What Makes A Polypropylene Pneumatic Diaphragm Pump Reliable In Chemicals?

2026.01.27

2026.01.27

Industry News

Industry News

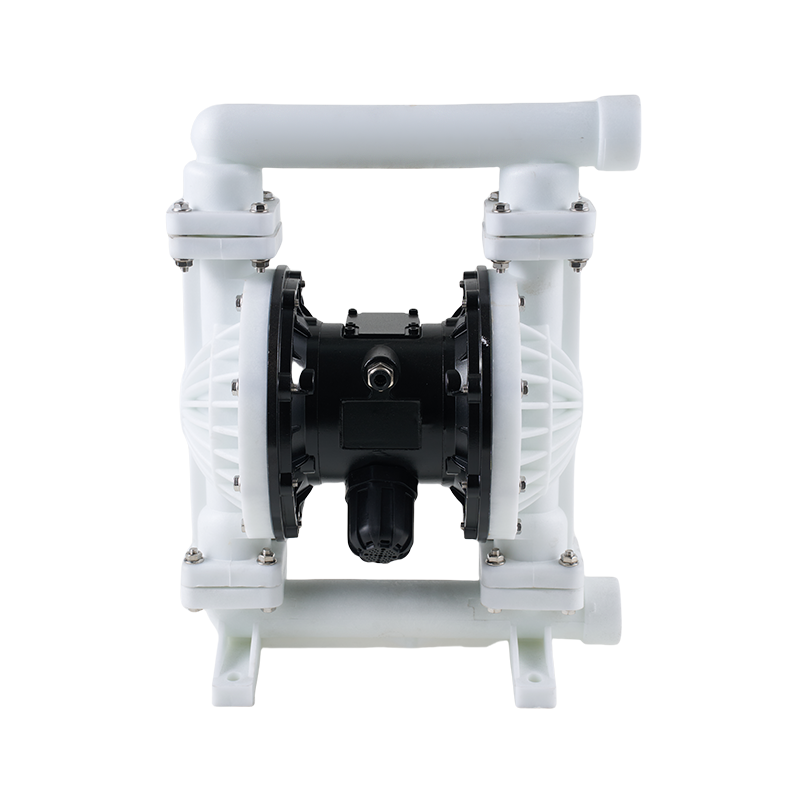

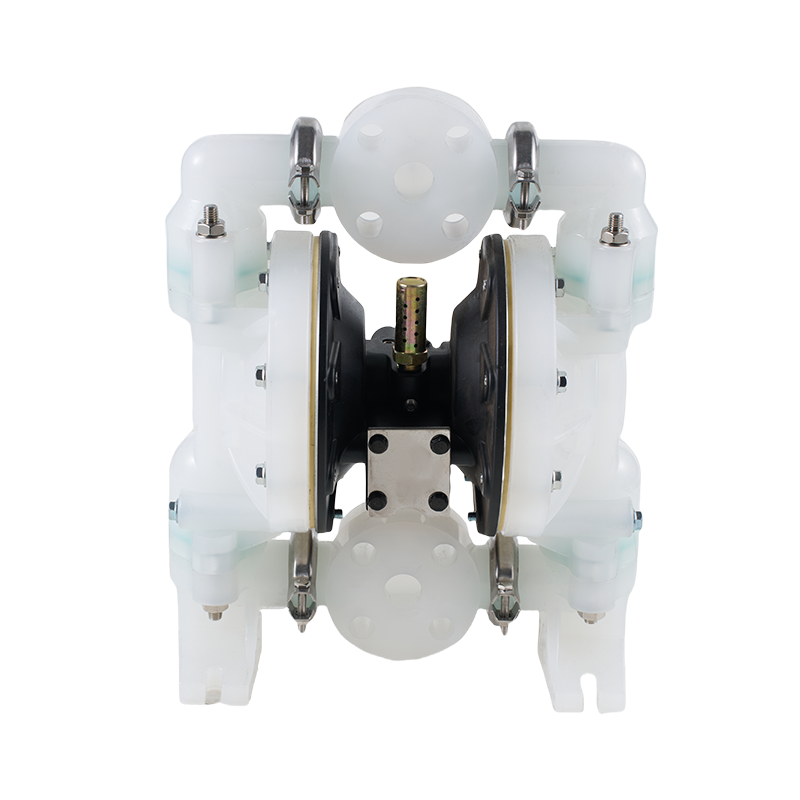

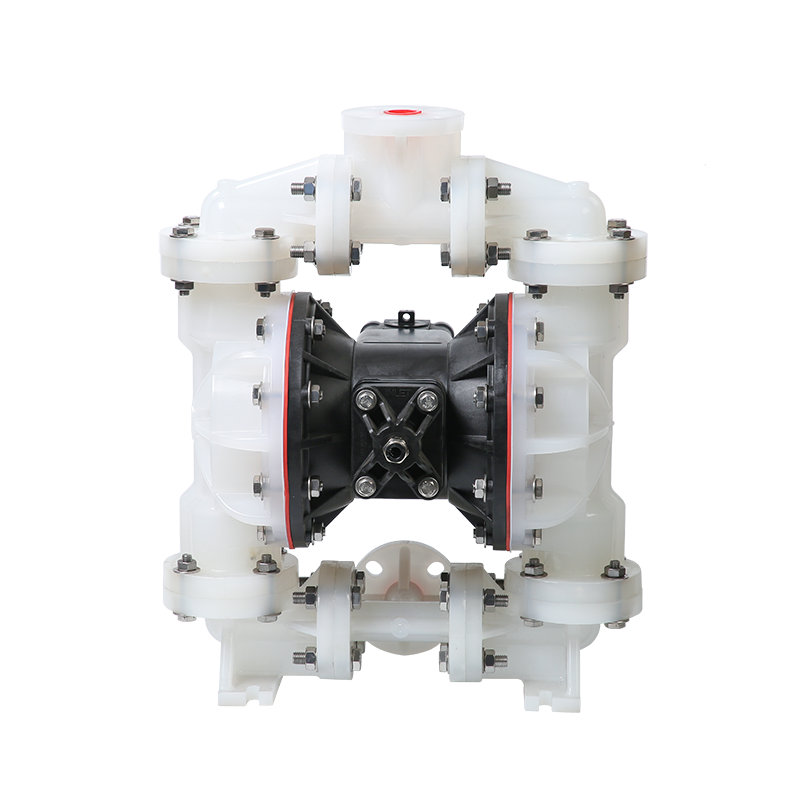

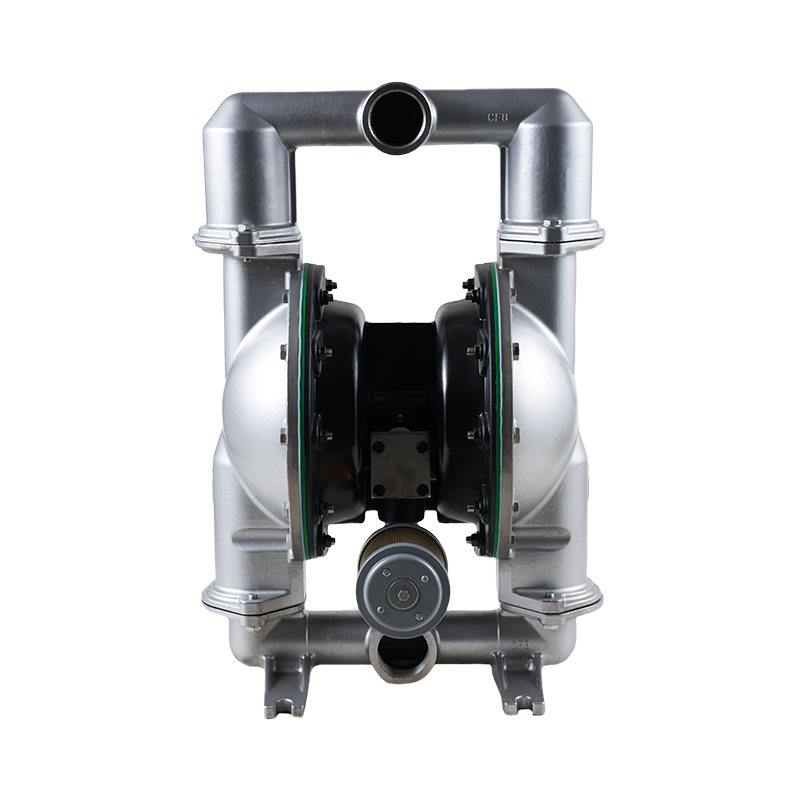

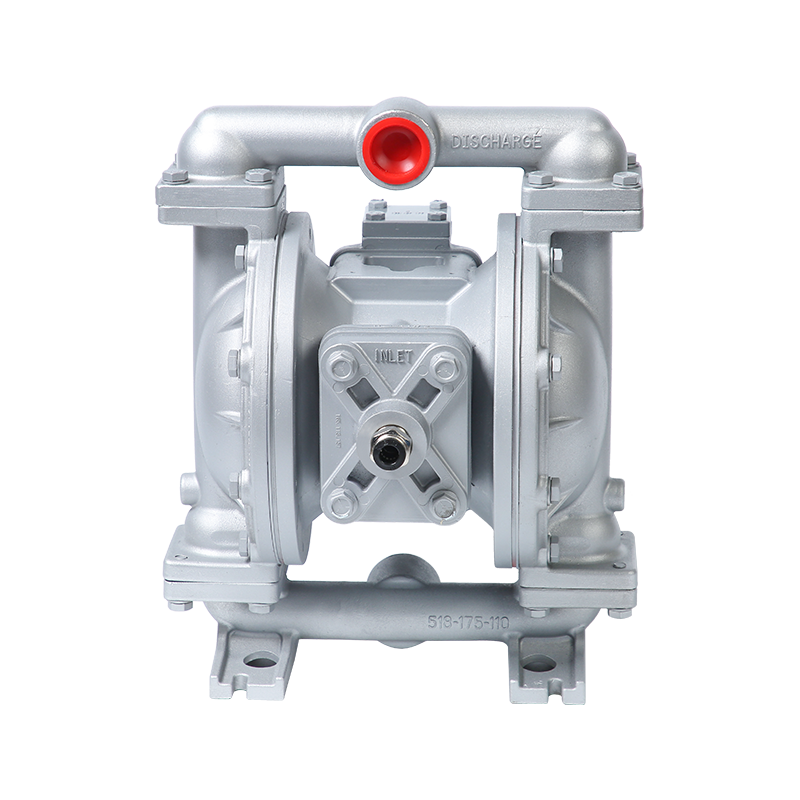

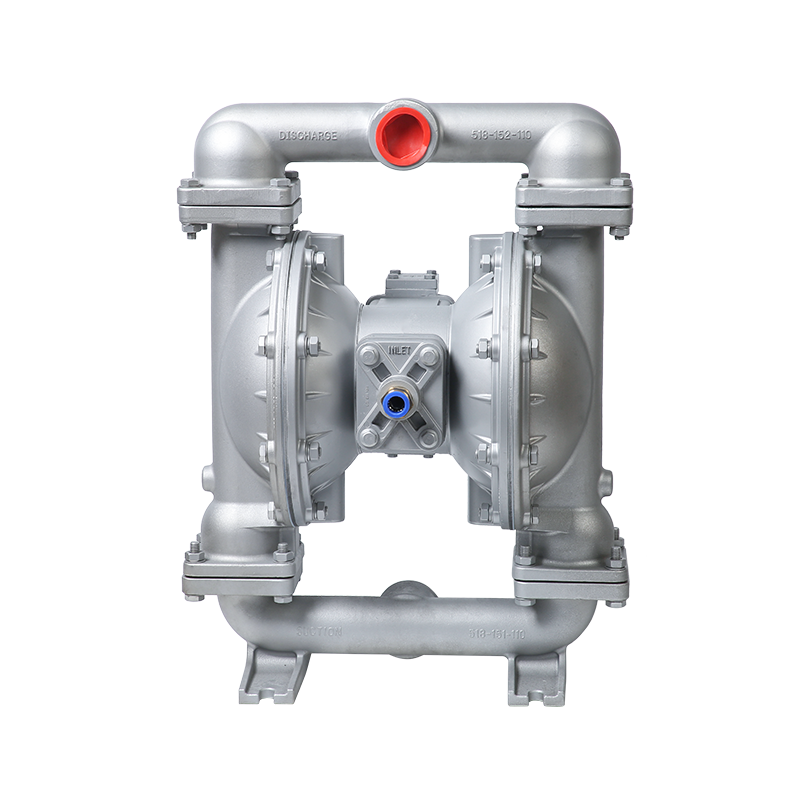

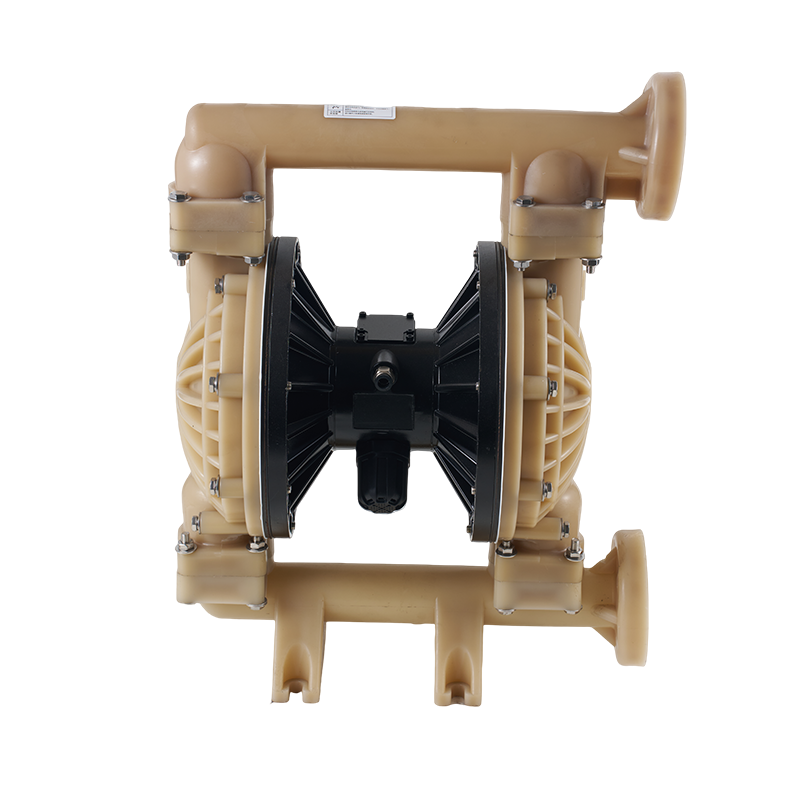

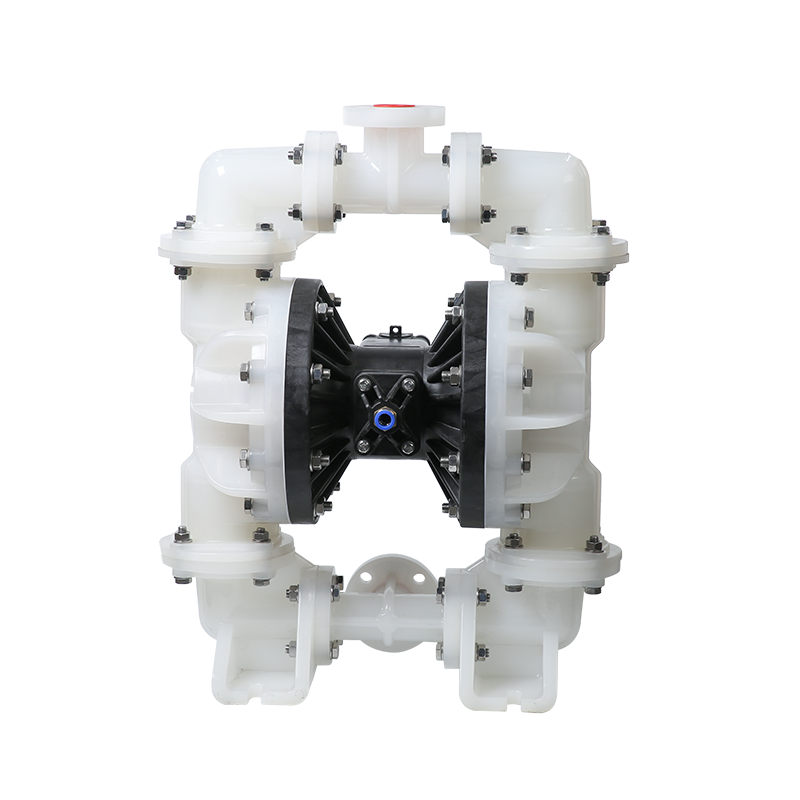

Polypropylene has become a widely accepted material in fluid handling systems where chemical resistance is a priority. A Polypropylene Pneumatic Diaphragm Pump is designed to manage acidic and corrosive liquids without reacting with the media being transferred. This material stability allows the pump to maintain structural integrity over long operating periods, even in demanding chemical environments.

