How Does A Customized Diaphragm Pump Fit Unique Industrial Tasks?

2025.12.12

2025.12.12

Industry News

Industry News

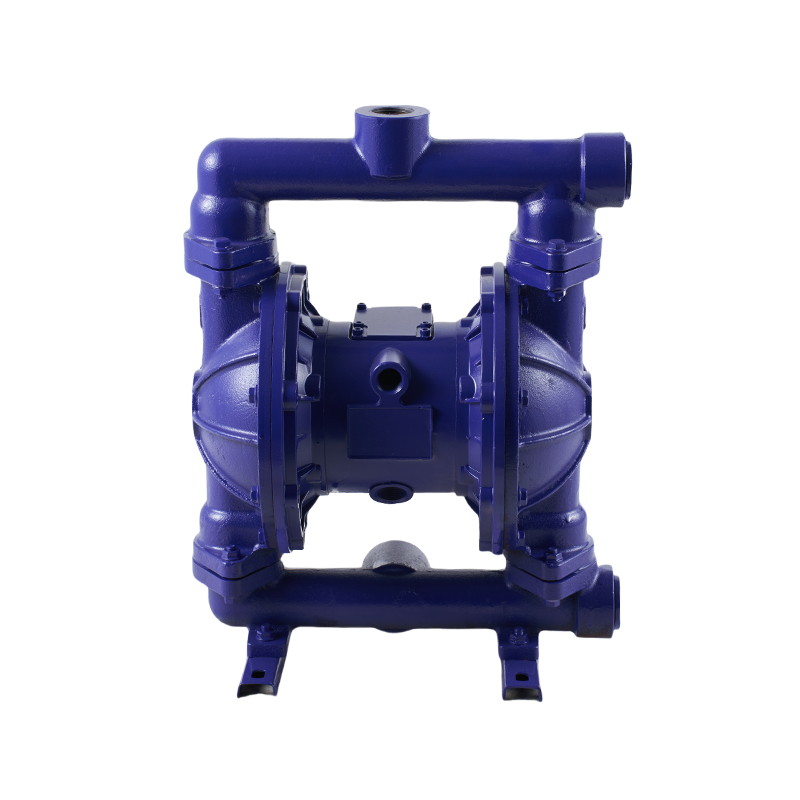

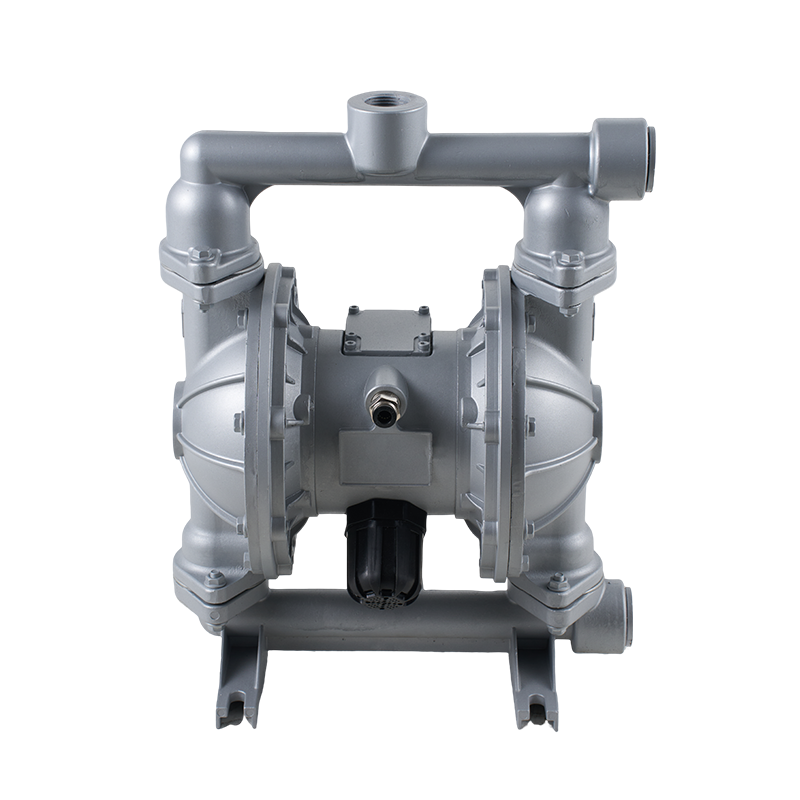

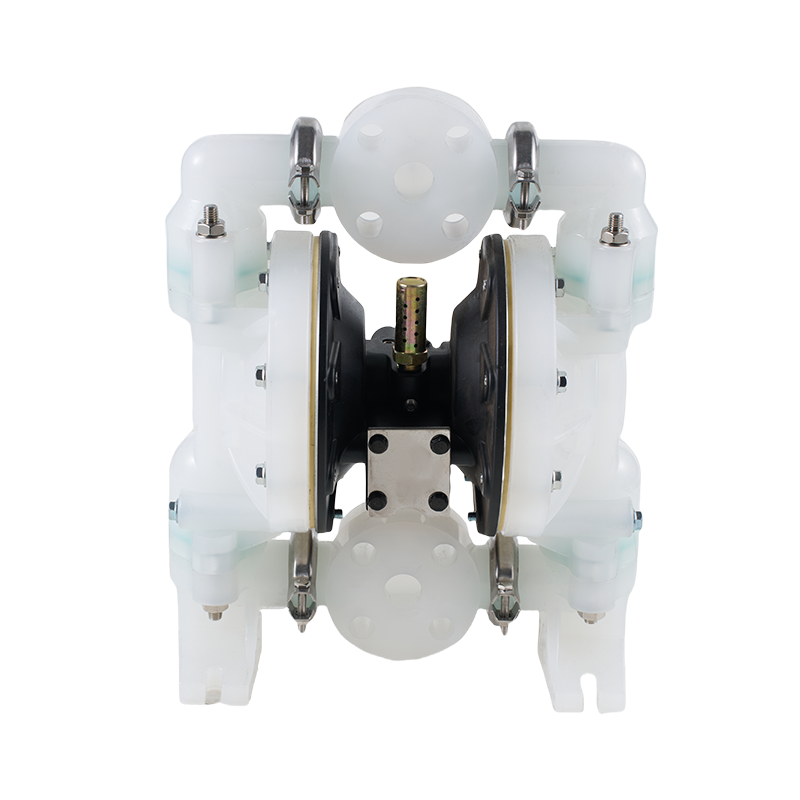

Industrial production environments constantly face challenges related to fluid transfer. Many users work with corrosive chemicals, mixed materials, variable viscosities, or unstable operating pressures. Standard equipment does not always solve these problems. This is where a Customized Diaphragm Pump becomes valuable, giving factories the flexibility needed to match specific working requirements. When managed by an experienced manufacturer, the pump offers a stable structure and dependable performance that fits day-to-day operations.

