Understanding the Operating Principles of Diaphragm Powder Pumps for Bulk Handling

2025.08.18

2025.08.18

Industry News

Industry News

In the field of bulk material handling, the demand for efficient and reliable pumping solutions has steadily increased. Among the various types of pumps available, the Powder Transfer Pumps have become essential tools for transferring dry bulk powders with minimal dust generation and product degradation. Particularly, the Powder Diaphragm Pump has emerged as a preferred choice due to its unique design and operating principles that cater specifically to the challenges faced in powder handling applications.

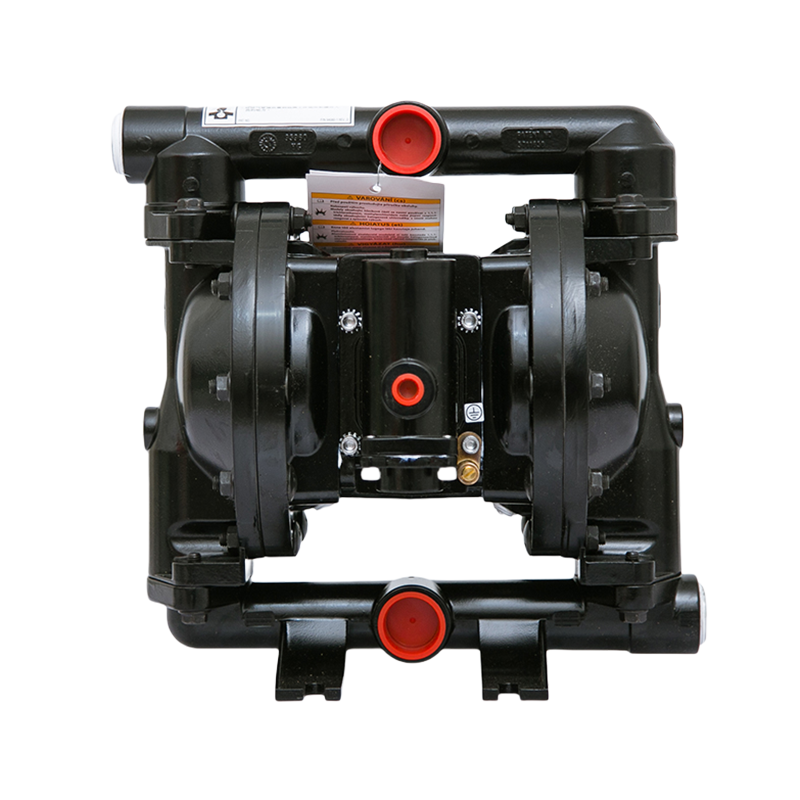

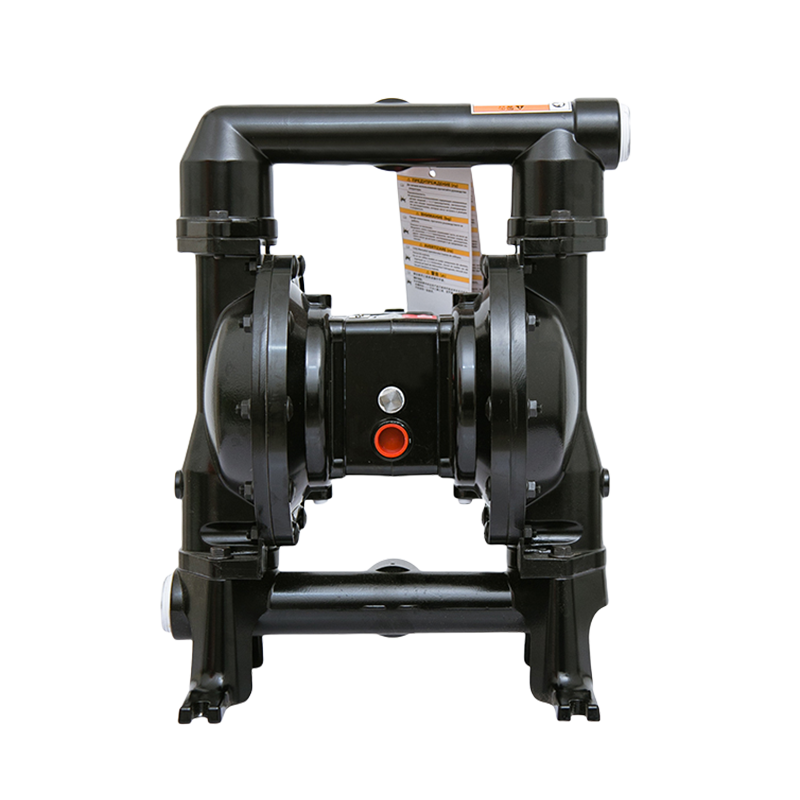

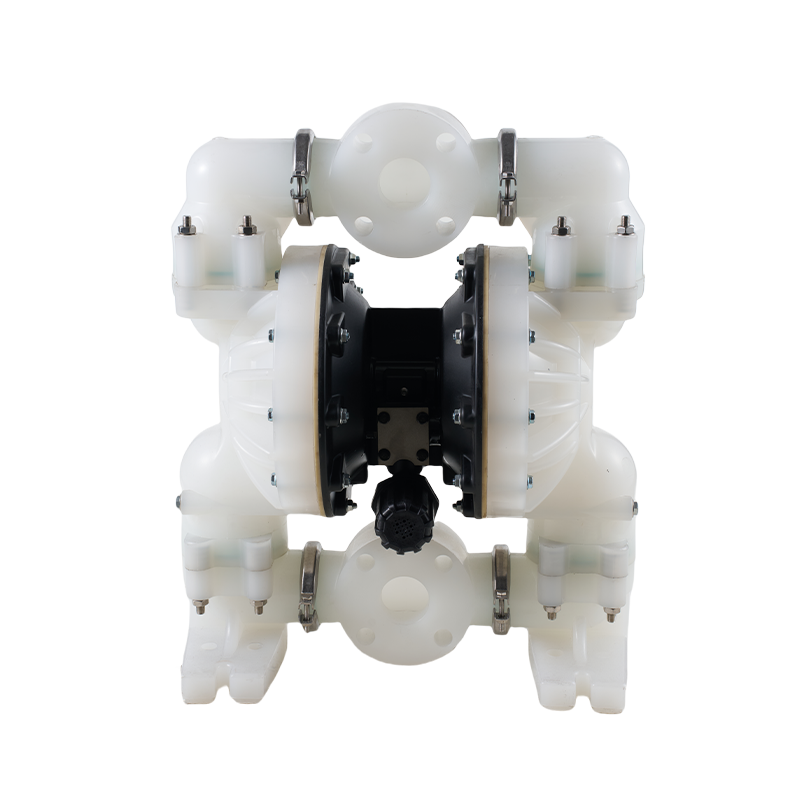

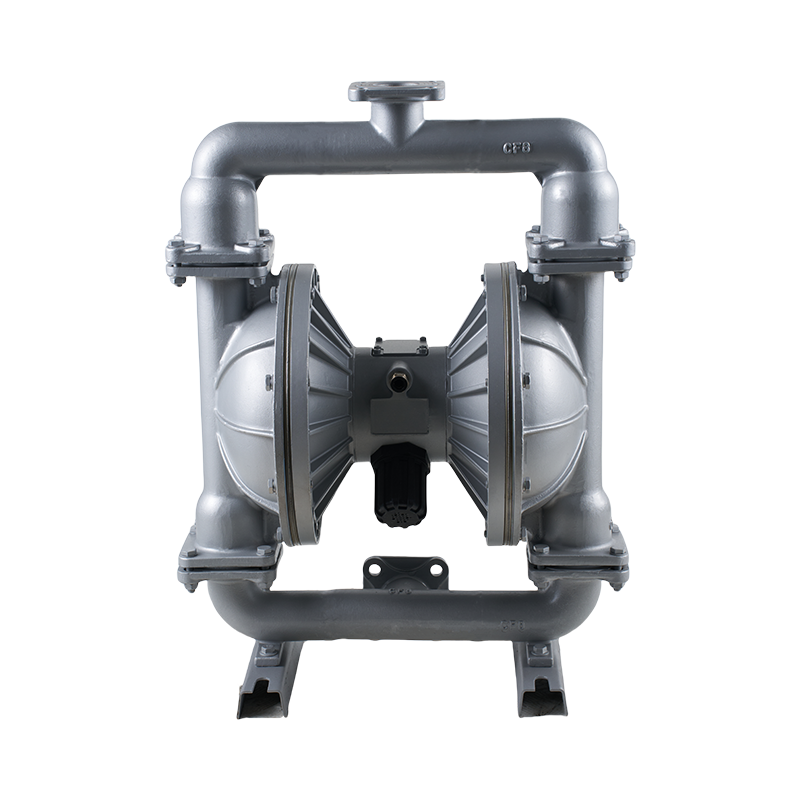

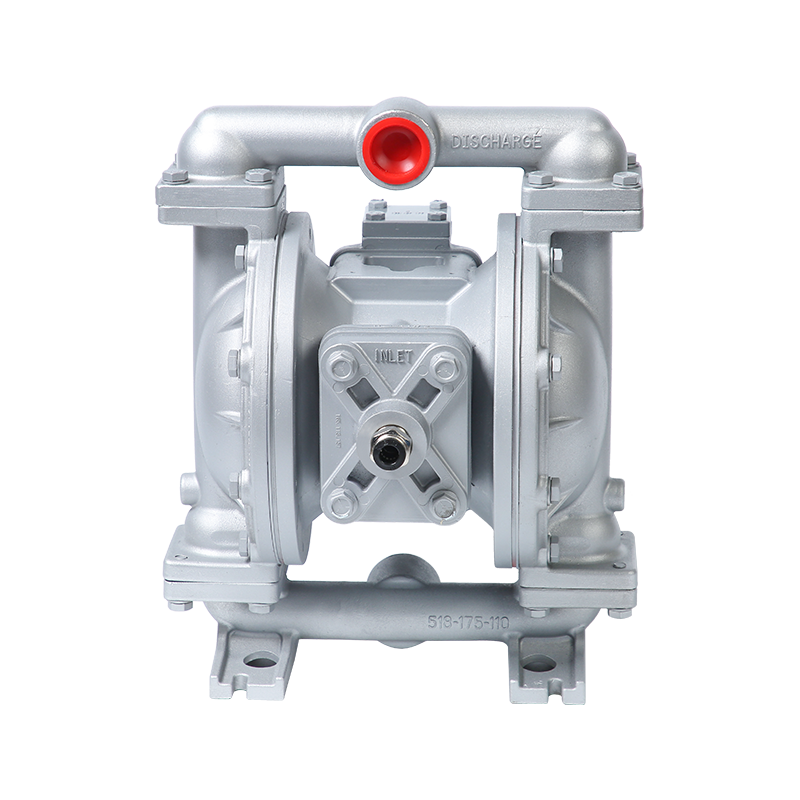

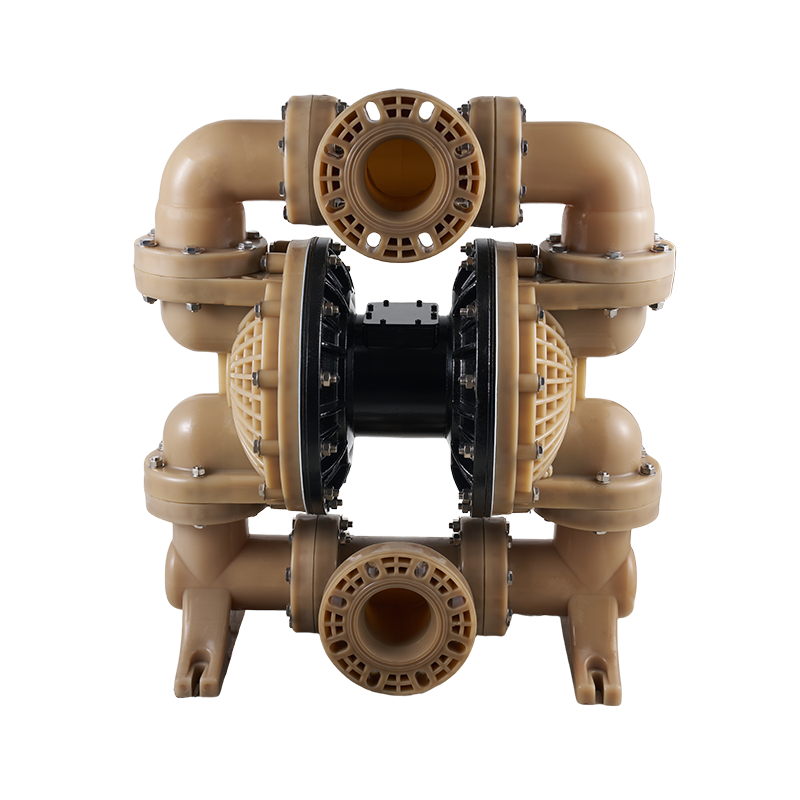

A Diaphragm Powder Pump operates on a fundamentally different principle compared to traditional rotary or centrifugal pumps. Instead of using impellers or rotating parts to move material, this pump relies on a flexible diaphragm that oscillates within the pump chamber. This diaphragm movement creates a vacuum that draws the powder