In applications involving acids such as sulfuric or hydrochloric solutions, polypropylene offers consistent resistance compared to many metal alternatives. This is why many chemical plants rely on a Polypropylene Pneumatic Diaphragm Pump to avoid corrosion-related downtime. The smooth internal surfaces of polypropylene also help reduce residue buildup, supporting steady flow and easier cleaning.

From a manufacturing perspective, a Polypropylene Pneumatic Diaphragm Pump Factory focuses heavily on material selection and molding accuracy. Uniform wall thickness and smooth pump chambers are essential for maintaining consistent performance during long-term acid transfer operations.

Air Operated Design and Process Flexibility

A Polypropylene Pneumatic Diaphragm Pump operates using compressed air, making it suitable for environments where electric pumps are not practical. The air-driven mechanism moves the diaphragms back and forth, creating alternating suction and discharge cycles. This design allows the pump to handle fluids with varying viscosities and even small solid content without complex mechanical parts.

The pneumatic drive system offers simple flow adjustment through air pressure control. This flexibility is useful in processes where flow rates change frequently. Since the pump does not rely on rotating seals, leakage risks are reduced, which is important when transferring chemical fluids.

Factories producing these pumps pay close attention to air valve design and diaphragm movement balance. A well-designed Polypropylene Pneumatic Diaphragm Pump Factory will test air distribution systems to maintain stable operation and reduce vibration during continuous use.

Design Considerations for Acid Applications