1. Pump Design That Matches Real Application Conditions

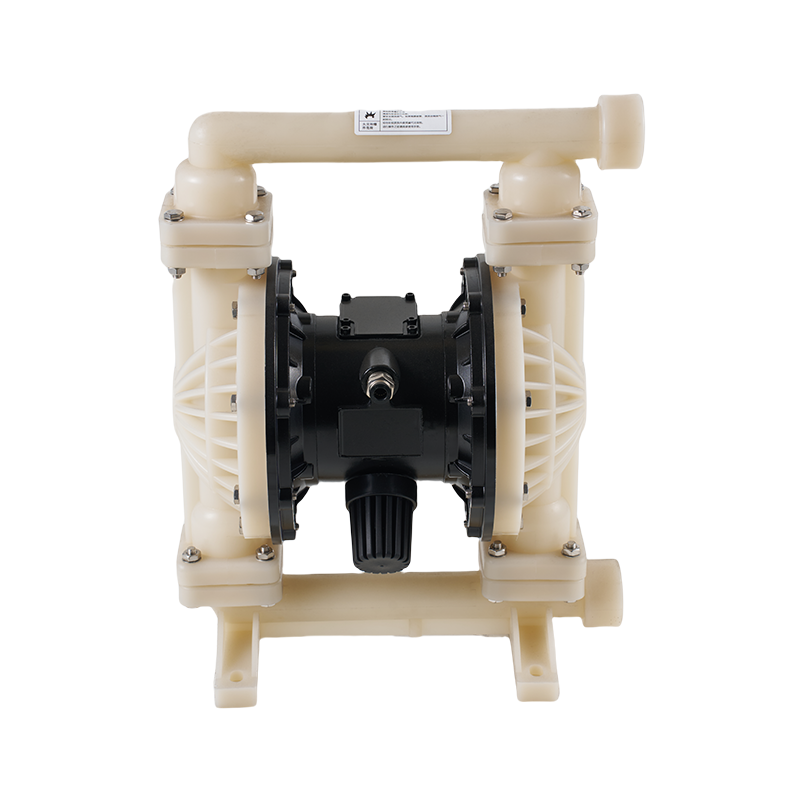

Different industries face different pain points. Chemical plants need corrosion-resistant materials. Water treatment sites need pumps that handle sludge or dosing additives. Food and pharmaceutical plants require smooth inner surfaces and steady pneumatic operation. A Diaphragm Pump can support these environments, but a custom version gives users even better alignment with their daily tasks.

