Top Features to Look for in a Sealcoating Diaphragm Pump

2025.08.18

2025.08.18

Industry News

Industry News

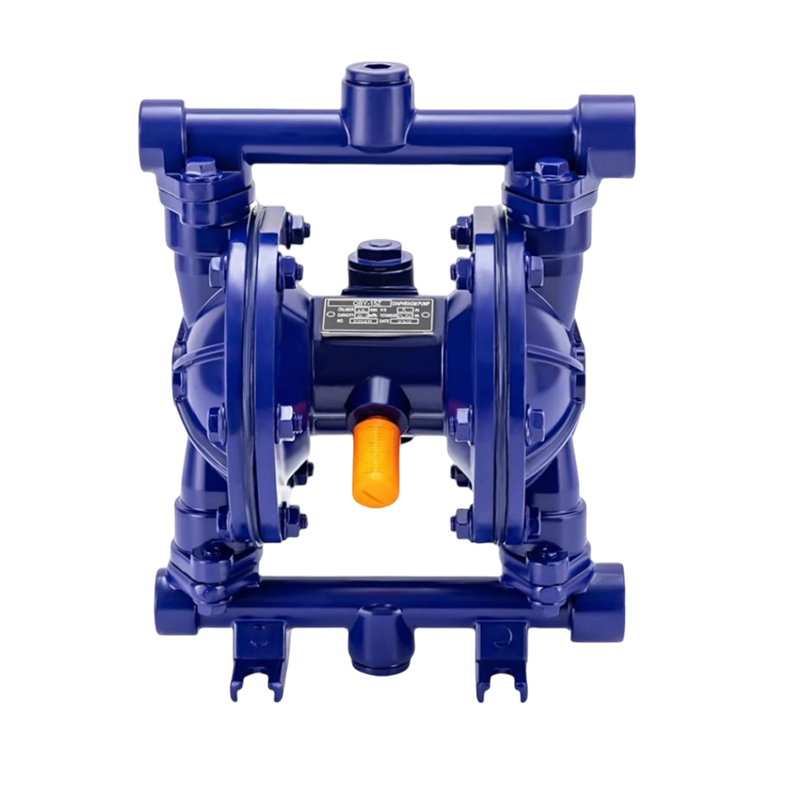

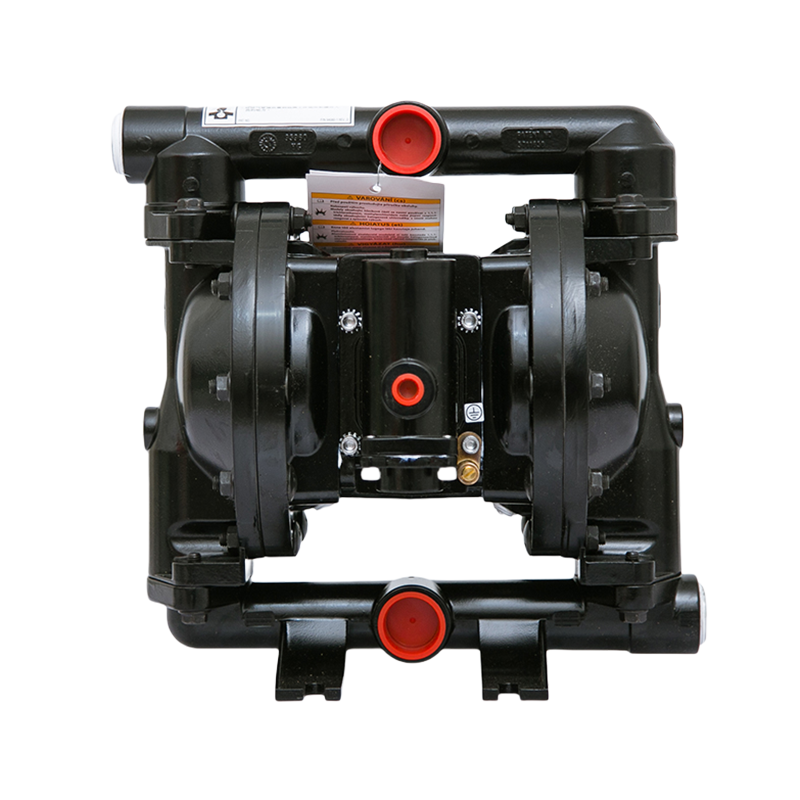

In the world of industrial fluid handling, the importance of selecting the right diaphragm pump cannot be overstated. Among various types available, the Sealcoating Diaphragm Pump stands out due to its versatility and reliability, especially in applications involving viscous materials like sealcoating emulsions. When choosing a sealcoating diaphragm pump, understanding the top features that ensure performance, durability, and ease of maintenance is essential.