into the pump and subsequently pushes it out through the discharge outlet. The design allows for gentle handling of powders, preventing damage to fragile particles and reducing the risk of clogging or bridging.

One of the key advantages of Powder Transfer Pumps is their ability to handle abrasive and corrosive powders without significant wear and tear. The diaphragm, typically made of durable elastomeric materials, acts as a barrier between the powder and the mechanical components of the pump. This isolation enhances the pump's longevity and reduces maintenance frequency, which is a critical factor in industrial environments where downtime can be costly.

The operation of a Powder Diaphragm Pump is powered either pneumatically or electrically. Pneumatic models are particularly popular in environments where explosion-proof equipment is required, as they eliminate the risk of sparks that could ignite fine powders. The alternating pressure applied to the diaphragm chambers creates the pumping action, allowing for precise control over the flow rate and pressure, which is vital when handling bulk powders that may vary in density and particle size.

In bulk handling applications, the ability to transfer powders efficiently and safely is paramount. Powder Transfer Pumps are designed to minimize dust emissions during operation, which not only protects the work environment but also ensures the health and safety of workers. The sealed nature of diaphragm pumps prevents leakage, reducing the risk of contamination and material loss. This feature is particularly important when dealing with pharmaceutical, food-grade, or chemical powders that require strict handling protocols.

The versatility of Diaphragm Powder Pumps extends across various industries, including pharmaceuticals, chemicals, food processing, and construction materials. Their capacity to handle powders ranging from fine talc to coarse cement makes them indispensable for manufacturers and processors who need reliable solutions for moving bulk solids. The pump's modular construction also allows for customization and easy integration into existing systems, enhancing operational efficiency.

When selecting a Powder Diaphragm Pump for bulk handling, it is important to consider several factors, such as powder characteristics, required flow rates, and system compatibility. Understanding the pump's operating principles helps in making informed decisions to ensure performance. For example, powders with high moisture content or stickiness may require specific diaphragm materials or additional features to prevent clogging.

Regular maintenance of Powder Transfer Pumps is relatively straightforward due to the simple design of the diaphragm and valve assemblies. Routine inspection and replacement of diaphragms can prevent unexpected failures and extend the pump's operational life. Moreover, the ease of cleaning makes diaphragm pumps suitable for applications where cross-contamination must be avoided.

The Powder Diaphragm Pump plays a crucial role in the efficient and safe transfer of bulk powders. Its operating principles—centered on diaphragm movement to create suction and discharge—provide distinct advantages in handling abrasive, fragile, or hazardous powders. Powder Transfer Pumps have thus become a cornerstone in bulk material handling industries, offering durability, flexibility, and improved workplace safety. As industries continue to evolve and demand higher standards for powder handling, understanding the functionality of diaphragm powder pumps will remain essential for engineers and operators aiming to optimize their processes.

English

English русский

русский Español

Español عربى

عربى