How Do Cheap Diaphragm Pump Manufacturers Handle Material Selection?

2025.12.19

2025.12.19

Industry News

Industry News

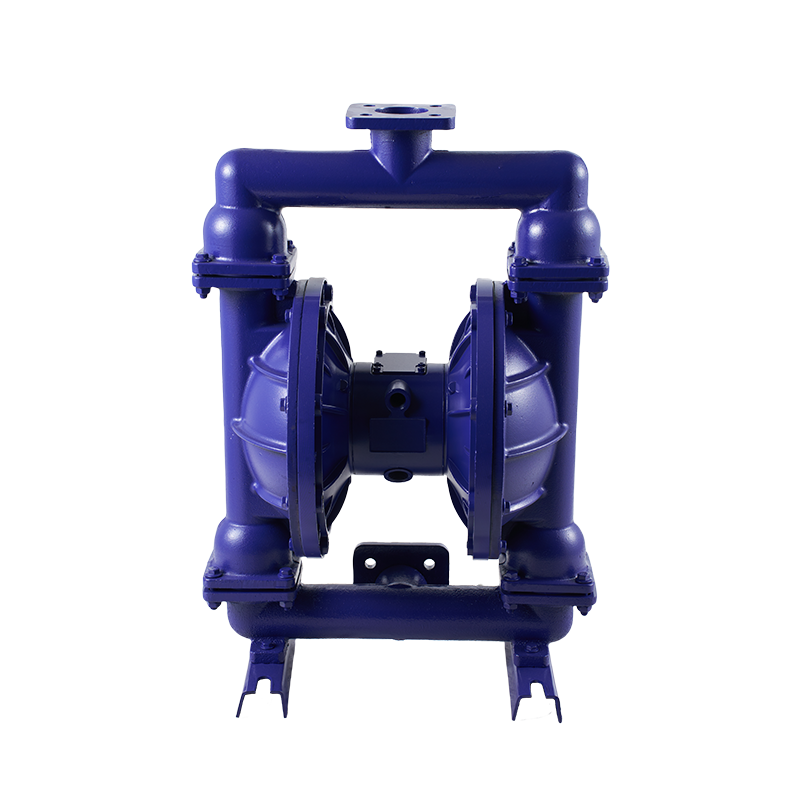

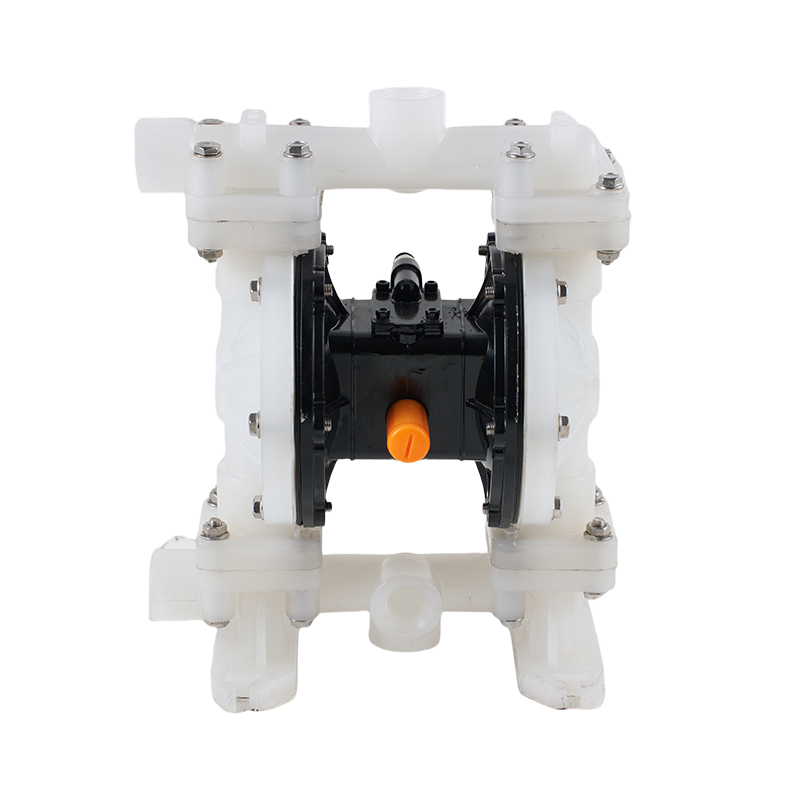

Many users deal with chemicals, mixed compounds, or corrosive substances daily. They want something that works, stays stable under routine cycles, and does not require frequent replacement. When produced by experienced Cheap Diaphragm Pump Manufacturers, these pumps provide a reasonable balance of affordability and performance.