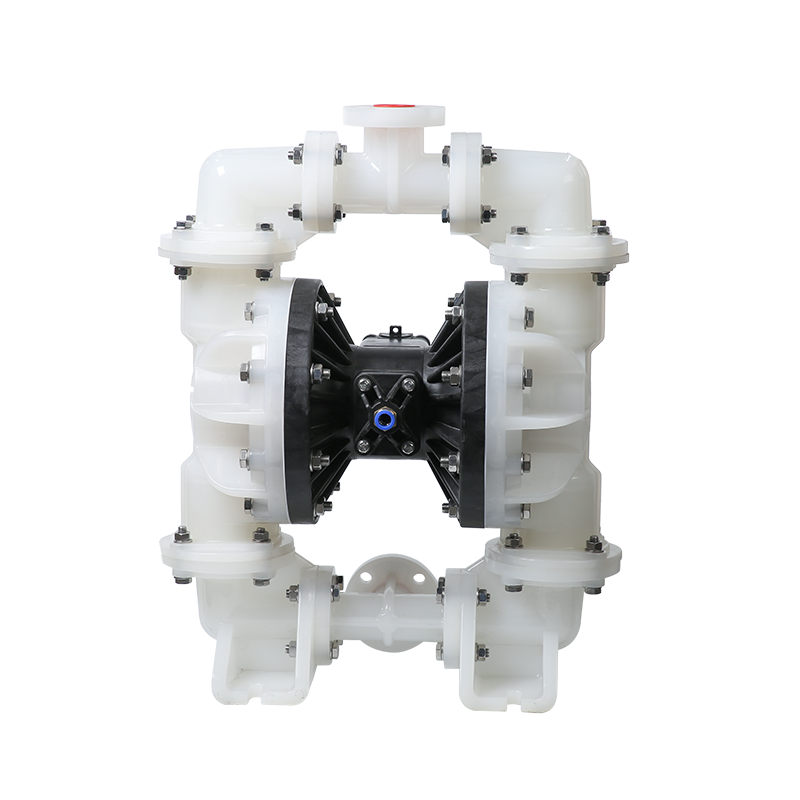

One critical aspect to consider is the pump's ability to handle abrasive and thick fluids. Sealcoating materials are often gritty and can cause wear and tear on standard pumps. A high-quality Sealcoating Diaphragm Pump typically features heavy-duty diaphragms and robust materials such as stainless steel or specialized polymers to withstand these harsh conditions. This design helps extend the pump's service life while maintaining consistent flow rates.

Another important feature is the pump's self-priming capability. The Sealcoating Diaphragm Pump must be able to start pumping without manual priming, which increases operational efficiency and reduces downtime. This is especially important in field applications where quick setup and continuous operation are required.