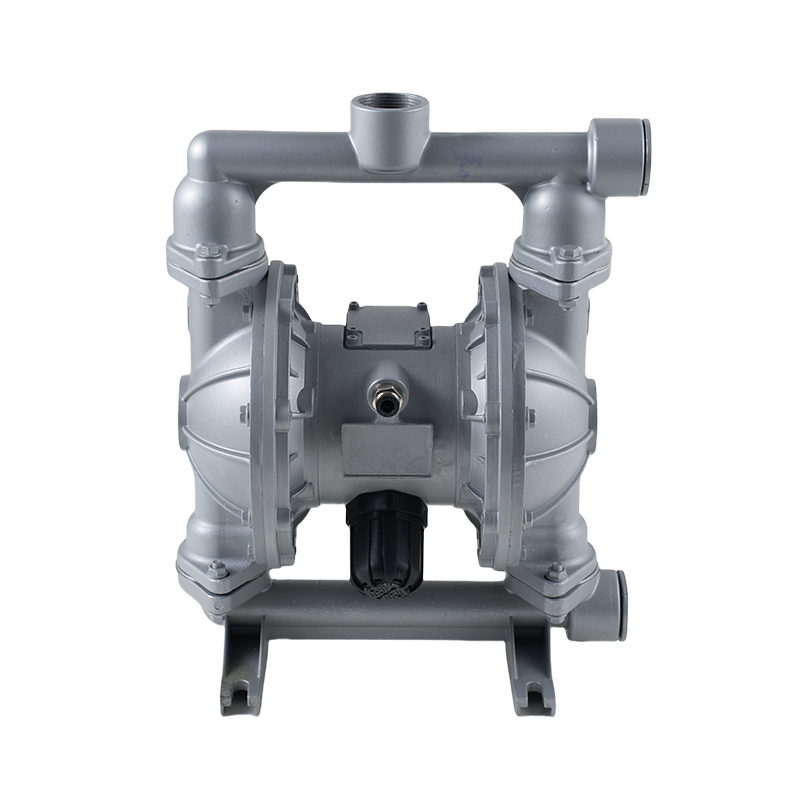

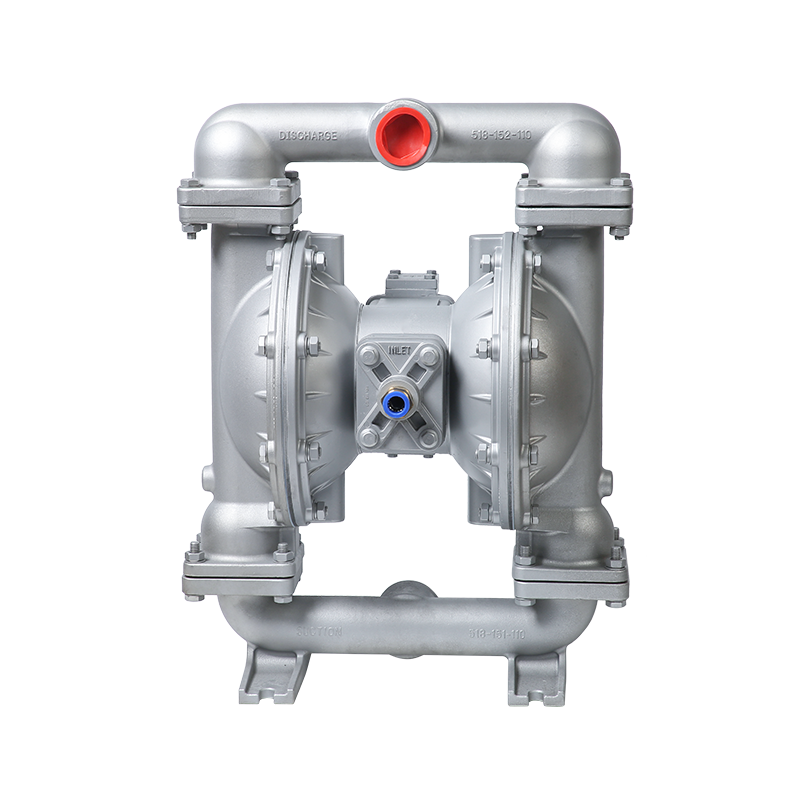

For example, some buyers request modified inlet sizes to support higher viscosity fluids. Others need specific diaphragm materials to match solvent-based liquids. Adjusting these features during production helps the pump deliver stable flow without overloading system components. The Customized Diaphragm Pump also fits locations with tight installation spaces, since the factory can change the pump layout or orientation.

