How to Choose the Right Diaphragm Pump Internals for Your Specific Needs?

2025.08.18

2025.08.18

Industry News

Industry News

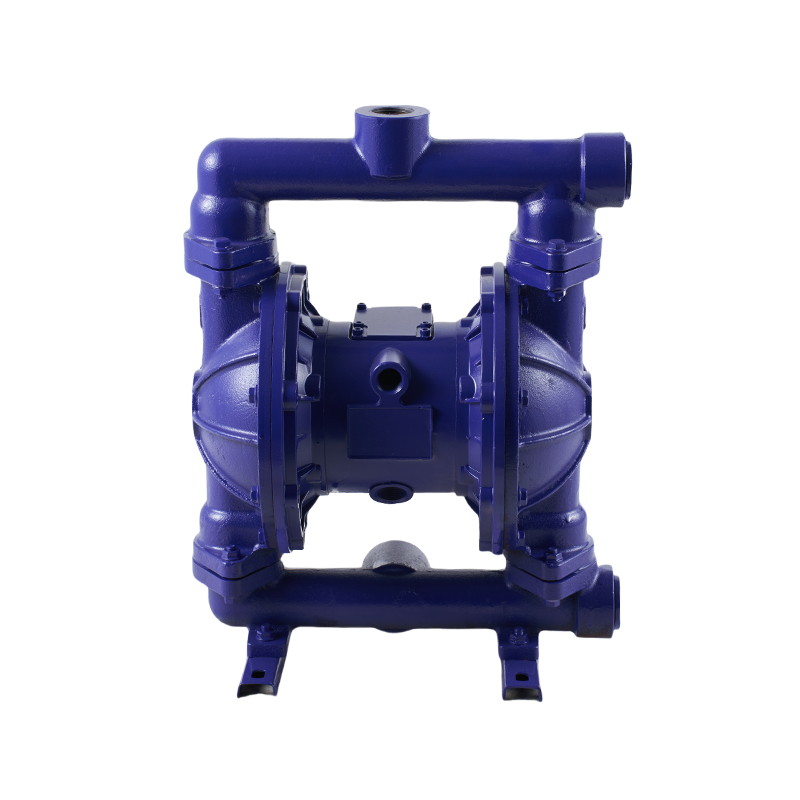

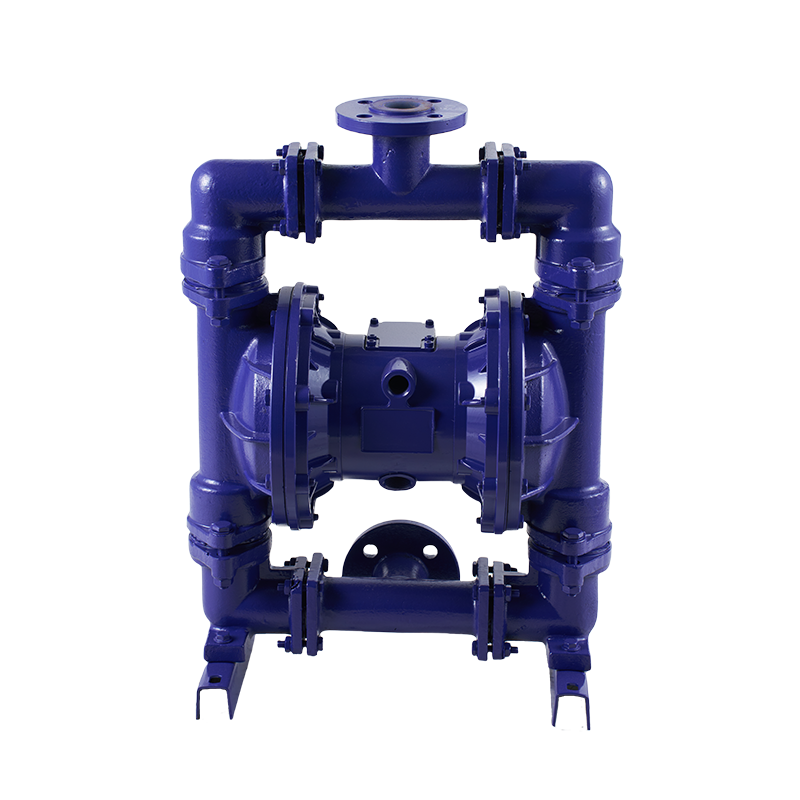

Diaphragm pumps are versatile tools used across various industries, from transferring corrosive chemicals to pumping abrasive slurries. Whether you are working with a Diaphragm Aeration Pump or a Pressure Diaphragm Pump, selecting the right Diaphragm Pump Internals is crucial for better performance and longevity. Here's a comprehensive guide to help you make the right choice.