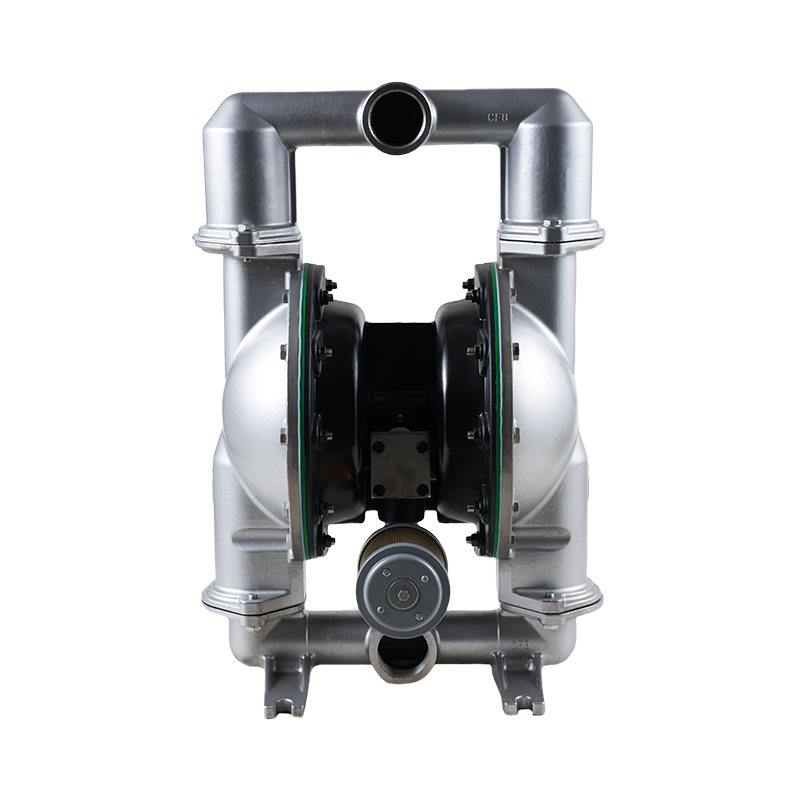

Beyond sealcoating, diaphragm pumps also find extensive use in the food and dairy industries, where the Double Diaphragm Milk Pump is particularly popular. This type of pump is designed to gently handle milk and other delicate liquids, preventing damage to the product while maintaining hygiene standards. For users involved in dairy processing, the Double Diaphragm Milk Pump offers a sanitary and efficient solution thanks to its easy-to-clean design and compatibility with food-grade materials.

When looking for a Double Diaphragm Milk Pump, consider features like FDA-approved components and smooth surfaces that minimize bacterial buildup. The pump should also provide a steady flow without pulsation, which is critical for preserving milk quality during transfer or processing.