2. Factory Capabilities That Support Strong Performance

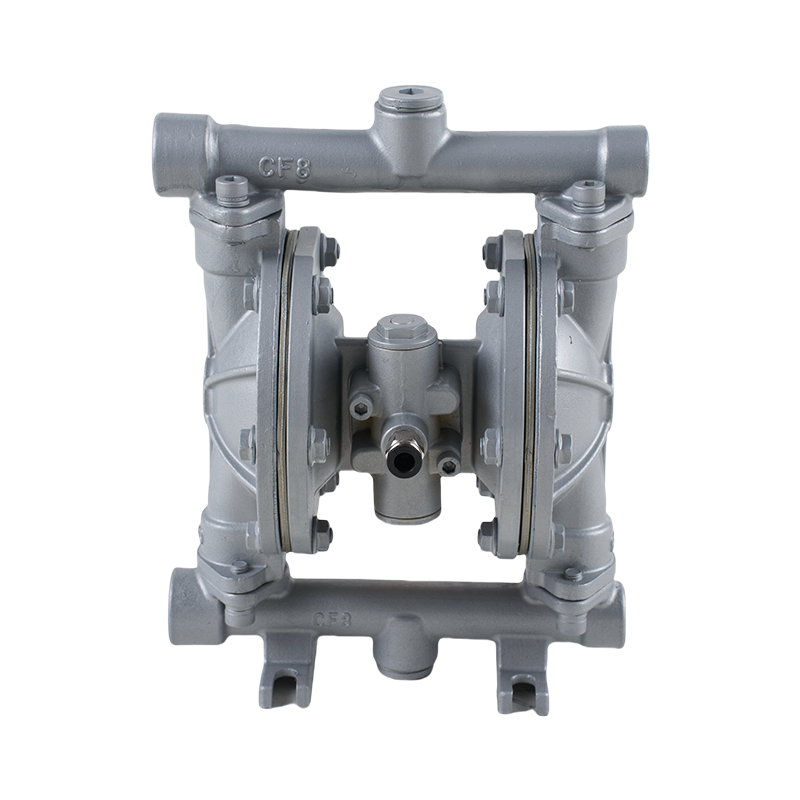

A high-quality Chinese manufacturer with experience in pneumatic diaphragm equipment brings several advantages. Skilled technicians and established workflows support accurate machining, stable assembly, and clean internal sealing. A Diaphragm Pump produced in such an environment benefits from consistent quality across batches.