The important step in choosing the right Diaphragm Pump Internals is understanding the specific requirements of your application. Consider the type of fluid you will be pumping, its viscosity, temperature, and whether it contains abrasive particles. For instance, if you are using a Diaphragm Aeration Pump in a wastewater treatment plant, you need internals that can handle high volumes of air and water without corroding.

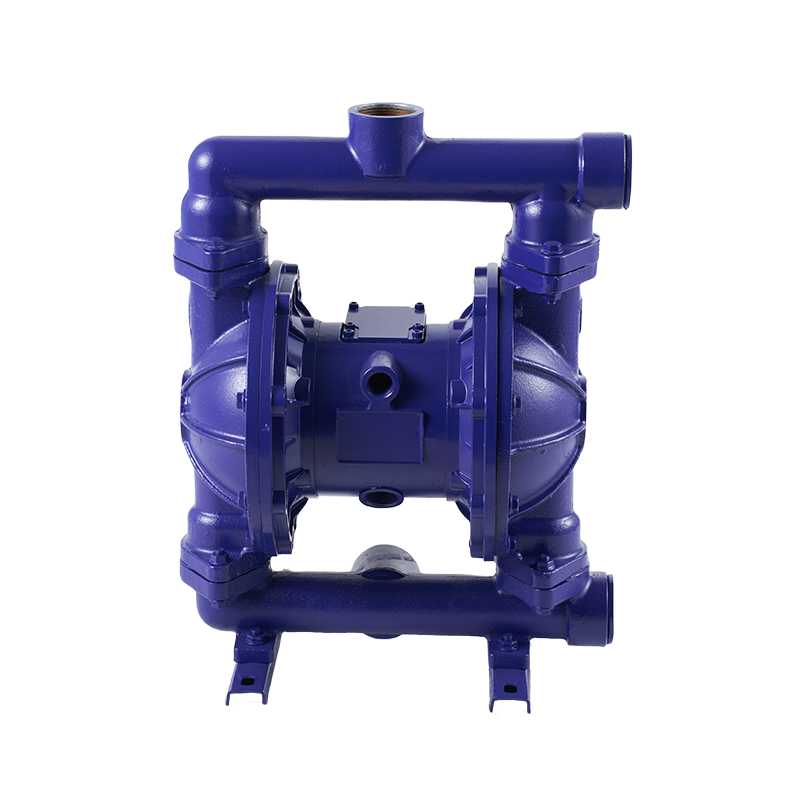

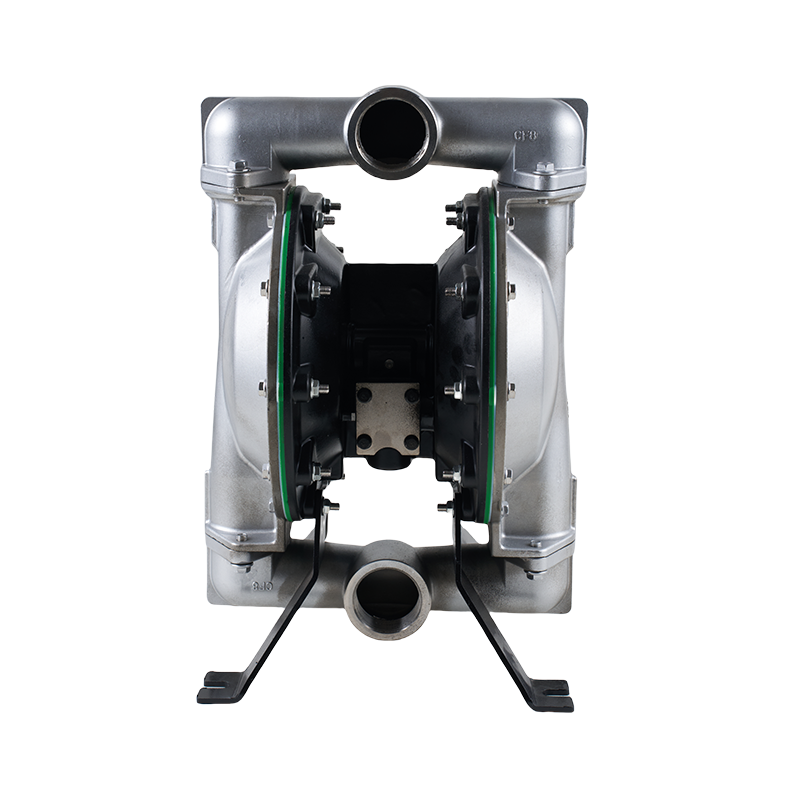

Material Selection

The material of the Diaphragm Pump Internals plays a significant role in its performance and durability. Common materials include:

NBR (Nitrile Buna Rubber): Offers nice elasticity and resistance to solid particles, making it ideal for applications involving abrasive fluids.

