Key Factors to Consider When Choosing a Medical Diaphragm Pump

2025.08.18

2025.08.18

Industry News

Industry News

In the medical industry, precision and reliability are paramount when selecting equipment, especially when it comes to fluid handling. A Medical Diaphragm Pump plays a crucial role in various medical devices and applications, ranging from dialysis machines to respiratory systems. With numerous options available, understanding the key factors that influence the choice of a diaphragm pump ensures performance, safety, and cost-effectiveness.

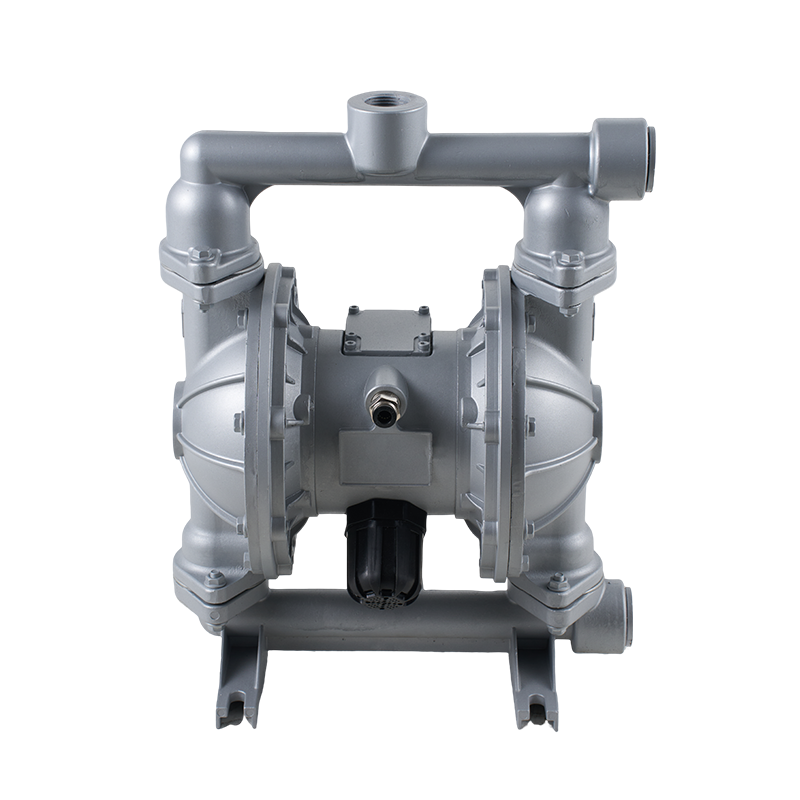

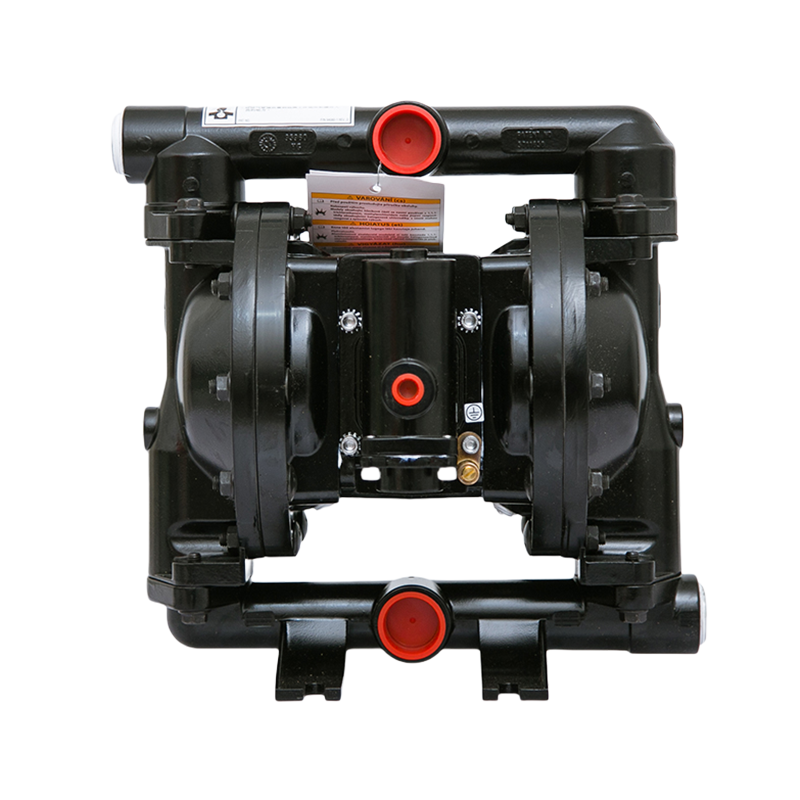

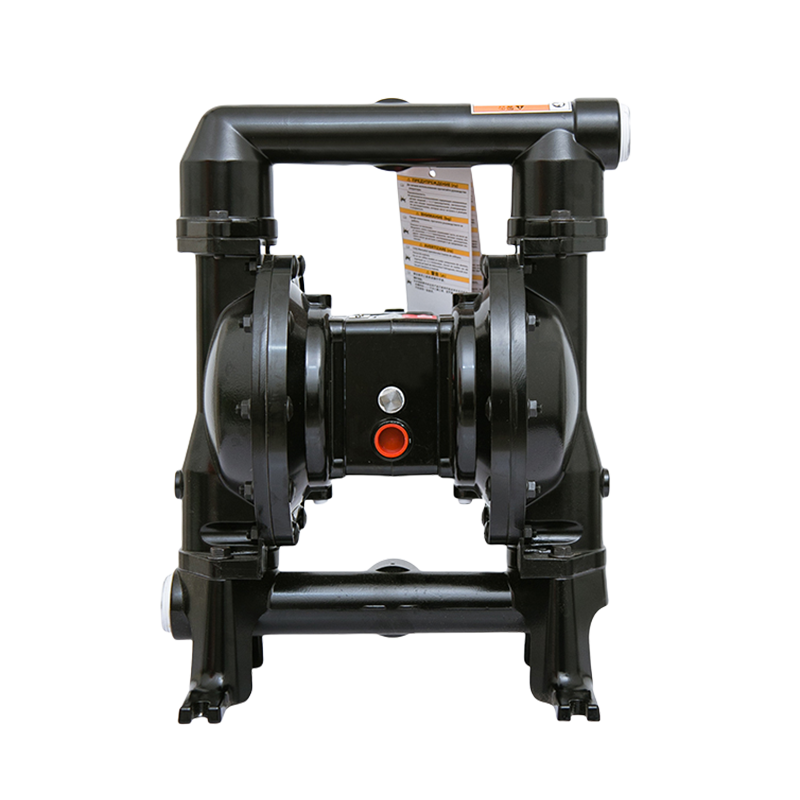

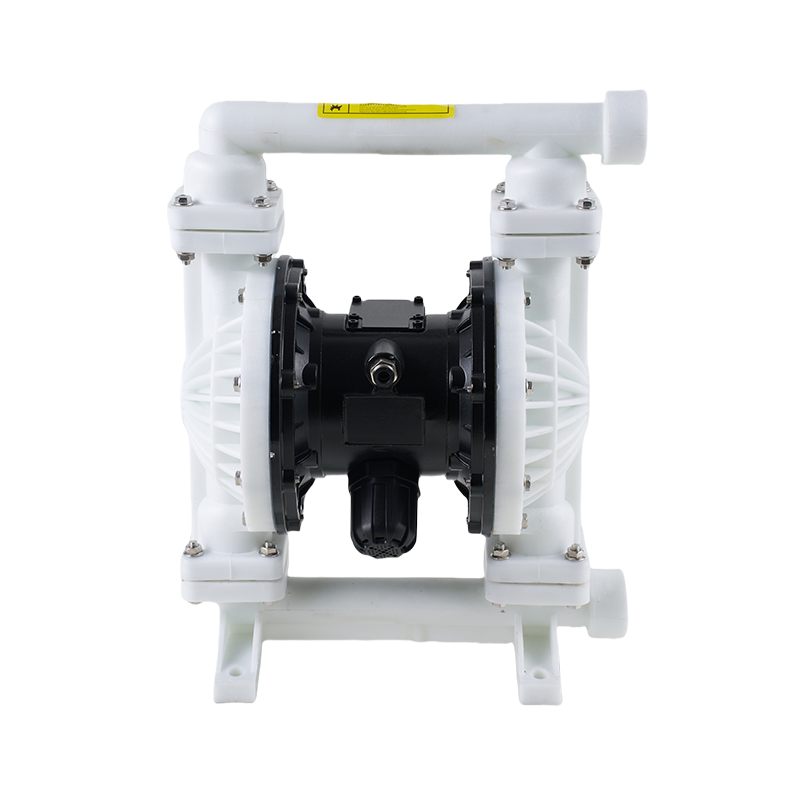

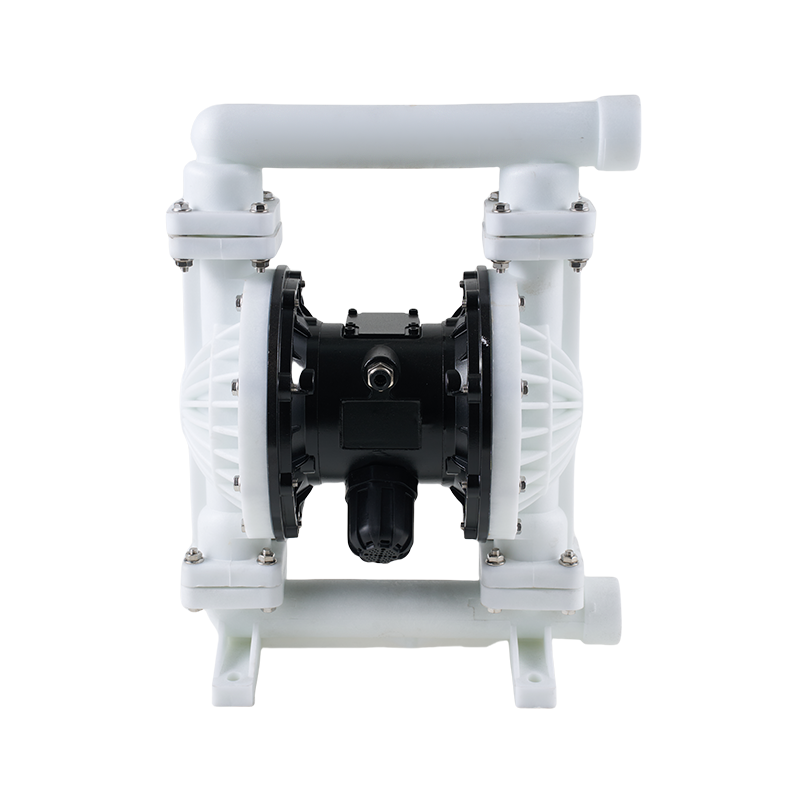

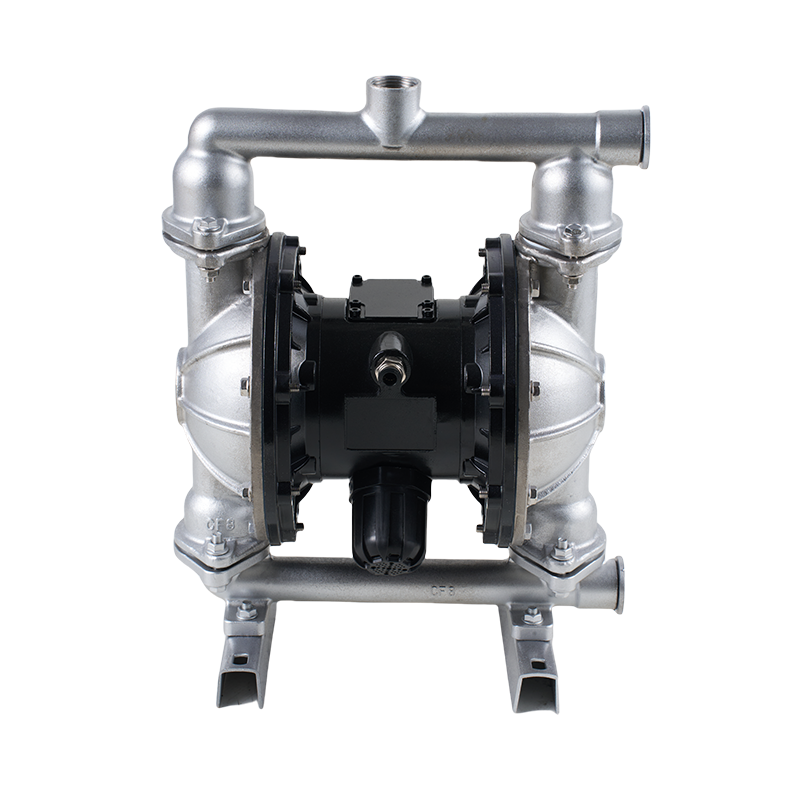

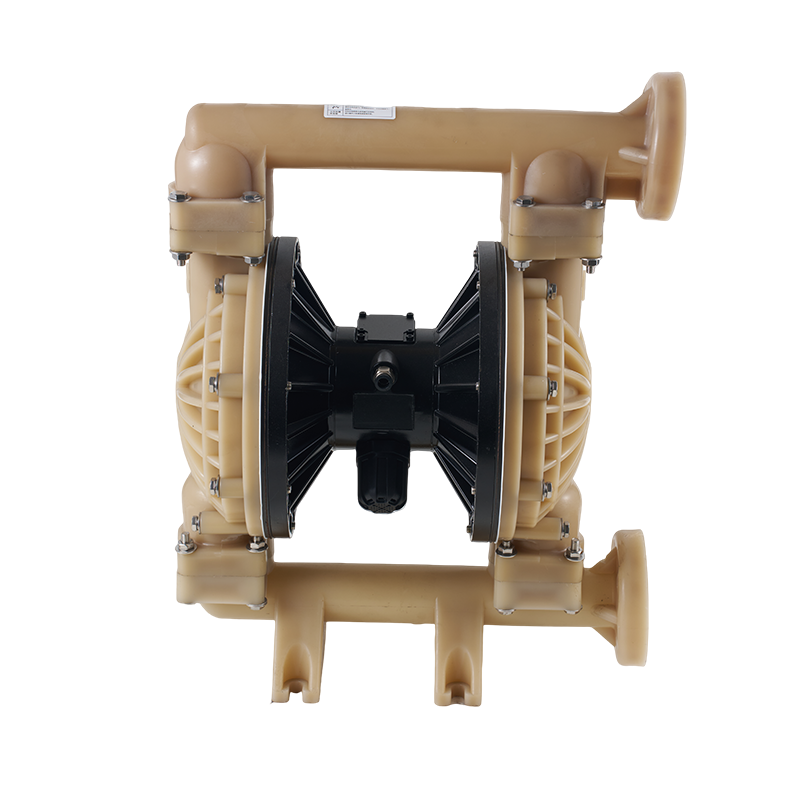

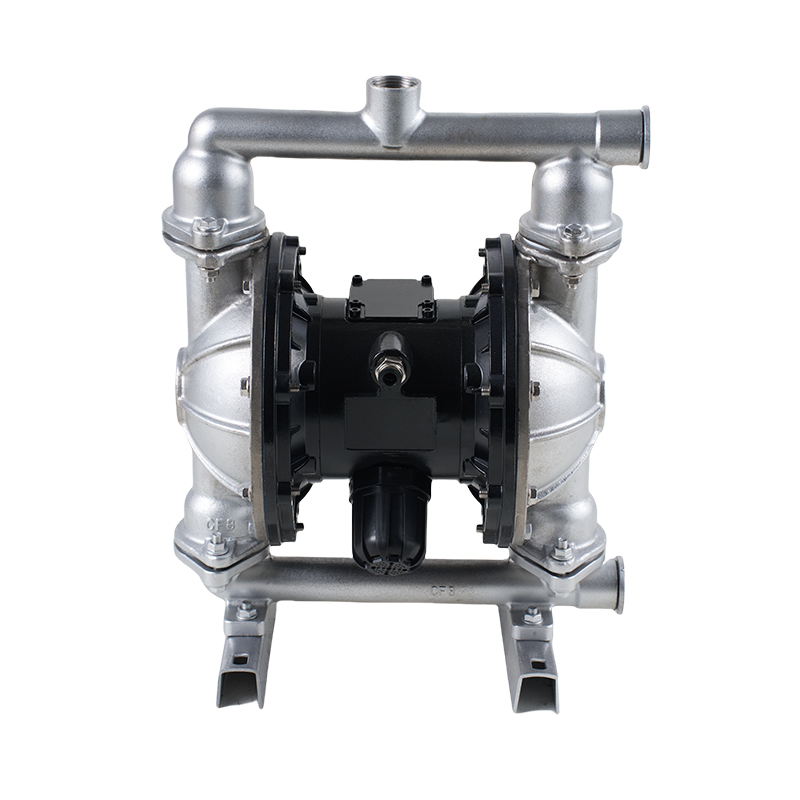