A major advantage comes from materials like polypropylene. This material supports chemical resistance and handles acidic fluids without corroding. When fluid properties vary, polypropylene gives the pump a strong foundation. It helps users avoid issues commonly seen in metal-based units when handling acids.

1. A Practical Structure That Fits Real-World Applications

A Cheap Diaphragm Pump is widely used in chemical processing, water treatment, coatings production, and other fluid-handling environments. Polypropylene versions, for example, work well with acids such as hydrochloric or sulfuric mixtures. The surface helps reduce buildup and clogging, keeping the pump running smoothly.

This is valuable for plants that frequently adjust between different materials. Many users also appreciate that the pump remains lightweight, making installation, relocation, and routine checks easier. Weight reduction supports maintenance teams who prefer equipment that does not add unnecessary strain during disassembly.

Buyers working with abrasive or viscous materials also benefit. The pump can handle these fluids without heavy wear on internal parts. This reduces the frequency of repair work and minimizes interruptions.

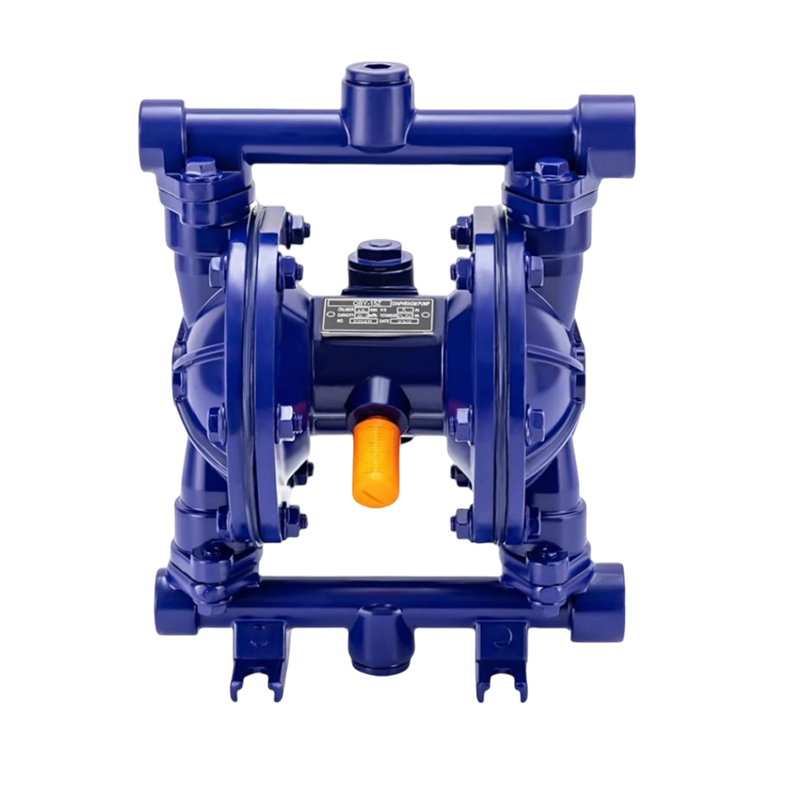

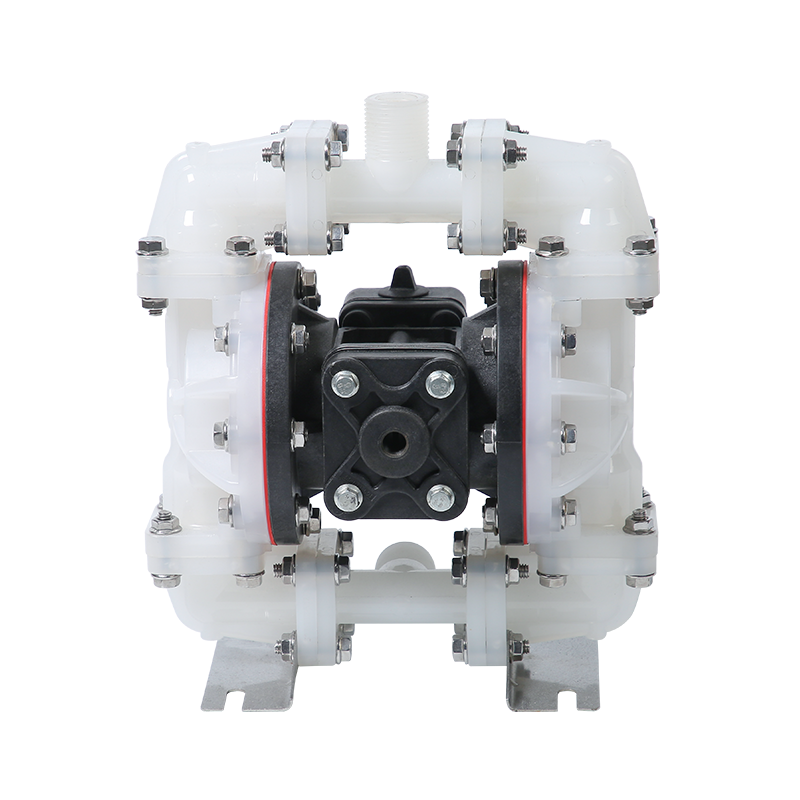

2. Factory Capabilities That Influence Performance

Cheap Diaphragm Pump Manufacturers in China often run organized production systems with controlled molding, machining, and assembly steps. Their experience in polypropylene processing allows them to produce uniform chambers and smooth internal paths. This helps avoid fluid stagnation and contributes to steadier flow output.

Manufacturers commonly conduct pressure tests and chemical resistance evaluations. These procedures confirm that the unit can handle typical industrial pressure ranges and contact with acidic liquids. Testing also supports predictable diaphragm movement, which is important for long-term reliability.

By balancing cost and production efficiency, these manufacturers meet the needs of buyers who require steady operation without unnecessary features. Many users appreciate that the pumps can be replaced or scaled easily as production grows.