Viton® (Fluoroelastomer): Provides chemical resistance and can withstand badness temperatures, making it suitable for aggressive chemicals.

PTFE (Polytetrafluoroethylene): Known for its non-reactivity and ability to handle a wide range of chemicals, PTFE is often used in Pressure Diaphragm Pumps where chemical compatibility is critical.

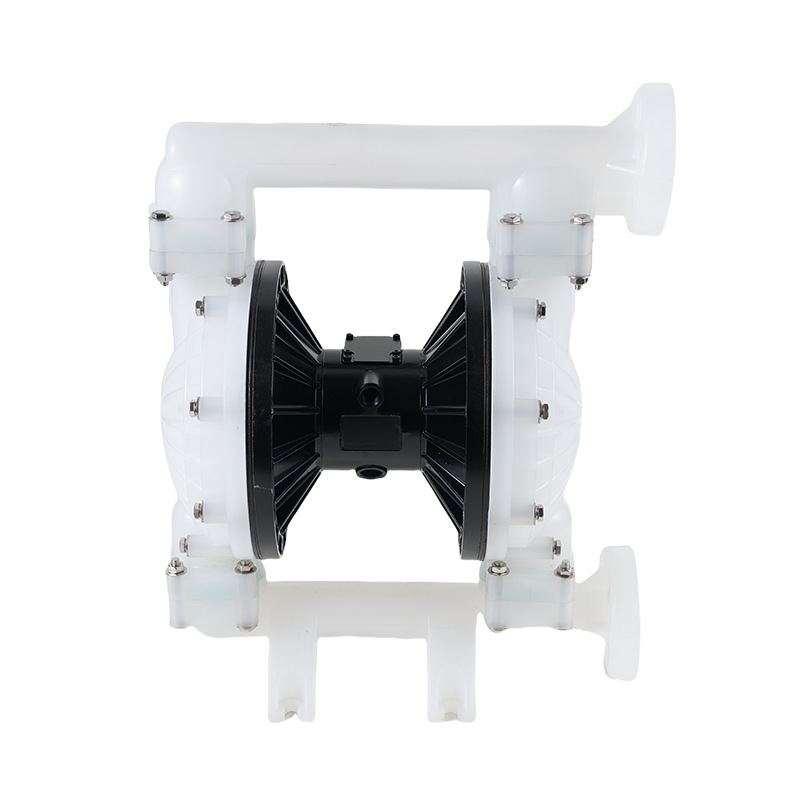

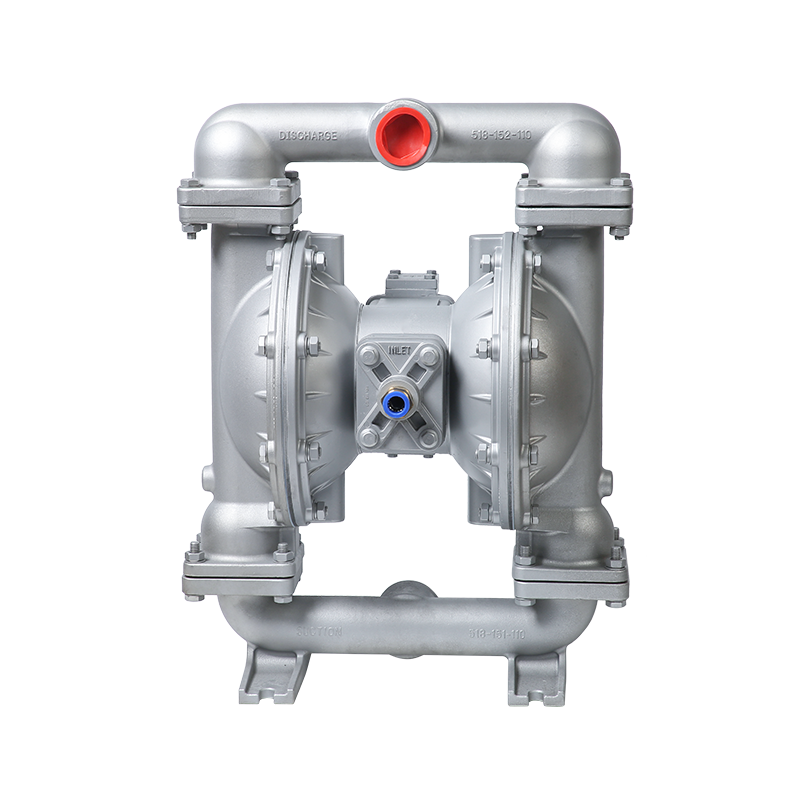

Diaphragm Design

The diaphragm is the heart of the pump, and its design can significantly impact performance. Diaphragms come in various configurations, such as bonded PTFE diaphragms that offer enhanced durability and chemical resistance. When selecting a diaphragm, consider the following:

Flexibility: The diaphragm should be flexible enough to withstand repeated flexing without cracking.