A Medical Diaphragm Pump is designed to handle sensitive fluids with care, avoiding contamination and ensuring sterile conditions. Unlike traditional pumps, diaphragm pumps utilize a flexible diaphragm that moves back and forth, creating suction and discharge without direct contact between the fluid and moving mechanical parts. This design reduces the risk of leaks and contamination, making it ideal for medical applications where hygiene is critical.

When considering a Medical Diaphragm Pump, one of the important aspects is the type of diaphragm material used. Materials must be biocompatible and resistant to the chemicals and fluids they will encounter. For instance, silicone, PTFE, and EPDM are commonly chosen for their durability and compatibility with bodily fluids and medications. The choice of diaphragm material directly affects the pump's lifespan, maintenance frequency, and overall reliability.

Another critical factor is the pump's flow rate and pressure capacity. Medical devices require precise control over fluid delivery, often at low flow rates and steady pressure. Therefore, selecting a Medical Diaphragm Pump that can provide consistent output without pulsation is essential. Pumps with adjustable stroke lengths or multiple diaphragm chambers can offer more control, adapting to specific medical needs.

The Tubular Diaphragm Pump is a variant gaining attention for medical applications due to its compact design and efficiency. This pump features a tubular diaphragm that moves within a cylindrical chamber, reducing dead volume and improving fluid displacement accuracy. The Tubular Diaphragm Pump design is especially useful in devices where space is limited and precision is critical, such as portable infusion pumps or compact respiratory machines.

When evaluating a Medical Diaphragm Pump, the power source and control system should also be considered. Many medical diaphragm pumps are pneumatically driven, offering explosion-proof operation and quiet function, which are important in hospital environments. Others may use electric motors for precise electronic control. The choice depends on the device's requirements and the setting in which it will operate.