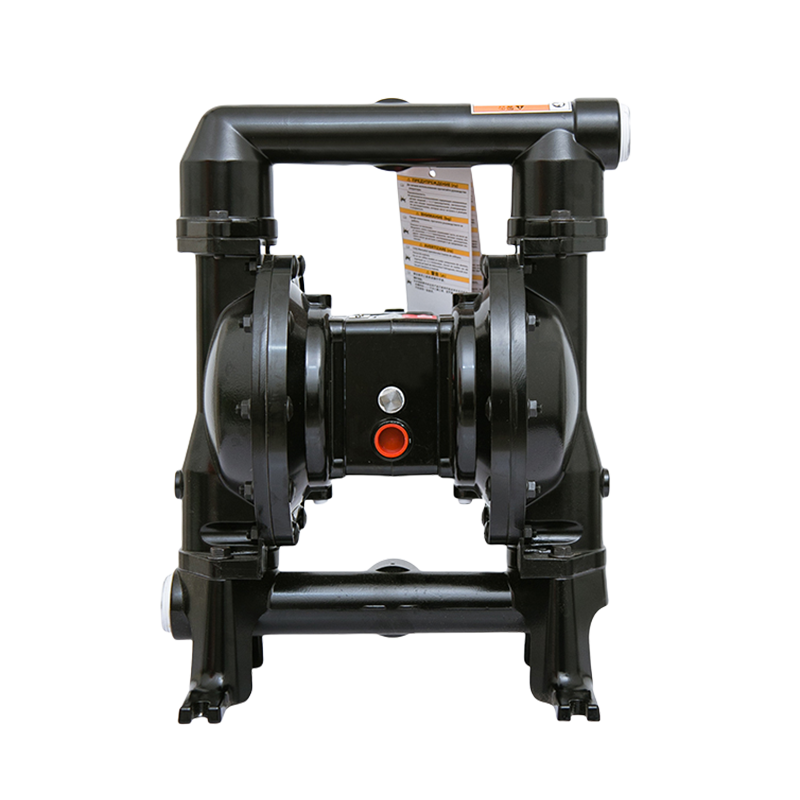

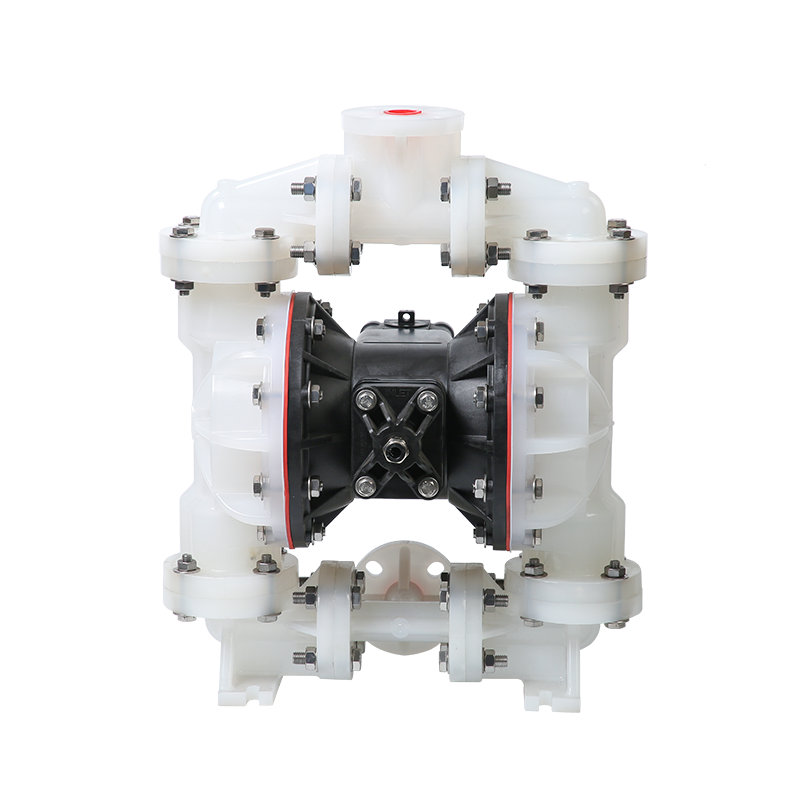

3. Suitable for Multiple Chemical and Utility Operations

Polypropylene diaphragm pumps are known for their compatibility with acids, solvents, and corrosive chemicals. This adaptability makes the Cheap Diaphragm Pump a practical option for chemical plants that need stable transfer without metal corrosion.

In water treatment environments, the pump handles dosing, sludge movement, or filtration support jobs with consistent performance. Paint and coating factories use it due to its resistance to solvents and ease of cleaning. The air-operated design keeps operation simple, especially in locations where electrical components may not be ideal.

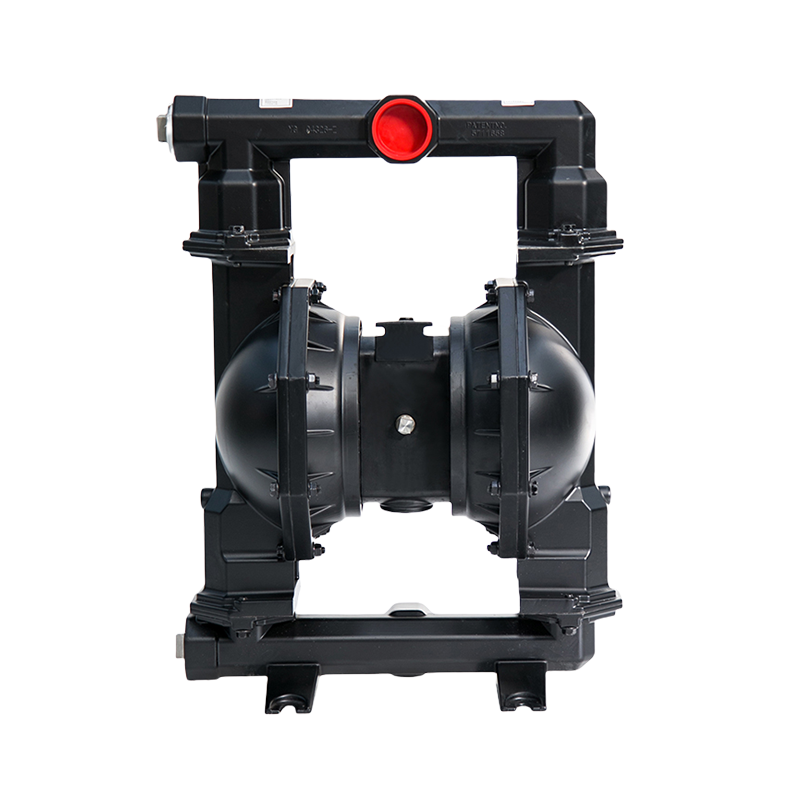

For many plants, purchasing decisions center on long-term practicality rather than high technical complexity. A Cheap Diaphragm Pump provides this balance. The pump can run dry when needed, handle solids in many cases, and maintain stable performance even with repeated cycles.

Technicians often prefer polypropylene units because of their manageable maintenance demands. The surface resists buildup, which reduces cleaning time. With fewer wear-prone parts, downtime decreases, and operating stress on teams becomes lighter.

Working with reliable Cheap Diaphragm Pump Manufacturers also gives buyers a consistent supply, model variety, and steady support. The result is a piece of equipment that fits real industrial environments, supports daily tasks, and meets budget targets without sacrificing usability.

English

English русский

русский Español

Español عربى

عربى