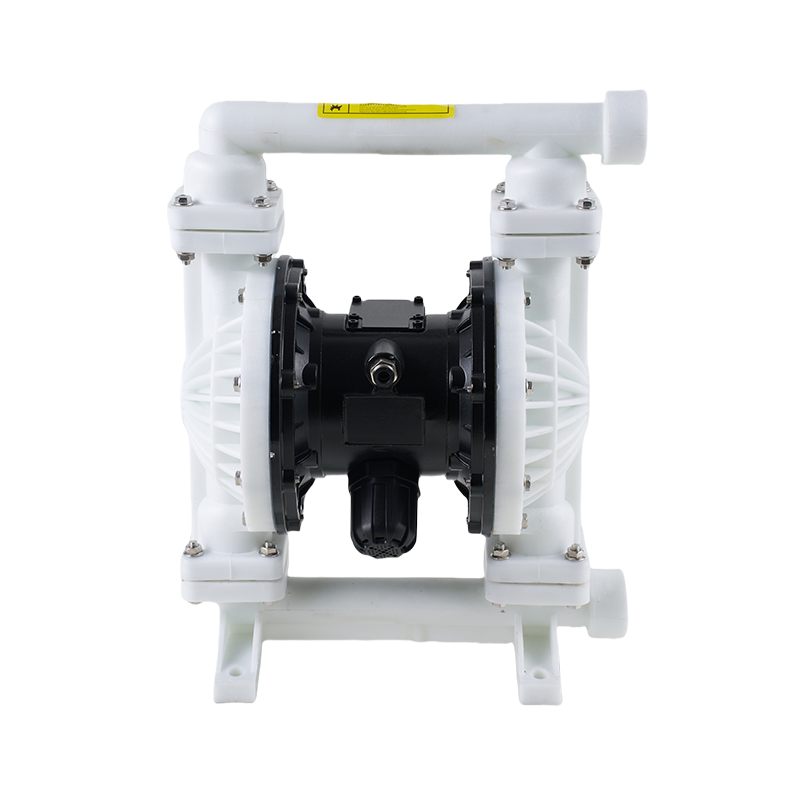

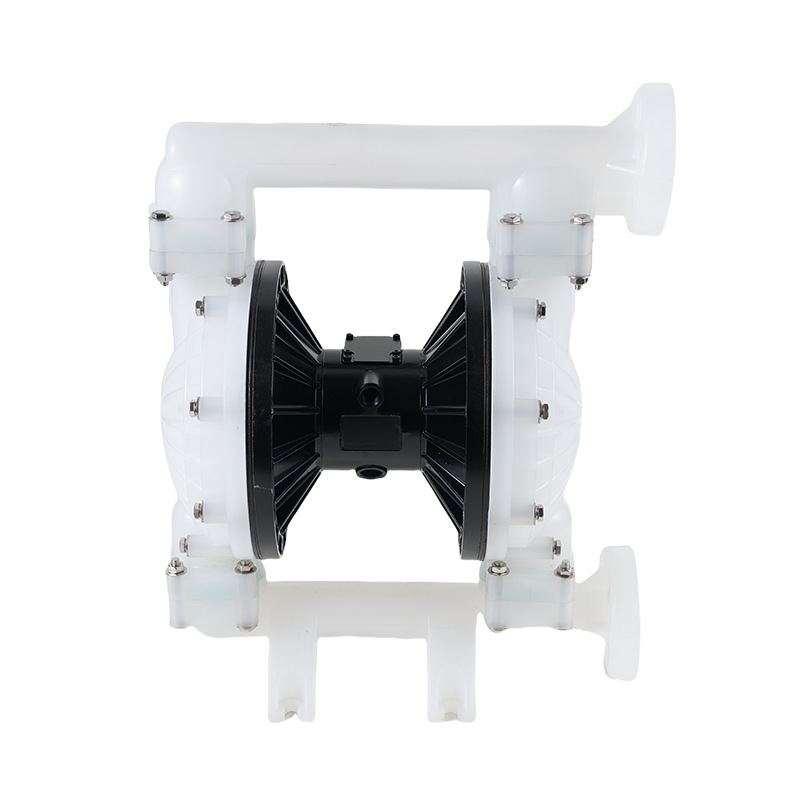

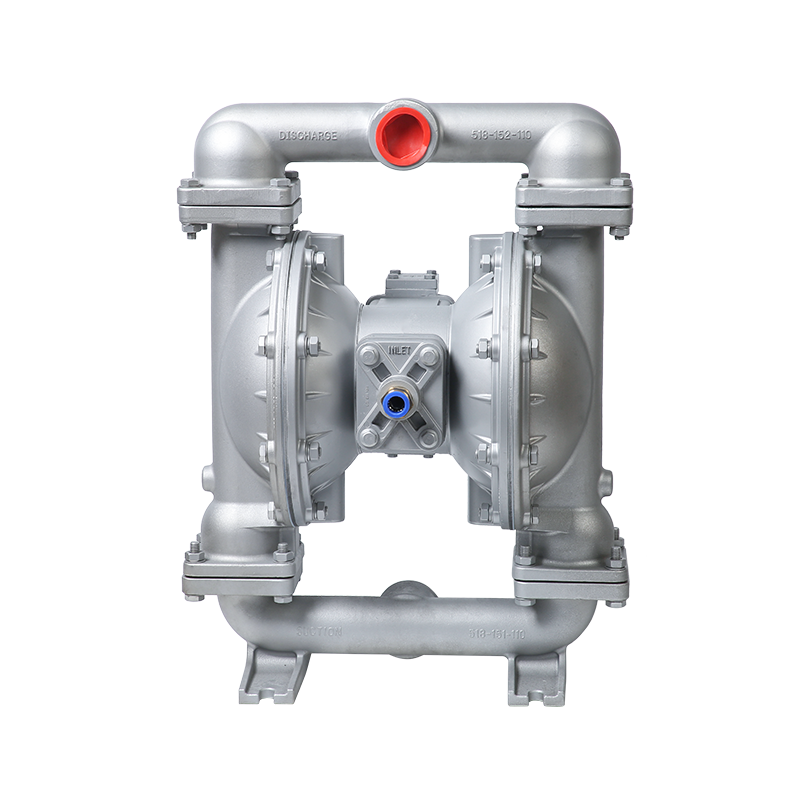

Small operations or precision applications often benefit from Small Line Diaphragm Pumps. These pumps are compact yet powerful, ideal for handling low flow rates with accuracy. The Small Line Diaphragm Pumps are used in a variety of industries, including chemical dosing, water treatment, and laboratory processes, where space and precision are priorities.

A key feature of effective Small Line Diaphragm Pumps is their ability to maintain consistent pressure and flow in confined spaces. Their compact design should not compromise durability; look for corrosion-resistant materials and seals that can withstand chemical exposure.

In addition, noise reduction and energy efficiency are gaining importance in diaphragm pump design. Modern Sealcoating Diaphragm Pumps and Double Diaphragm Milk Pumps now often incorporate features to minimize operational noise, making them more suitable for both industrial and semi-enclosed environments. Likewise, energy-efficient motors and air valve designs contribute to lower operating costs and environmental impact.

Maintenance and ease of repair also play a vital role in choosing the right pump. Pumps like the Sealcoating Diaphragm Pump and Small Line Diaphragm Pumps should allow for quick diaphragm replacement and straightforward access to internal parts. This reduces downtime and maintenance costs, which is crucial for continuous operations.

Another feature worth noting is the versatility of diaphragm pumps to handle different fluids by simply changing diaphragm materials. This flexibility is beneficial when switching between applications such as sealcoating and milk processing, where fluid properties differ significantly.

When selecting a Sealcoating Diaphragm Pump, focus on durability, self-priming capabilities, and resistance to abrasive materials. For dairy applications, the Double Diaphragm Milk Pump should offer a hygienic design and gentle handling of products. For precision and compact needs, Small Line Diaphragm Pumps provide control and reliability. Considering these features will ensure that you choose a diaphragm pump that meets your operational demands while delivering consistent performance.

English

English русский

русский Español

Español عربى

عربى