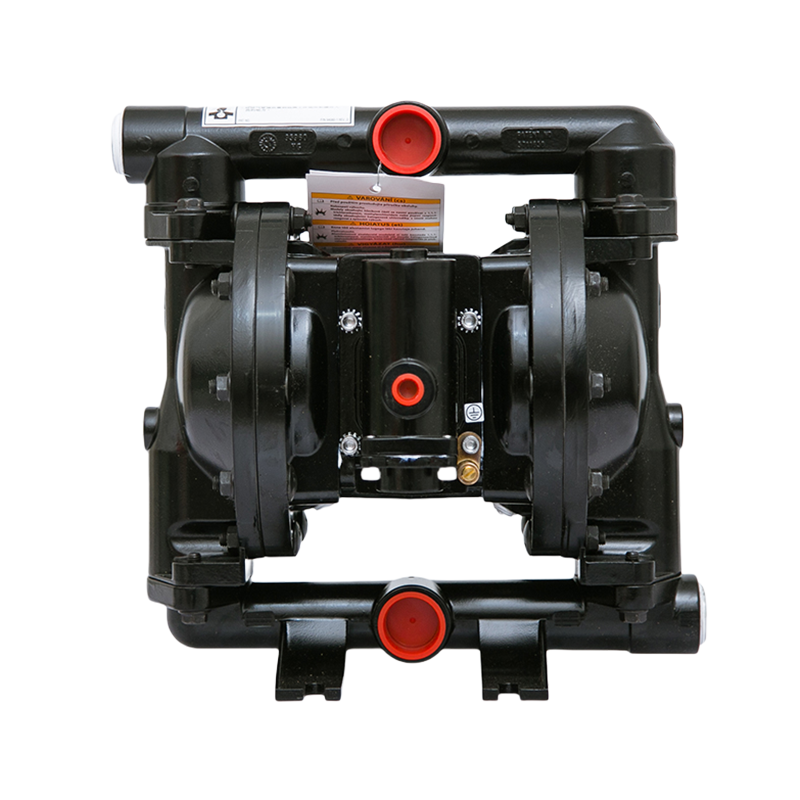

Manufacturers conduct performance checks such as pressure cycling, chemical compatibility testing, and flow consistency observations. These steps help confirm that the pump can handle routine operation without unexpected wear. Buyers who rely on continuous production appreciate this stability because it reduces maintenance pressure.

3. Suitable for Various Industrial Fields

A Customized Diaphragm Pump works across industries because of its flexible structure. Chemical processors use it to handle aggressive liquids. Water treatment teams choose it for sludge transfer and precise dosing. Fluid manufacturers value the pump's ability to move mixed or abrasive materials without damaging internal parts.

In more sensitive environments, such as food and pharmaceutical plants, pneumatic operation supports stable performance without electrical components near processing areas. The Diaphragm Pump also handles intermittent or continuous cycles, making it suitable for packaging lines, mixing systems, or filling processes.

Each industry benefits from customization differently. Some require larger flow ranges, others require lightweight construction for easier maintenance. Having the ability to adjust materials, valve systems, or air chambers helps users get exactly what their production lines need.

Stable performance matters to every plant manager. A Customized Diaphragm Pump reduces the chance of unexpected breakdowns because the components are selected based on the actual working fluid. This reduces diaphragm wear, improves sealing life, and supports smoother run cycles.

Another advantage is easier field maintenance. When a pump is selected with the right materials from the start, technicians spend less time troubleshooting repeated issues. This supports steady daily operations and simplifies inventory planning since users do not need to stock multiple incompatible parts.

Working with a capable manufacturer gives buyers access to technical guidance and flexible product options. The Diaphragm Pump becomes not just a piece of equipment but a practical tool shaped for long-term use in industrial systems. For companies dealing with variable working conditions, a customized approach brings reliable and efficient performance that aligns with real production needs.

English

English русский

русский Español

Español عربى

عربى