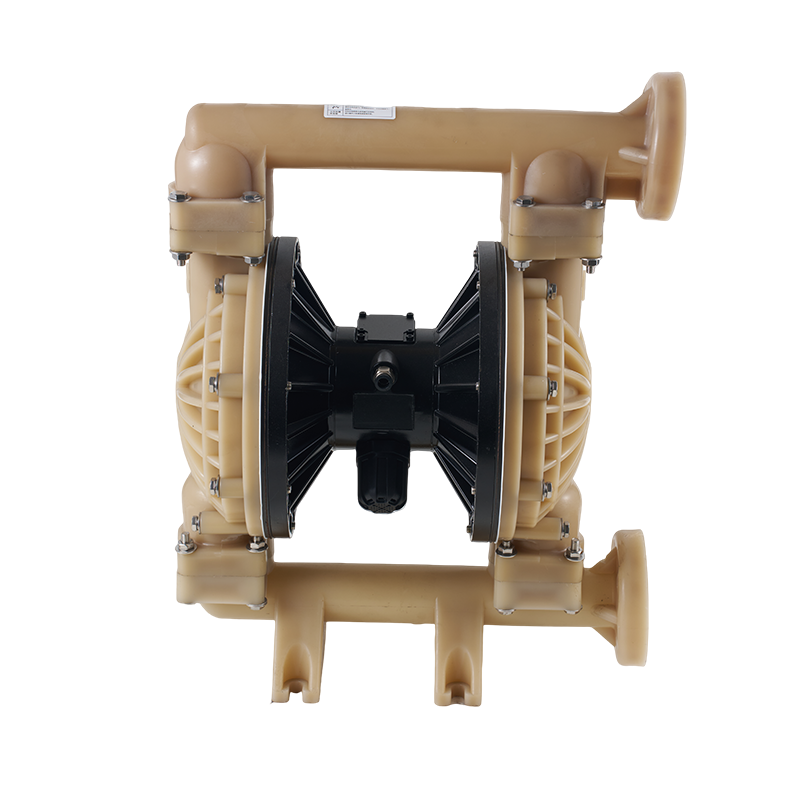

Diaphragm sump pumps are specifically designed to handle the challenging conditions associated with industrial wastewater. Unlike traditional pumps that may struggle with abrasive materials, corrosive substances, or high-viscosity fluids, diaphragm sump pumps excel in these environments. The key to their success lies in their unique design, which incorporates a flexible diaphragm that moves back and forth to create suction and pressure. This mechanism ensures that even viscous or particulate-laden fluids can be transferred with ease.

One of the critical components of a diaphragm sump pump is the diaphragm pump ball. These small yet essential parts play a crucial role in regulating the flow of wastewater through the pump. Diaphragm pump balls are specifically engineered to withstand the harsh conditions of industrial wastewater, ensuring long-lasting performance and minimal maintenance. They are typically made from durable materials such as stainless steel or advanced composites, which resist corrosion and wear. By precisely controlling the flow, diaphragm pump balls help maintain the efficiency of the pump, ensuring that wastewater is processed and transferred effectively.

The versatility of diaphragm sump pumps is another significant advantage in industrial wastewater management. These pumps are available in a range of sizes and configurations, making them suitable for various applications. Whether it is a small-scale operation or a large industrial facility, there is a diaphragm sump pump that can meet the specific needs. For instance, a large diaphragm pump can handle high volumes of wastewater, making it ideal for heavy-duty industrial processes. These large diaphragm pumps are designed to operate continuously, providing reliable performance even under demanding conditions.

One of the standout features of diaphragm sump pumps is their ability to handle solids. Industrial wastewater often contains a variety of solid materials, from small particles to larger debris. Traditional pumps may clog or fail when faced with such solids, to costly downtime and repairs. Diaphragm sump pumps, however, are built to handle these challenges. Their design allows them to pass solids without clogging, ensuring smooth and uninterrupted operation. This capability is particularly important in industries such as manufacturing, mining, and food processing, where wastewater is likely to contain a high concentration of solids.

Another significant benefit of diaphragm sump pumps is their energy efficiency. These pumps are designed to operate with minimal energy consumption, making them a cost-effective solution for industrial wastewater management. By reducing energy usage, industries can lower their operational costs while also contributing to environmental sustainability. In addition, diaphragm sump pumps are relatively easy to install and maintain. Their simple design means that they require less maintenance compared to other types of pumps, reducing the need for frequent repairs and replacements.

The reliability of diaphragm sump pumps is further enhanced by their ability to operate in dry conditions. Unlike some other pumps that may suffer damage when run dry, diaphragm sump pumps can handle occasional dry running without adverse effects. This feature is particularly useful in industrial settings where wastewater levels may fluctuate. It ensures that the pump can continue to operate effectively even when the water level drops, providing consistent performance.

In terms of environmental impact, diaphragm sump pumps play a crucial role in reducing the risk of contamination. By efficiently transferring wastewater to treatment facilities, these pumps help ensure that harmful substances are properly managed and treated. This not only protects the environment but also helps industries comply with stringent environmental regulations. The ability of diaphragm sump pumps to handle a wide range of wastewater characteristics makes them an ideal solution for various industrial applications.

Diaphragm sump pumps have significantly enhanced industrial wastewater management through their innovative design, durability, and versatility. The use of diaphragm pump balls ensures precise flow control, while the availability of large diaphragm pumps caters to high-volume requirements. These pumps offer reliable performance, energy efficiency, and ease of maintenance, making them a valuable asset in any industrial setting. As industries continue to seek sustainable and effective solutions for wastewater management, diaphragm sump pumps are poised to play a vital role in shaping the future of industrial operations.

English

English русский

русский Español

Español عربى

عربى