Chemical Compatibility: Ensure the diaphragm material is compatible with the fluid being pumped.

Temperature Resistance: Choose a diaphragm that can operate within the temperature range of your application.

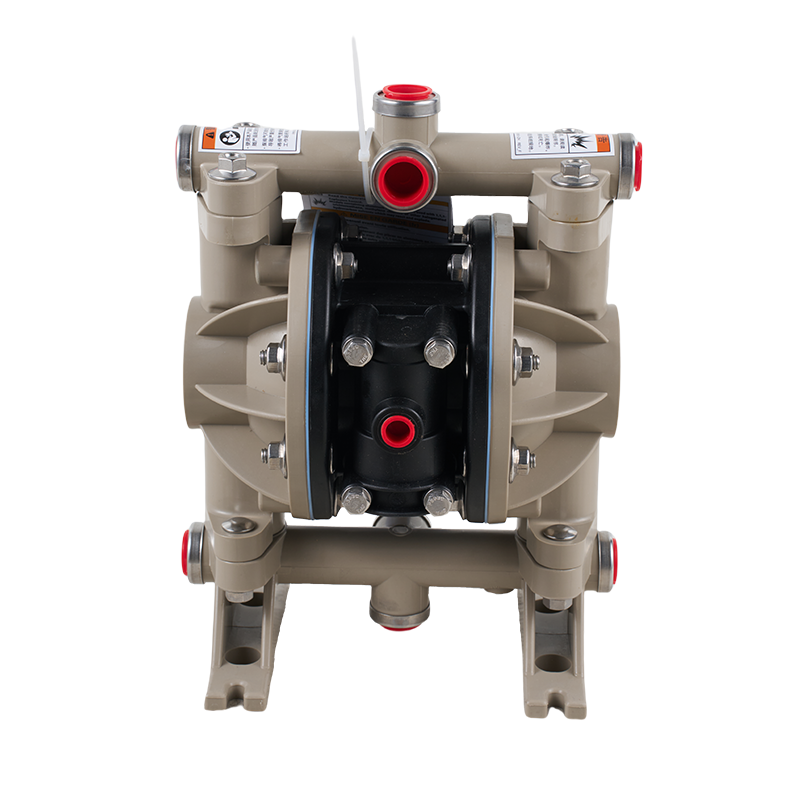

Valve Selection

Valves are another critical component of Diaphragm Pump Internals. They control the flow of fluid into and out of the pump chamber. When selecting valves, consider:

Material: Valves should be made from materials that are resistant to the fluid being pumped. For example, stainless steel valves are more durable in abrasive applications.

Design: Some valves are designed to handle high viscosity fluids better than others. Heavy or weighted valve balls are recommended for thick, viscous liquids.

Manifolds and Fittings

Manifolds gather multiple pumping units into a single suction and delivery line, simplifying installation. When selecting manifolds and fittings, consider:

Material: Brass, aluminum, and techno-polymers are common choices. Each material has its advantages in terms of strength, corrosion resistance, and cost.

Design: Internal manifolds are more compact and cost-effective, while external manifolds offer higher resistance to damage.

Safety Features

Safety valves are essential in Pressure Diaphragm Pumps to prevent overpressure, which can to pump damage. Ensure that your pump is equipped with a safety valve that is calibrated to the appropriate pressure for your application.

Maintenance and Replacement

Regular maintenance is key to extending the life of your Diaphragm Pump Internals. Keep an eye on wear and tear, especially on the diaphragms and valves. Replace worn-out components promptly to avoid leaks and ensure consistent performance.

Choosing the right Diaphragm Pump Internals involves a careful consideration of your application's specific needs, material compatibility, and the design of key components like diaphragms and valves. By understanding these factors and selecting high-quality internals, you can ensure that your Diaphragm Aeration Pump or Pressure Diaphragm Pump operates efficiently and reliably for years to come.

English

English русский

русский Español

Español عربى

عربى