Designing a reliable acid diaphragm pump involves more than selecting polypropylene as the housing material. Diaphragms, valve balls, and sealing components must also be compatible with acidic fluids. Elastomer selection plays a major role in maintaining sealing performance under chemical exposure.

Manufacturers typically combine polypropylene pump bodies with diaphragms that resist swelling or hardening in acidic environments. Proper alignment of internal components helps reduce uneven wear and maintains smooth diaphragm movement.

Quality control is an important step in a Polypropylene Pneumatic Diaphragm Pump Factory. Pressure testing, leakage inspection, and chemical compatibility checks help verify that each pump can operate under real working conditions. These steps support consistent performance and predictable maintenance intervals.

Maintenance and Long-Term Operation

Routine inspection helps keep a Polypropylene Pneumatic Diaphragm Pump running steadily. Diaphragms and valve components are wear parts and should be checked periodically based on operating hours and fluid characteristics. Clean compressed air also plays a role in stable pump behavior, as contaminated air can affect valve movement.

One advantage of polypropylene construction is that it does not rust or scale internally. This simplifies maintenance and reduces the risk of contamination when handling sensitive chemical fluids. Replacement parts are generally straightforward to install, allowing a quick return to operation.

A capable Polypropylene Pneumatic Diaphragm Pump Factory usually provides clear maintenance guidelines and spare part support, helping users plan servicing without unnecessary downtime.

English

English русский

русский Español

Español عربى

عربى