Cost remains a practical consideration when selecting a diaphragm pump for medical use. While performance and safety cannot be compromised, understanding the Diaphragm Air Pump Price helps healthcare providers and manufacturers balance quality with budget constraints. The Diaphragm Air Pump Price can vary significantly depending on factors such as pump size, diaphragm material, control features, and certifications required for medical compliance.

Certification and regulatory approval are non-negotiable when choosing a Medical Diaphragm Pump. Pumps used in medical devices must comply with standards such as ISO 13485 or FDA requirements to ensure they meet safety, reliability, and performance benchmarks. Selecting a pump with proper certifications helps avoid costly delays and regulatory issues during device approval.

Maintenance and serviceability also influence the choice of a medical diaphragm pump. Pumps that allow easy access to diaphragms and valves reduce downtime and maintenance costs. Since medical applications demand high uptime and consistent operation, investing in pumps designed for straightforward maintenance can enhance long-term reliability.

Furthermore, noise level is a relevant consideration in medical environments where patient comfort matters. Many Medical Diaphragm Pumps operate quietly, but differences exist based on design and power source. Pneumatic diaphragm pumps tend to have quieter operation compared to some electric models, which is an important factor in sensitive settings like neonatal care or intensive care units.

Selecting the right Medical Diaphragm Pump involves careful evaluation of diaphragm material, flow rate, pressure control, and design variations such as the Tubular Diaphragm Pump. Cost considerations, including the Diaphragm Air Pump Price and compliance with medical regulations, also play vital roles. By thoroughly understanding these factors, medical device manufacturers and healthcare providers can ensure the integration of pumps that deliver reliability, safety, and efficiency in critical medical applications.

English

English русский

русский Español

Español عربى

عربى